Patents

Literature

43results about How to "Uniform movement speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Vacuum aluminizing method of surface of neodymium-iron-boron permanent magnet

ActiveCN101736304AGood directionHigh hardnessVacuum evaporation coatingSputtering coatingIonizationHigh energy

The invention relates to a vacuum aluminizing method of the surface of a neodymium-iron-boron permanent magnet. The method sequentially comprises the following steps of: (1) polishing and cleaning the surface of the neodymium-iron-boron permanent magnet by adopting a wet method; (2) putting the neodymium-iron-boron permanent magnet on a rotating workpiece fame in a film plating chamber to ensure that the temperature of the neodymium-iron-boron permanent magnet is kept between 250 DEG C and 300 DEG C; (3) starting a vacuum pump on the film plating chamber and adjusting the vacuum degree of the film plating chamber to be 1-9*10<-3>Pa; (4) meanwhile, starting multi-arc cathode evaporators at both sides of the film plating chamber, a plane magnetic sputtering target and the rotating workpiece frame to carry out magnetic control multi-arc sputtering for 2-7 hours; (5) maintaining the film plating chamber to be cooled for 30-60 minutes under vacuum, aerating, opening the chamber, taking out the aluminized neodymium-iron-boron permanent magnet and carrying out passivation with a non-chrome passivation solution. High energy ions generated by magnetron sputtering strike low-energy ions generated by the multi-arc method so as to promote the low-energy ions to generate more ionization, wherein the speeds and the trends of the high-energy ions and the low-energy ions are uniform, thus the efficiency is improved.

Owner:YANTAI ZHENGHAI MAGNETIC MATERIAL

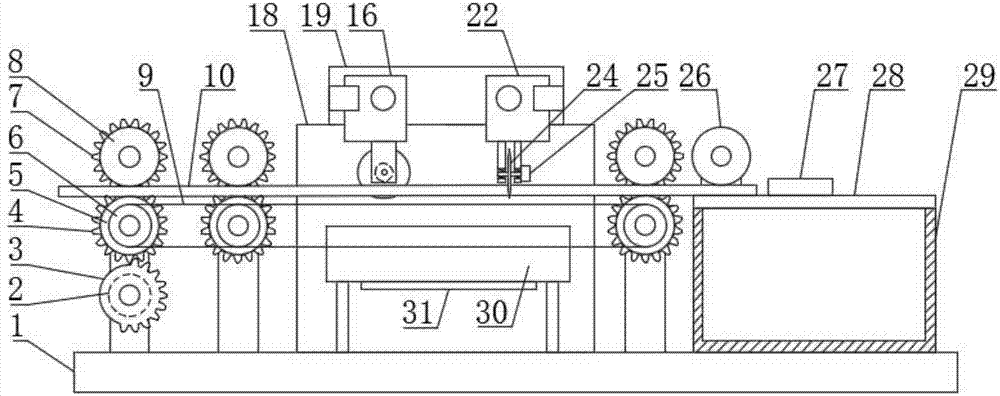

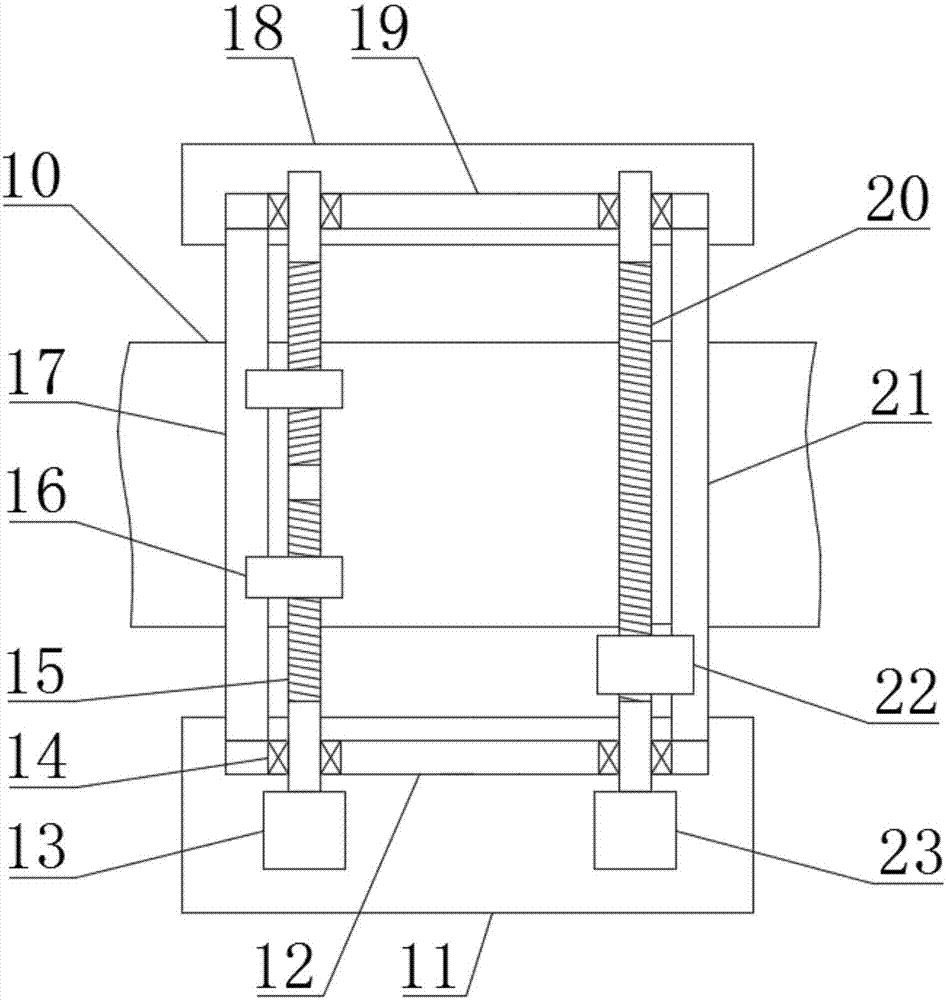

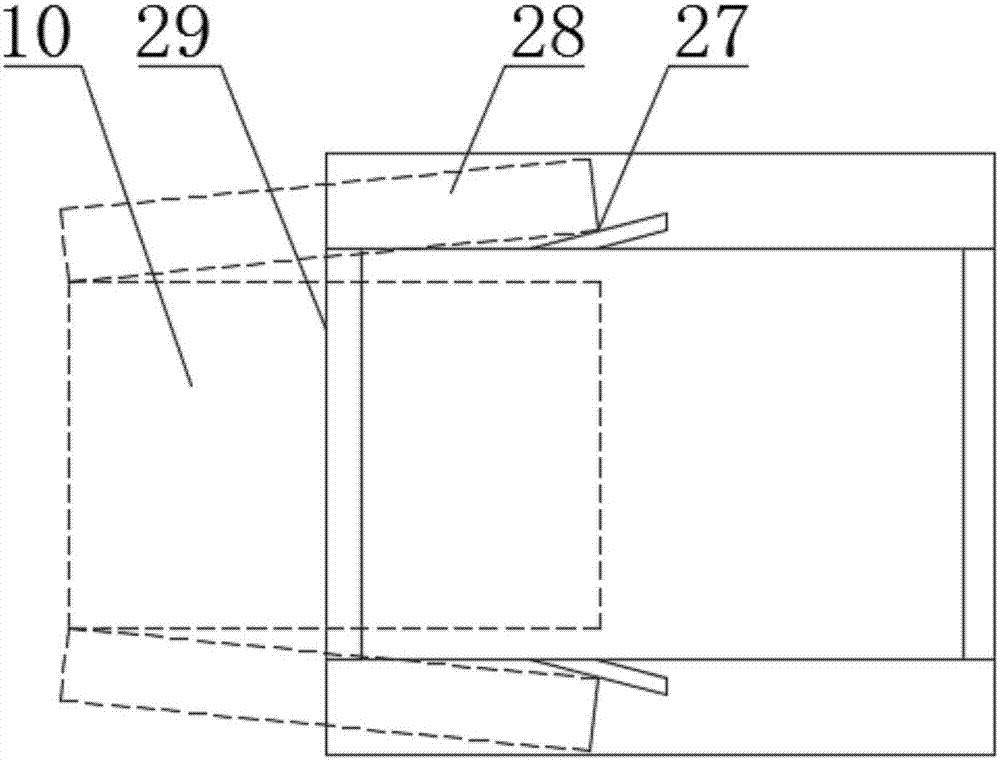

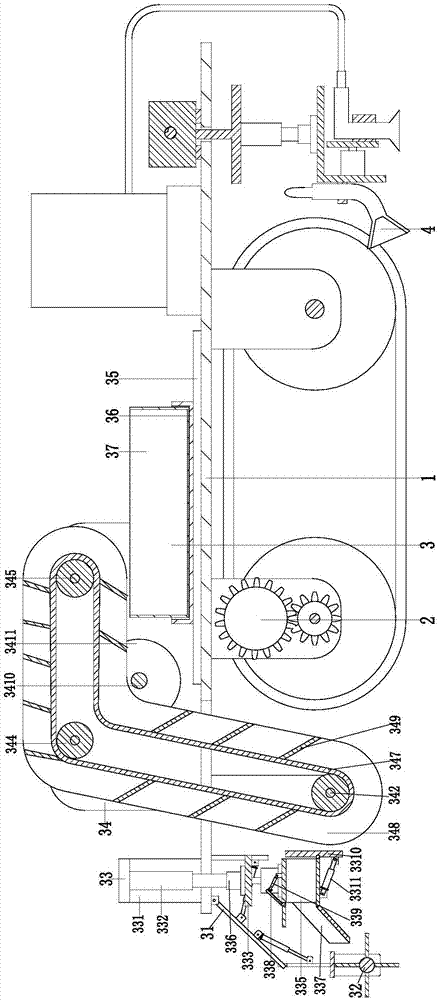

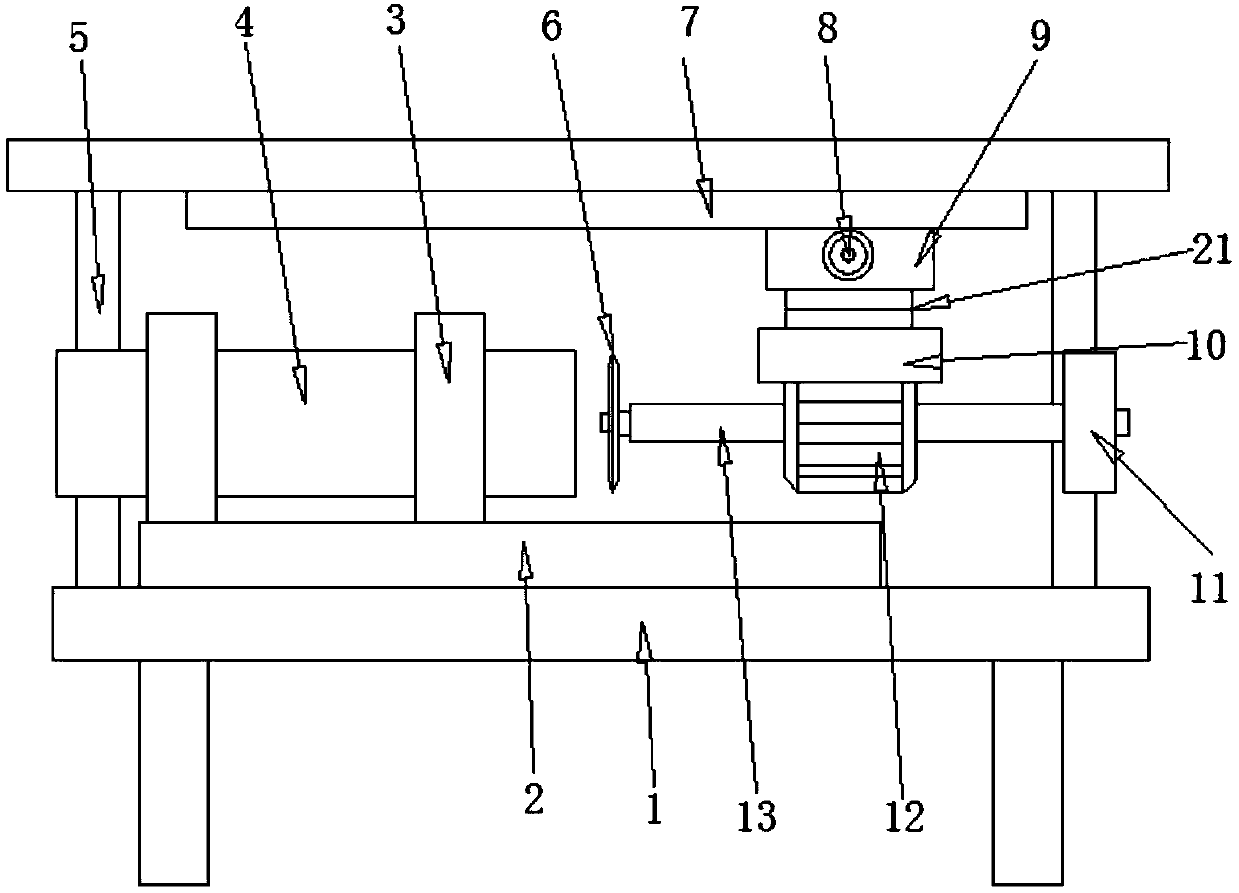

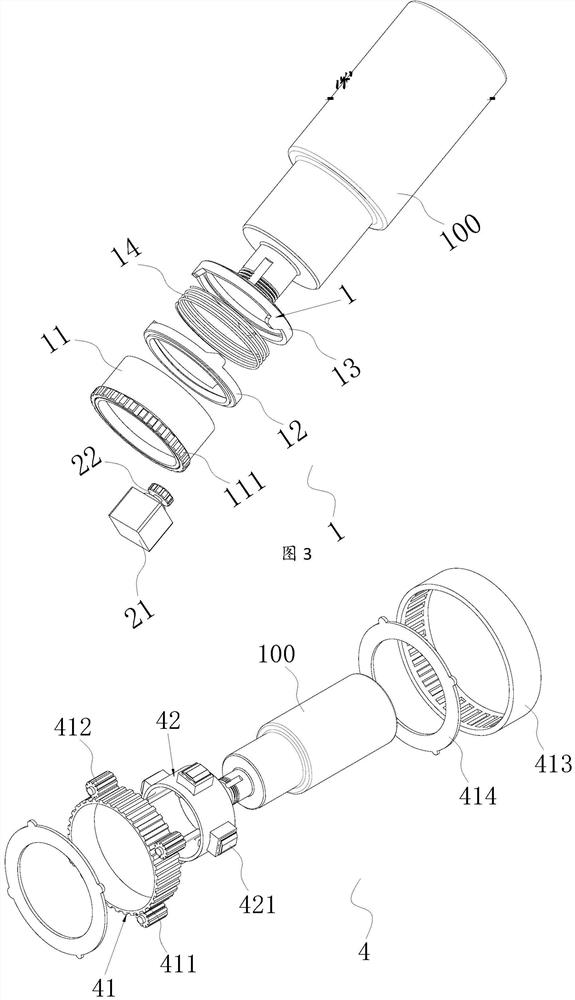

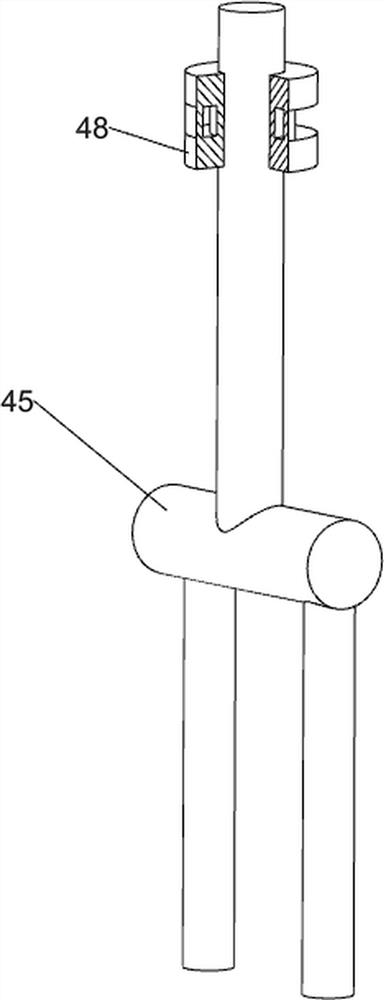

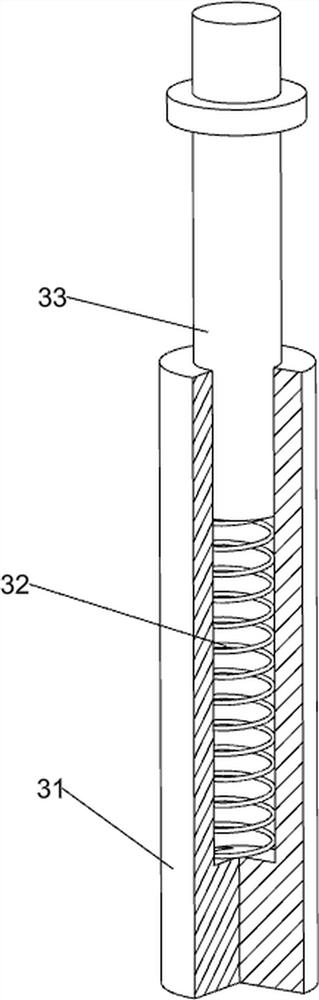

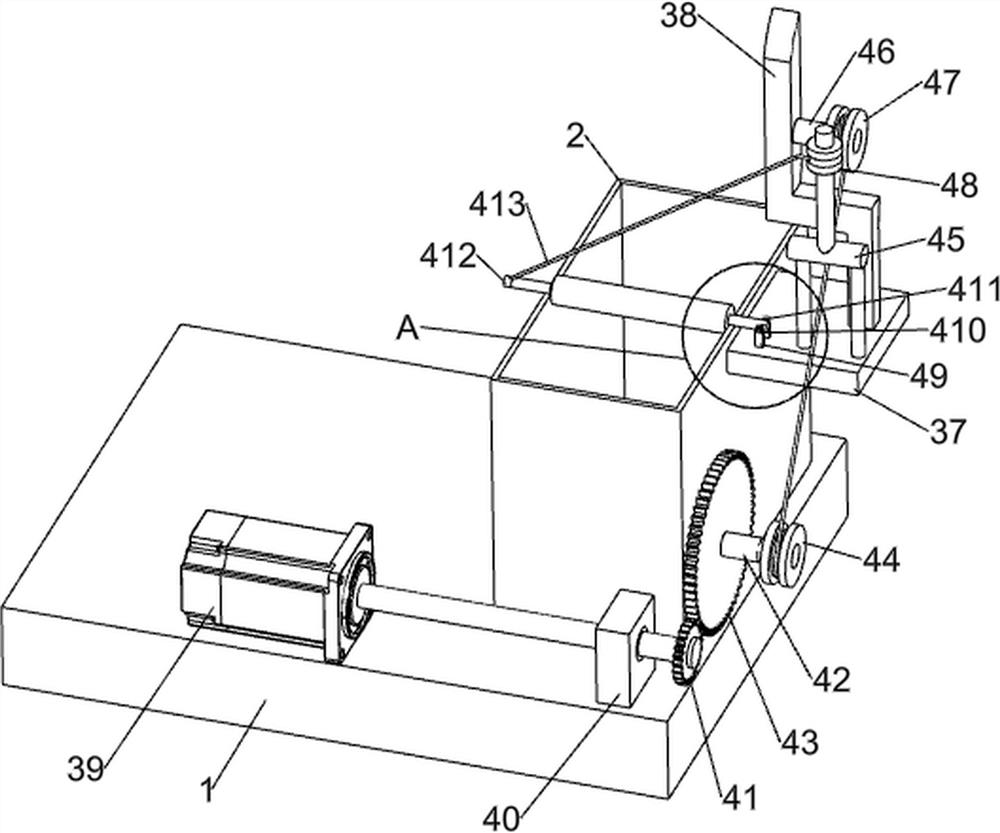

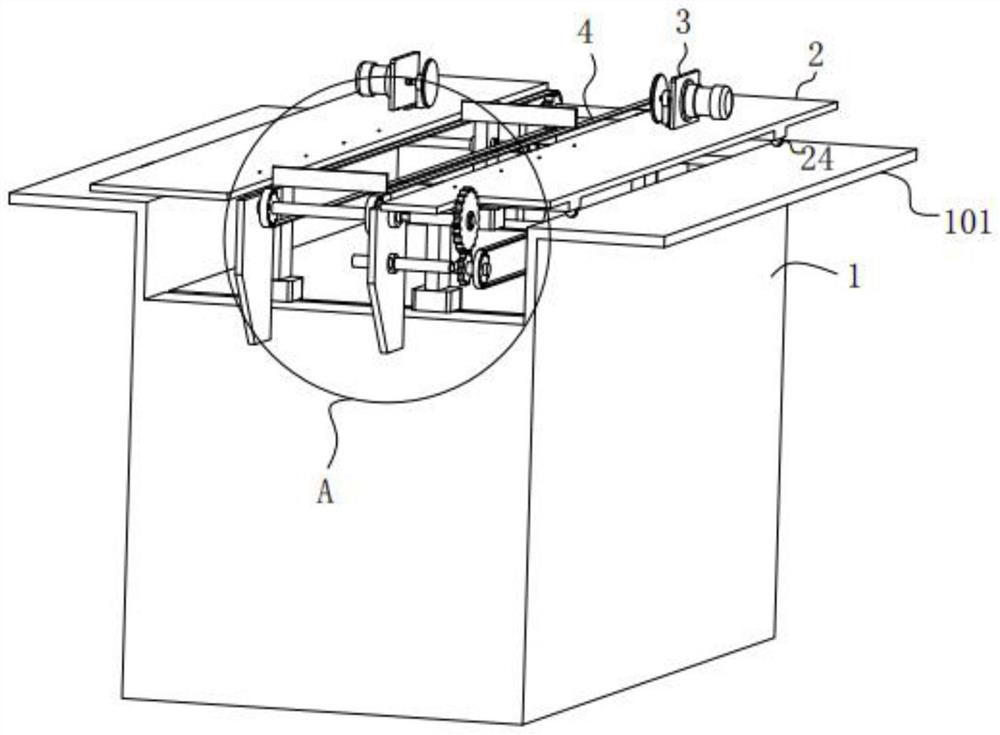

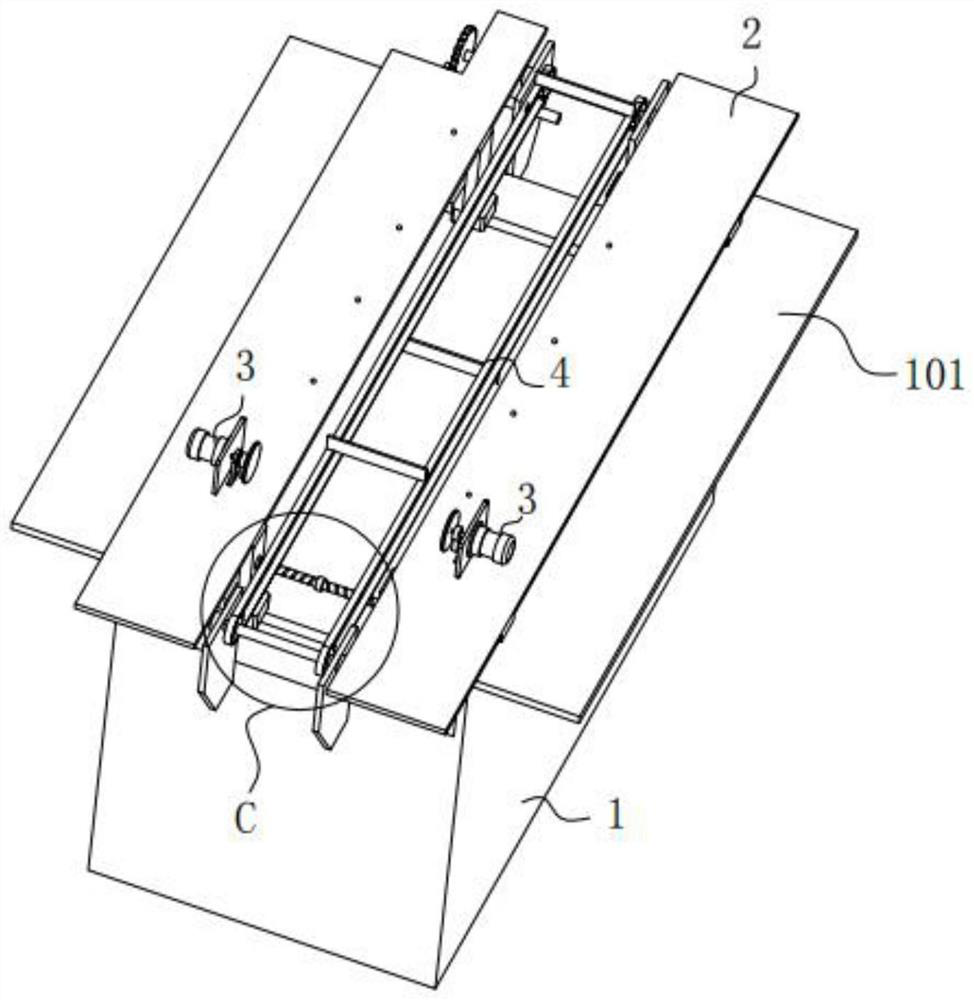

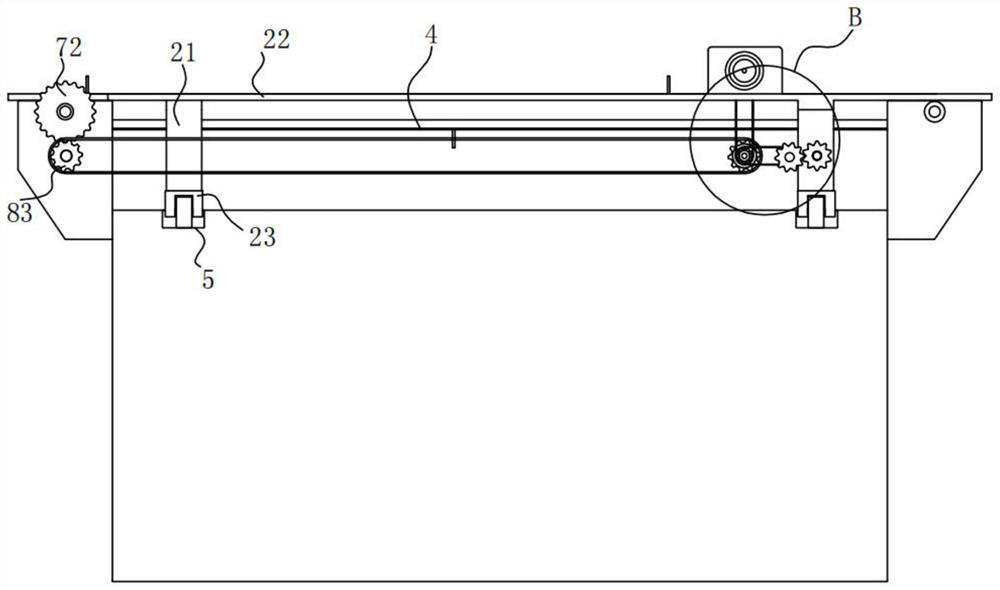

Multi-specification adjustable cutting machine for steel plates

InactiveCN107297540AUniform movement speedEasy to operateMetal working apparatusMaintainance and safety accessoriesSteel platesEngineering

The invention discloses a multi-standard adjustable steel plate cutting machine, which includes a base and a steel plate, the base is provided with a front support and a rear support, the top of the front support is provided with a front fixing plate, and the top of the rear support is provided with a rear fixing plate , the left side of the top of the front support is provided with a second deceleration motor, the motor shaft at the rear end of the second deceleration motor is connected with a first screw, the first screw is rotationally connected with the front fixing plate and the rear fixing plate, and the first screw is connected with a first Spiral seat; the right side of the top of the front support is provided with a third deceleration motor, the motor shaft at the rear end of the third deceleration motor is connected with a second screw, the second screw is rotationally connected with the front fixing plate and the rear fixing plate, and the second screw is connected with a The second spiral seat matched with it; the bottom of the first spiral seat and the bottom of the second spiral seat are both rotatably connected with cutting knives. The invention is simple in operation and convenient in use. The cutting width of the steel plate can be adjusted by rotating the first screw rod, and the cutting length of the steel plate can be adjusted by changing the number of teeth of the driving gear.

