Anti-swinging device for lifting appliance for bridge type crane

A bridge crane and anti-swing device technology, which is applied in the direction of walking bridge cranes, cranes, transportation and packaging, etc., can solve the problem of material loading and unloading speed that affects production efficiency, difficulty in positioning the final position of the spreader, and limited lifting height and other issues to achieve the effect of reducing the possibility of dangerous accidents, avoiding swings, and accurate distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

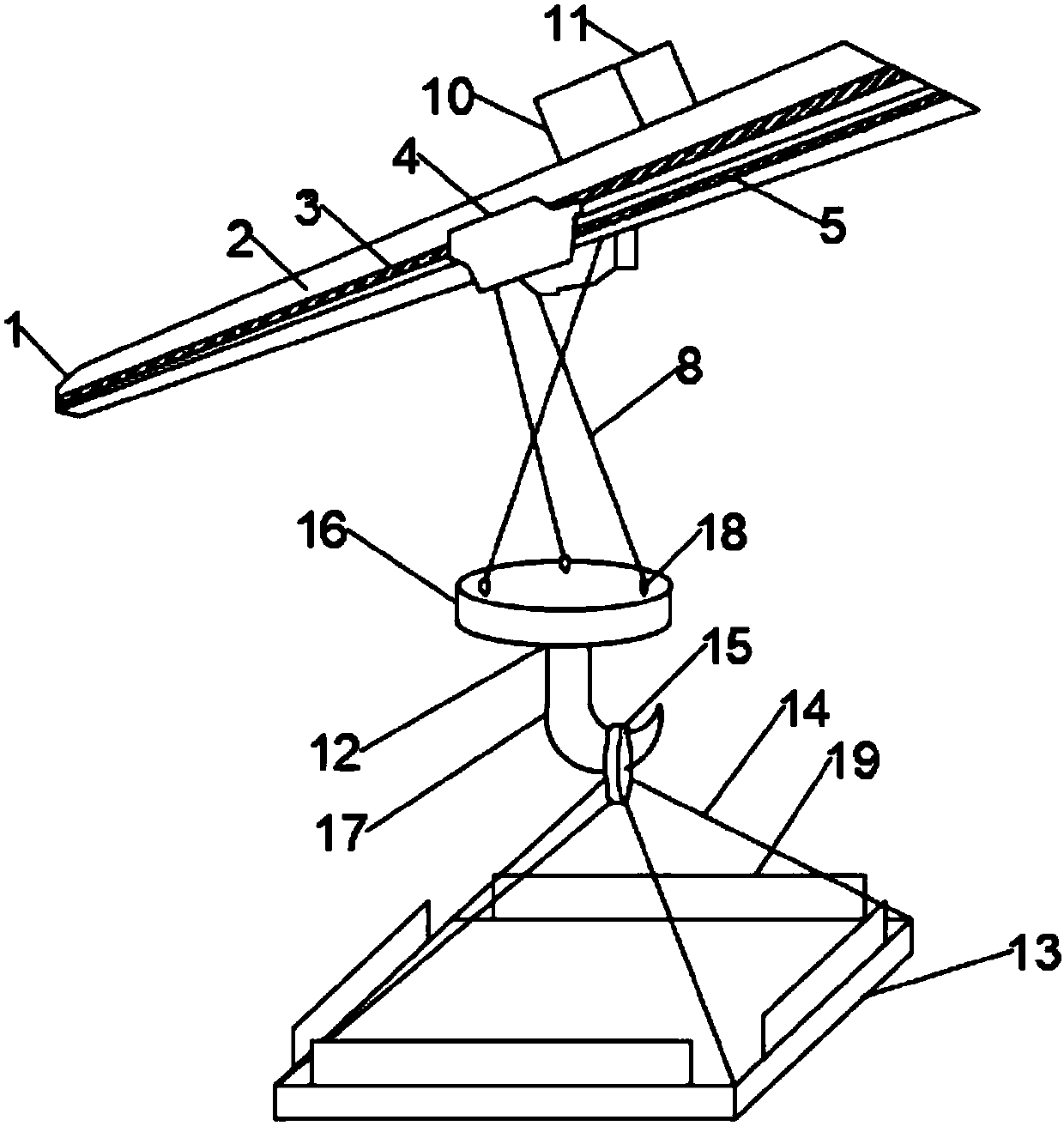

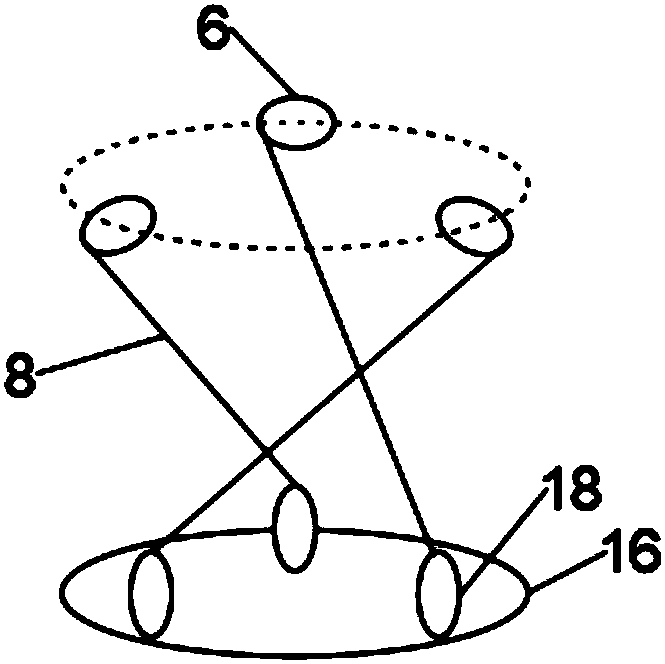

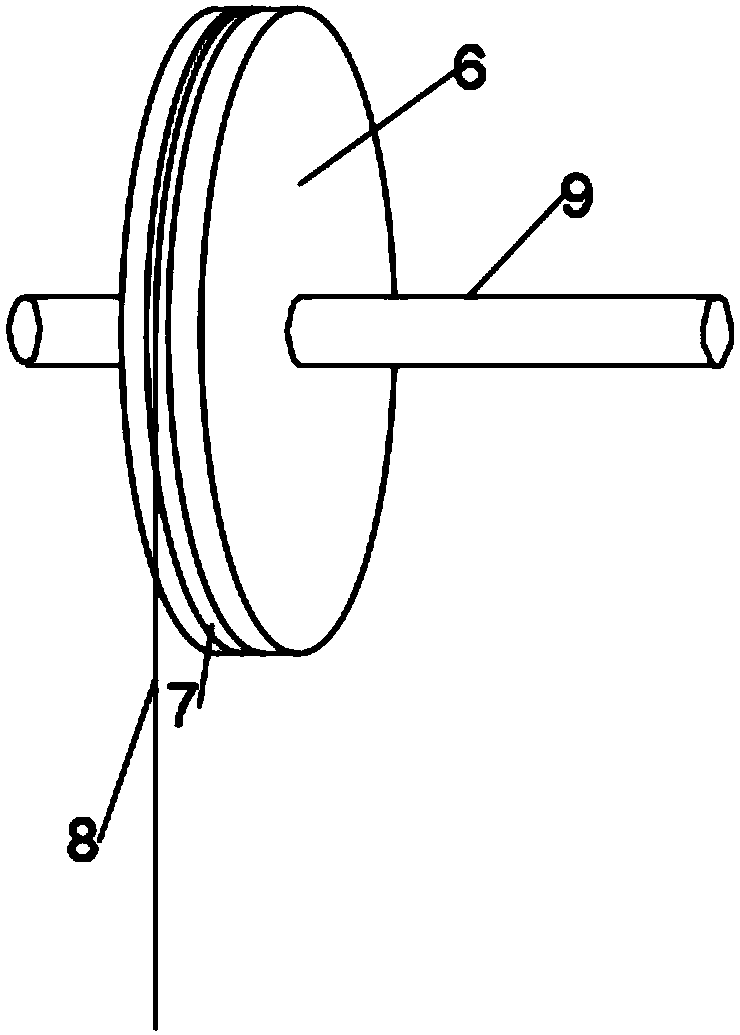

[0026] Such as Figure 1 to Figure 4 As shown, a suspension anti-swing device for a bridge crane includes a bridge 1, and the bridge 1 includes a main girder 2 of a box-type structure, and rails 3 are welded on both front and rear sides of the main girder 2, A slider 4 is arranged below the main beam 2, and a hydraulic rod 5 is arranged at the right end of the slider 4. The hydraulic rod 5 realizes expansion and contraction under the control of the control system, thereby completing the lateral movement of the slider 4 on the track 3. movement, the inside of the slider 4 is a hollow structure, and the top and bottom ends of the slider 4 are open, the slider 4 is clamped on the track 3, and the slider 4 can move along the track 3 Lateral movement, three reels 6 are installed on the inner wall of the slider 4, grooves 7 are all arranged on the three reels 6, steel wire ropes 8 are arranged inside the grooves 7, and a steel wire rope 8 is arranged inside the three reels 6. The w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com