Cooling liquid jetting mechanism

A technology of spray mechanism and coolant, applied in metal processing machinery parts, maintenance and safety accessories, metal processing equipment, etc. There are no problems such as good cooling and lubrication, so as to achieve the effect of improving flexibility and versatility, various spraying methods, and avoiding the dead angle of spraying.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The coolant injection mechanism of the present invention will be described in detail below in conjunction with the accompanying drawings.

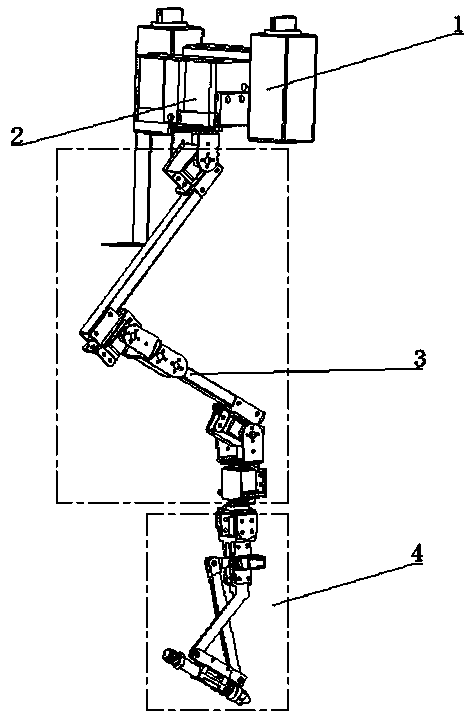

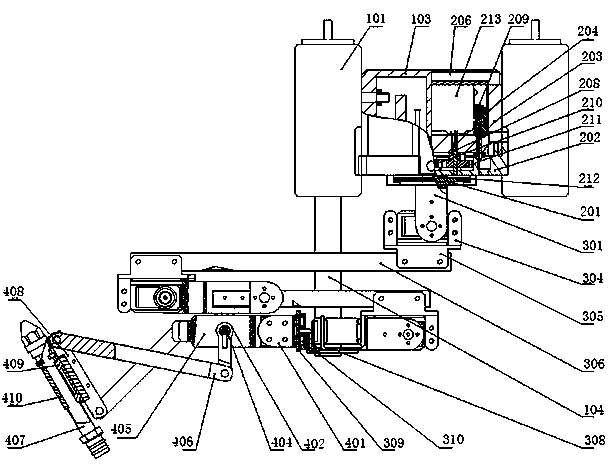

[0026] like figure 1 , figure 2 As shown, the coolant injection mechanism of the present invention includes four parts, which are sequentially connected from top to bottom: the adsorption base 1 , the main body frame 2 , the mechanical arm 3 and the swing head.

[0027] 1.1 Adsorption base structure

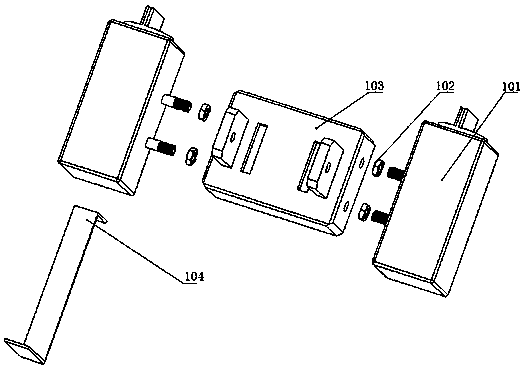

[0028] combine image 3 As shown, the design of the adsorption base 1 uses the adsorption principle of the magnetic watch base 101 to support the overall weight, including the hanger 104, the magnetic watch base 101 located at the left and right ends and the base 103 in the middle. The fastening between the base 103 and the magnetic watch base 101 is supported by four M8 nuts 102 . A groove is provided at the lower end of one of the magnetic watch bases; one end of the hanger 104 is inserted into the groove. The base 103 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com