Owner:赖高生

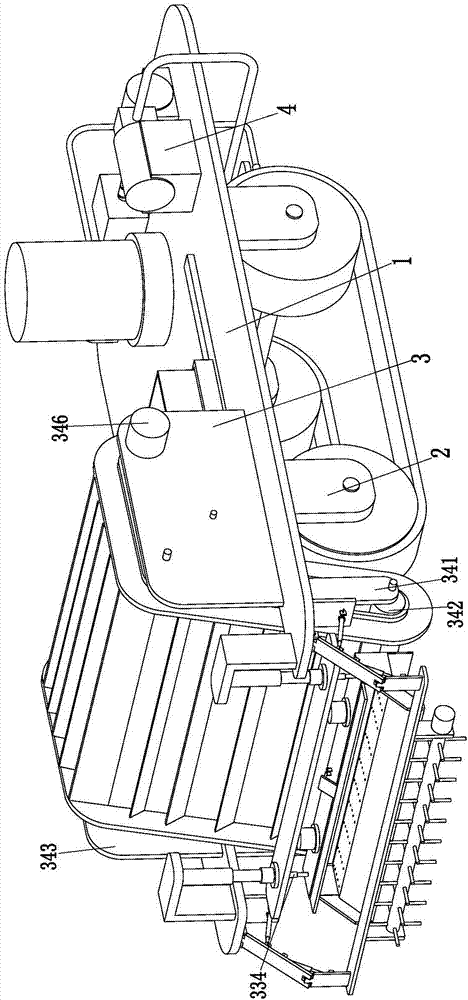

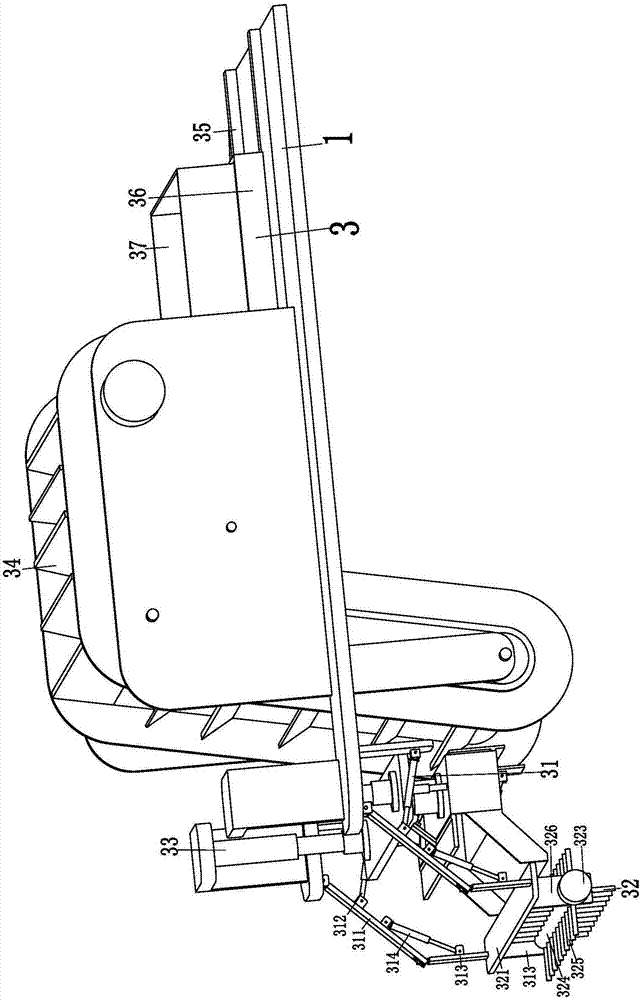

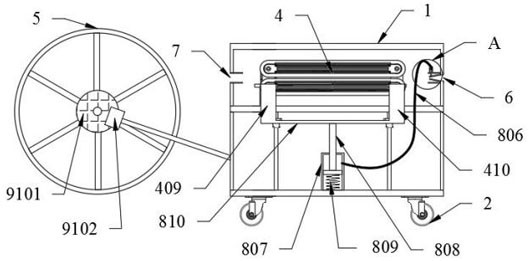

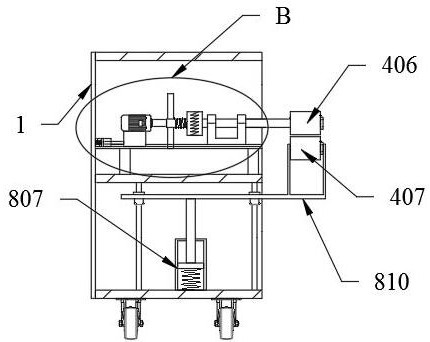

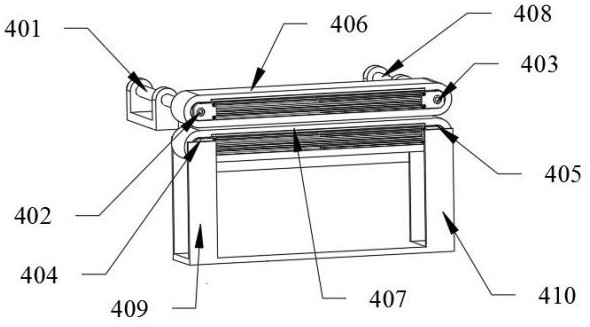

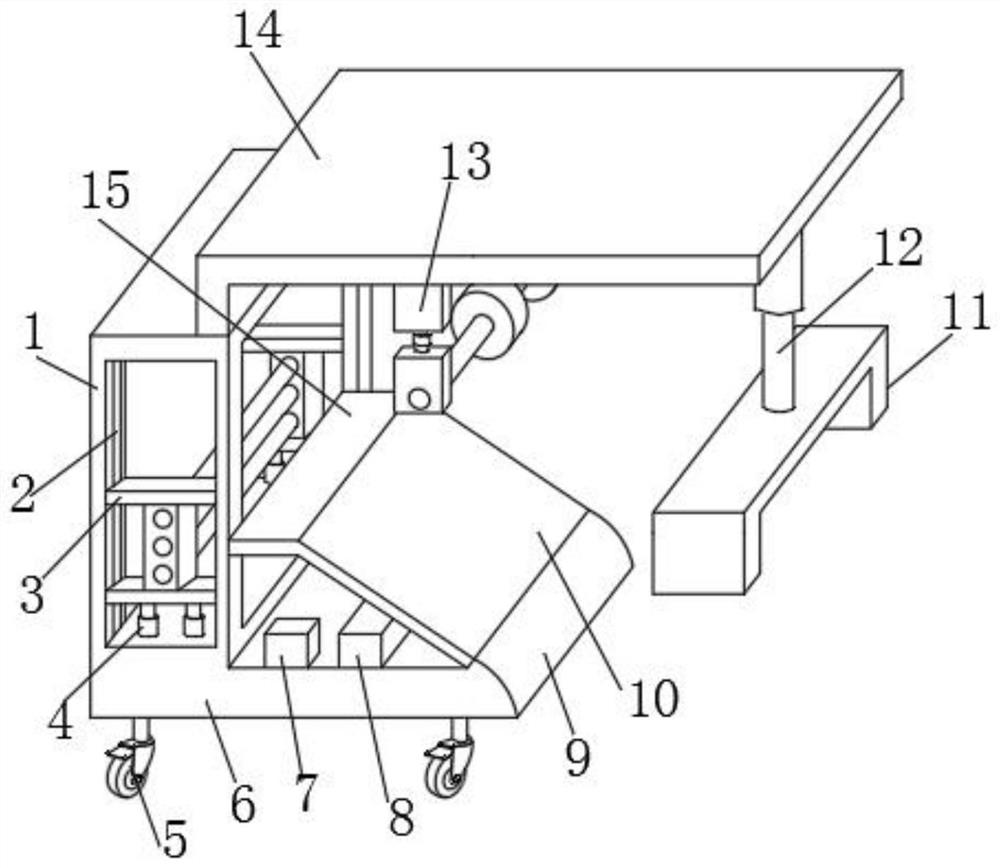

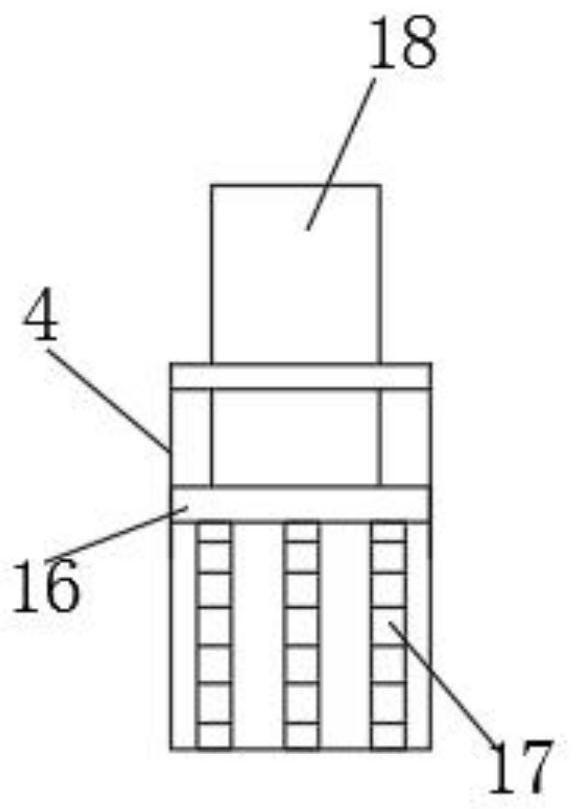

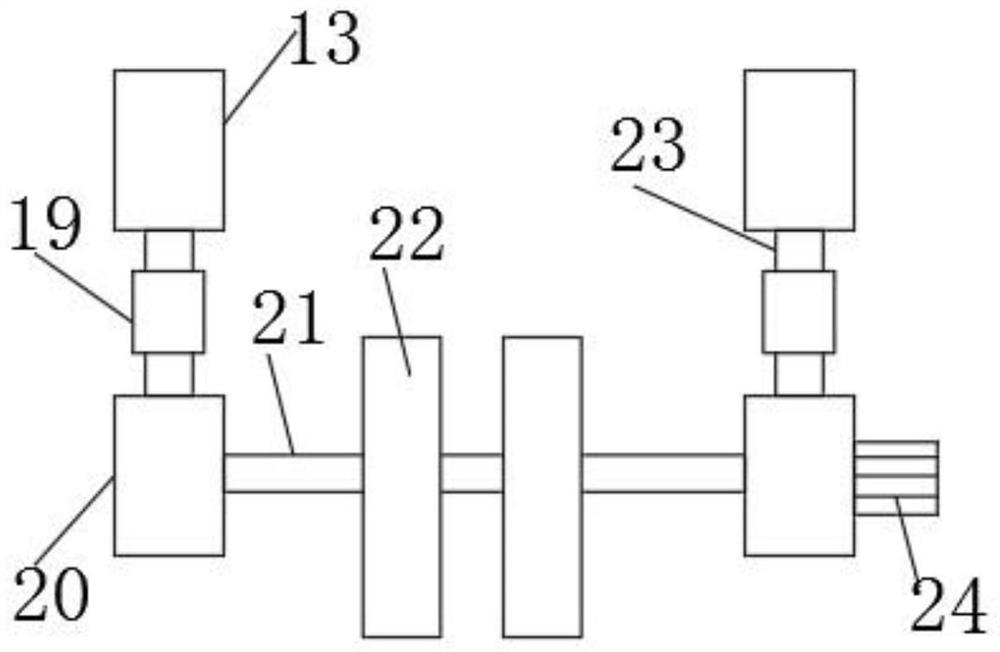

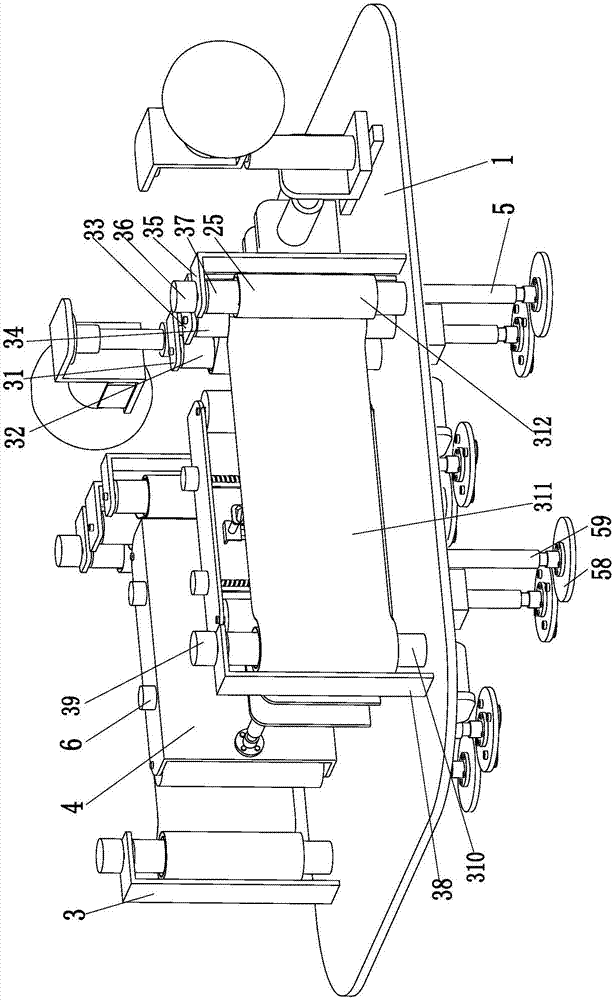

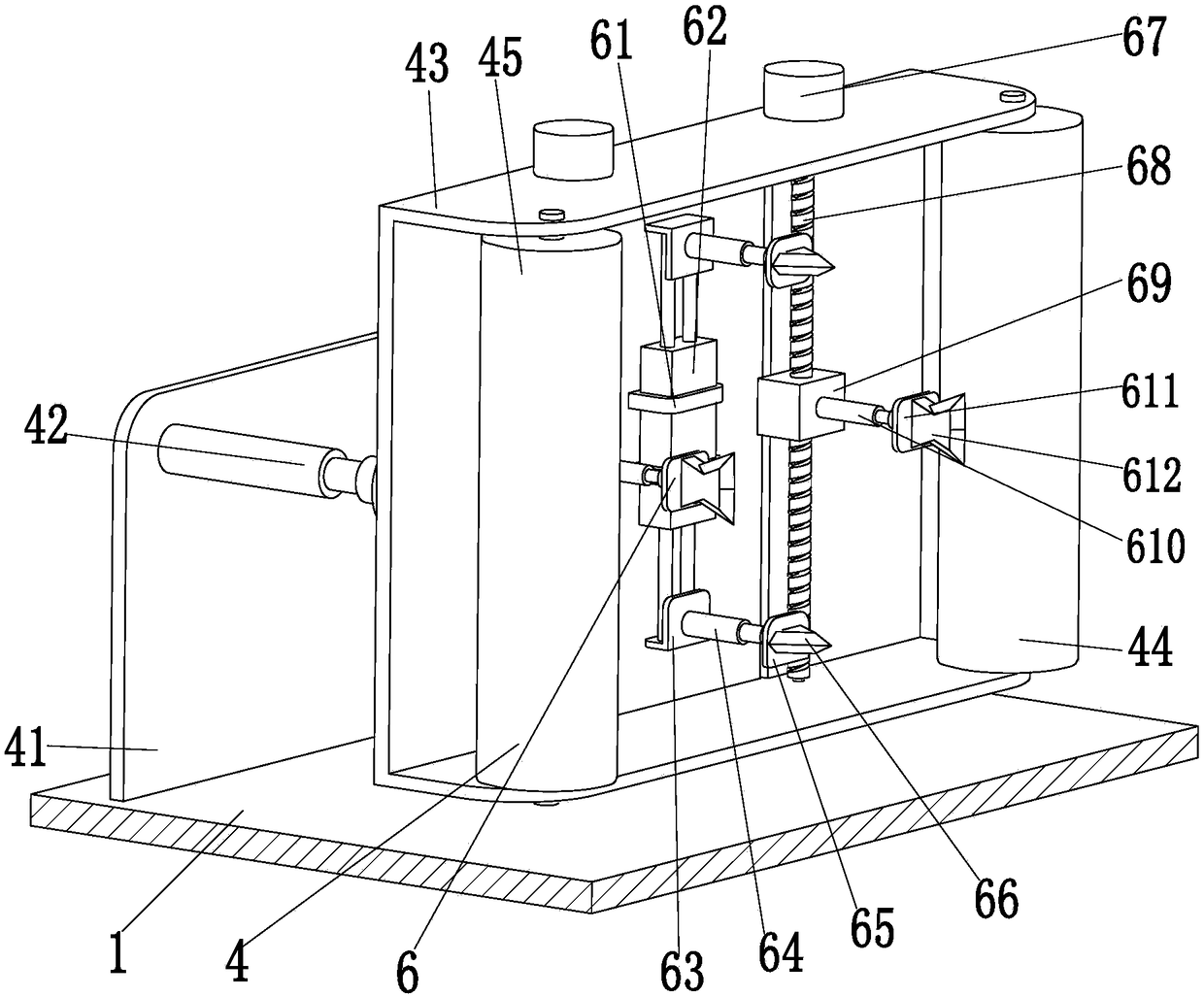

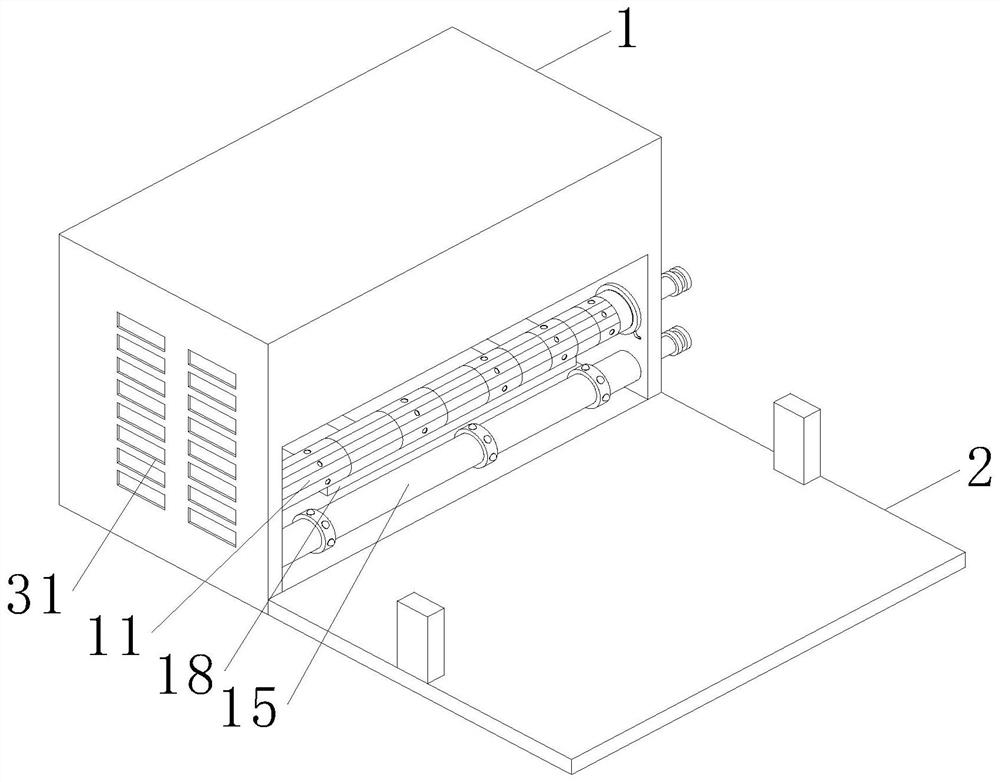

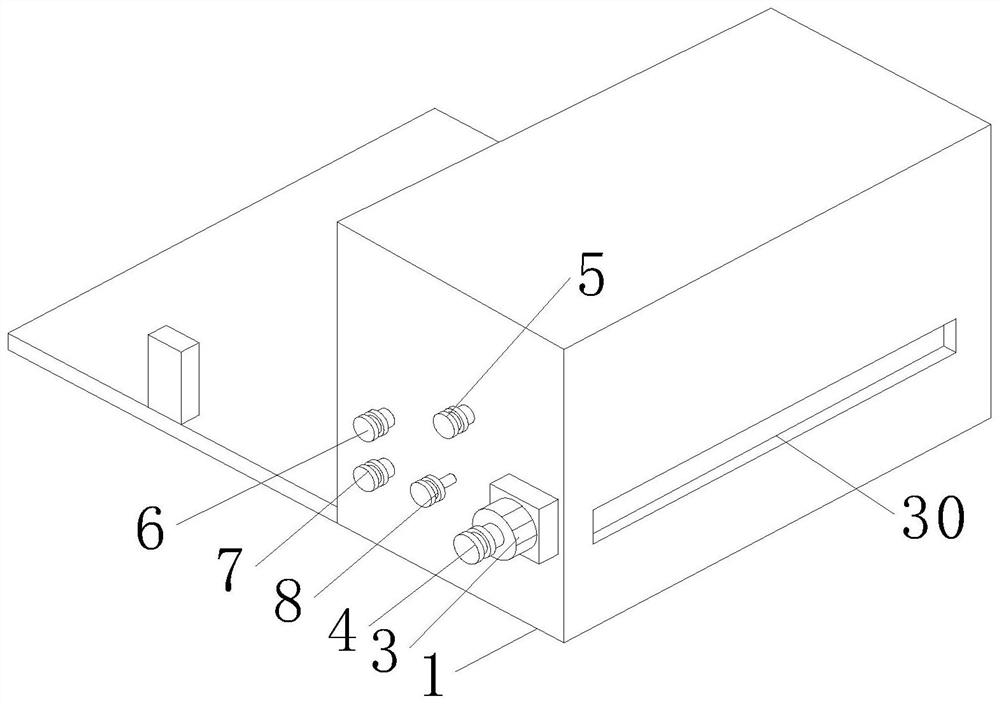

Automatic environment-friendly plastic runway glue spraying equipment with plastic particle recycling function

InactiveCN107321522AFlatness does not affectEasy to operatePretreated surfacesGround pavingsEngineeringMechanical engineering

The invention relates to automatic environment-friendly plastic runway glue spraying equipment with a plastic particle recycling function. The equipment comprises a bottom plate, a moving device is installed at the lower end of the bottom plate, a particle recycling device is installed on the front side of the upper end of the bottom plate, a glue spraying device is installed at the back end of the bottom plate, and an automatic mixed plastic runway particle recycling and automatic glue spraying technology is completed through cooperative use of the moving device, the particle recycling device and the glue spraying device. According to the equipment, the problems that in the existing plastic runway construction process, redundant particles on a plastic runway need to be manually cleaned and collected, the collected particles need to be manually screened, existing glue spraying equipment needs to be manually pushed to conduct glue spraying operation on the plastic runway according to regulations, dust on the plastic runway needs to be manually removed before glue spraying operation, and the glue spraying flatness is influenced, the consumed time is long, the labor intensity is high, and the working efficiency is low due to the fact that the speed that the glue spraying equipment is manually pushed to move is not uniform can be solved, and the automatic mixed plastic runway particle recycling and automatic glue spraying function can be achieved.

