Water transfer printing device for wooden stair railing fixing pile

A technology of stair handrail and water transfer printing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

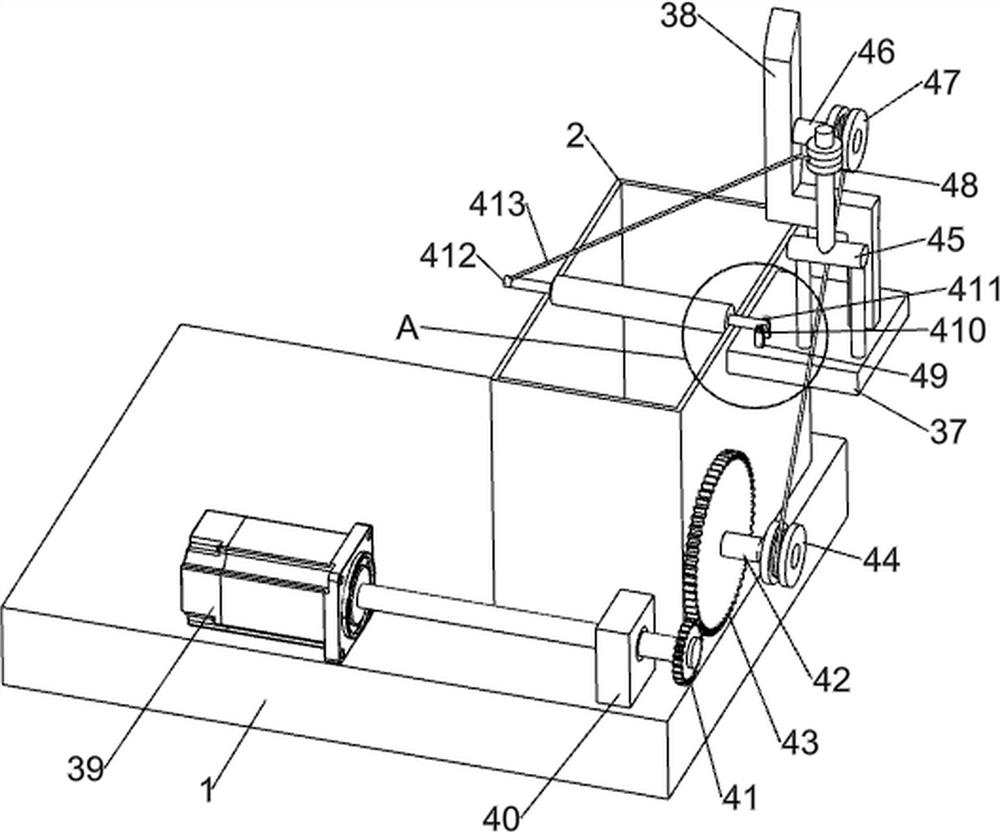

[0023] A wooden stair handrail fixed pile water transfer printing device, such as figure 1 As shown, it includes a base 1 , a transfer box 2 and a water transfer mechanism 3 , the transfer box 2 is provided on the top right side of the base 1 , and the water transfer mechanism 3 is provided on the left side of the top side of the base 1 .

[0024] When workers need to carry out water transfer printing on the wooden stair handrail fixed pile, first, fix the fixed pile on the water transfer printing mechanism 3, start the water transfer printing mechanism 3 to work, under the operation of the water transfer printing mechanism 3, drive The fixed pile moves down to the transfer box 2, and the water transfer printing is performed on the fixed pile. Print, repeat the above operation.

Embodiment 2

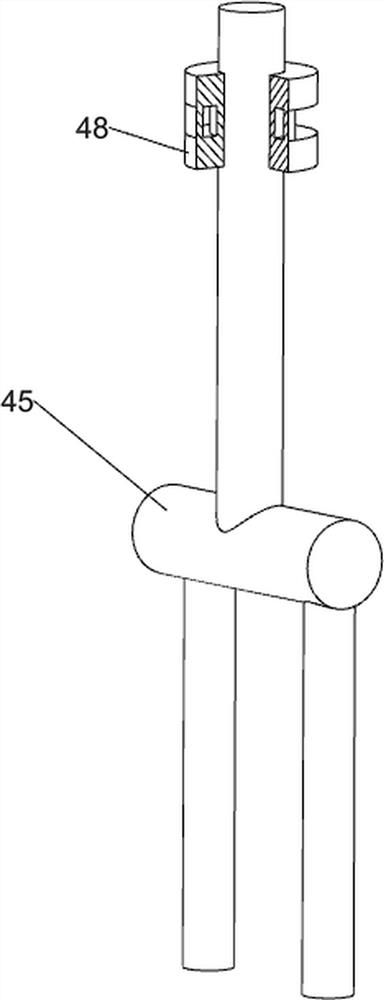

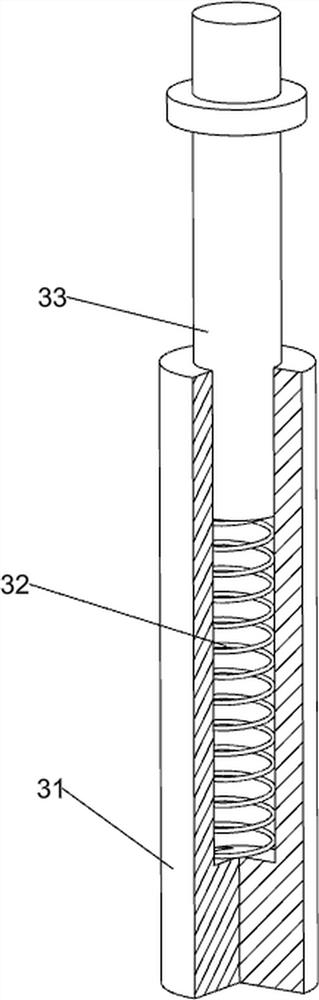

[0026] On the basis of Example 1, such as Figure 2-5 As shown, the water transfer printing mechanism 3 includes a support seat 30, a sleeve 31, a first spring member 32, a support column 33, a mounting block 34, an electric clamp 35, a first fixing rod 36, a fixing plate 37, a fixing frame 38, Servo motor 39, first winding wheel 310, first bearing seat 311, first rotating shaft 312, first wire passing wheel 313, first pull cord 314, connecting block 315, first fixing block 316, second fixing rod 317 , the second spring part 318, the support block 319, the guide rod 320 and the third spring part 321, the left side of the top of the base 1 is provided with a support seat 30, the top of the support seat 30 is provided with a sleeve 31, and the sleeve 31 is slidingly connected with The support column 33, the first spring member 32 is connected between the bottom of the support column 33 and the inner bottom wall of the sleeve 31, the top of the support column 33 is connected with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com