Paper box forming machine

A technology of forming machine and carton, which is applied in papermaking, paper/cardboard containers, container manufacturing machinery, etc., and can solve the problems of cardboard position deviation, abrasion and scratching of the inner wall of the carton, and deformation of the carton.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

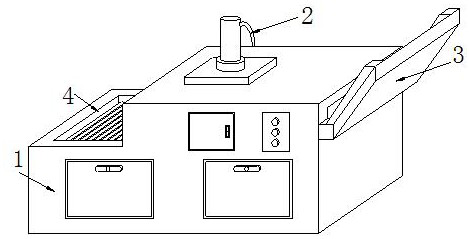

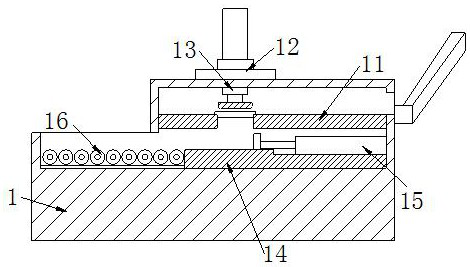

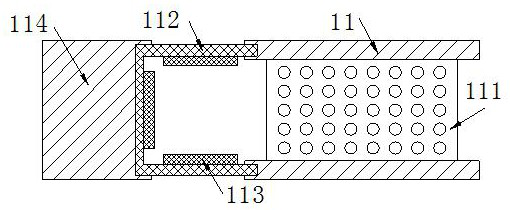

[0029] The present invention provides a carton forming machine, the structure of which includes a forming box 1, an air pipe 2, a feeding plate 3, and a discharge port 4, which are installed on the top of the forming box 1, and the bottom of the feeding plate 3 is connected by welding On the right wall of the forming box 1, the discharge port 4 is embedded on the upper surface of the left side of the forming box 1, and the forming box 1 includes a cardboard conveyor 11, a fixed table 12, an extruder 13, a bottom plate 14, and a push rod 15 , guide roller 16, the right end of the cardboard conveyor 11 is located on the same level as the bottom of the feeding plate 3, and the cardboard conveyor 11 is connected to the inner wall of the forming box 1 by welding, and the bottom of the fixed table 12 is embedded on the upper surface of the forming box 1 , the extruder 13 runs through the fixed table 12 and the upper wall of the forming box 1 and is located above the conveyor 11, the ...

Embodiment 2

[0035]The present invention provides a carton forming machine, the structure of which includes a forming box 1, an air pipe 2, a feeding plate 3, and a discharge port 4, which are installed on the top of the forming box 1, and the bottom of the feeding plate 3 is connected by welding On the right wall of the forming box 1, the discharge port 4 is embedded on the upper surface of the left side of the forming box 1, and the forming box 1 includes a cardboard conveyor 11, a fixed table 12, an extruder 13, a bottom plate 14, and a push rod 15 , guide roller 16, the right end of the cardboard conveyor 11 is located on the same level as the bottom of the feeding plate 3, and the cardboard conveyor 11 is connected to the inner wall of the forming box 1 by welding, and the bottom of the fixed table 12 is embedded on the upper surface of the forming box 1 , the extruder 13 runs through the fixed table 12 and the upper wall of the forming box 1 and is located above the conveyor 11, the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com