Rolling lever-type piston pump

A lever type, piston pump technology, used in piston pumps, pumps, liquid variable capacity machinery and other directions, can solve the problems of uneven speed, force distance, reduce mechanical efficiency and other problems, achieve uniform speed, reduce vibration, reduce piston ring The effect of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

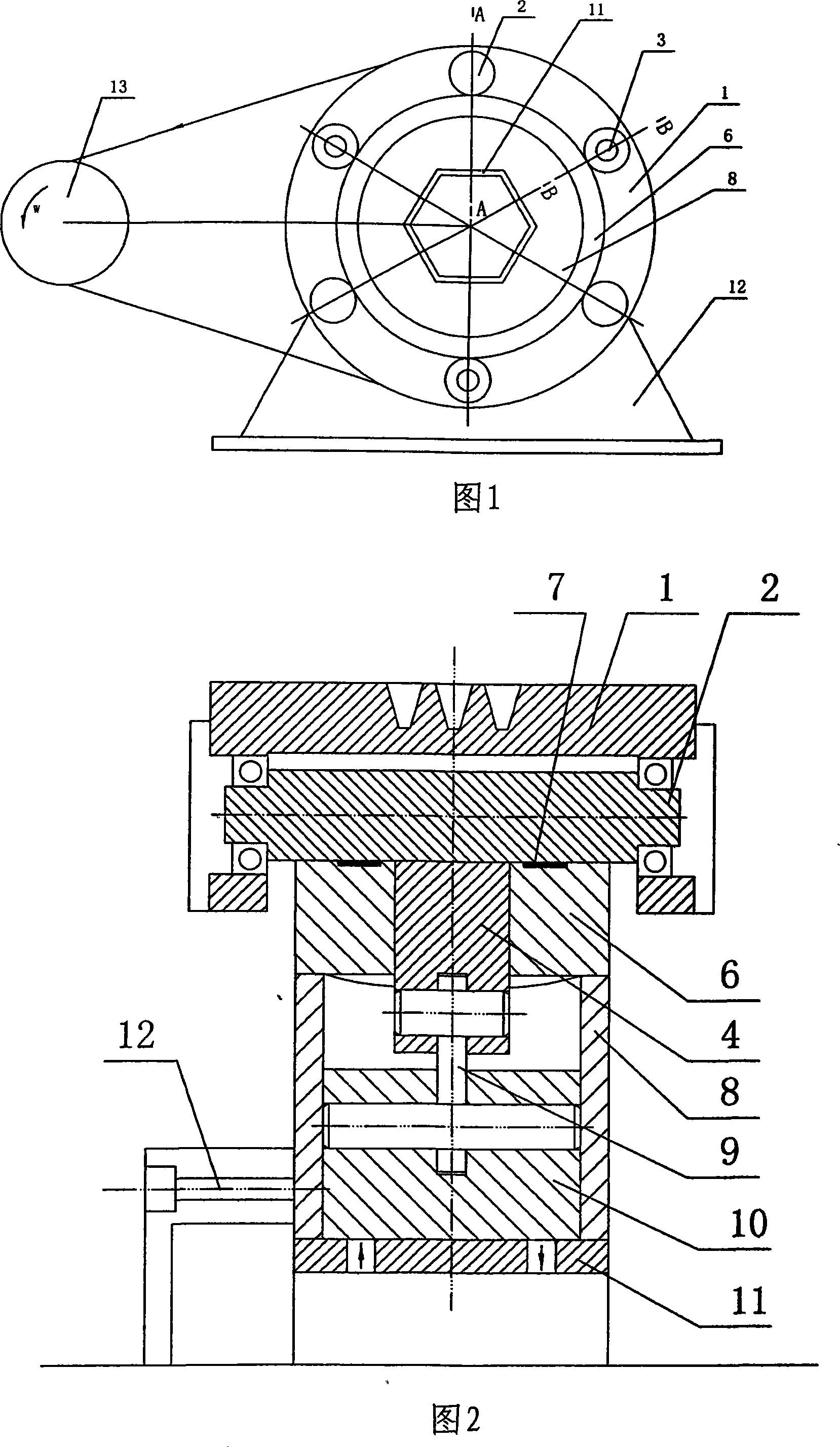

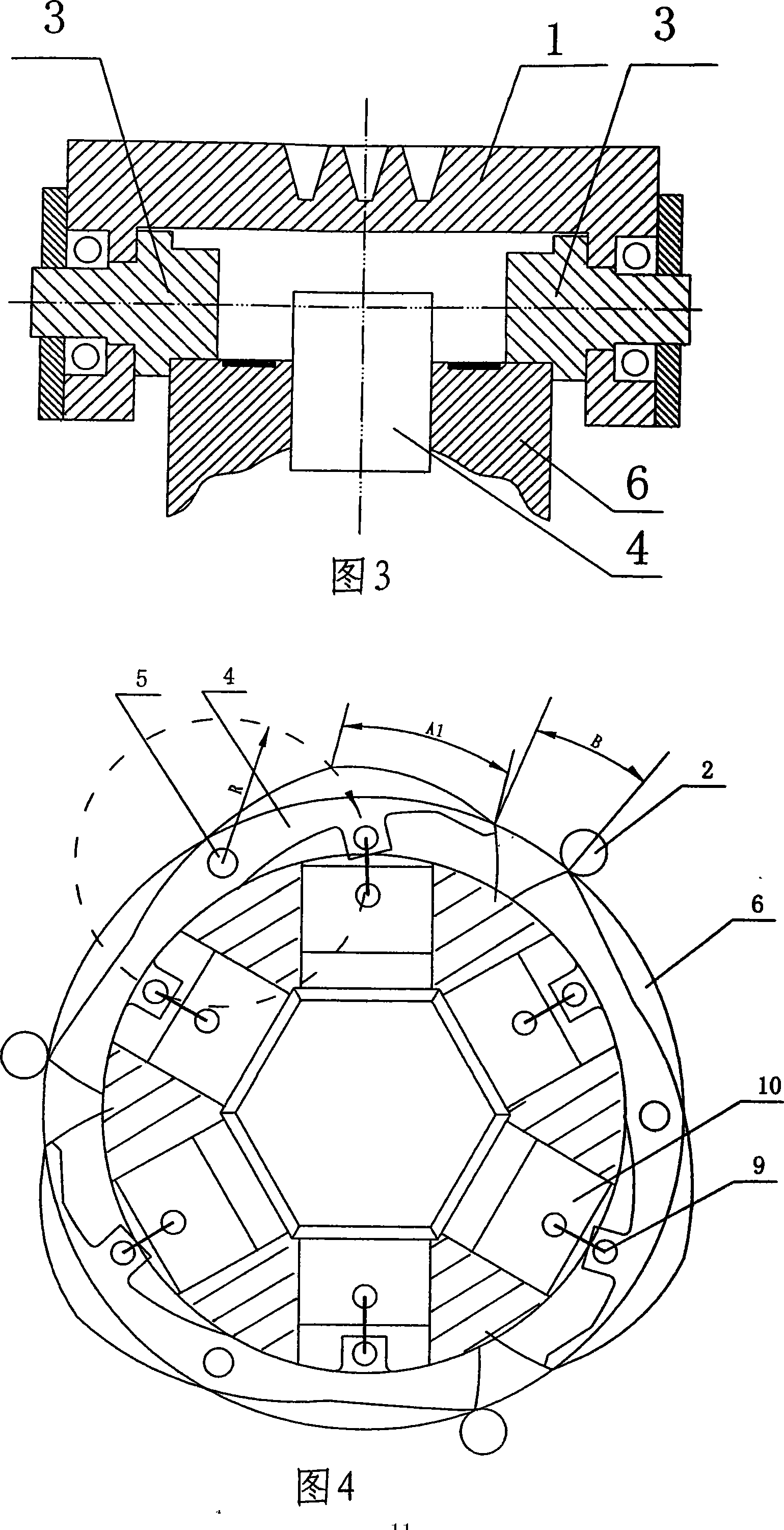

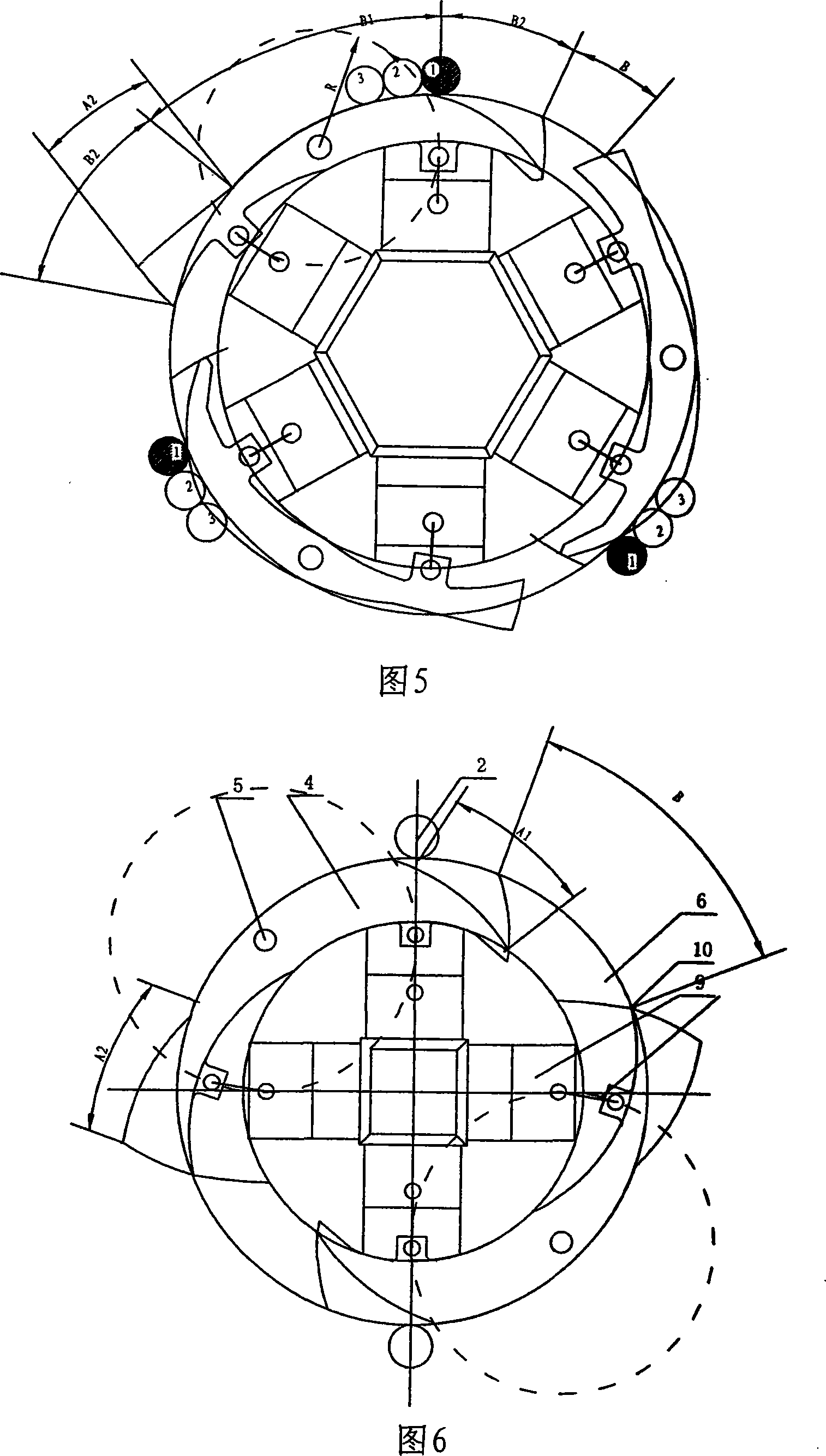

[0023] Referring to Fig. 1~3, the present invention is a kind of rolling lever type piston pump, mainly by support 12, cylinder block 8, piston 10, valve seat 11, runner seat 6, lever 4, connecting rod 9, runner 1, The pressure roller 2 and the supporting roller 3 are composed.

[0024] The cross section of the cylinder body 8 is circular, and the cylinder body 8 is fixedly mounted on the bracket 12. Several piston cavities are radially arranged in the cylinder body 8, and a piston 10 is arranged in each piston cavity. The valve seat 11 is fixedly installed in the inner hole of the cylinder body 8, the inlet and outlet on the valve seat 11 communicate with the corresponding piston chambers in the cylinder body 8, the cross section of the runner seat 6 is circular, and the runner seat 6 is fixedly set The entire pump body is fixed on the outer edge of the cylinder body 8, and a plurality of lever installation grooves are evenly distributed along the circumferential direction in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com