Owner:丁建丽

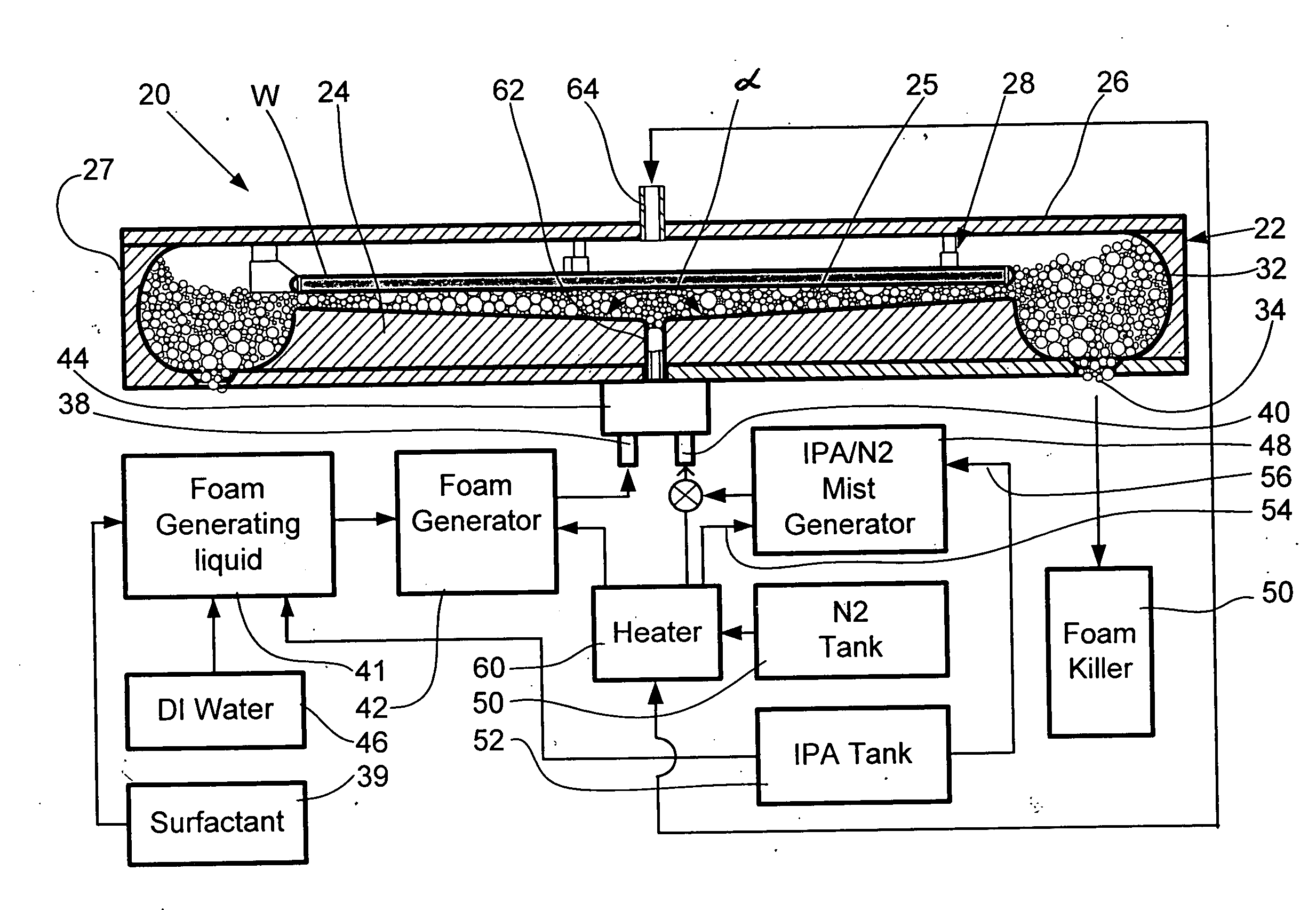

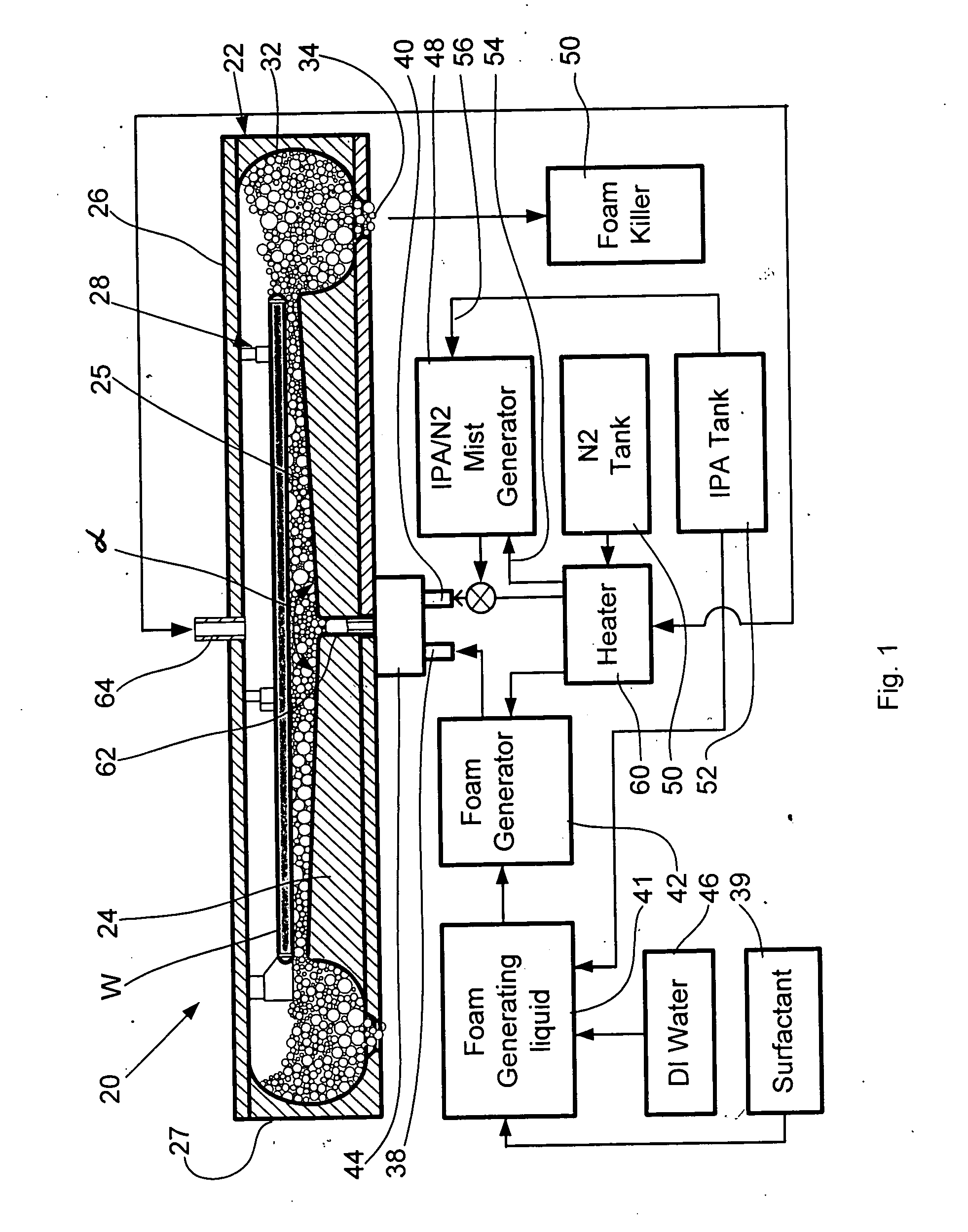

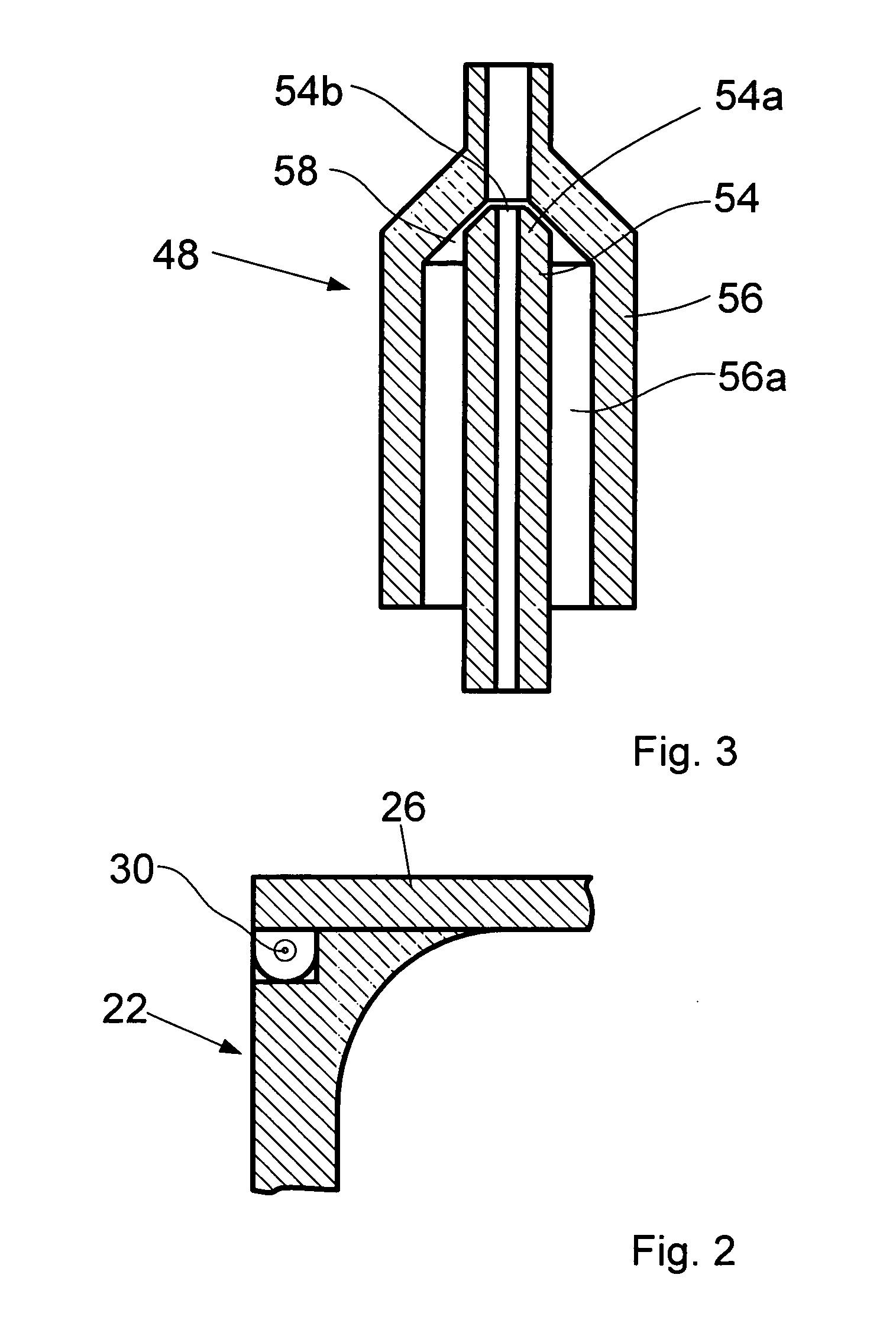

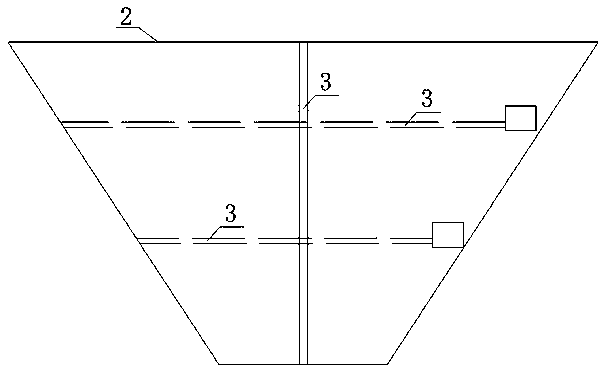

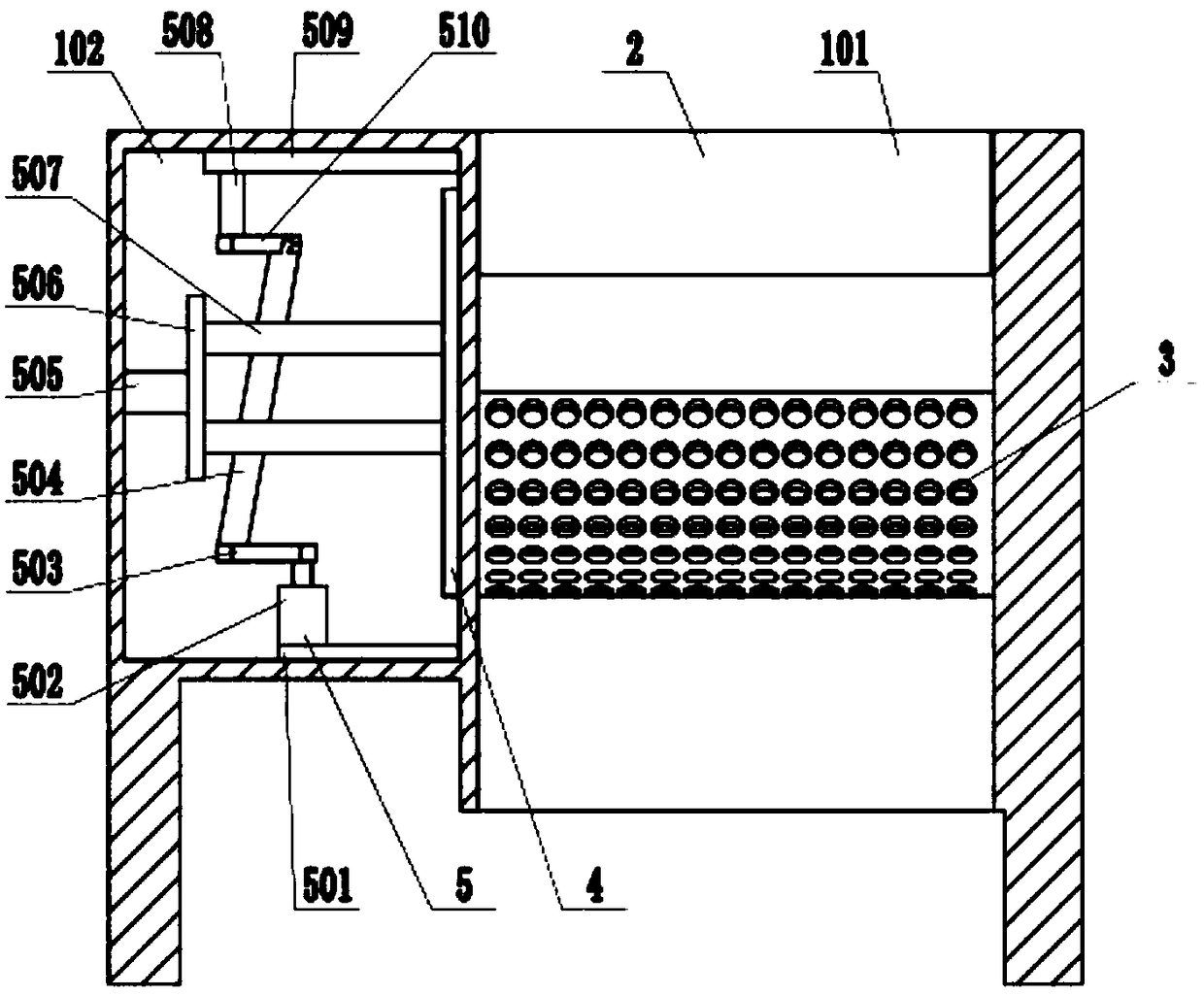

Method and apparatus for foam-assisted wafer cleaning

InactiveUS20090217950A1Improve efficiencyLow costSemiconductor/solid-state device manufacturingElectrostatic cleaningNanoparticleEngineering

A foam-assisted wafer-cleaning and drying method and apparatus based on forming a funnel-shaped space between the base plate of the apparatus and the wafer to be cleaned and supplying a foam cleaning liquid to the aforementioned space through the central opening of the base plate for displacing the cleaning liquid foam consisting of a plurality of bubbles from the center of the wafer toward the wafer periphery with a constant speed of movement of the bubbles provided by gradually decrease of distance from the base plate to the wafer in the radial outward direction from the center of the wafer. The nanoparticles of contaminants are caught with a surface-tension force developed by bubble meniscuses on the wafer surface.

Owner:MULTIMETRIXS

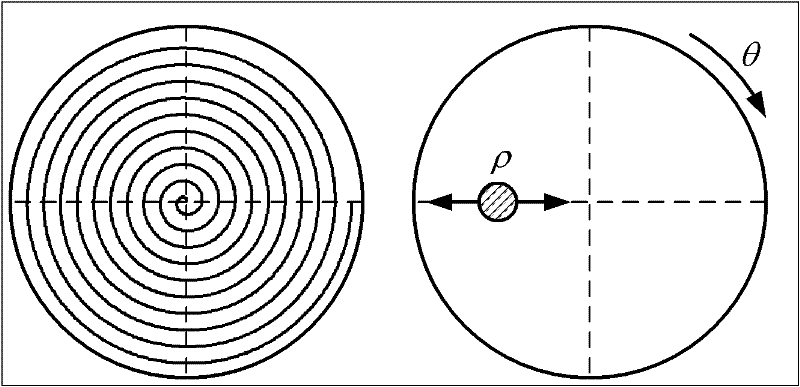

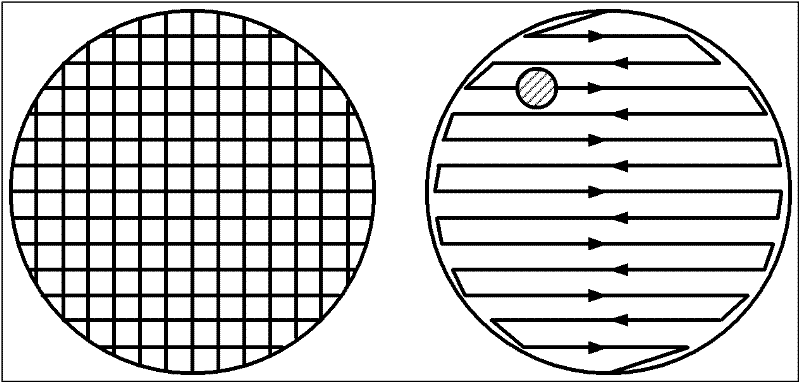

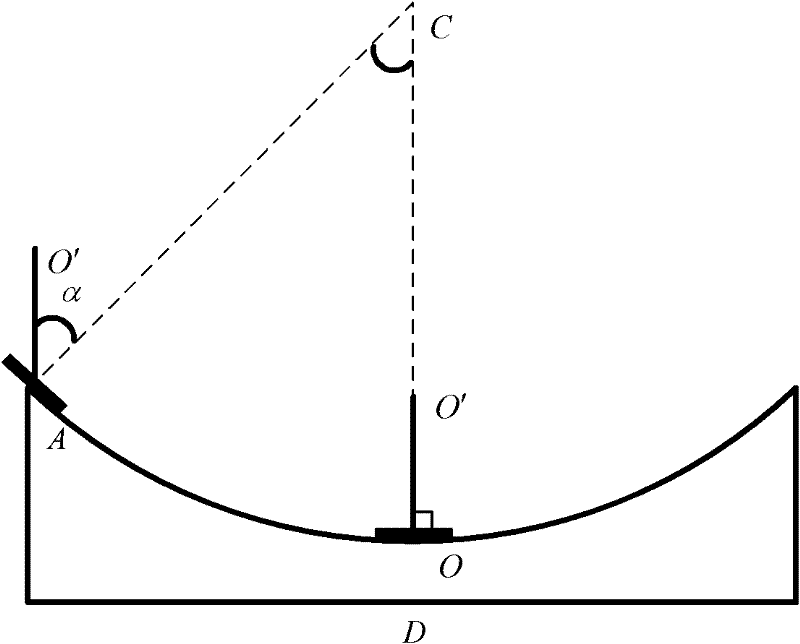

Modification processing method of optical element surface and numerical control machine used thereby

ActiveCN101898325BUniform movement speedDwell time calculation is simpleOptical surface grinding machinesNumerical controlCoupling

The invention discloses a modification processing method of an optical element surface, comprises the following steps: planning a processing and scanning route, converting coordinates, calculating processing dwell time, modifying and processing, converging step by step and the like, is combined with the advantages of an X-Y scanning mode and a rho-theta scanning mode, has the advantages of good stability, strong controllability, simple processing operation and high processing precision, and is especially suitable for the modification processing of the optical element surface of a high gradient workpiece. The invention also discloses a numerical control machine used in the modification processing method, an abrasive disk thereof and a rotation axis thereof are connected with a universal coupling, the rotation axis of a removal function generator is aslant arranged on an engine base in a mode of having an included angle beta with the optical axis of a workpiece to be processed, and the numerical control machine has the advantages of simple structure, low cost and the like.

Owner:NAT UNIV OF DEFENSE TECH

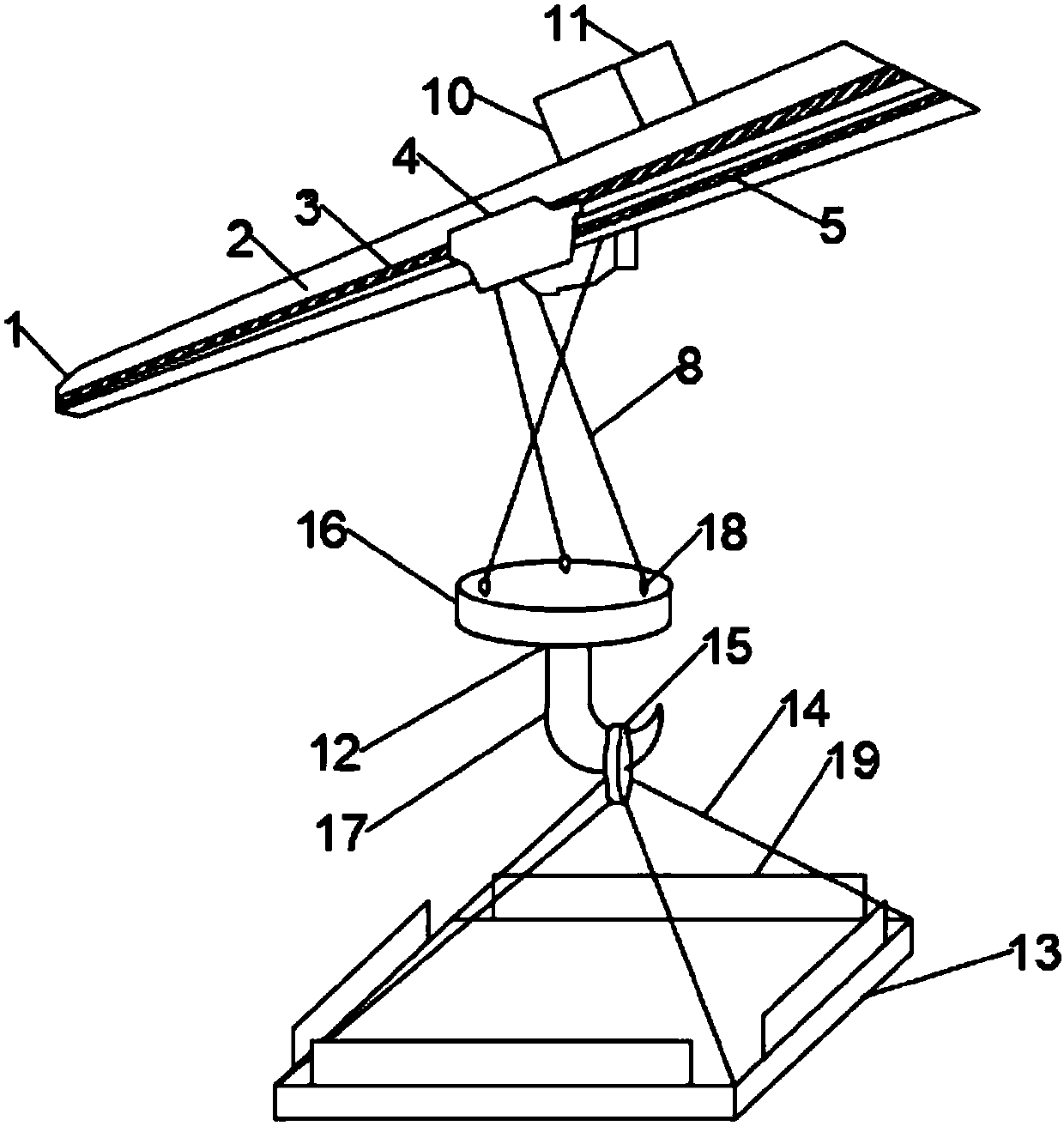

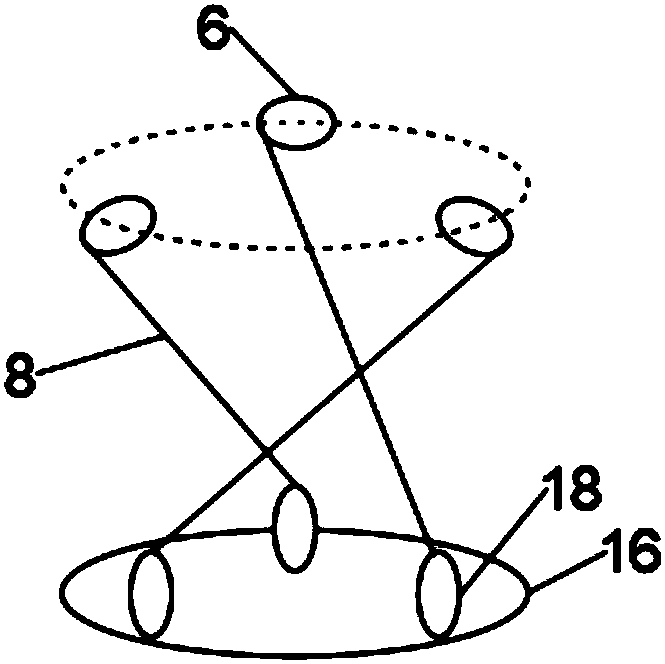

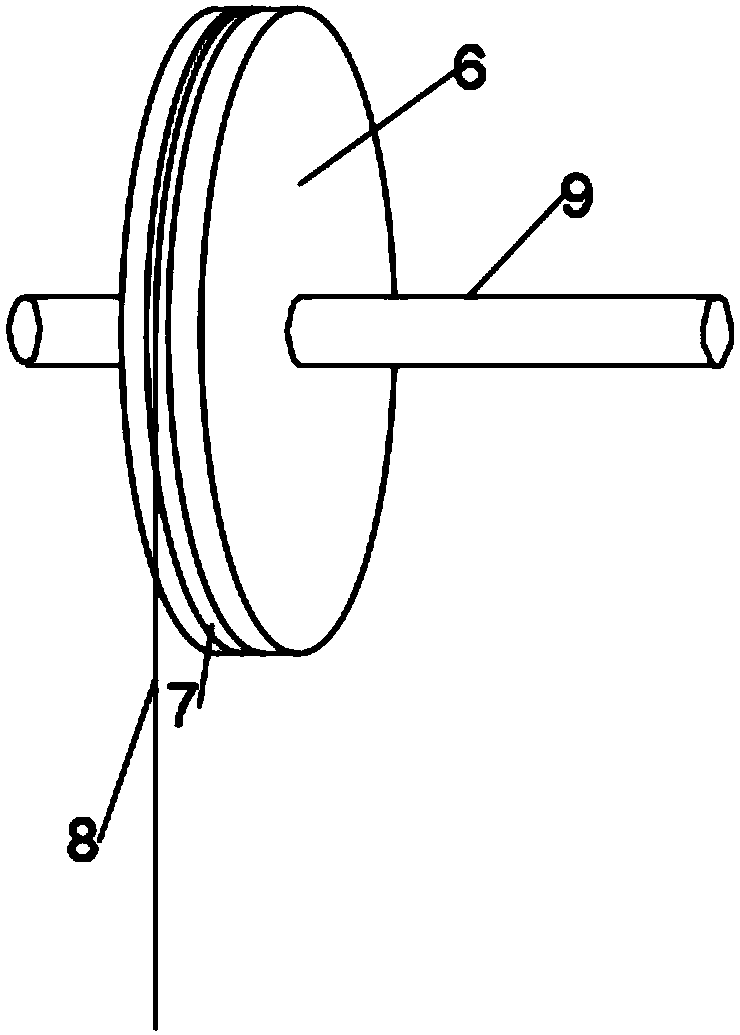

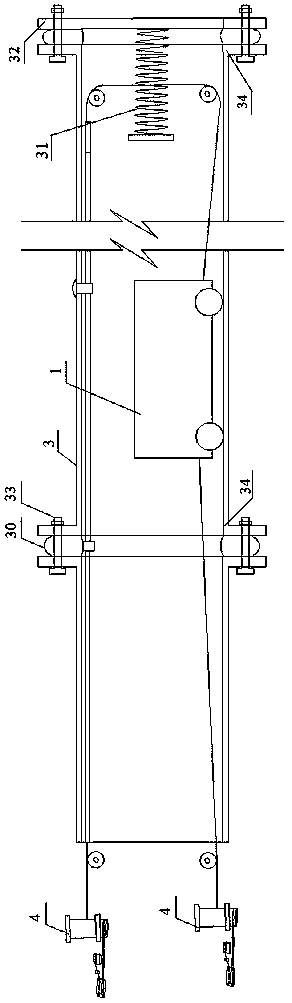

Anti-swinging device for lifting appliance for bridge type crane

InactiveCN107686057AIncrease the number ofAvoid shakingTravelling cranesLoad-engaging elementsFrequency changerBridge type

The invention discloses an anti-swinging device for a lifting appliance for a bridge type crane. The anti-swinging device comprises a bridge which comprises a main beam, tracks are welded to the frontside face and the rear side face of the main beam correspondingly, and a sliding block is arranged below the main beam. A hydraulic rod is arranged at the right end of the sliding block, the slidingblock is clamped to the tracks, and three rolls are mounted on the inner wall of the sliding block. Grooves are formed in the three rolls correspondingly, steel wire ropes are arranged in the groovescorrespondingly, and rotary shafts are arranged in the centers of the three rolls correspondingly. One ends of the rotary shafts are connected with a motor through a belt, the motor is connected witha frequency changer, and the lower ends of the steel wire ropes are connected with a hanger. A consigning plate is arranged below the hanger, branched ropes are arranged at the four corners of the consigning plate, and one ends of the branched ropes are jointly connected with a hanging ring. The hanging ring is hung on the hanger, the function of material hanging can be achieved, shaking can be reduced in the use process, the stability of the lifting appliance for the bridge type crane is improved, the problems put forward by the background technology can be effectively solved, and the anti-swinging device is worth popularizing.

