Water quality sample injecting method, analyzing method and device

A technology for water quality analysis and sample injection, which is used in material analysis, measurement devices, and analysis materials by optical means. The effect of reducing reagent consumption and reducing maintenance workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

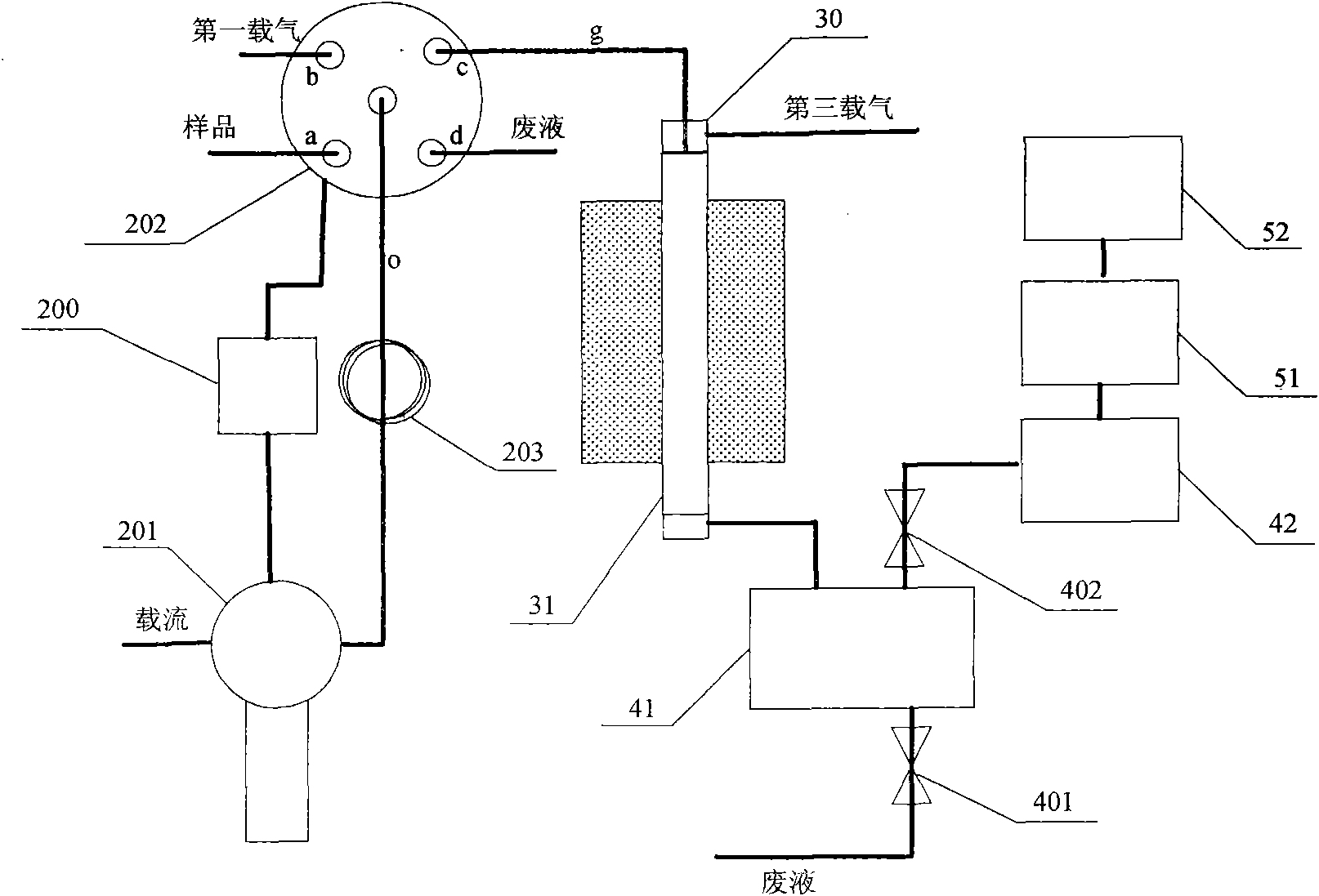

[0065] Such as image 3As shown, a water quality analysis device is used for total carbon analysis in water bodies, including a sampling unit, a control module 200, a reaction unit, a purification unit and a detection unit; the sampling unit is connected to a sample and a reagent, and the reagent Including the first carrier gas, the second carrier gas and the carrier flow;

[0066] The sampling unit includes a syringe pump 201, a multi-channel selector valve 202, a liquid storage ring 203 and pipelines;

[0067] One end of the syringe pump 201 is connected to the carrying current, and the other end is connected to the liquid storage ring 203 to accurately quantify the pumped substance; the carrying current can be distilled water or pure water with very low carbon content, and the carrying current in this embodiment is pure water;

[0068] The other end of the liquid storage ring 203 is connected with the multi-channel selector valve 202, and is used for temporarily storing t...

Embodiment 2

[0105] A water quality analysis device, used for total carbon analysis in water bodies, is the same as the water quality analysis device described in Example 1.

[0106] This embodiment also provides a water quality sampling method, which is different from the sampling method described in Example 1:

[0107] 1. In step A2, the control module 200 controls the syringe pump 201 to draw 100 μl of the carrier fluid into the liquid storage ring 203; and push the 100 μl carrier fluid through the injection channel c into the sample injection pipeline g for temporary storage;

[0108] 2. The sample injection method of the present embodiment also includes step A3, specifically:

[0109] The control module 200 controls the multi-channel selector valve 202 to select the carrier gas channel b, and the syringe pump 201 draws 1000 μl of the second carrier gas, namely air, into the liquid storage ring 203;

[0110] The control module 200 controls the multi-channel directional valve 202 to se...

Embodiment 3

[0115] A water quality analysis device, used for total carbon analysis in water bodies, is the same as the water quality analysis device described in Example 2.

[0116] This embodiment also provides a water quality sampling method, which is different from the water quality sampling method in Example 2:

[0117]1. Step A2 is to inject the first carrier gas into the sampling pipeline: the control module 200 controls the multi-channel selector valve 202 to select the carrier gas channel b, and the syringe pump 201 draws 50 μl of the first carrier gas, namely air, into the liquid storage ring 203 ;

[0118] The control module 200 controls the multi-channel selector valve 202 to select the injection channel c, and the syringe pump 201 pushes the air to push the air in the liquid storage ring 203 to the sample injection pipeline g through the injection channel c for temporary storage;

[0119] 2. Step A3 is to inject the carrier current into the sample injection pipeline and injec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com