Sand screening device

A sand screening and power device technology, applied in the direction of filtering, solid separation, grille, etc., can solve the problems of manpower consumption, increase construction cost, low efficiency, etc., and achieve the effect of improving work efficiency, saving manpower, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

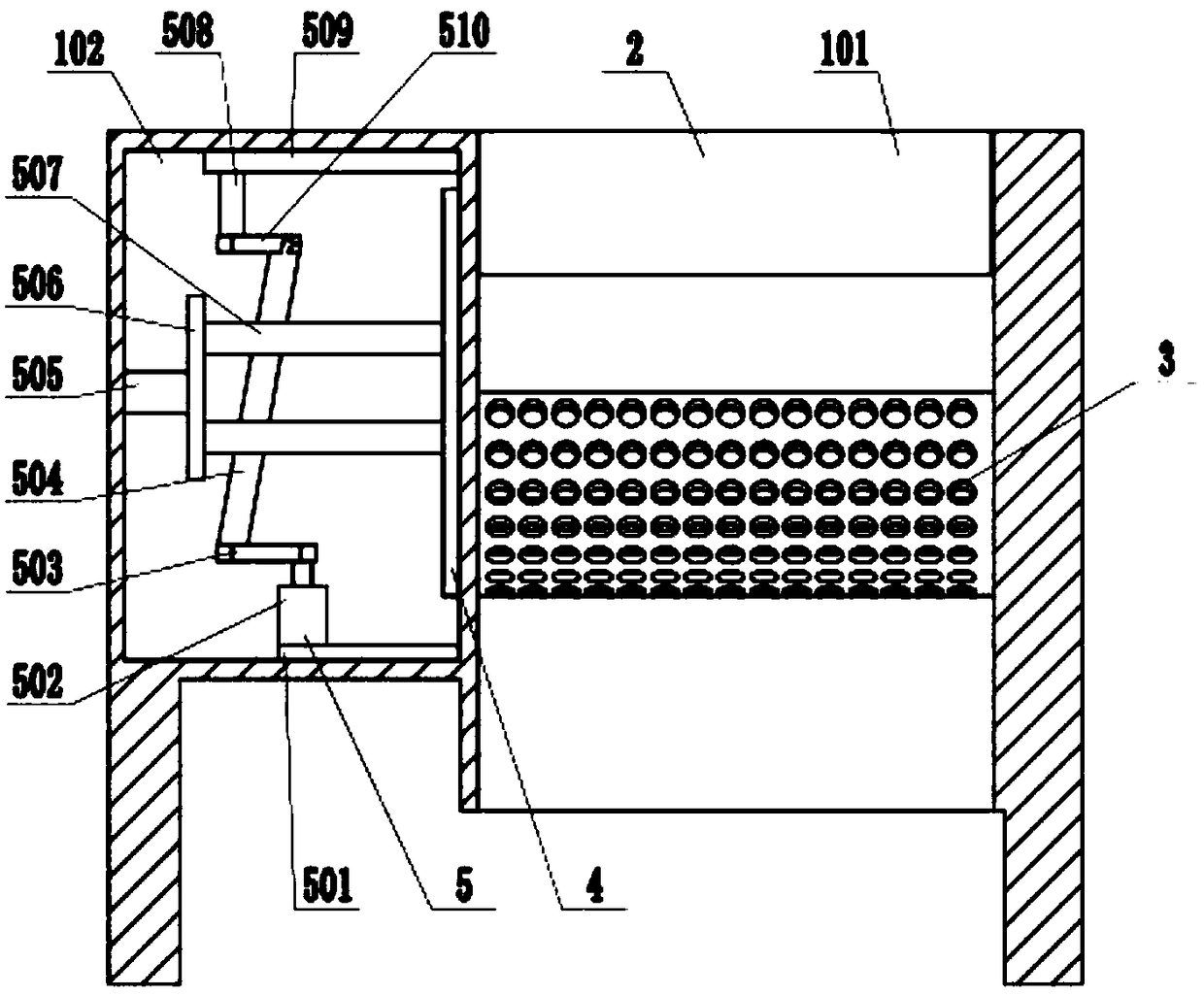

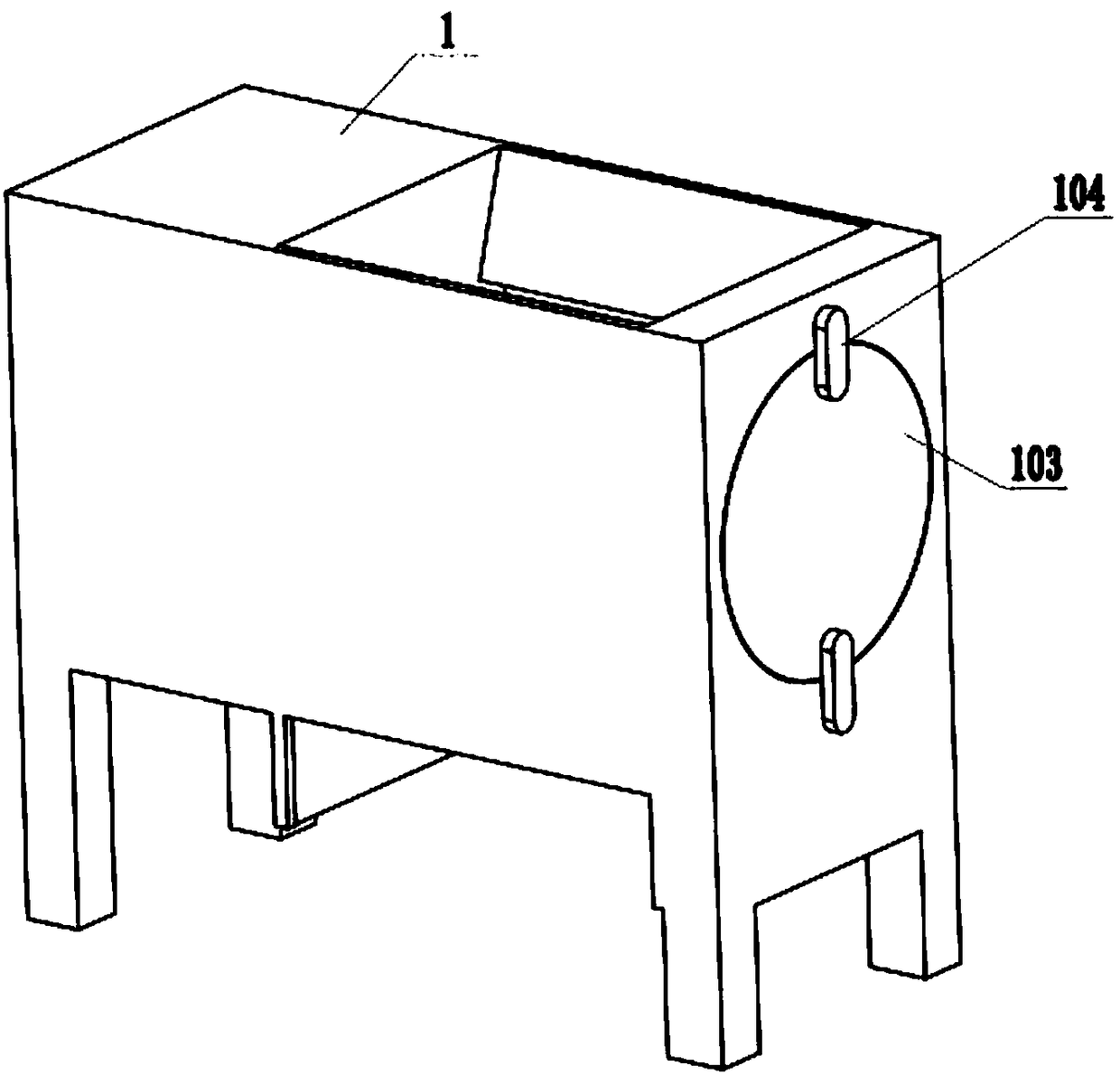

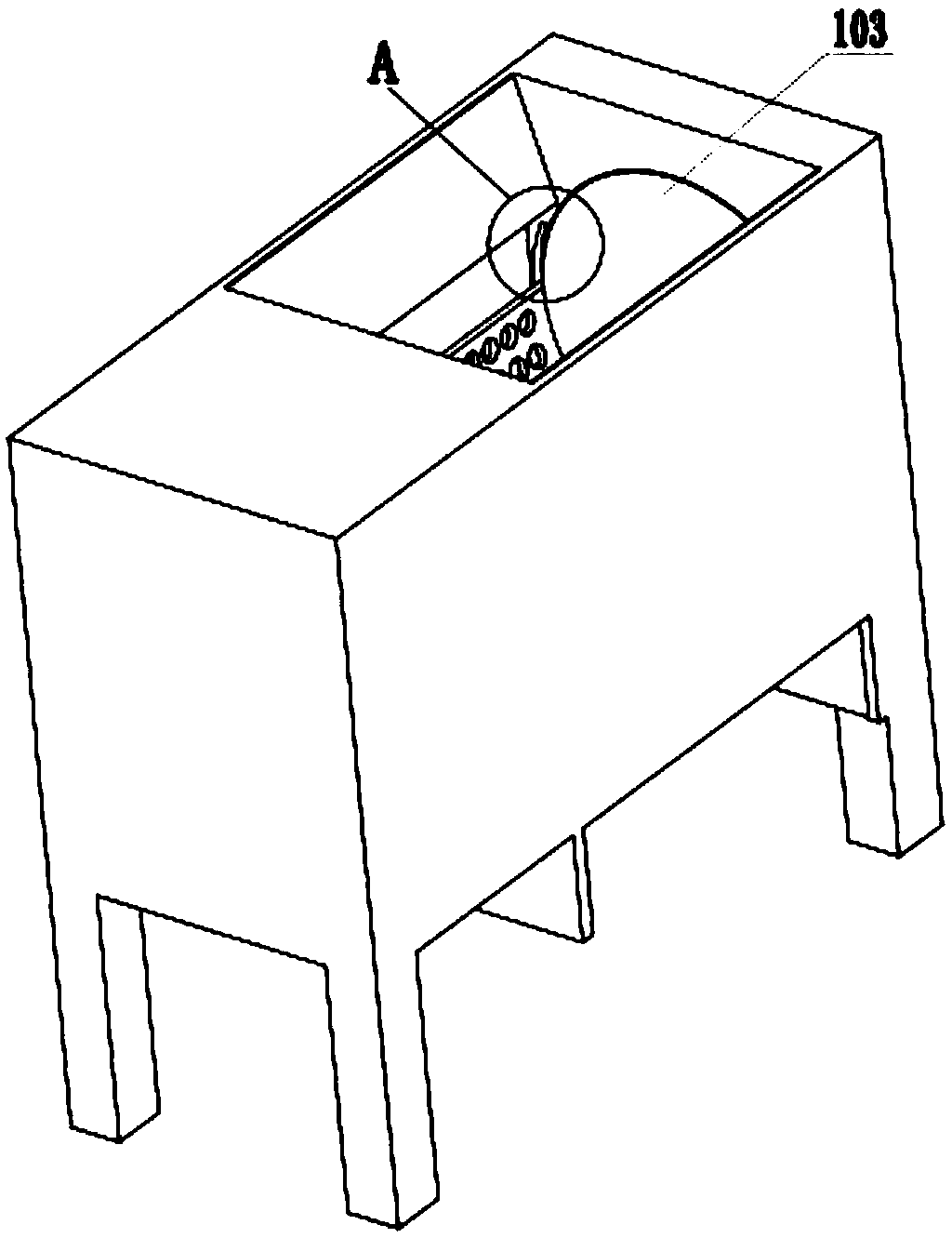

Embodiment 1

[0026] see Figure 1-7 As shown, a sand screening device of the present embodiment includes a box body 1, a screen 3, and a power unit 5. The box body 1 includes a sand inlet bin 101 and a power chamber 102. The upper and lower sides of the sand inlet bin 101 are The lower two ends are opening structures, one side of the sand inlet 101 is provided with a cleaning port 107, the cleaning port 107 is provided with a cleaning cover 103, and the cleaning cover 103 is provided with a cover lock 104, and the screen 3 is located at the inlet. In the sand bin 101, the screen 3 is a semi-cylindrical structure, and the two ends of the screen 3 are respectively connected to the inner wall of