Owner:ANHU WUHU CHANGJIANG JACK UP EQUIP CO LTD

Vacuum aluminizing method of surface of neodymium-iron-boron permanent magnet

ActiveCN101736304BGood directionHigh hardnessVacuum evaporation coatingSputtering coatingHigh energyMetallurgy

The invention relates to a vacuum aluminizing method of the surface of a neodymium-iron-boron permanent magnet. The method sequentially comprises the following steps of: (1) polishing and cleaning the surface of the neodymium-iron-boron permanent magnet by adopting a wet method; (2) putting the neodymium-iron-boron permanent magnet on a rotating workpiece fame in a film plating chamber to ensure that the temperature of the neodymium-iron-boron permanent magnet is kept between 250 DEG C and 300 DEG C; (3) starting a vacuum pump on the film plating chamber and adjusting the vacuum degree of thefilm plating chamber to be 1-9*10<-3>Pa; (4) meanwhile, starting multi-arc cathode evaporators at both sides of the film plating chamber, a plane magnetic sputtering target and the rotating workpieceframe to carry out magnetic control multi-arc sputtering for 2-7 hours; (5) maintaining the film plating chamber to be cooled for 30-60 minutes under vacuum, aerating, opening the chamber, taking outthe aluminized neodymium-iron-boron permanent magnet and carrying out passivation with a non-chrome passivation solution. High energy ions generated by magnetron sputtering strike low-energy ions generated by the multi-arc method so as to promote the low-energy ions to generate more ionization, wherein the speeds and the trends of the high-energy ions and the low-energy ions are uniform, thus theefficiency is improved.

Owner:YANTAI ZHENGHAI MAGNETIC MATERIAL CO LTD

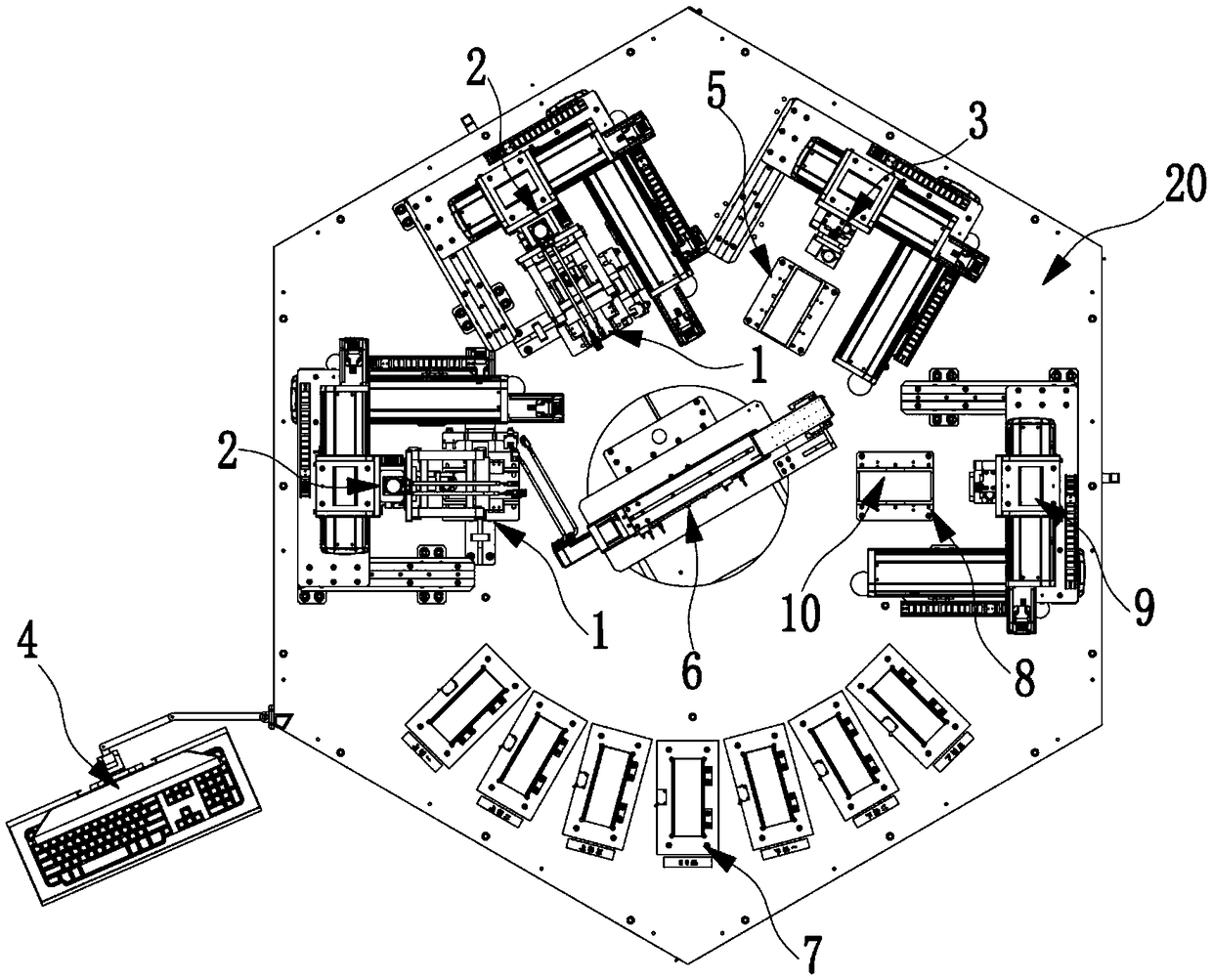

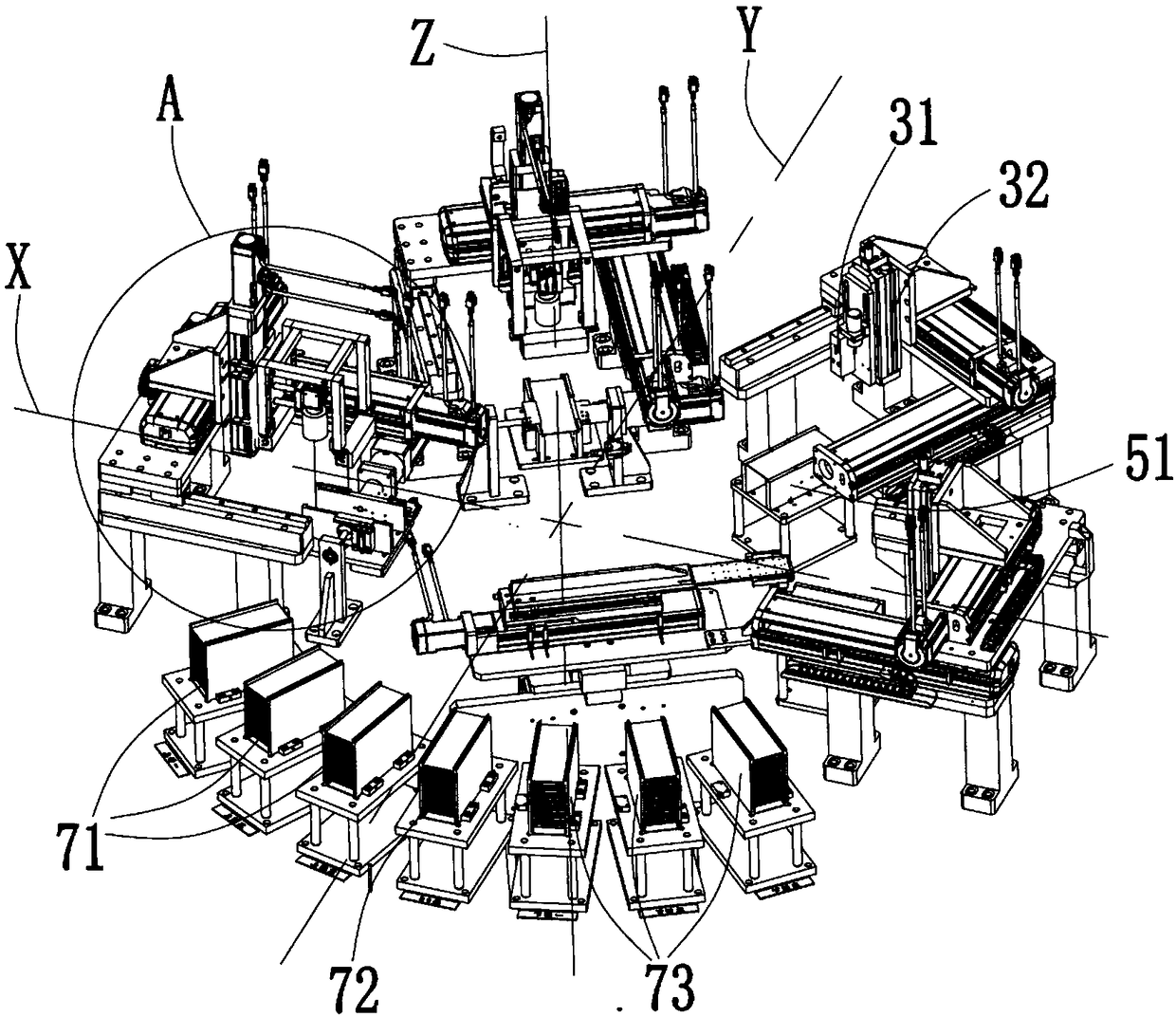

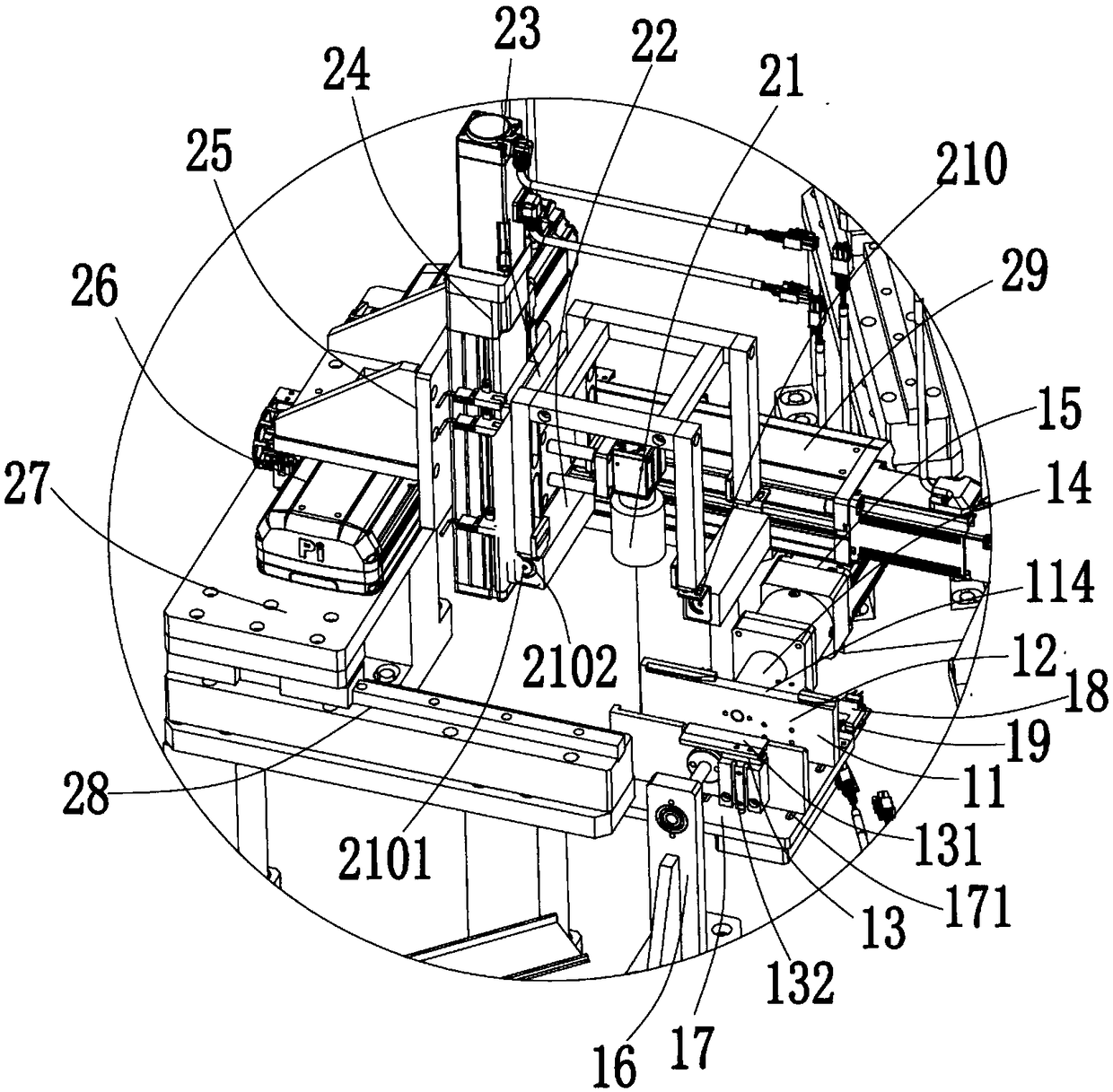

A two-side visual detection robot and a detection method thereof

PendingCN108931534ARealize acquisitionHigh speedOptically investigating flaws/contaminationCamera lensMachine vision

A two-side visual detection robot and a detection method thereof are disclosed. The robot at least includes turnover devices accommodating and fixing LED backlight sheets, driving the LED backlight sheets to turn over, and allowing a zone to be detected of at least one surface of the LED backlight sheets on the turnover devices to be exposed; image collection devices movably arranged on the turnover devices to collect images of the exposed zones to be detected of the LED backlight sheets on the turnover devices; and a control device connected to the turnover devices and the image collection devices. The robot is exquisite in design and simple in structure, and two surfaces to be detected of each LED backlight sheet can be pointed at a camera lens respectively through turnover to achieve image collection, and therefore, automatic two-side defect detection of LED backlight sheets can be performed by utilizing a visual recognition technique, manual intervention on a detection process is low, problems of detection leakage and a low detection precision are solved, the speed and accuracy of detection with machine vision are far higher than those of detection with human eyes, and good detection precision and a high efficiency are effectively achieved.

Owner:SUZHOU JIANGJIN AUTOMATION TECH

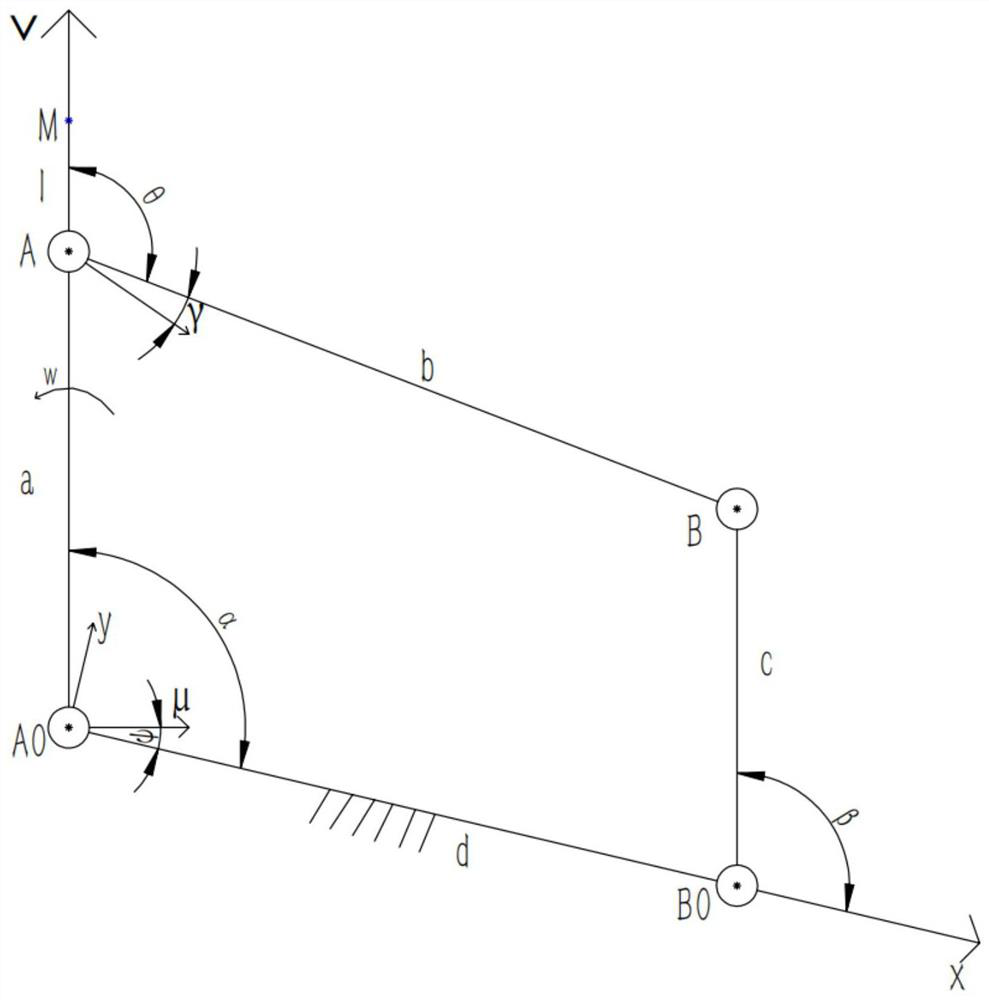

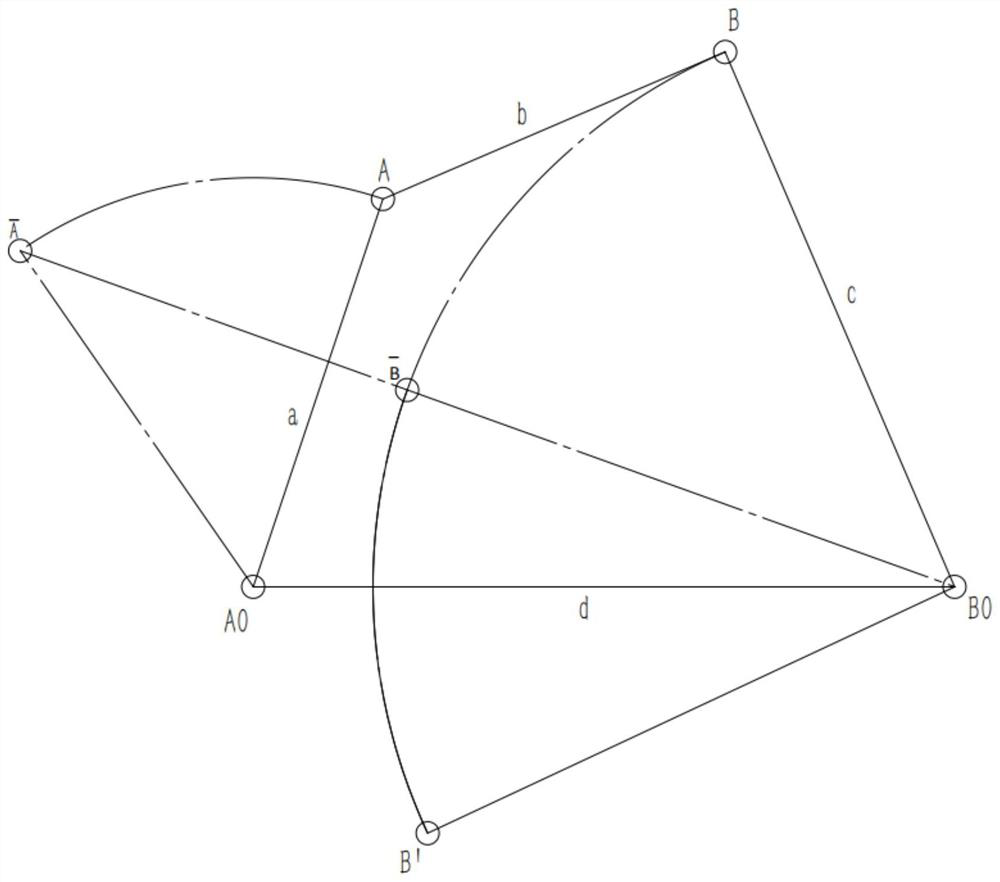

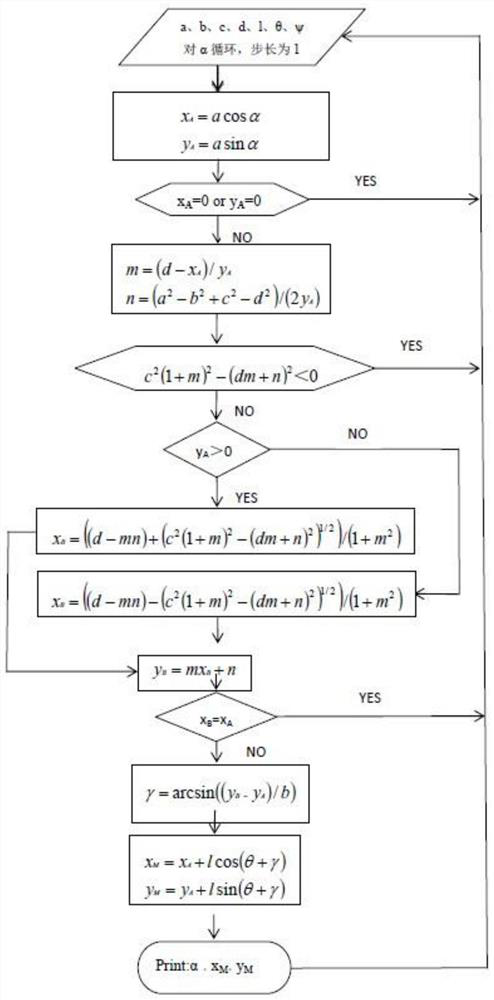

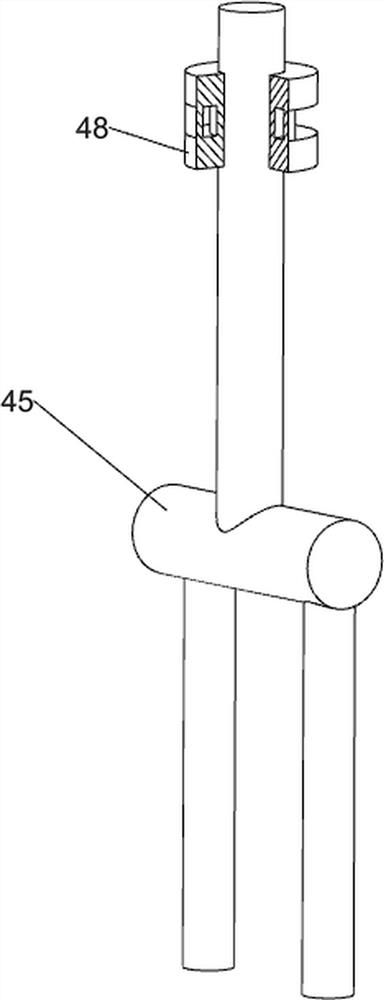

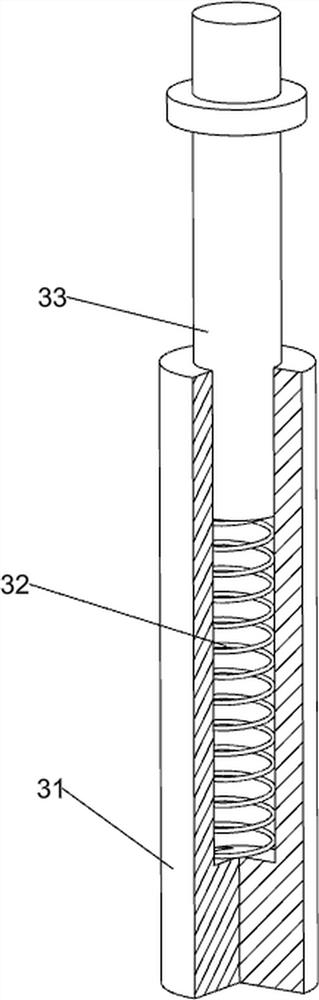

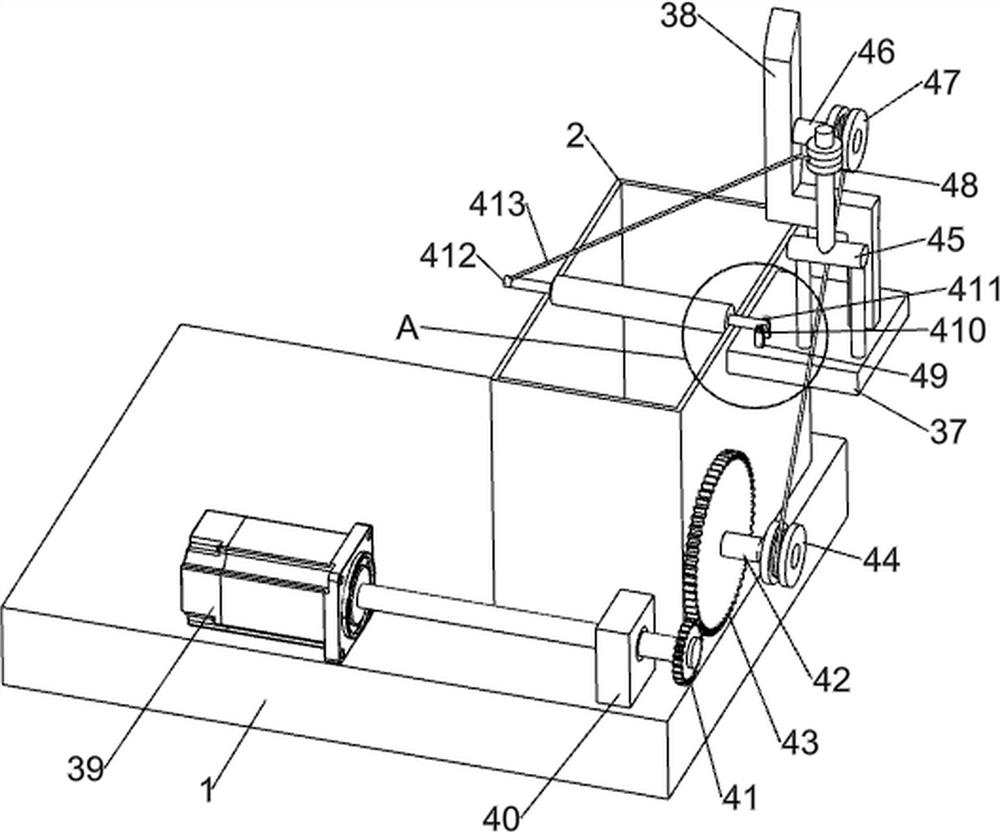

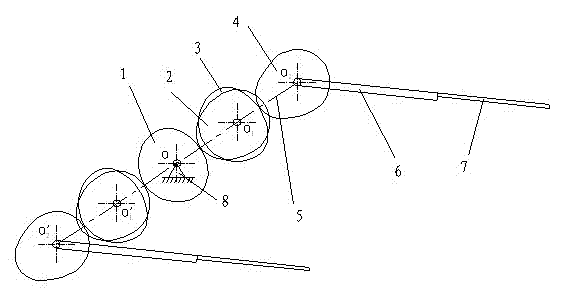

Connecting rod mechanism and connecting rod mechanism track determination method

PendingCN112668115AGuaranteed uptimeUniform movement speedGeometric CADConstraint-based CADStructural engineeringMechanical engineering

The invention provides a connecting rod mechanism and a connecting rod mechanism track determination method. The method comprises the following steps: the first end of a first connecting rod is connected with an installation foundation, the first end of a second connecting rod is hinged to the second end of the first connecting rod, the first end of a third connecting rod is connected with the installation foundation, and the second end of the third connecting rod is hinged to the second end of the second connecting rod; the first end of the first connecting rod and the first end of the third connecting rod are arranged at a distance, and a fourth connecting rod is formed between the first end of the first connecting rod and the first end of the third connecting rod; coordinates of a plane point M of the connecting rod mechanism are determined according to the lengths of the first connecting rod, the second connecting rod, the third connecting rod and the fourth connecting rod, and thus determining a movement track of the connecting rod mechanism according to the coordinates of the plane point M. According to the connecting rod mechanism obtained through the method, the movement speed of the connecting rod mechanism is uniform, operation is more stable, the impact force of the connecting rod mechanism of the structure on equipment is small, and the service life of the equipment is effectively prolonged.

