Modification processing method of optical element surface and numerical control machine used thereby

A processing method and technology of optical components, which are applied to optical surface grinders, metal processing equipment, grinding machines, etc., can solve the problems of complex calculation of the rotation axis 21 and high requirements on the CNC system of the machine tool, and achieve simple residence time and good controllability. , The effect of low requirements on processing equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

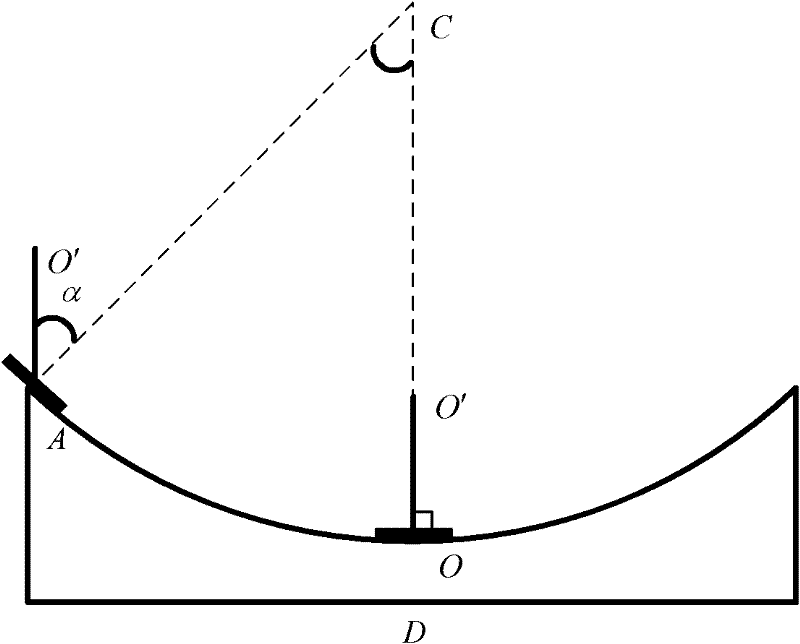

[0048] Using the method for modifying the surface of an optical element of the present invention to process a workpiece to be processed comprises the following steps:

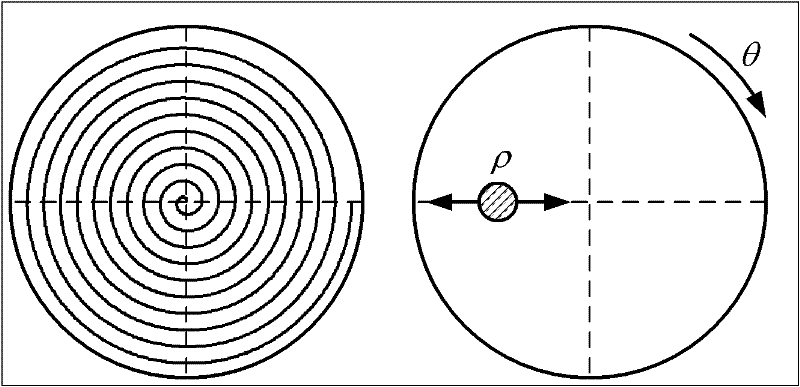

[0049] 1. Planning the processing and scanning route

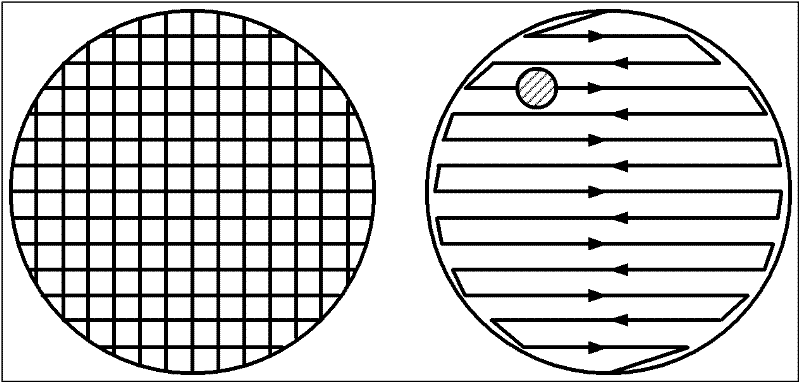

[0050] 1.1 Take a workpiece to be processed, take the center of the workpiece as the coordinate origin, and establish an X-Y rectangular coordinate system; then according to the size of the workpiece, use a square grid composed of intersecting lines parallel to the coordinate axis and equally spaced (each small unit The side length of the grid is about 10mm) to discretize the workpiece into several processing points S; the coordinates of each processing point on the workpiece are marked as S(x i ,y i ), where x i and y i Represents the position of each point on the workpiece in the discrete grid; the discretized surface of the workpiece is as attached Figure 5 shown.

[0051] 1.2 Connect all the processing points with a number of parallel lines parall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com