the sand inlet 101. The adjacent inner wall is provided with a turntable 4, one side of the turntable 4 is connected to the screen 3, and the other side of the turntable 4 is connected to the power unit 5, and the power unit 5 is connected to the upper and lower inner walls of the power chamber 102 re...

Embodiment 2

[0028] A sand screening device comprises a box body 1, a screen 3, and a power unit 5. The box body 1 includes a sand inlet bin 101 and a power chamber 102. The upper and lower ends of the sand inlet bin 101 are open structures. One side of the sand inlet bin 101 is provided with a cleaning port 107, the cleaning port 107 is provided with a cleaning cover 103, and the cleaning cover 103 is provided with a cover lock 104, and the screen 3 is arranged in the sand inlet bin 101, and the screen cloth 3 is a semi-cylindrical structure, the two ends of the screen 3 are respectively connected to the inner wall of the sand inlet bin 101, the power device 5 is arranged in the power chamber 102, and a turntable is arranged on the inner wall adjacent to the power chamber 102 and the sand inlet bin 101 4. One side of the turntable 4 is connected to the screen 3 , and the other side of the turntable 4 is connected to the power unit 5 , and the power unit 5 is connected to the upper and lowe...

Embodiment 3

[0031] A sand screening device comprises a box body 1, a screen 3, and a power unit 5. The box body 1 includes a sand inlet bin 101 and a power chamber 102. The upper and lower ends of the sand inlet bin 101 are open structures. One side of the sand inlet bin 101 is provided with a cleaning port 107, the cleaning port 107 is provided with a cleaning cover 103, and the cleaning cover 103 is provided with a cover lock 104, and the screen 3 is arranged in the sand inlet bin 101, and the screen cloth 3 is a semi-cylindrical structure, the two ends of the screen 3 are respectively connected to the inner wall of the sand inlet bin 101, the power device 5 is arranged in the power chamber 102, and a turntable is arranged on the inner wall adjacent to the power chamber 102 and the sand inlet bin 101 4. One side of the turntable 4 is connected to the screen 3 , and the other side of the turntable 4 is connected to the power unit 5 , and the power unit 5 is connected to the upper and lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com