Owner:ZHUHAI GREE INTELLIGENT EQUIP CO LTD +1

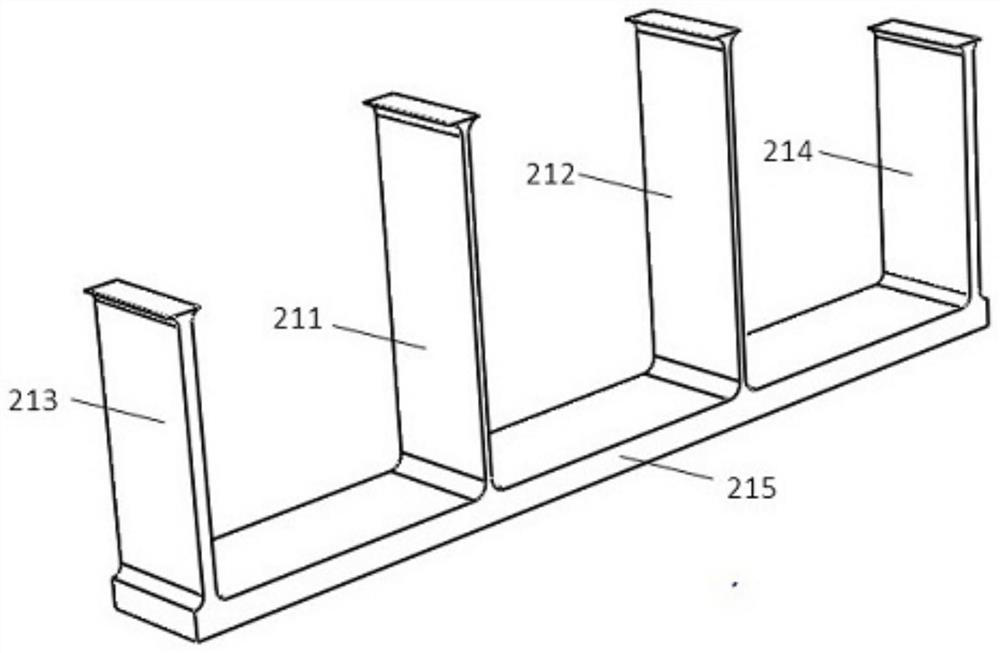

Water transfer printing device for wooden stair railing fixing pile

ActiveCN112060754AUniform movement speedImprove work efficiencyTransfer printingElectric machineryStructural engineering

The invention relates to a water transfer printing device, in particular to a water transfer printing device for a wooden stair railing fixing pile. According to the water transfer printing device forthe wooden stair railing fixing pile, the speed of the fixing pile can be uniform, and the production efficiency can be improved. The water transfer printing device for the wooden stair railing fixing pile comprises a transfer printing box, which is arranged at one side of the top of a base; and a water transfer printing mechanism, which is arranged at the top of the base. According to the watertransfer printing device, the fixing pile is fixed through an electric clamp, the fixing pile is driven to move downwards through cooperation of a first winding wheel and a first pull rope to be completely immersed in the transfer printing box, the first pull rope drives a mounting block to move forwards when a first fixing rod is no longer blocked by a fixing frame, so that the fixing pile is driven to move forwards for uniform transfer printing, a motor operates to enable the fixing pile to move at uniform speed, and water transfer printing is more uniform and attractive.

Owner:NANJING HANMINGZHI INTELLIGENT TECHNOLOGY CO LTD

Line type monitoring device and monitoring method for internal appearance and external appearance of dam

ActiveCN110319809AUniform movement speedAccurate displacementNavigation by speed/acceleration measurementsHeight/levelling measurementContinuous measurementMeasuring instrument

The invention discloses a line type monitoring device and monitoring method for internal appearance and external appearance of a dam. By arranging a measuring rail in advance on the surface of a dam panel or inside a dam body, a measuring instrument operates at a uniform speed in the measuring rail; and a measuring system comprises a uniform speed hoist, the measuring instrument, the measuring rail, a DSP processor, a power line and the like. According to the invention, the T-shaped measuring rail is mounted on the surface of the dam so as to implement line type monitoring on the external appearance of the dam; the measuring instrument is assisted by the uniform speed hoist in operating at the uniform speed in the measuring rail arranged in advance, so that a measurement error is reduced;a deviation between an attitude angle of an optical fiber gyroscope strapdown update matrix and an attitude angle of an attitude measuring instrument is optimized, and a zero drift is subjected to distinguishing compensation, so that monitoring accuracy can be improved; and by designing a waterproof ring, waterproofness of the monitoring device is reinforced. The line type monitoring device and monitoring method are applicable to continuous measurement on surface and internal deformations of the dam and particularly continuous measurement on panel deflection and sedimentation and horizontal displacement inside the dam.

Owner:江西省水利厅工程建设稽察事务中心 +2

Sand screening device

PendingCN108372109ASolve the problem of low efficiency and unable to meet work needsSave human effortSievingScreeningEngineering

Owner:BEIFANG UNIV OF NATITIES

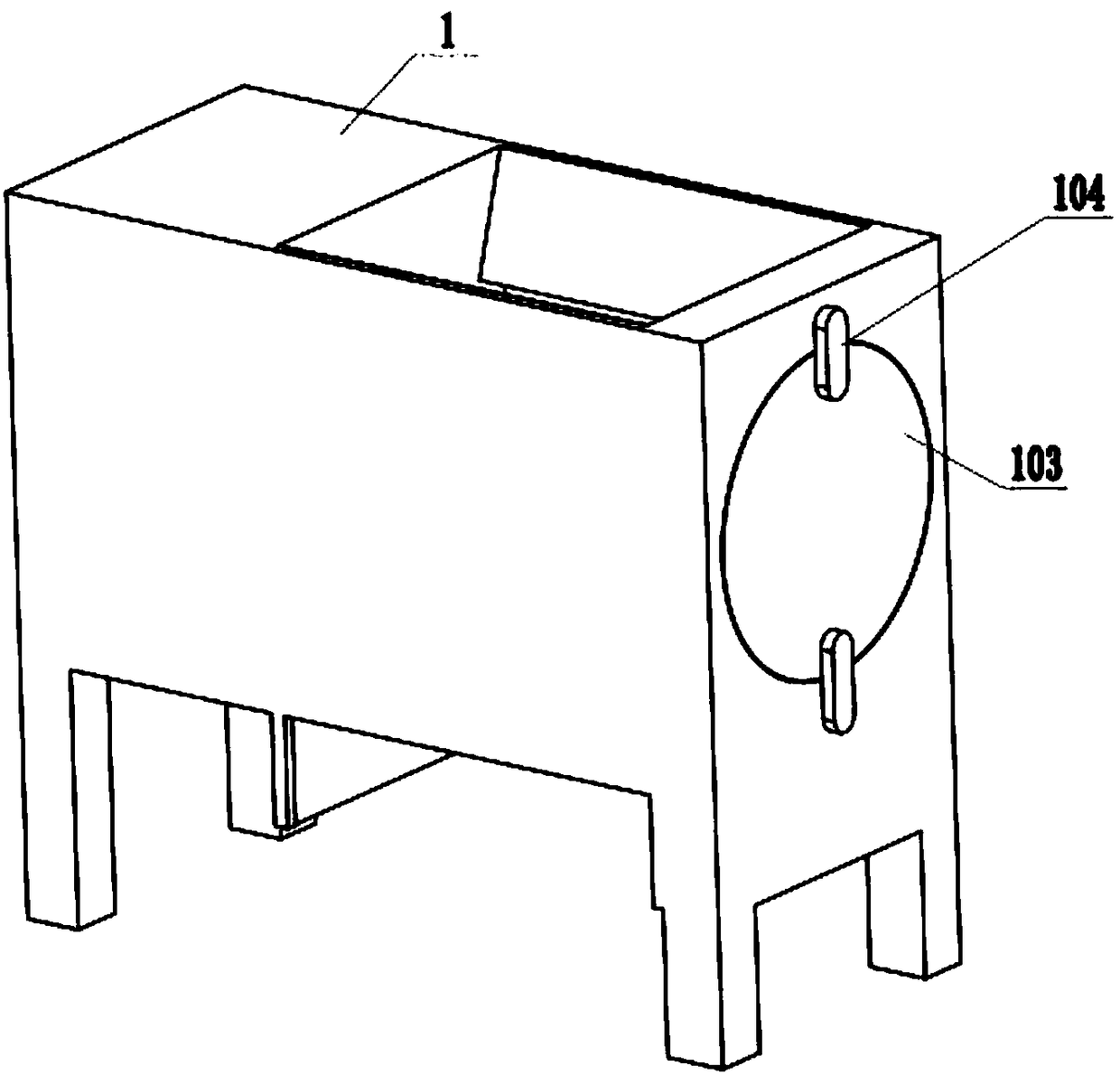

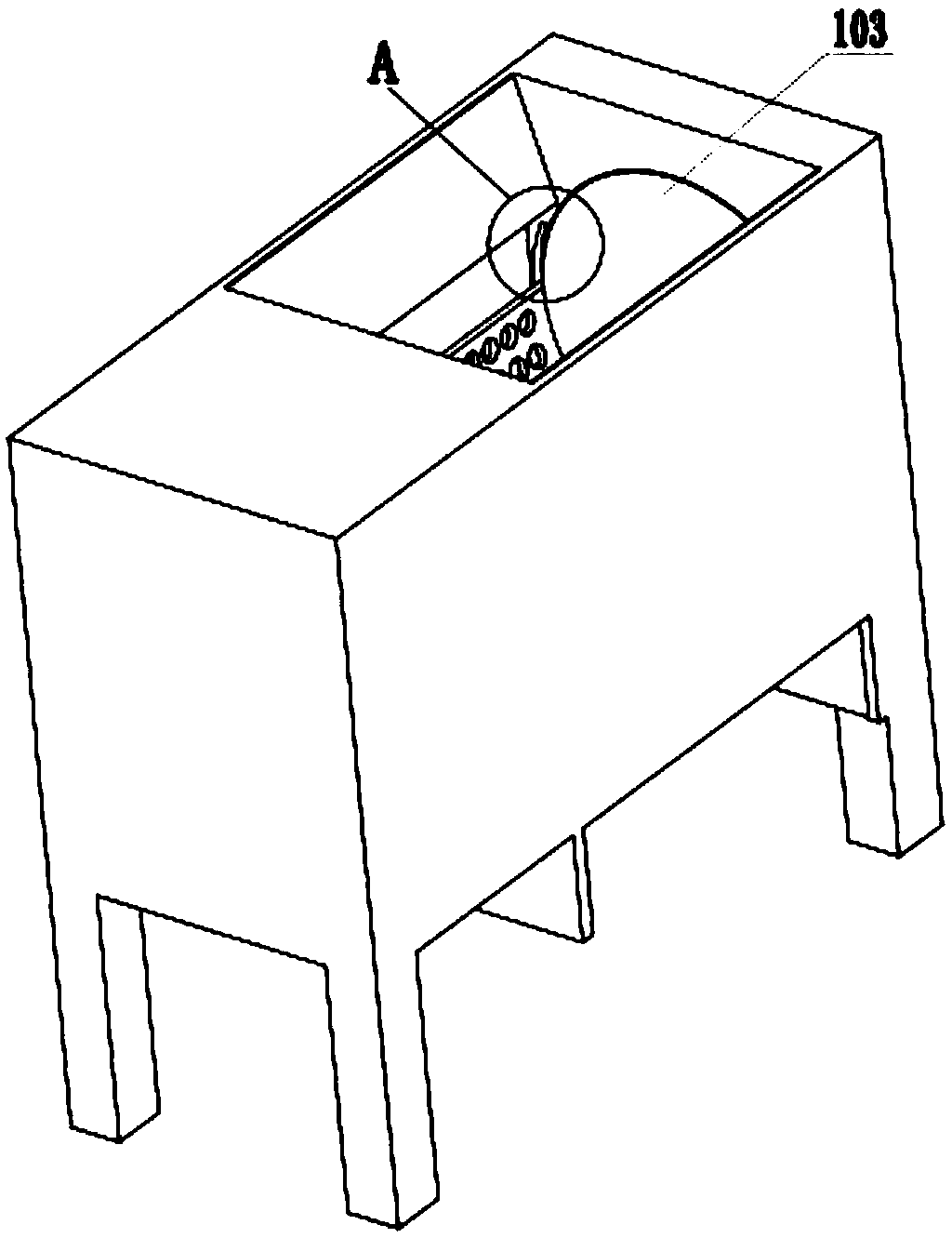

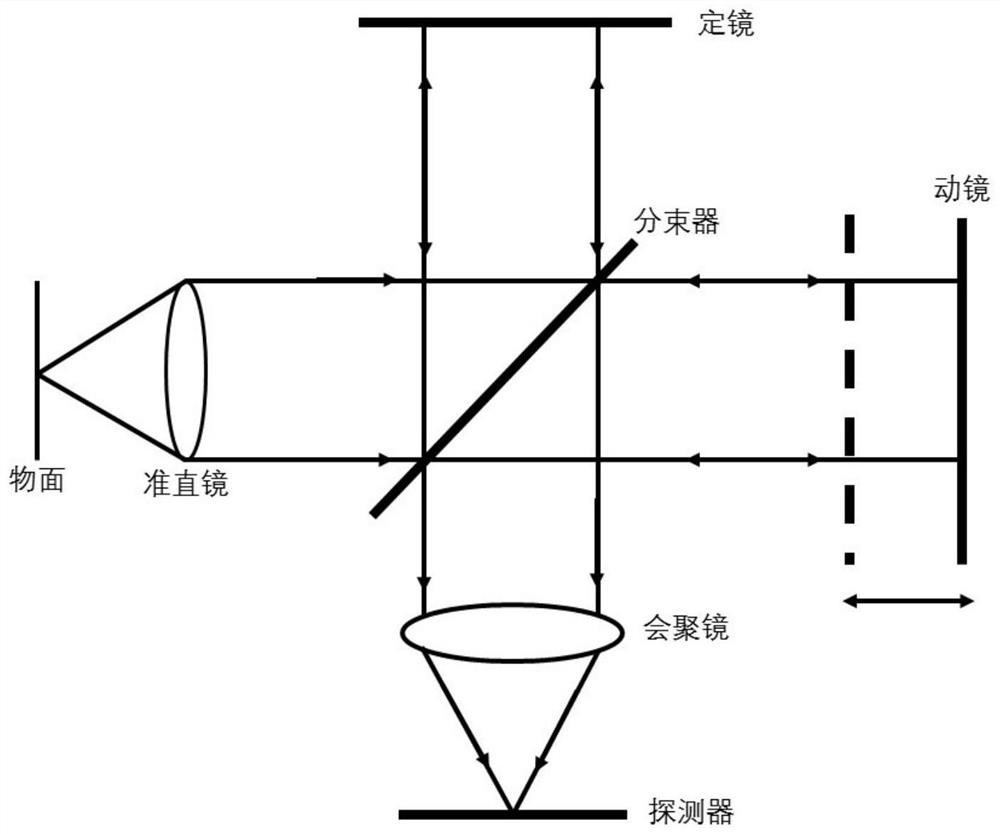

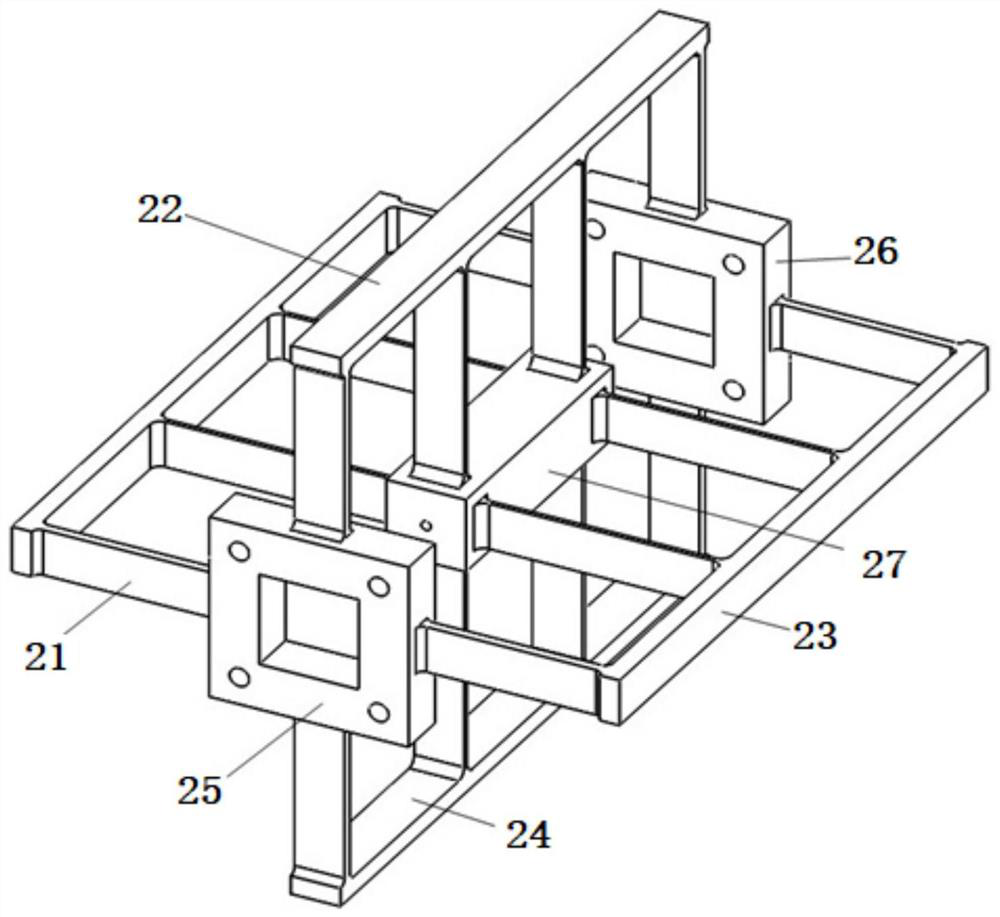

Symmetrical flexible supporting mechanism

PendingCN113532642AGuaranteed motion accuracyFrictionlessRadiation pyrometrySpectrum investigationOptical spectrometerImage resolution

In order to overcome the defects that a traditional movable mirror supporting mechanism is short in service life, large in coupling displacement, prone to inclination of a displacement output end face and small in movement stroke, the invention provides a symmetrical flexible supporting mechanism which comprises four movable arms, two fixed bodies and a movable body. The four movable arms are the same in structural size, are connected with the movable body through two connecting bodies in the middle of each movable arm and are connected with the two fixed bodies through compensation bodies at the two ends of each movable arm, the four movable arms are symmetrically arranged in the space relative to the center of the movable body, and every two adjacent movable arms are spaced by 90 degrees; the connecting body and the compensation body on each movable arm are flexible hinges, movement transmission is achieved through the flexible hinges, the advantages of zero-clearance transmission, zero friction and the like are achieved, and the movement precision of the mechanism is effectively guaranteed; and a double-parallelogram nested structure is formed in each movable arm, so that the movement stroke of a movable mirror can be effectively increased, a compensation function is achieved, and the spectral resolution of an imaging spectrometer can be improved. The symmetrical flexible supporting mechanism of the invention has the advantages of simple and compact structure, low cost and long service life.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

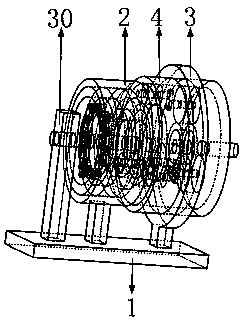

Centrifugal block clamping block transmission

InactiveCN108591382APrevent reactive violent collisionsUniform movement speedToothed gearingsGearing controlGear driveEngineering

The invention belongs to the technical field of transmissions and particularly relates to a centrifugal block clamping block transmission. The centrifugal block clamping block transmission comprises an installing plate, a drum wheel, an input shaft, a Z-shaped ring and an output shaft; when the input shaft rotates, a driving plate rotates and drives arc-shaped strips to rotate; when the rotating speed of the arc-shaped strips is small, the effect of the centrifugal force borne by centrifugal blocks is small; the arc-shaped strips can drive a fixed shaft disk to rotate, and a third fixed shaft,a second one-way ring, a second sun gear and a second planet gear rotate and drive an inner gear ring to rotate; the inner gear ring drives the output shaft to rotate; when the arc-shaped strips moveat a high speed, in the moving process of the first centrifugal block, when the first centrifugal block makes contact with the drum wheel, the first centrifugal block can perform friction with the drum wheel; the arc-shaped strips drive the drum wheel to rotate through friction of the first centrifugal block and the drum wheel; a Z-shaped wheel rotates, and due to rotation of a first one-way ringand a first sun gear, a first planet gear drives the inner gear ring to rotate; the inner gear ring drives the output shaft to rotate; and a simple structure is used, and the beneficial effect of two-gear transmission is achieved.

Owner:HANGZHOU FUYANG XINYUAN NEW ENERGY CO LTD

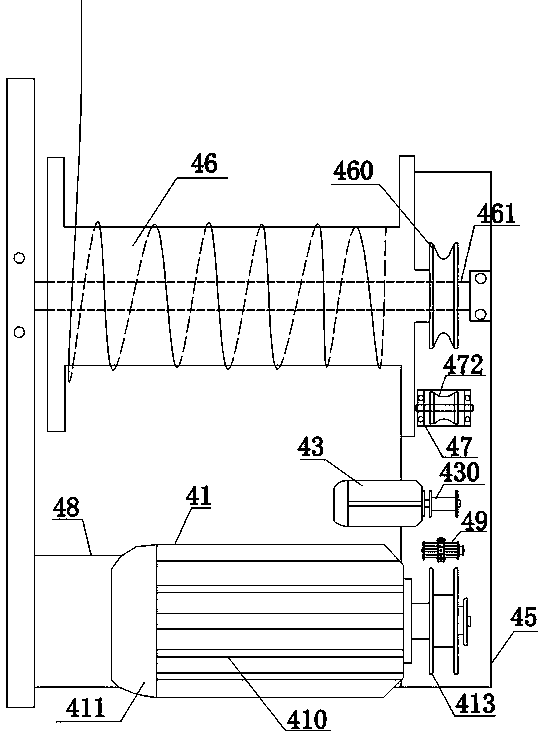

Efficient automatic loosening and tightening type optical cable traction machine for pipe dredging device

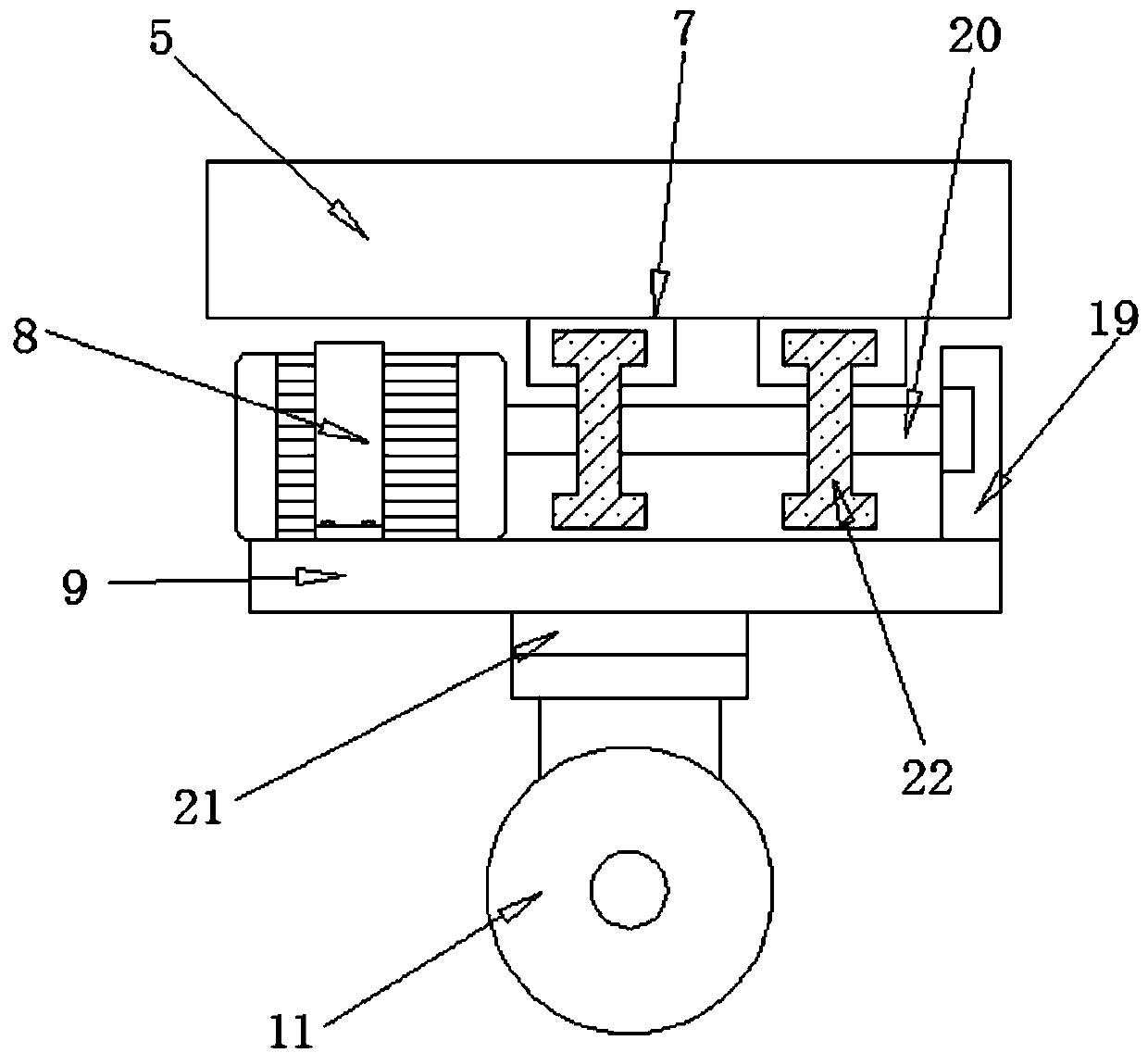

ActiveCN113277372AEven by forceUniform movement speedFilament handlingOptical fibre/cable installationElectric machineryControl theory

The invention discloses an efficient automatic loosening and tightening type optical cable traction machine for a pipe dredging device. The efficient automatic loosening and tightening type optical cable traction machine comprises a vehicle body, wheels, a motor, a conveying mechanism, the pipe dredging device, a wire inlet, a wire outlet, a pressing mechanism and a clutch mechanism. A cavity is formed in the vehicle body, and the motor, the conveying mechanism, the pressing mechanism and the clutch mechanism are all located in the cavity; the wheels are arranged on the lower part of the vehicle body, one end of the motor is fixedly connected with the conveying mechanism, the wire inlet is formed in one end of the vehicle body, the wire outlet is formed in the end, away from the wire inlet, of the vehicle body, the pipe dredging device is arranged at the position, close to the wire outlet, of the vehicle body, the pressing mechanism is arranged below the conveying mechanism, and the clutch mechanism is arranged between the motor and the conveying mechanism. The pressing mechanism enables the traction machine to change the traction force of the conveying mechanism on the optical cable according to different optical cable pipe diameters; and the clutch mechanism is used for separating the motor from the conveying mechanism when an accident occurs, so that the motor cannot be damaged.

