Foamed aluminum side edge grinding device

A technology of aluminum foam and grinding mechanism, which is applied to grinding drive devices, grinding machines, grinding slides, etc., to achieve the effects of improving grinding quality, moving at a uniform speed, and reducing manual labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

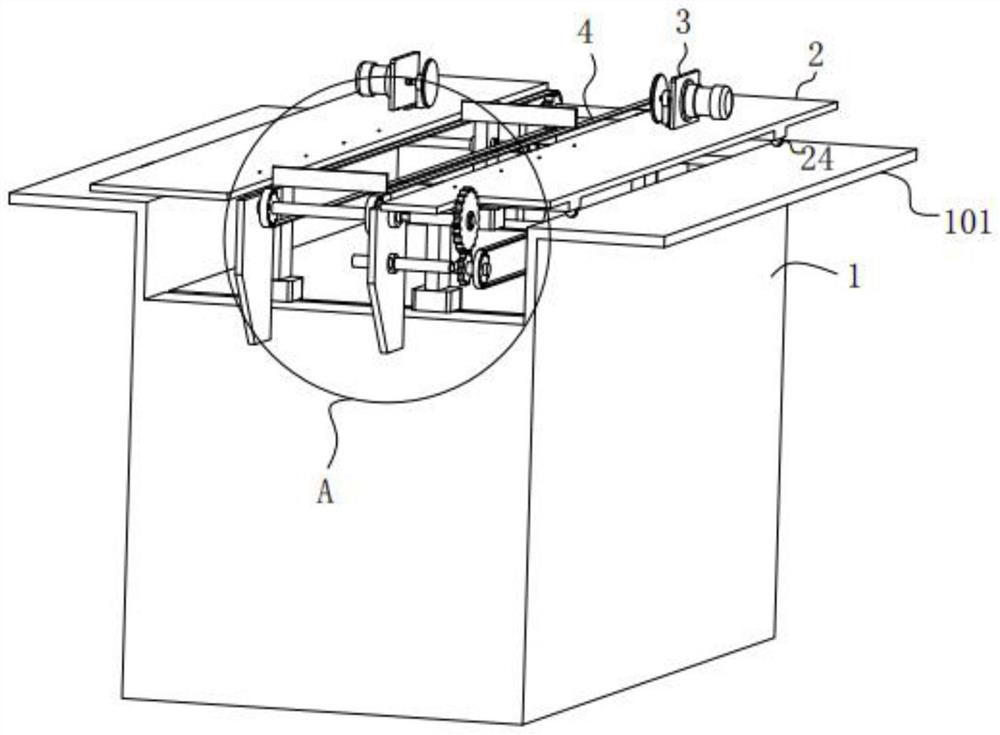

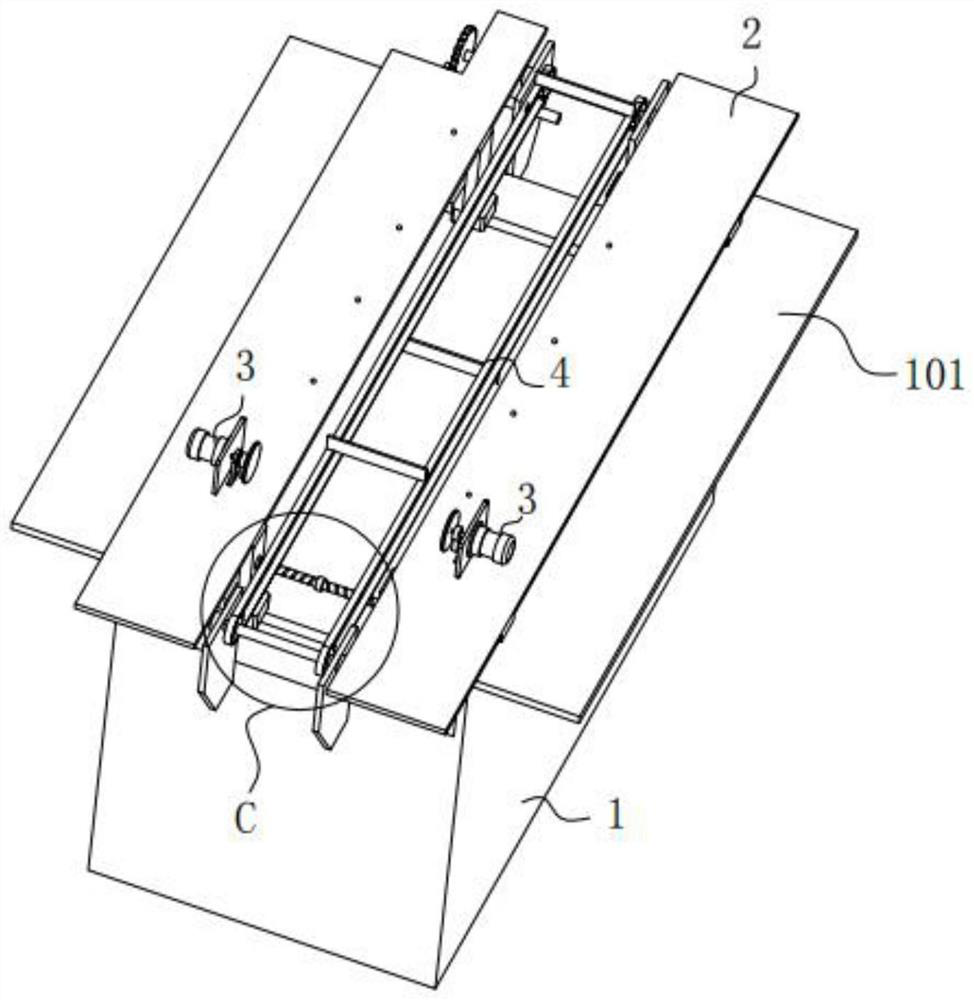

[0052] Please refer to figure 1 , figure 2 and image 3 ,in, figure 1 It is a schematic structural diagram of a preferred embodiment of the side grinding device for foamed aluminum provided by the present invention; figure 2 for figure 1 the top view shown; image 3 for figure 1 Cutaway view shown. Side sanding device for foam aluminum, including:

[0053] machine 1;

[0054] Two mounting seats 2, the two mounting seats 2 are symmetrically installed on both sides of the machine table 1, and a grinding mechanism 3 is installed on the two mounting seats 2;

[0055] The conveying mechanism 4 is installed on the machine table 1 and located between the two mounting bases 2. The conveying mechanism 4 includes two sets of mounting plates 41, driving rollers 42, sprockets 43, chains 44 and Pushing plate 45, two sets of mounting plates 41 are symmetrically installed on both sides of the machine table 1, each set of mounting plates 41 includes two, and driving rollers 42 are ...

no. 2 example

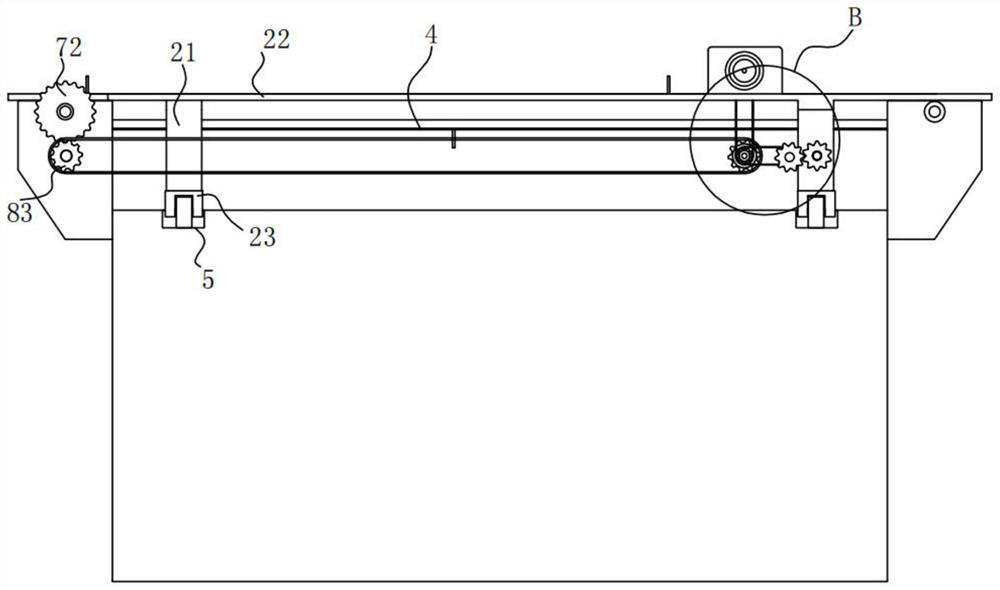

[0067] Please refer to figure 1 , image 3 , Figure 4 , Figure 5 and Figure 7 , Based on the foamed aluminum side grinding device provided in the first embodiment of the present application, the second embodiment of the present application proposes another foamed aluminum side grinding