Surface processing method of disc component of sealing device and sealing device

A technology for sealing devices and disc components, which can be used in engine sealing, metal processing equipment, surface polishing machine tools, etc., and can solve problems such as static leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

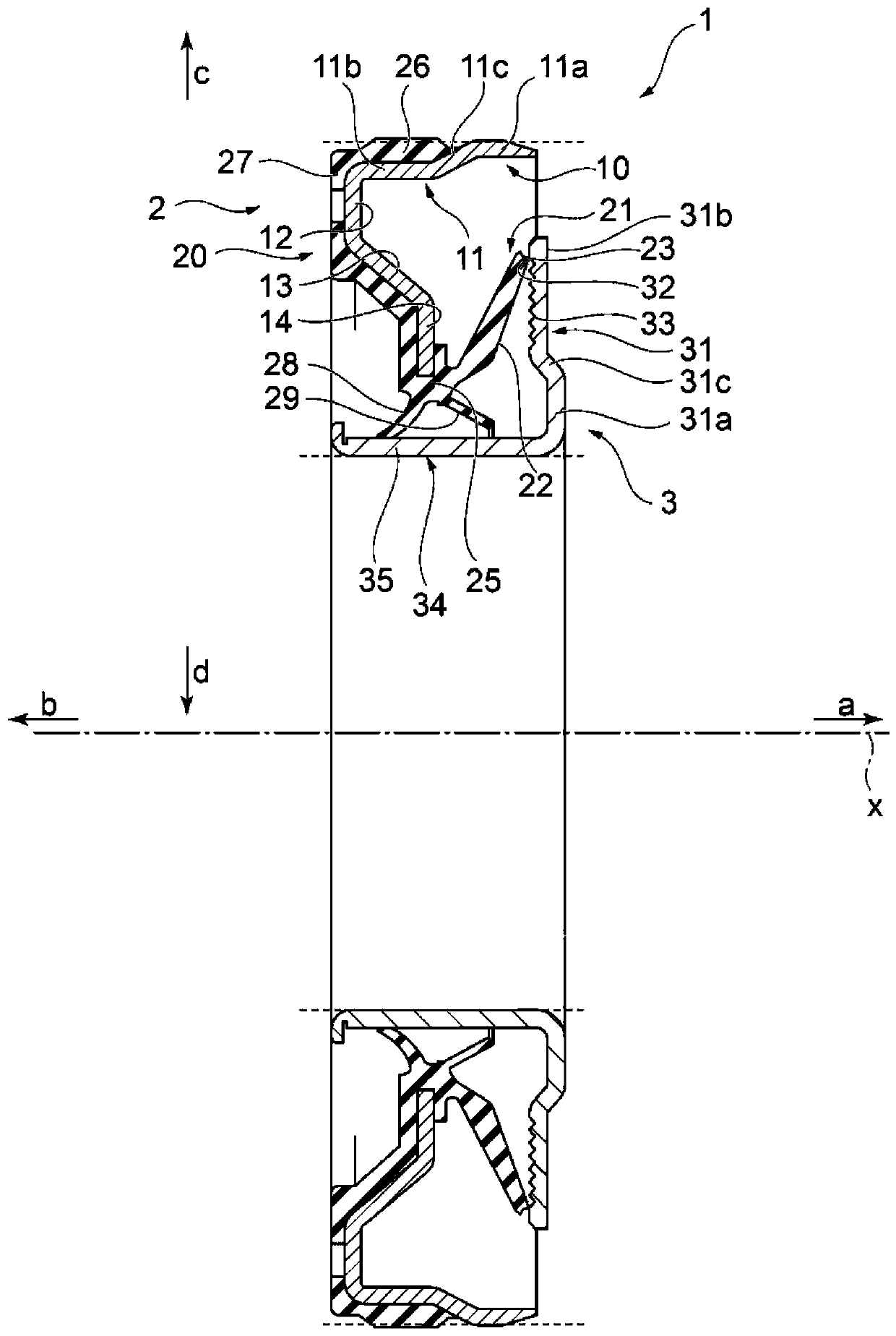

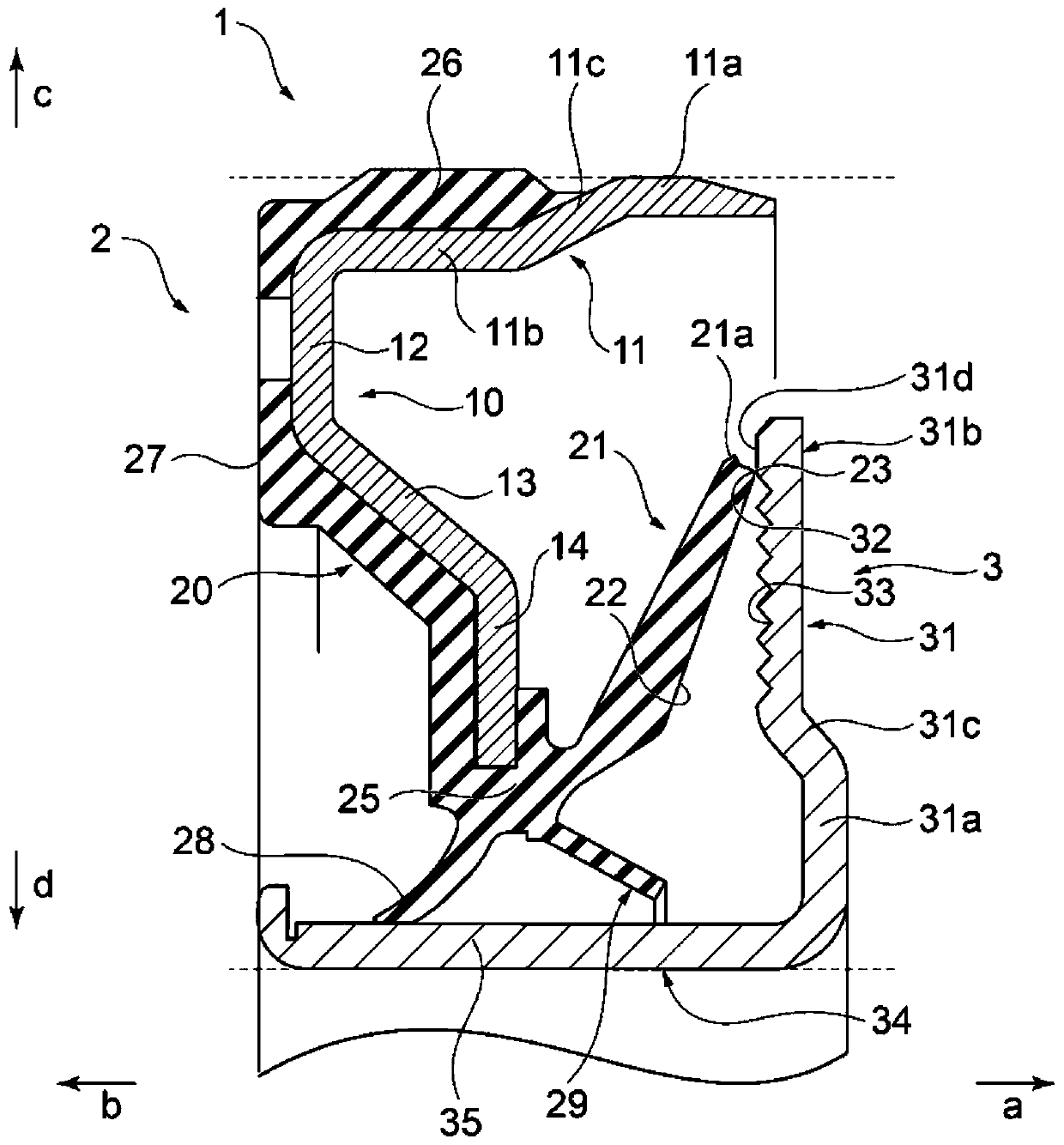

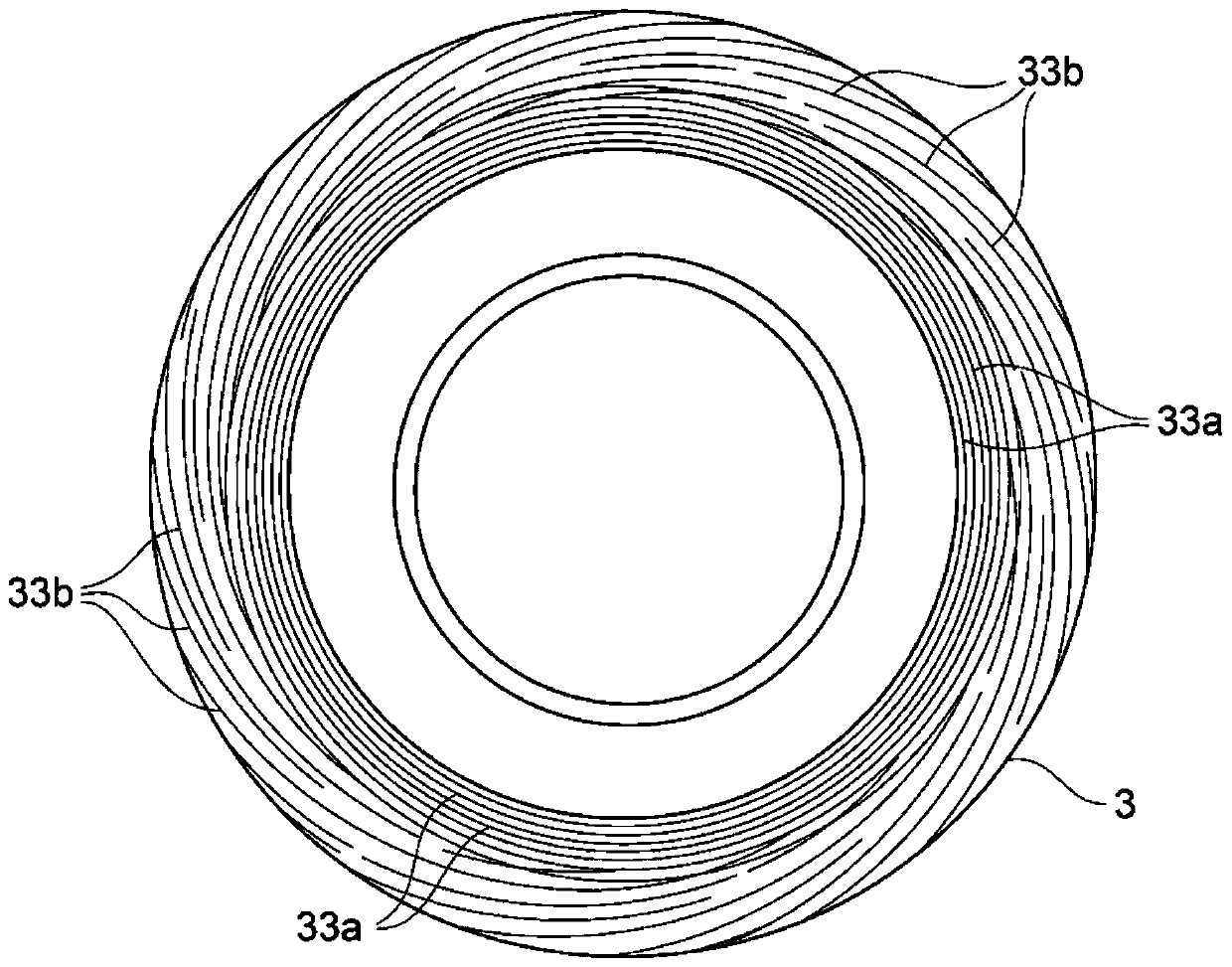

[0030] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

[0031] figure 1 is a cross-sectional view taken along the axis x for showing the schematic structure of the sealing device 1 according to the embodiment of the present invention, figure 2 It is a partially enlarged cross-sectional view showing an enlarged part of the cross-section along the axis x of the sealing device 1 .

[0032] The sealing device 1 according to the embodiment of the present invention is a sealing device for sealing an annular gap between a shaft and a hole into which the shaft is inserted. etc. between the holes (shaft holes) into which the shaft is inserted. For example, it is used to seal an annular space between a crankshaft of an engine and a crankshaft hole formed in a front cover, a cylinder block, and a crankcase. In addition, the object to which the sealing device 1 is applied is not limited to the above.

[0033] Hereinafter, for the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com