Owner:骥志(江苏)新能源科技有限公司

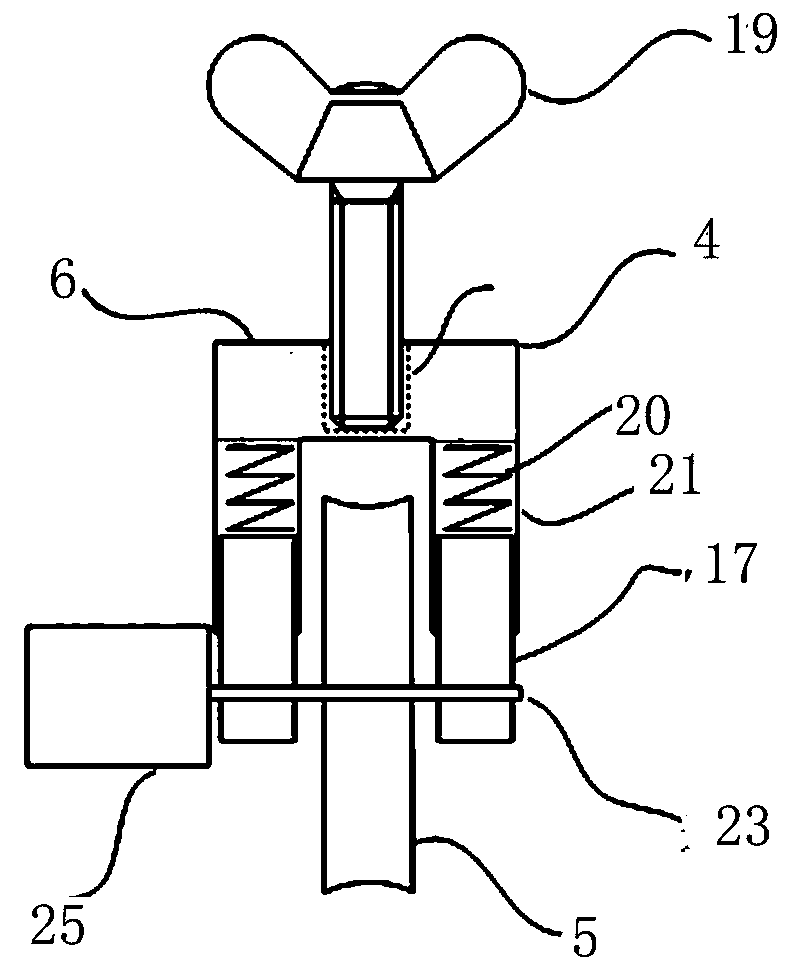

Handheld far field eddy current probe pushing and pulling device

PendingCN110243928AUniform movement speedReduce physical exertionMaterial magnetic variablesPush and pullRolling resistance

The invention discloses a handheld far field eddy current probe pushing and pulling device, which relates to the field of far field eddy current detection, in particular to the handheld far field eddy current probe pushing and pulling device. The device comprises a shell and is characterized in that the shell is provided with a channel through which a probe penetrates; two ends of the channel are independently provided with a cleaning device; clamping and driving devices are arranged in the shell in pairs; the channel penetrates through an area between the same pair of clamping and driving devices; and the clamping and driving devices are in rolling friction connection with the probe which penetrates through the channel. The device has the advantages of small volume and light weight, is simple in operation, can be held with one hand, and can be suitable for small-space far field eddy current detection operation, the movement speed of the probe is even, the influence of human factors on a signal can be greatly lowered, the physical power consumption of workers is greatly reduced, and the quality and the speed of detection work are improved. The device has a simple structure and is convenient for cleaning after use and later-period disassembling and maintenance.

Owner:NORTHWEST BRANCH OF CHINA DATANG CORP SCI & TECH RES INST

Plastic steel coiling pipe processing device

ActiveCN109927275AAvoid meltingPlay a limiting roleTubular articlesEngineeringMechanical engineering

The invention belongs to the technical field of plastic processing, and specifically discloses a plastic steel coiling pipe processing device. The device comprises a cutting unit and a conveying unit,wherein the cutting unit comprises a first cutter and a second cutter which are used for cutting a plastic steel coiling pipe; the first cutter is positioned in the plastic steel coiling pipe and isrotated by treating the center of a circle of the plastic steel coiling pipe as the center; the second cutter is positioned at the outer part of the plastic steel coiling pipe and is rotated by treating the center of the circle of the plastic steel coiling pipe as the center; and the first cutter and the second cutter are positioned on the same vertical surface. The device aims at solving the problem that a cutter with sufficient size can linearly move to simply cut the plastic steel coiling pipe is not provided at present.

Owner:重庆昌兴塑胶有限责任公司

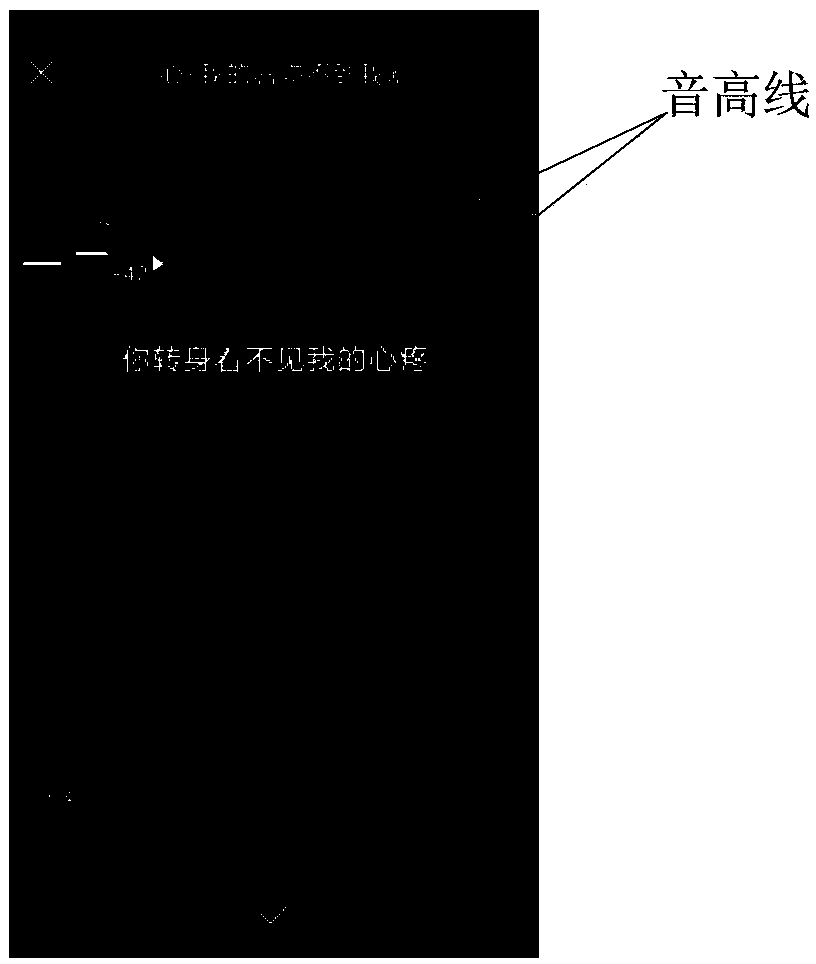

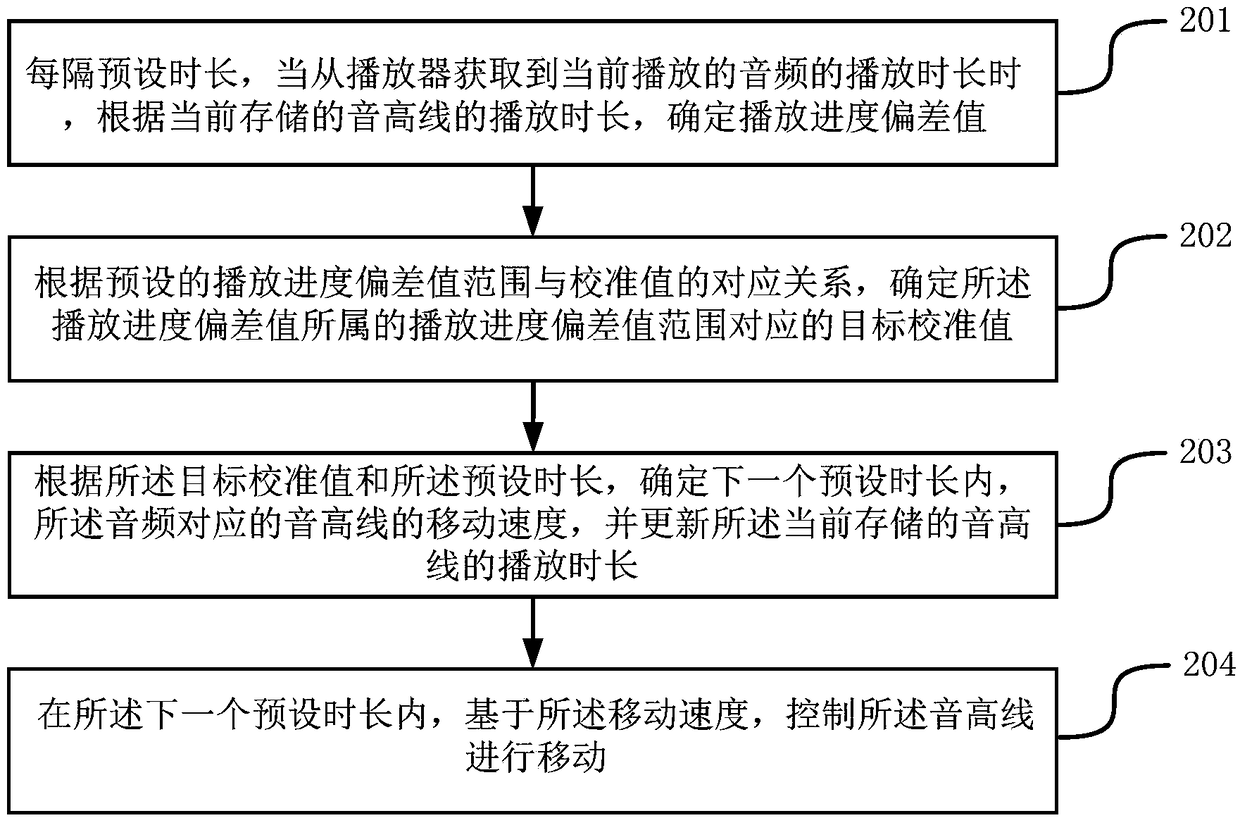

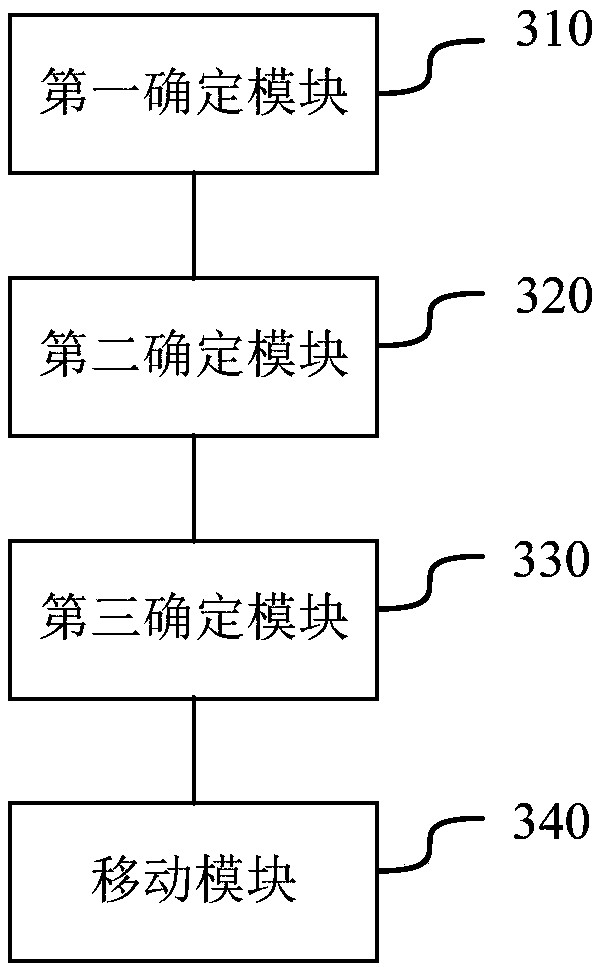

Method and device for controlling movement of pitch line

ActiveCN108965990AUniform movement speedReduce jitterSelective content distributionComputer scienceAudio frequency

The application provides a method and a device for controlling movement of a pitch line, and belongs to the technical field of computers. The method comprises: every a preset duration when the play duration of the currently played audio is acquired from the player, determining the play progress deviation value according to the play duration of the currently stored pitch line, determining a targetcalibration value corresponding to the play progress deviation value range to which the play progress deviation value belongs according to a correspondence between the preset play progress deviation value range and the calibration value, determining a moving speed of the pitch line corresponding to the audio within the next preset duration according to the target calibration value and the preset duration, updating the playing duration of the currently stored pitch line, and controlling the pitch line to move based on the moving speed within the next preset duration. With this application, thejitter during the movement of the pitch line may be reduced.

Owner:GUANGZHOU KUGOU COMP TECH CO LTD

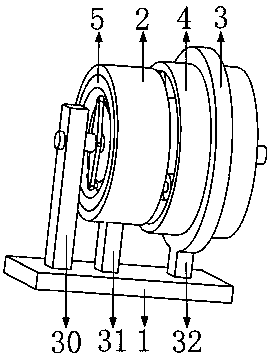

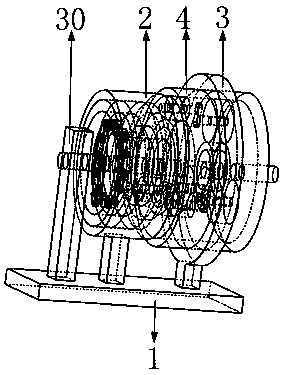

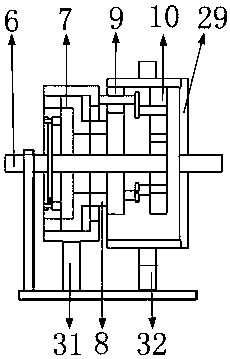

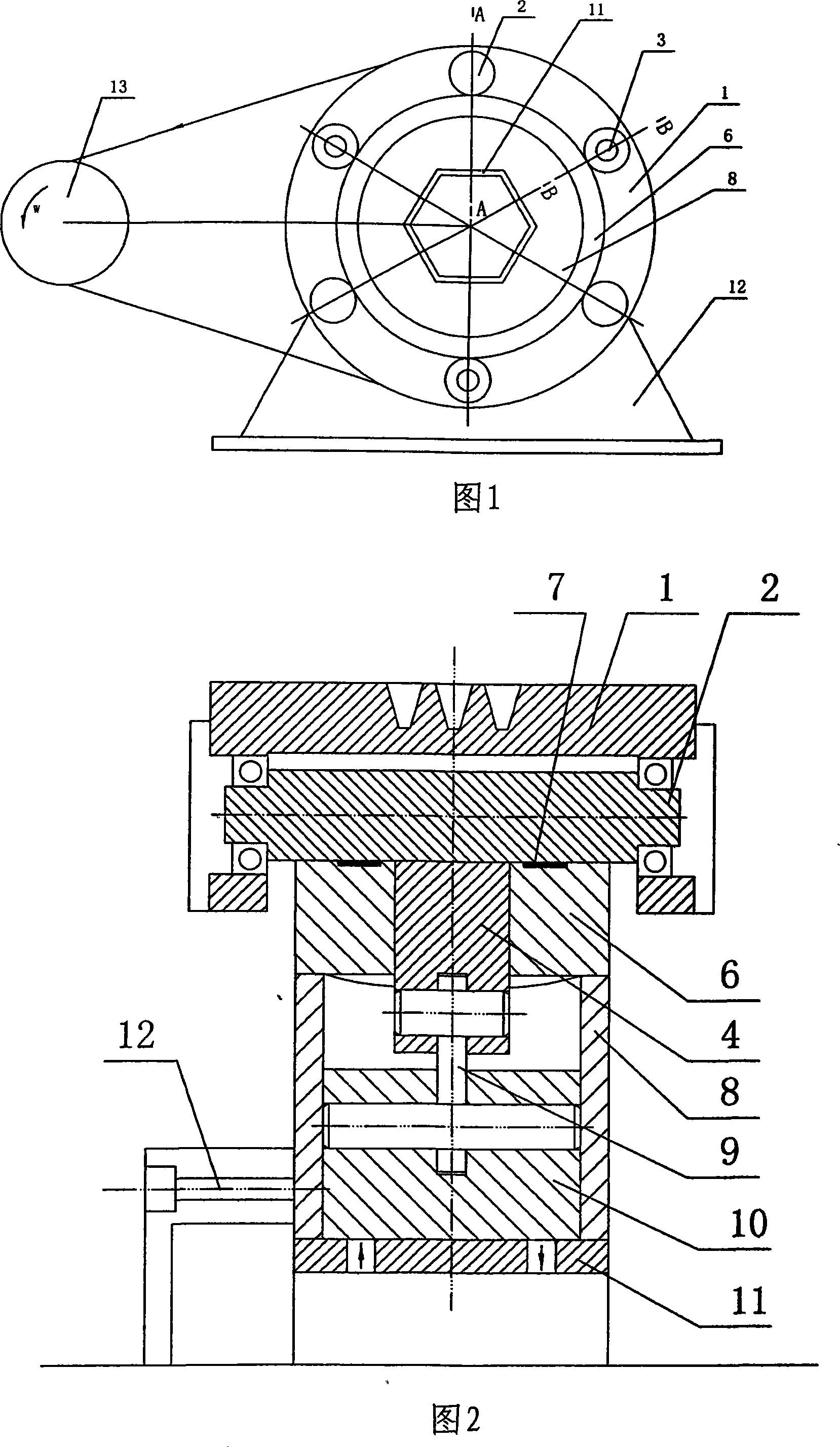

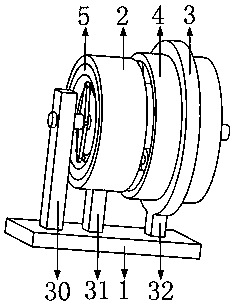

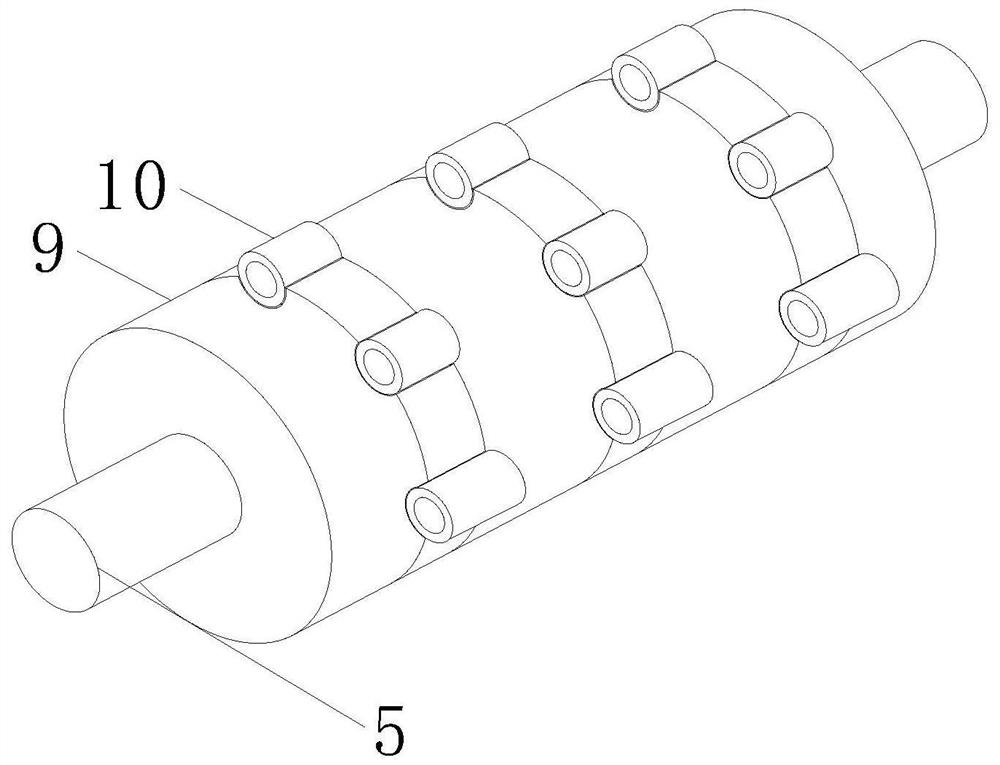

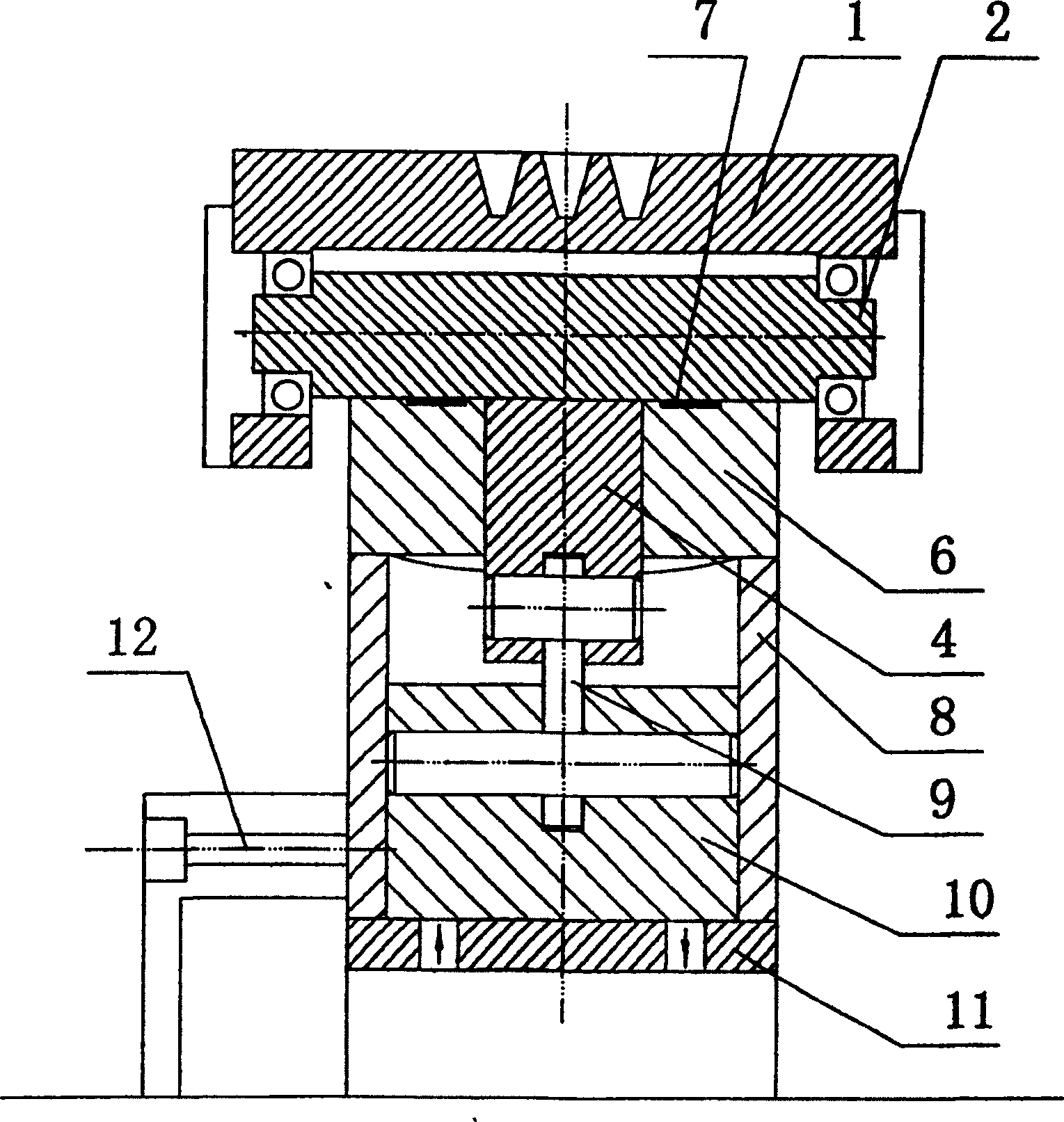

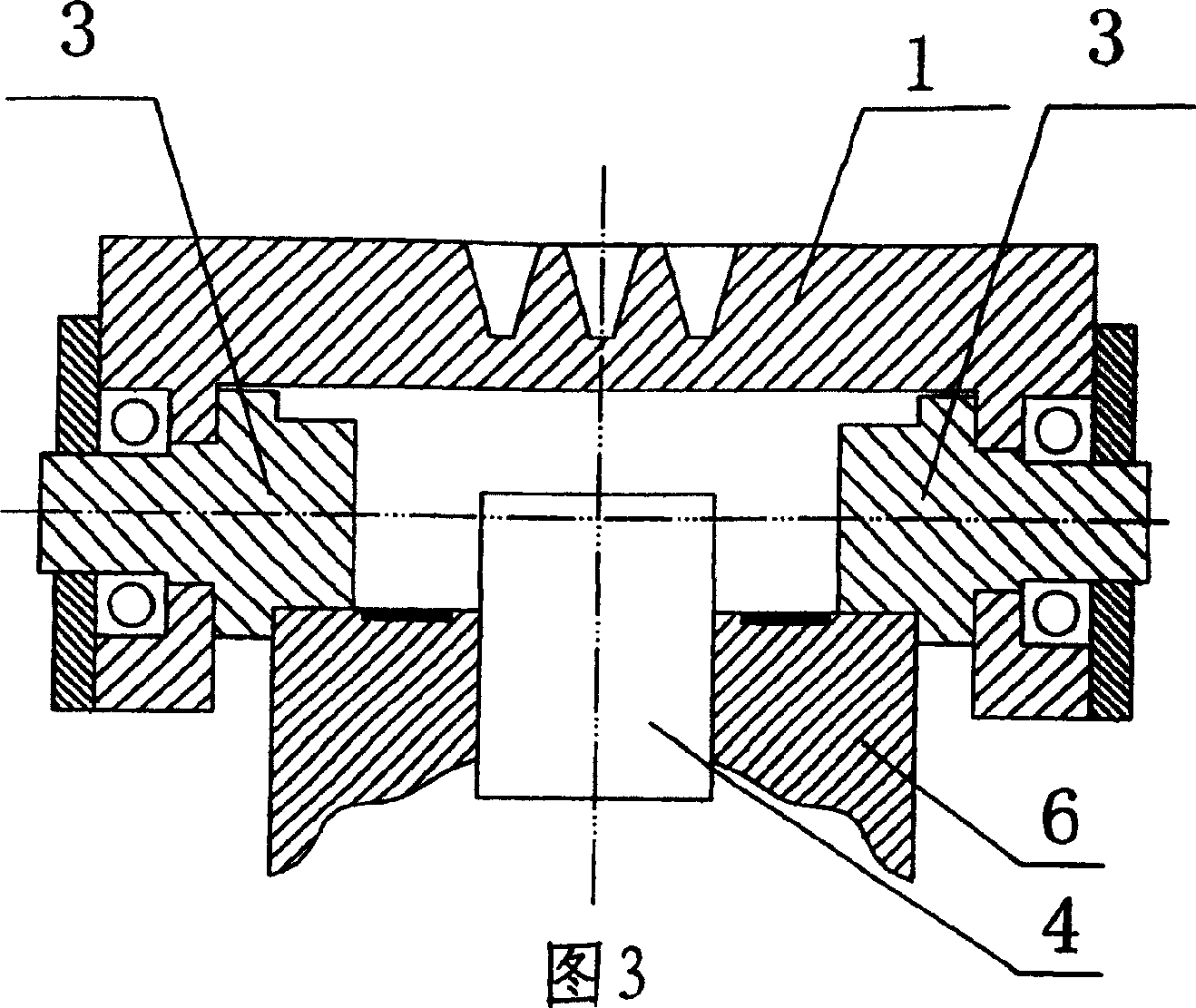

Rolling lever-type piston pump

InactiveCN101109372AReduce speedReduce frictionPiston pumpsPositive-displacement liquid enginesEngineeringCylinder block