device. Specifically, the difference between the foamed aluminum side grinding device provided by the second embodiment of the present application is that the transmission mechanism includes a driving wheel 61 , a driven wheel 62 , a driving arm 71 , a driving gear 72 , a transmission member 8 and The rotating shaft 13, the rotating shaft 13 is installed inside the machine table 1, the driving wheel 61 is installed on the main shaft 32, the driven wheel 62 is installed on the rotating shaft 13, the driving wheel 61 is connected with the driven wheel 62 through a transmission belt, the driving arm 71 is fixed on one of the main shafts 32, the driving gear 72 is mounted on the driving arm 7...

no. 3 example

[0075] Please refer to Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 and Figure 10 , Based on the foamed aluminum side grinding device provided by the first embodiment of the present application, the third embodiment of the present application proposes another foamed aluminum side grinding device. Specifically, the difference between the foamed aluminum side grinding device provided by the third embodiment of the present application is that the mounting seat 2 includes a support arm 21 , a mounting plate 22 , a pulley 23 and a support wheel 24 , and the pulley 23 Installed on the bottom end of the support arm 21, the top of the machine table 1 is provided with a cavity, the pulley 23 slides into the chute 5 opened in the cavity, and the mounting plate 22 is fixed to the On the support arm 21 , a support wheel 24 is symmetrically arranged at the bottom of the mounting plate 22 .

[0076] By slidably setting the support arm 21 and the machine table 1, the dista...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com