A linear guide rail type cooling system control mechanism

A cooling system control, linear guide technology, applied in the direction of manufacturing tools, metal processing machinery parts, maintenance and safety accessories, etc., can solve the problem of affecting the flexibility of the tool, easy to cause interference, etc. The effect of reducing usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

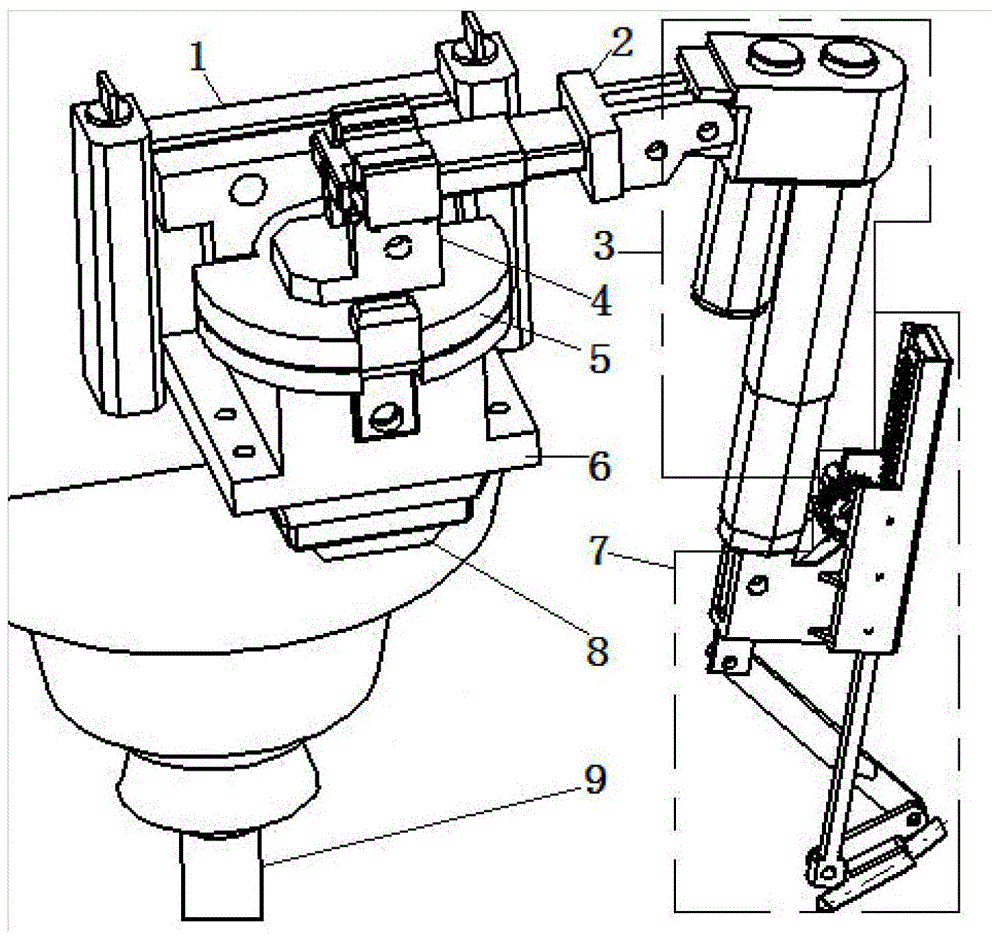

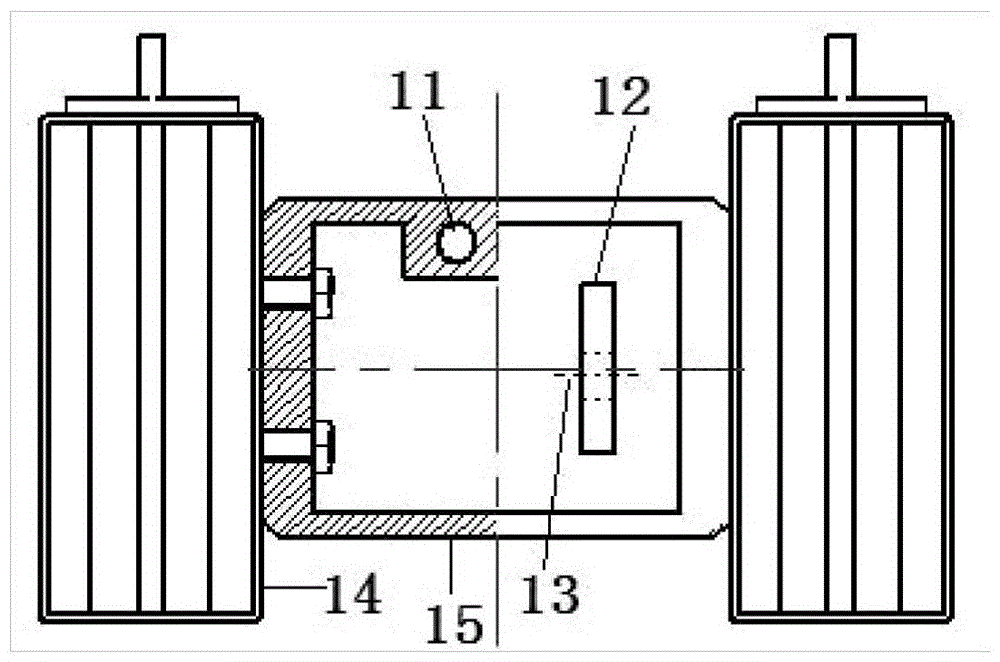

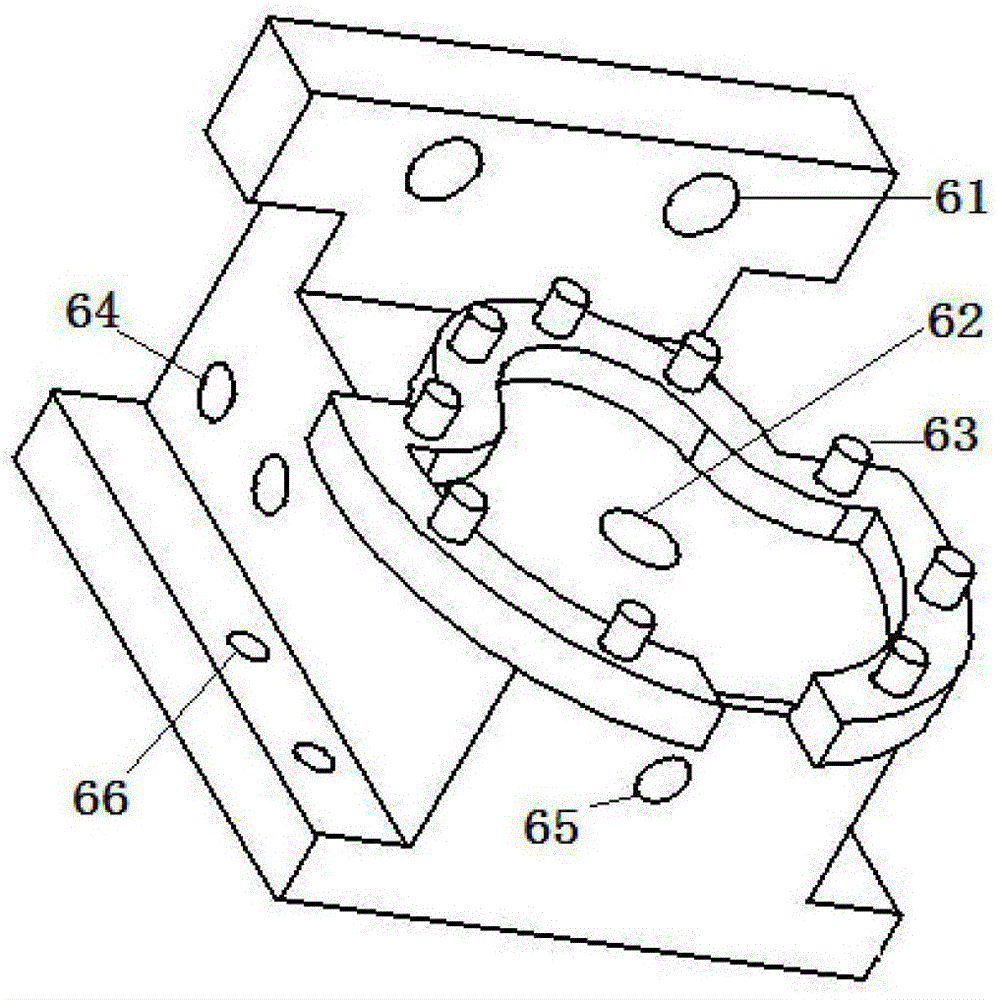

[0026] A linear guide rail type cooling system control mechanism, including a base 1, a swing arm 2, a telescopic arm 3, a rotating bracket 4, a fixed frame 6, a swing head 7 and a servo motor 8, the base is fixed on the machine tool, and the fixed frame is installed on the base , the servo motor is fixed on the fixed frame, and the rotary bracket connected with the servo motor is rotatably arranged on the fixed frame; one end of the swing arm is fixed on the rotary frame, and the other end is connected with the telescopic arm that can move up and down; the swing head is set on The top of the swing arm; the swing head is provided with a spray nozzle 77.

[0027] Such as figure 1 As shown in the figure, the cutter 9 and the base 1 are fixed on the machine tool, the servo motor 8 is fixed on the fixed frame 6, and the fixed frame 6 is installed on the base 1; the rotating bracket 4 is connected with the fixed frame cover 5 through the bearing; the swing arm 2 Fixed on the rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com