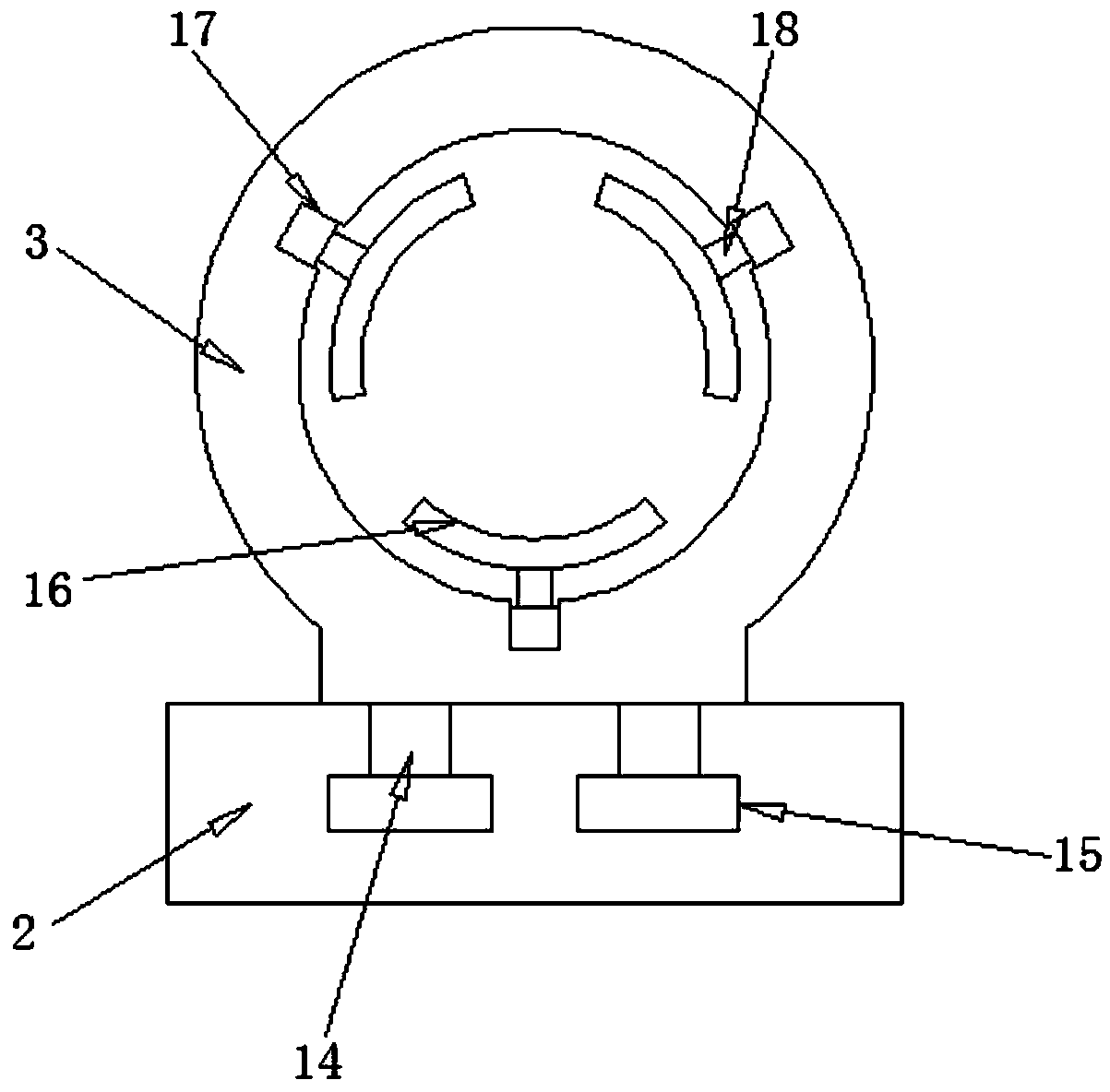

The invention relates to a rolling lever type piston pump, which comprises a support (12), a cylinder block (8), pistons (10), a valve seat (11), a roller seat (6), a plurality of levers (4), a link rod (9), a contact roller (1), a pressure roller (2) and an idler (3). The cylinder block (8) is fixedly mounted on the support (12); in the cylinder block (8), a plurality of piston cavities are provided, in each of piston cavity, a piston (10) is provided; the valve seat (11) is fixedly mounted in the inner hole of the cylinder block (8); the roller seat (6) is fixedly looped on the outer edge of the cylinder block (8); in the middle of the edge of the roller seat (6) and along the periphery, a plurality of lever-installing slots are arranged in equi-spaced way; the levers (4) are arranged in the lever-installing slots; the levers (4) are hinged with the link rod (9), which is hinged with the pistons (10); the contact roller (1) is looped on the periphery of the roller seat (6); the pressure roller (2) and the idler (3) are axially arranged on the inner ring of the contact roller (1), wherein, the middle of the pressure roller (2) contacts with the levers (4) and the outer edge of the roller seat (6), the left and the right edge of the pressure roller (2) contact with the outer edge of the roller seat (6). The invention enables the piston to move evenly, and is applicable for the compression of gas and liquid.

Owner:赵祖良

A two-speed centrifugal block block transmission

ActiveCN108050214BPrevent reactive violent collisionsUniform movement speedToothed gearingsGearing controlGear driveEngineering

The invention belongs to the technical field of transmissions, and particularly relates to a two-speed centrifugal block fixture block transmission. The transmission comprises a mounting plate, a drumwheel, an input shaft, a Z-shaped ring, and an output shaft; when the input shaft rotates, a driving plate rotates to drive arc-shaped strips to rotate, when the arc-shaped strips rotate at a small speed, centrifugal blocks are less affected by centrifugal force, the arc-shaped strips can drive a fixed shaft disc to rotate, and a third fixed shaft, a second one-way ring, a second sun wheel, and second planet wheels drive an annular gear to rotate; the annular gear drives the output shaft to rotate; when the arc-shaped strips move at a high speed, during the movement of a first centrifugal block, when the first centrifugal block contacts with the drum wheel, the first centrifugal block can rub against the drum wheel, the arc-shaped strips drive the drum wheel to rotate through the frictionof the first centrifugal block and the drum wheel, and a Z-shaped wheel rotates to drive the annular gear to rotate through a first one-way ring, a first sun wheel, and first planet wheels; the annular gear drives the output shaft to rotate; and the beneficial effect of two-speed drive is achieved by using a simple structure.

Owner:上海涛济医药科技有限公司

A roadside greening paving device and using method thereof

ActiveCN109006207BEasy to installStable fallHops/wine cultivationTurf growingRotational axisSlide plate

The invention discloses a road side greening laying device and a use method thereof. The road side greening laying device comprises a loading box, a top plate, a bottom plate and a slide plate. The top plate is connected with one side of the top of the loading box. A rotating shaft is horizontally connected between two installation blocks on the two sides. The middle of the rotating shaft is connected with two rotating plates. A rotary shaft is installed in the support in the length direction. The rotary shaft is sleeved with a pressing roller. Side plates are connected into the two ends of the loading box in the height direction. The upper end and the lower end of each side plate are each connected with a horizontal transverse plate. The bottom of a vertical rod is connected with a buckle. The buckle is provided with a positioning wheel. Push plates are connected with the two sides of the upper portion of the slide plate in the length direction respectively, the middle of one side ofthe push plate is connected with the slide plate through a fastening bolt. Turf does not need to be subsequently adjusted by workers after being laid, the laid turf keeps proper distance away from turf on the ground, and too large distance can hardly be left.

Owner:缙云县智禾环保科技有限公司

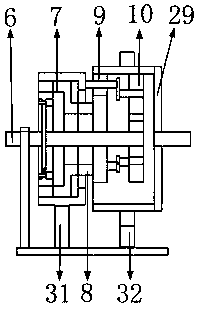

Air cooling wind tunnel wall manufacturing equipment of kilowatt-grade generators

ActiveCN109746804AImprove convenienceImprove practicalityRevolution surface grinding machinesDrive shaftSlag

The invention discloses air cooling wind tunnel wall manufacturing equipment of kilowatt-grade generators. The air cooling wind tunnel wall manufacturing equipment comprises a processing frame, a rotating seat and a fixing seat, wherein a sliding frame is fixed to the outer wall of the top of the processing frame through bolts; two guide rails which are distributed in the equal distance are fixedto the outer wall of the bottom of the sliding frame through bolts; a motor seat is fixed to the outer wall of the bottom of the rotating seat through bolts; a dual-shaft motor is fixed to the outer wall of the bottom of the motor seat through bolts; and transmission shafts are respectively welded to one ends of two output shafts of the dual-shaft motor, and a cutter seat and a polishing wheel mounting seat are separately welded to one ends of the transmission shafts. According to the air cooling wind tunnel wall manufacturing equipment disclosed by the invention, the diameter of a cutter is the same as the inner diameter of a wind channel pipe, so that in the advancing process of the cutter, protruded welding slags are removed; after removal is completed, the dual-shaft motor is rotated,so that a polishing wheel enters the inner part of the wind channel pipe again for polishing, and the convenience of removing the welding slags of the manufacturing equipment is improved; and besides,the device can perform slag removing and polishing without replacing the equipment, so that the practicality of the device is improved.

Owner:上海福源智业投资集团有限公司

An artificial intelligence walking device

ActiveCN114033836BUniform movement speedTimely response judgmentWheel based transmissionChildren cyclesRolloverGear wheel

Owner:YONGLANG GRP

A wooden stair handrail fixed pile water transfer printing device

ActiveCN112060754BUniform movement speedEasy transfer workTransfer printingElectric machineryWater transfer

The invention relates to a water transfer printing device, in particular to a water transfer printing device for a wooden staircase handrail fixing pile. Provided is a wooden stair handrail fixed pile water transfer printing device which can not only make the speed of the fixed pile uniform, but also improve production efficiency. A water transfer printing device for fixed piles of wooden stair handrails, comprising: a transfer printing box, which is provided on one side of the top of the base; and a water transfer printing mechanism, which is provided on the top of the base. The fixed pile is fixed by the electric clamp, and through the cooperation between the first winding wheel and the first pull rope, the fixed pile is driven to move downwards, so that it is completely immersed in the transfer box, when the first fixed rod is no longer When the fixed frame is blocked, the first pull cord drives the mounting block to move forward, thereby driving the fixed pile to move forward for uniform transfer. The operation of the motor makes the moving speed of the fixed pile uniform, and the water transfer is more uniform and beautiful.

Owner:NANJING HANMINGZHI INTELLIGENT TECHNOLOGY CO LTD

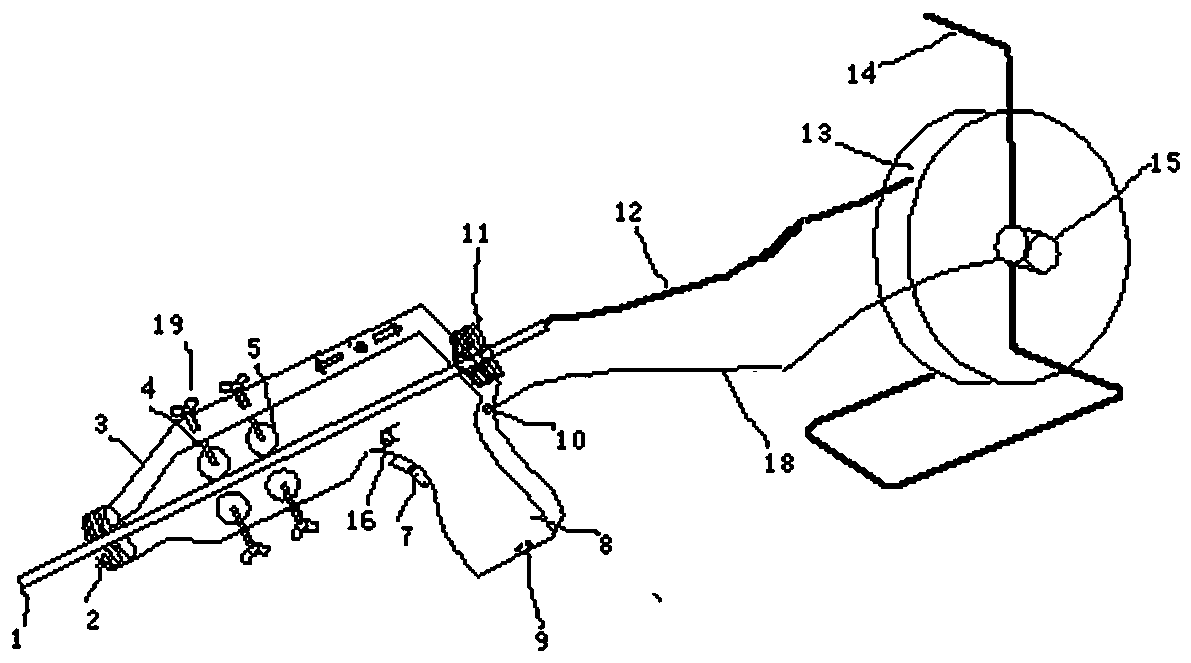

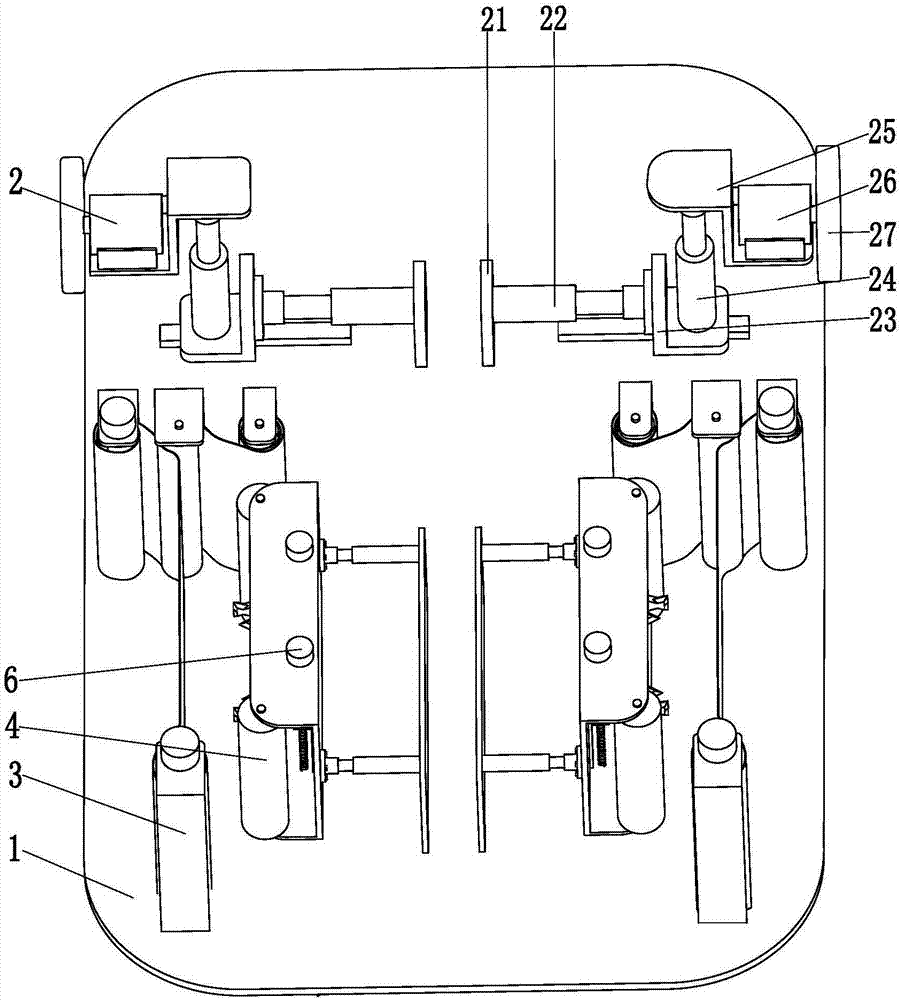

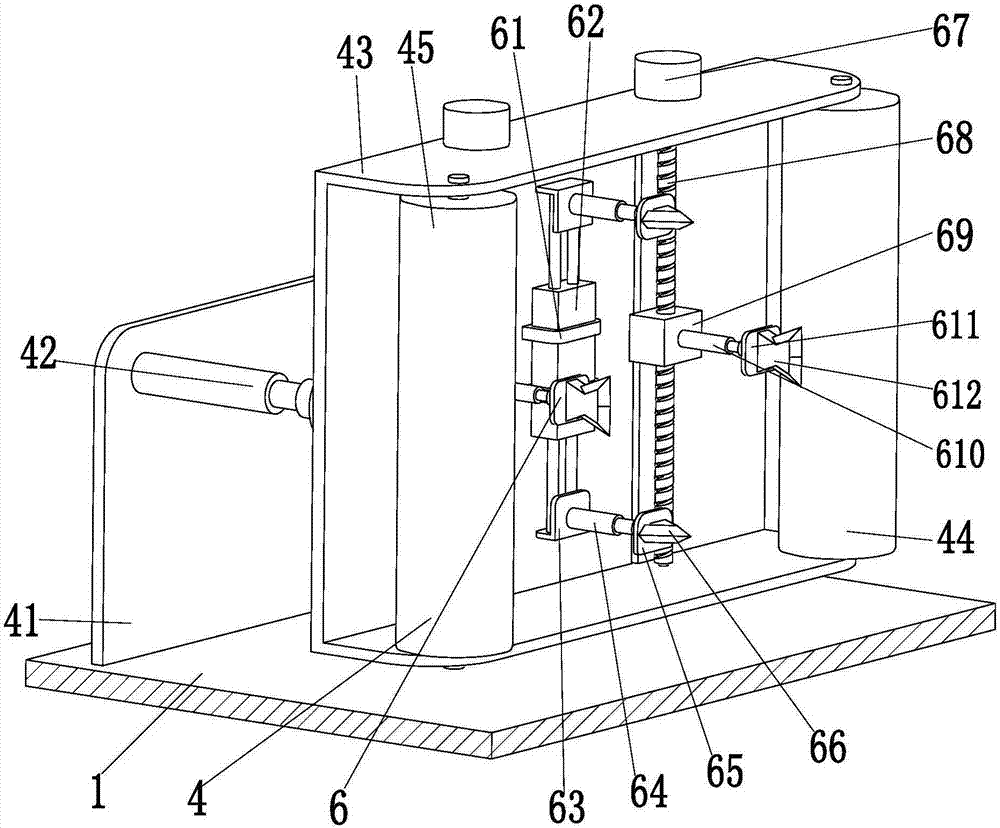

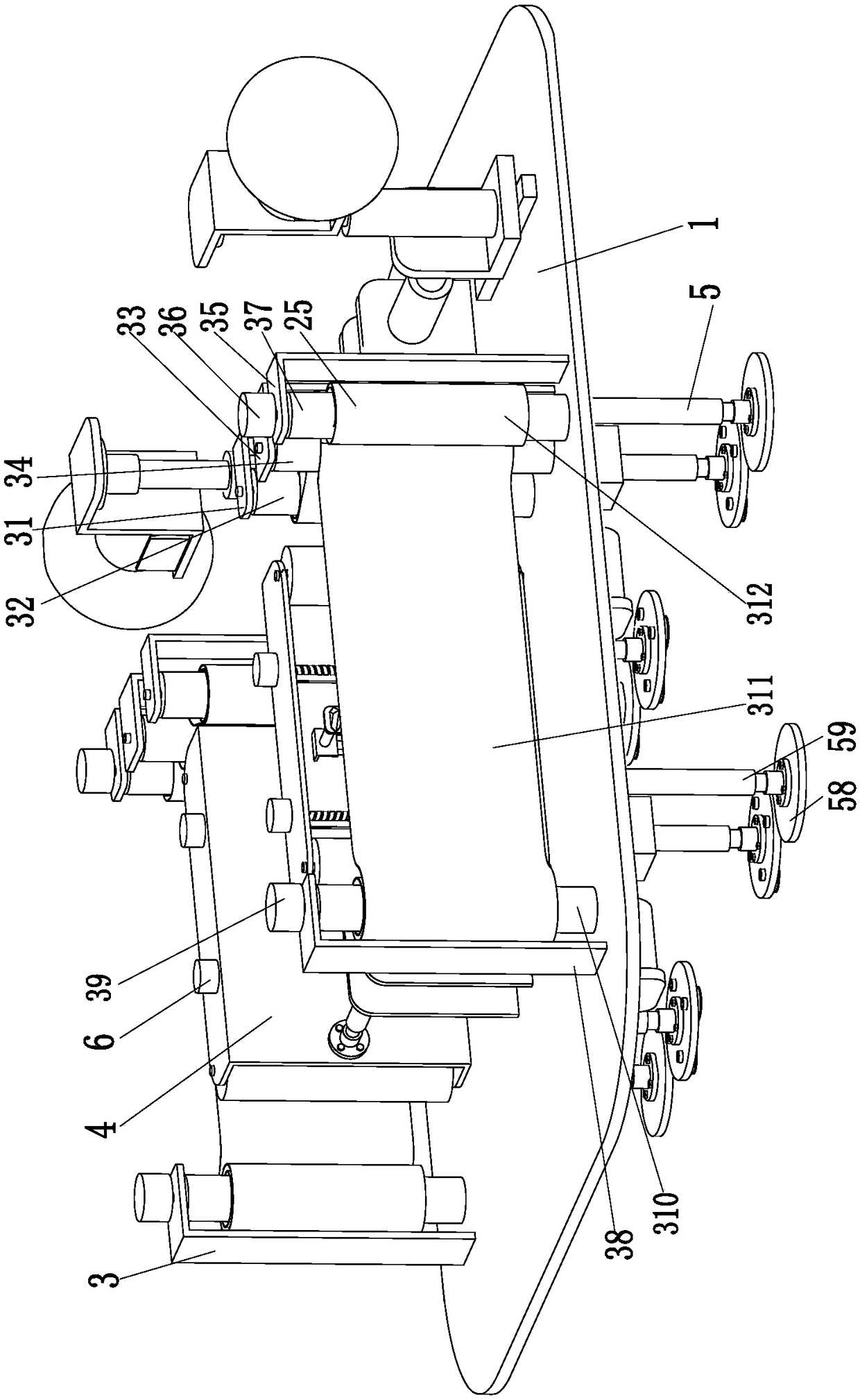

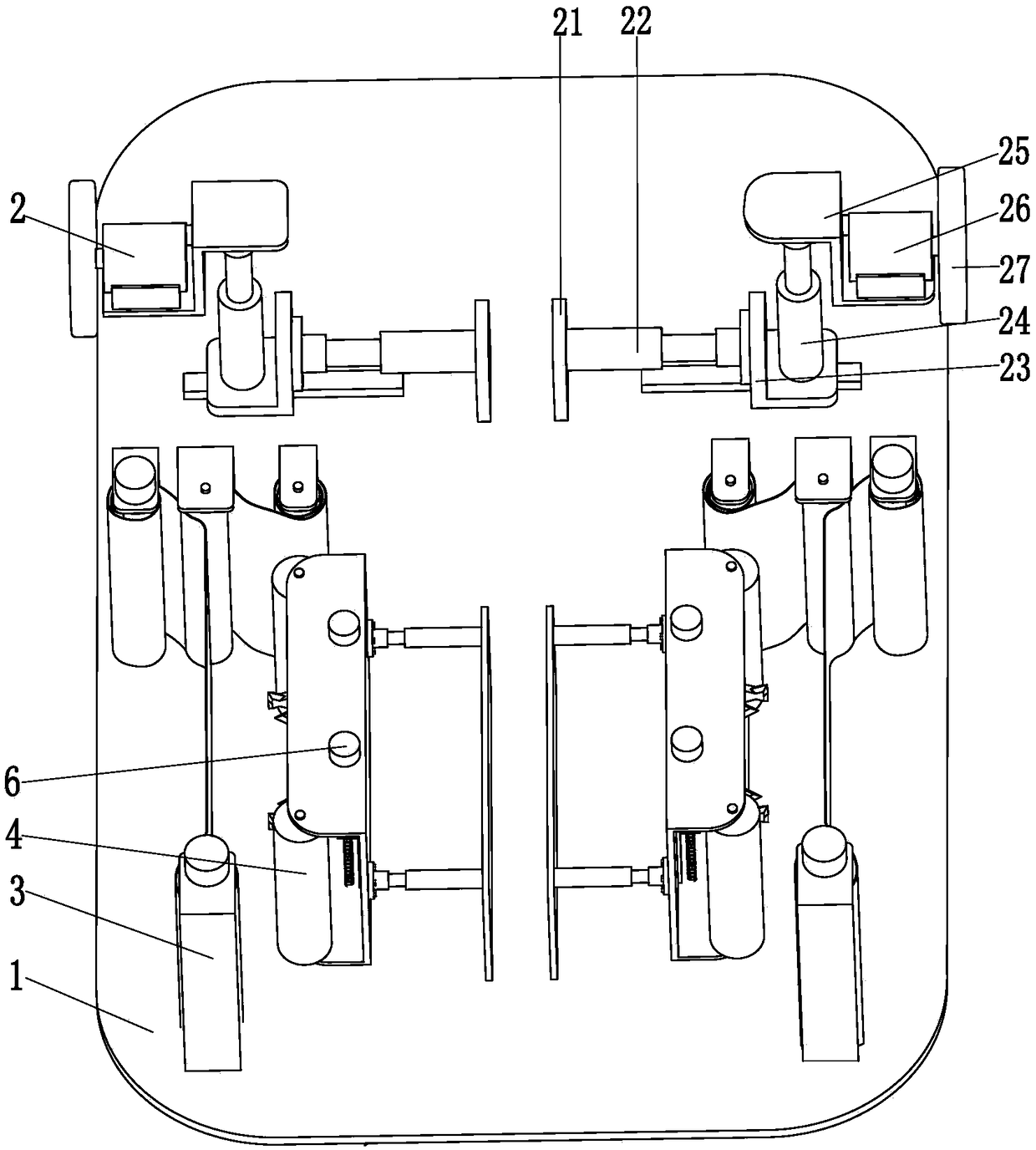

Stepping type escalator glass posted advertisement automatic posting facility

ActiveCN106904330ARealization of labor intensityNo secondary processing requiredLabelling machinesArchitectural engineering

The invention relates to a stepping type escalator glass posted advertisement automatic posting facility. The stepping type escalator glass posted advertisement automatic posting facility comprises a base plate. Two scrubbing devices are symmetrically installed at the front end of the base plate, two winding devices are symmetrically installed on the left side and the right side of the middle of the base plate, two rolling press devices are symmetrically installed in the middle of the base plate, a clipping device is installed on each rolling press device, and four travelling devices are symmetrically installed on the front side and the rear side of the lower end of the base plate. The stepping type escalator glass posted advertisement automatic posting facility can solve the problems that in the process of posting glass posted advertisements on glass protecting plates on the two sides of an existing stepping type escalator, the error of manual clipping of glass posted advertisements is big, the labor intensity of manual scrubbing of the glass protecting plates is high, secondary processing needs to be conducted on the glass posted advertisements, the glass posted advertisements are prone to deforming when the glass posted advertisements are pulled by workers, and time and labor are consumed when workers use scraper plates to clean away bubbles located between the glass posted advertisements and the glass protecting plates, and can fulfill the stepping type escalator glass posted advertisement automatic posting function.

Owner:贵州坤卓科技发展股份有限公司

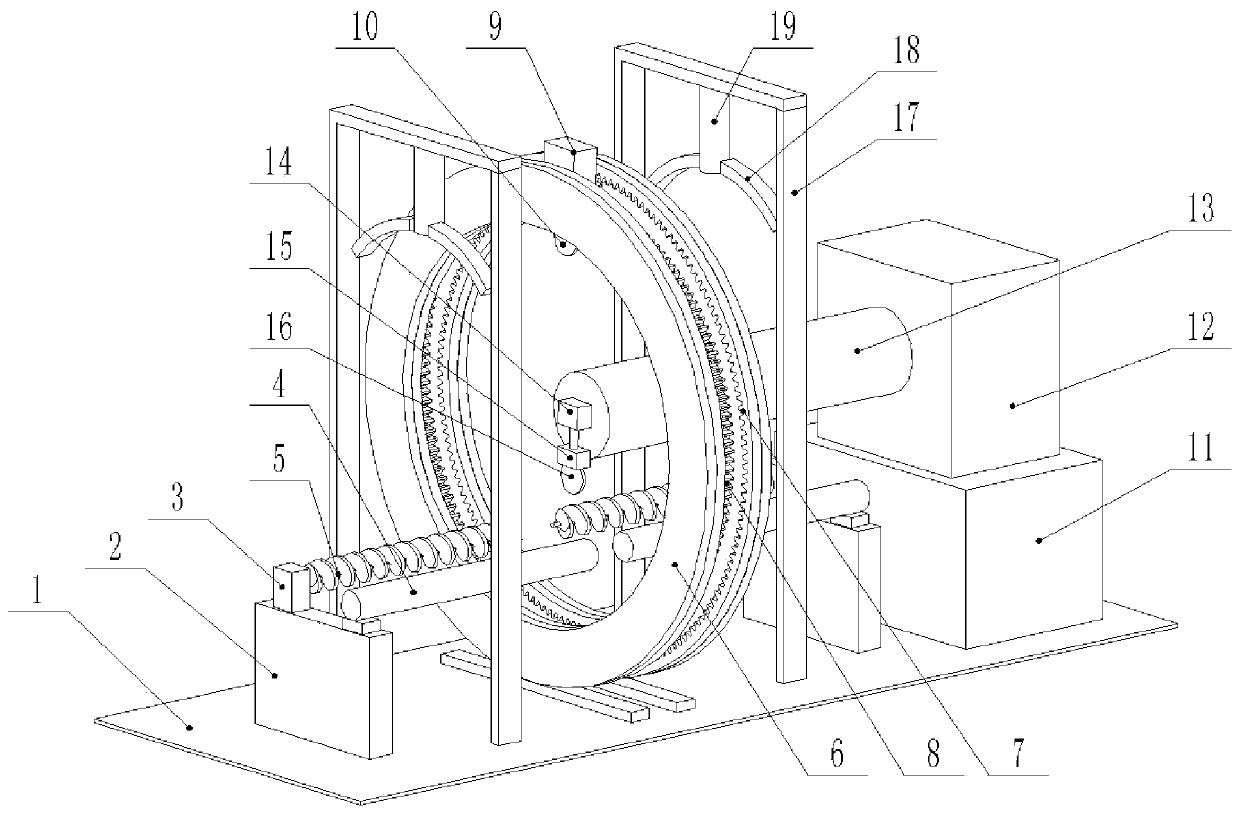

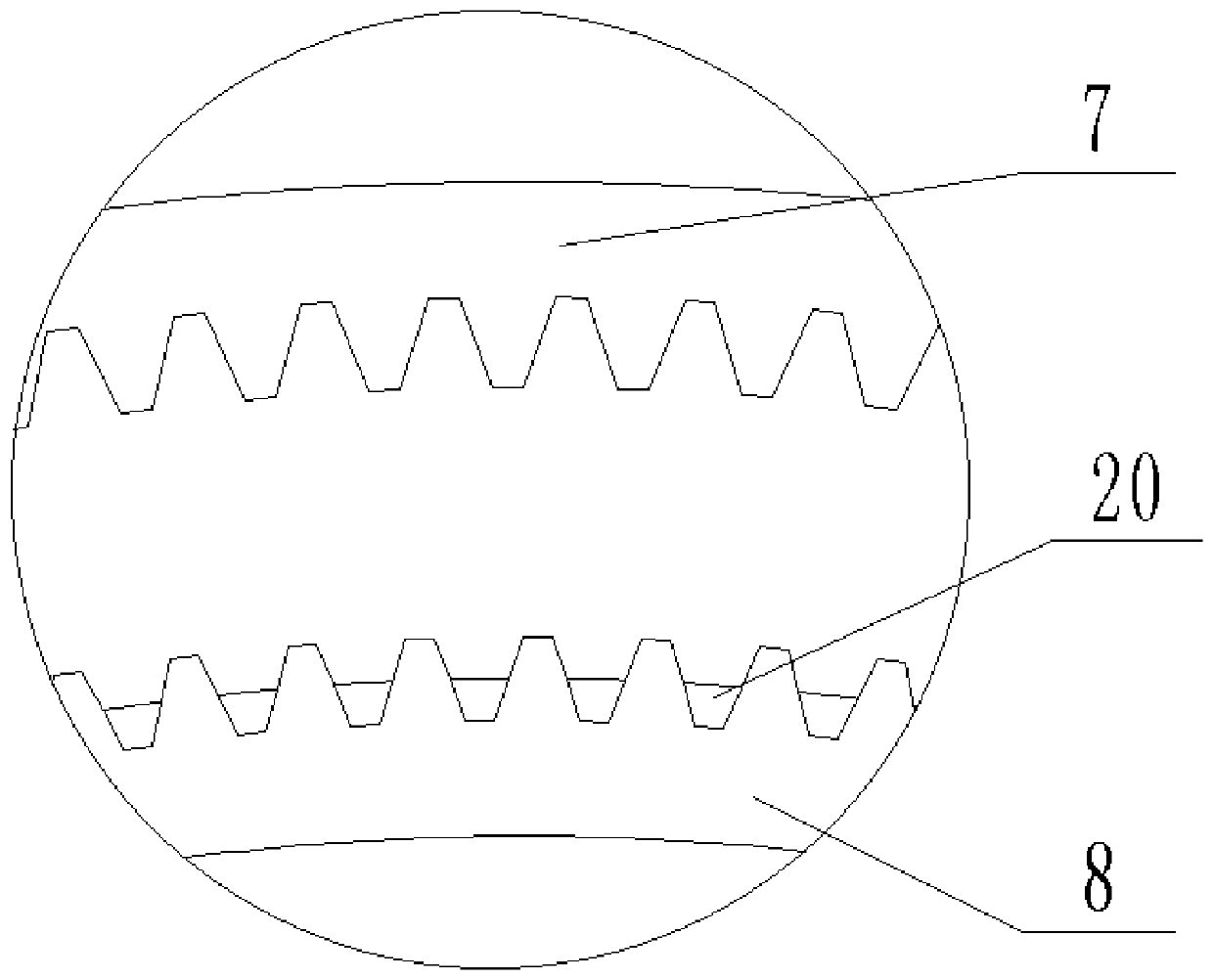

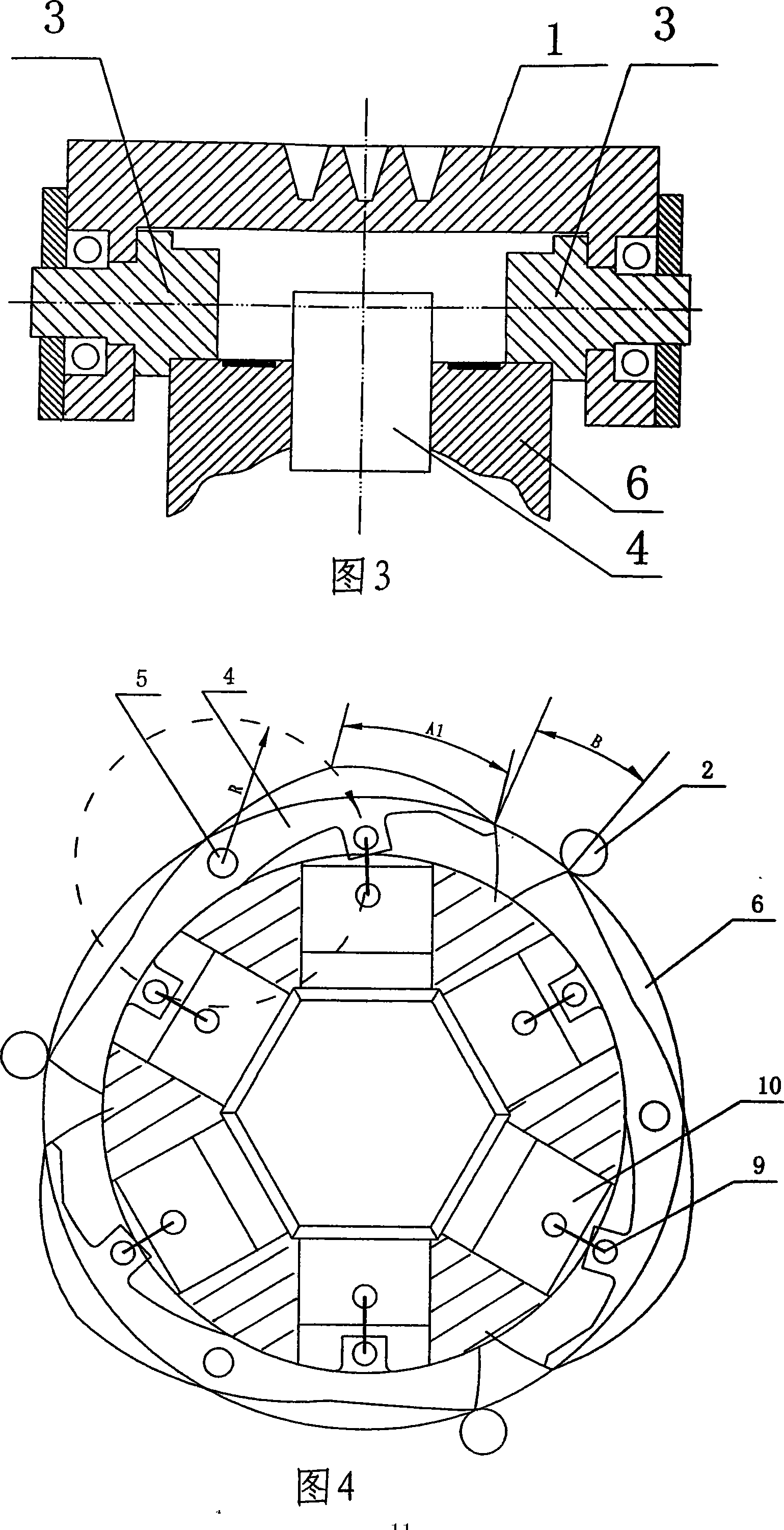

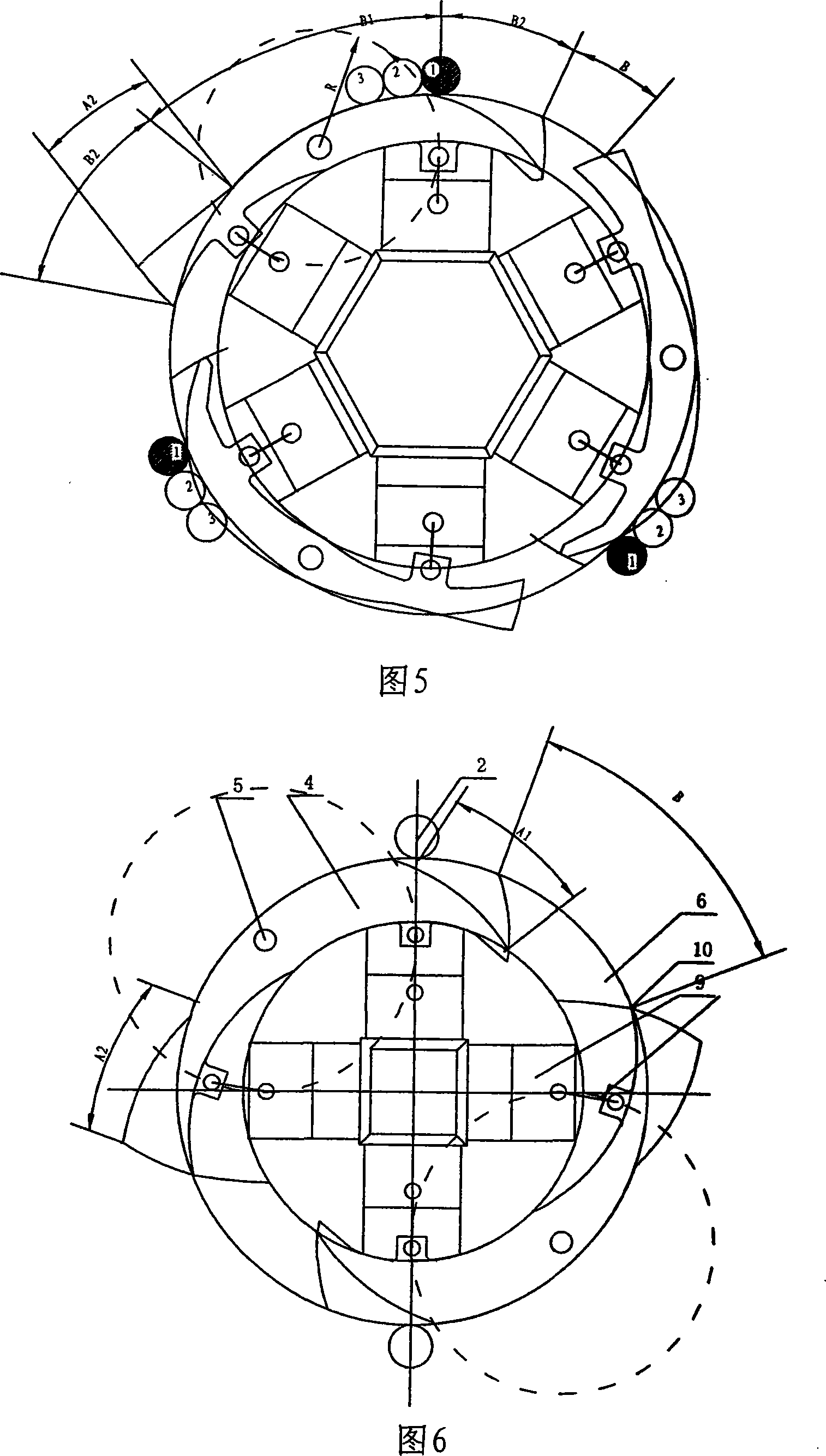

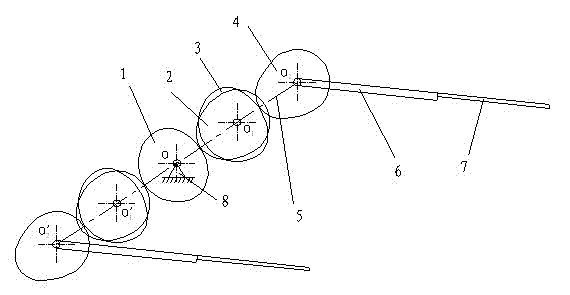

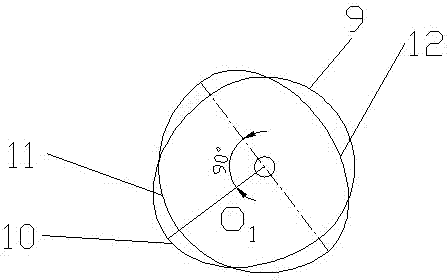

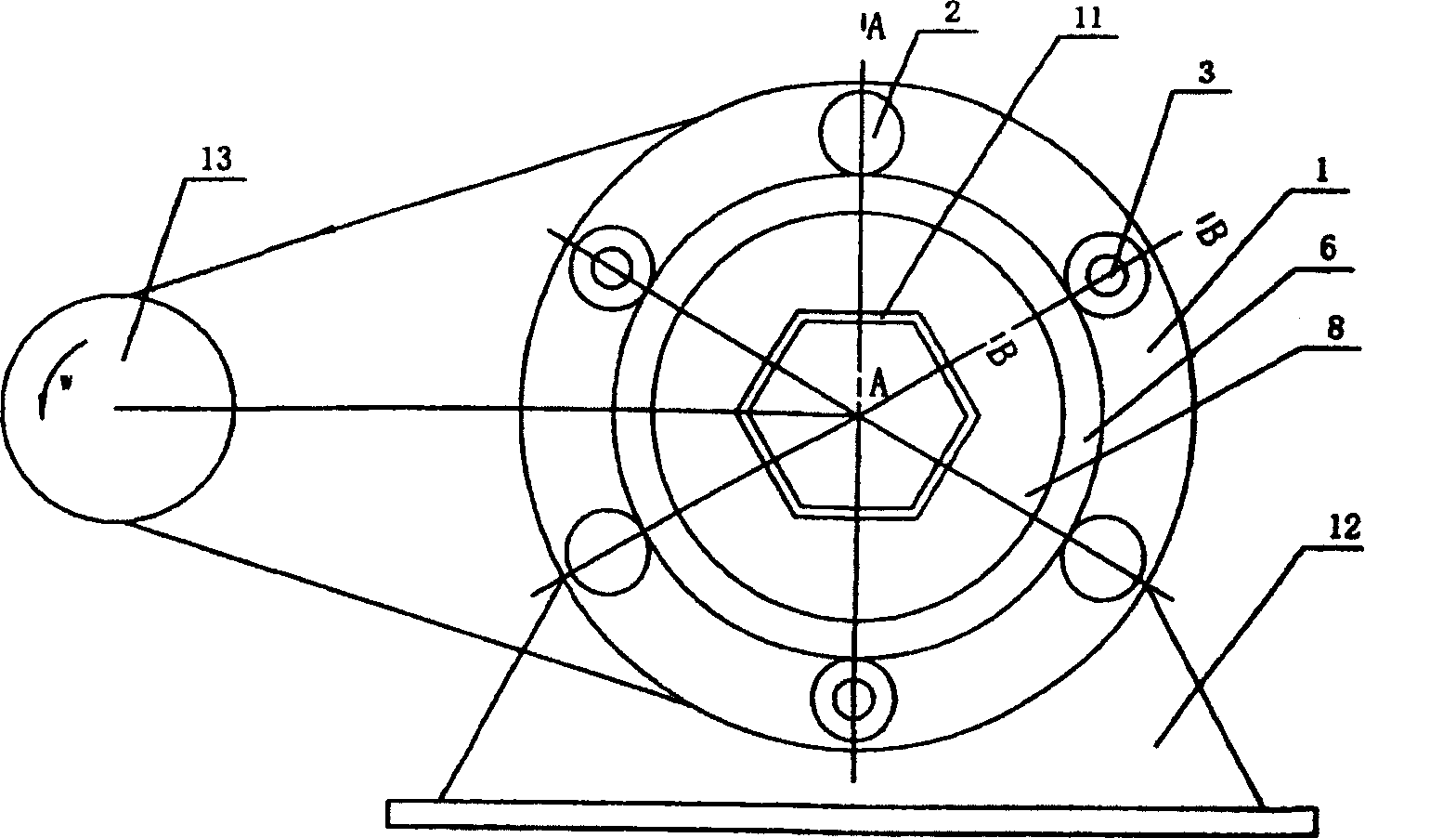

Circle-ellipse pitch curve gear planetary system transmission case of transplanting mechanism

InactiveCN102106212BSuitable for rice transplanting trackUniform movement speedToothed gearingsTransplantingEllipsePlanetary system

The invention discloses a circle-ellipse pitch curve gear planetary system transmission case of a transplanting mechanism, which comprises a gear sun wheel, a planet carrier, a stander, two intermediate gears, two planting arm gears, two planting arms and two seedlings needles; the transmission ratio design of the transmission gear of the transplanting mechanism is suitable for the seedlings transplanting path of the large seedlings; the pitch curve of the elliptic gear is formed by the means that a section of circular curve is in smooth connection with a section of elliptic curve, the seedlings needles are even in moving speed when the seedlings needles are used for pushing the seedlings due to the circular part of the pitch curve, the seedlings needles are lift up after a seedlings pushing rod is used for pushing the seedlings into the mud, the movement locus of the seedlings needles is changed to be small in a plant pit in the mud, and the seedlings laying and the seedlings floating are hardly generated; and the seedlings movement locus has the minimum attack to the seedlings due to the elliptic part of the pitch curve when the seedlings are withdrawn by the seedlings needles, so that the seedlings are hardly injured.

Owner:ZHEJIANG SCI-TECH UNIV

A step-type escalator glass sticker automatic posting equipment

ActiveCN106904330BRealization of labor intensityNo secondary processing requiredLabelling machinesArchitectural engineeringUltimate tensile strength

The invention relates to a stepping type escalator glass posted advertisement automatic posting facility. The stepping type escalator glass posted advertisement automatic posting facility comprises a base plate. Two scrubbing devices are symmetrically installed at the front end of the base plate, two winding devices are symmetrically installed on the left side and the right side of the middle of the base plate, two rolling press devices are symmetrically installed in the middle of the base plate, a clipping device is installed on each rolling press device, and four travelling devices are symmetrically installed on the front side and the rear side of the lower end of the base plate. The stepping type escalator glass posted advertisement automatic posting facility can solve the problems that in the process of posting glass posted advertisements on glass protecting plates on the two sides of an existing stepping type escalator, the error of manual clipping of glass posted advertisements is big, the labor intensity of manual scrubbing of the glass protecting plates is high, secondary processing needs to be conducted on the glass posted advertisements, the glass posted advertisements are prone to deforming when the glass posted advertisements are pulled by workers, and time and labor are consumed when workers use scraper plates to clean away bubbles located between the glass posted advertisements and the glass protecting plates, and can fulfill the stepping type escalator glass posted advertisement automatic posting function.

Owner:贵州坤卓科技发展股份有限公司

Foamed aluminum side edge grinding device

ActiveCN114800128AUniform movement speedReduce manual laborEdge grinding machinesGrinding carriagesElectric machinerySprocket

The invention provides a side edge grinding device for foamed aluminum. The side edge grinding device comprises a machine table; the two mounting seats are symmetrically mounted on the two sides of the machine table, and polishing mechanisms are mounted on the two mounting seats; the conveying mechanism is installed on the machine table and located between the two installation bases, the conveying mechanism comprises two sets of installation plates, driving rollers, chain wheels, chains and push plates, the two sets of installation plates are symmetrically installed on the two sides of the machine table, each set of installation plates comprises two installation plates, and the driving rollers are fixedly connected between the two installation plates of the two sets. According to the side edge grinding device for the foamed aluminum, the conveying mechanism is arranged, a push plate is beaten through a chain to automatically push a foamed aluminum plate to move, the two sides of the foamed aluminum plate make contact with grinding discs of the two grinding mechanisms for grinding, manual work is reduced, the rotating speed of a motor is the same, and therefore the moving speed of the foamed aluminum plate is constant; and the contact forces between the two sides of the foamed aluminum plate and the grinding disc are the same, and the grinding quality is improved.

Owner:贵州华清新材料科技有限公司

Six-color rotary press for printing bills and manufacturing method thereof

InactiveCN111730955AReduce staticReduce congestionRotary lithographic machinesIndustrial engineeringPaper sheet

The invention provides a six-color rotary press for printing bills and a manufacturing method thereof, and relates to the field of rotary presses. The six-color rotary press for printing bills comprises a rotary press body and a supporting plate, wherein the supporting plate is arranged on one side of the rotary press body, the rotary press body is fixedly connected with the supporting plate, oneside of the rotary press body is provided with a paper placing hole, the front side of the rotary press body is provided with heat dissipation through holes, the back of the rotary press body is provided with a driving structure, a printing assembly is arranged in the rotary press body, a traction assembly is arranged in the rotary press body, and a guide assembly is arranged inside the rotary press body. According to the six-color rotary press for printing bills, the static electricity on paper can be guided to a grounding wire through a conductive ring after making contact with a metal wire,so that the static electricity on the bill paper is reduced, the bill paper is prevented from adhering to other parts, and the blockage condition is reduced. The bill paper can be flattened by multiple groups of supporting rings and rolling balls, the folding condition of the bill paper is reduced, and wrinkles are reduced.

Owner:湖州军红印刷有限公司

A rolling lever-type piston pump

InactiveCN100465431CReduce speedReduce frictionPiston pumpsPositive-displacement liquid enginesEngineeringCylinder block

The invention relates to a rolling lever type piston pump, which comprises a support (12), a cylinder block (8), pistons (10), a valve seat (11), a roller seat (6), a plurality of levers (4), a link rod (9), a contact roller (1), a pressure roller (2) and an idler (3). The cylinder block (8) is fixedly mounted on the support (12); in the cylinder block (8), a plurality of piston cavities are provided, in each of piston cavity, a piston (10) is provided; the valve seat (11) is fixedly mounted in the inner hole of the cylinder block (8); the roller seat (6) is fixedly looped on the outer edge of the cylinder block (8); in the middle of the edge of the roller seat (6) and along the periphery, a plurality of lever-installing slots are arranged in equi-spaced way; the levers (4) are arranged in the lever-installing slots; the levers (4) are hinged with the link rod (9), which is hinged with the pistons (10); the contact roller (1) is looped on the periphery of the roller seat (6); the pressure roller (2) and the idler (3) are axially arranged on the inner ring of the contact roller (1), wherein, the middle of the pressure roller (2) contacts with the levers (4) and the outer edge of the roller seat (6), the left and the right edge of the pressure roller (2) contact with the outer edge of the roller seat (6). The invention enables the piston to move evenly, and is applicable for the compression of gas and liquid.

Owner:赵祖良

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com