A wear tip holder for a VSI crusher, a kit comprising a wear tip holder, and a method of reducing the wear rate of a wear tip holder

一种磨损速度、保持器的技术,应用在谷物处理等方向,达到增强保持能力、减少磨损、摩擦作用增大的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

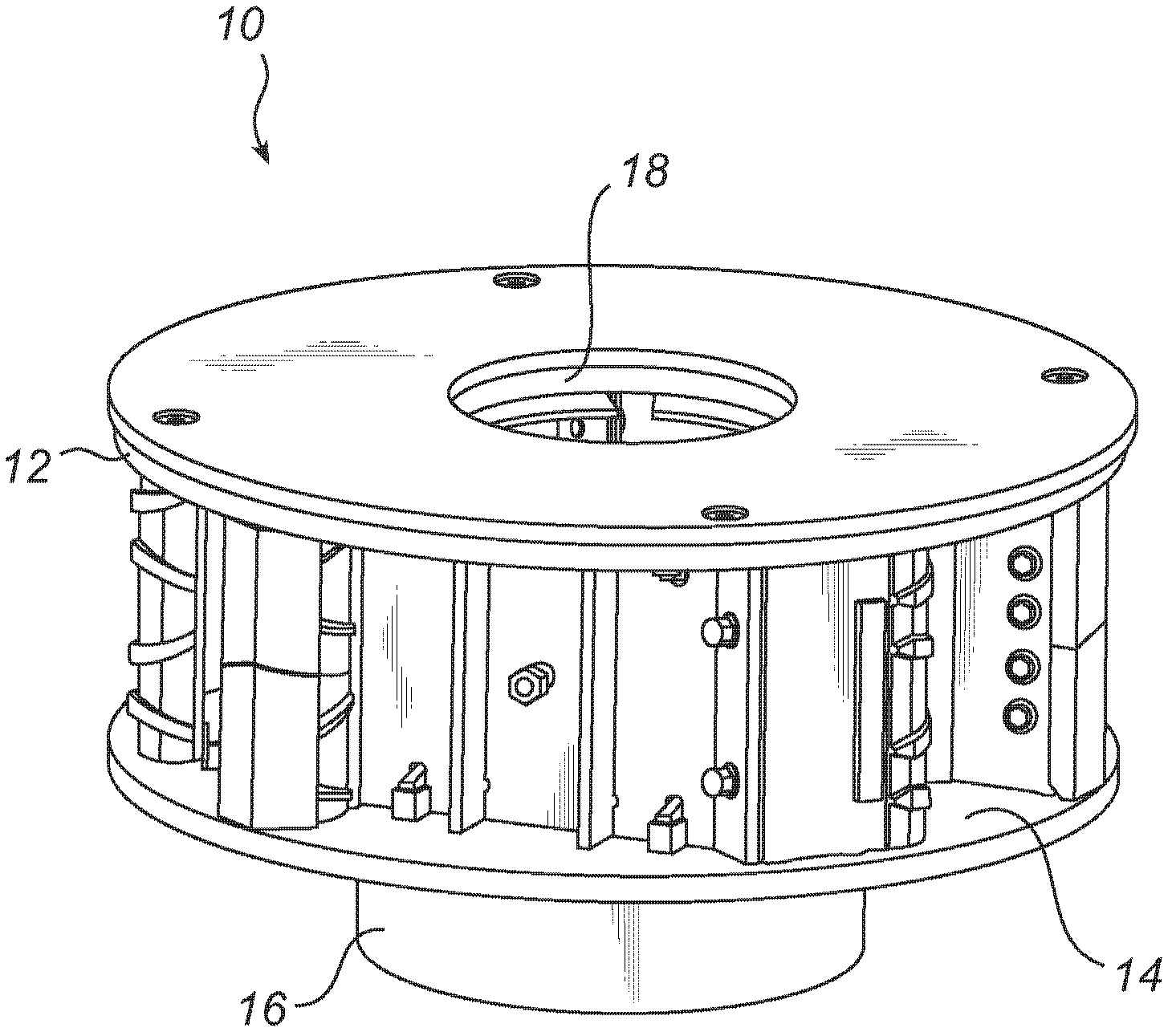

[0037] figure 1Shown is a rotor 10 for use in a vertical shaft impact crusher, ie a VSI crusher. The rotor 10 has a top in the form of a horizontal upper disk 12 and a bottom in the form of a horizontal lower disk 14 . The lower disc 14 has a hub 16 welded to the disc 14 . The hub 16 will be connected to a shaft (not shown) for rotating the rotor 10 within the housing of the VSI crusher. The upper disk 12 has a central hole 18 through which the material to be crushed can be fed into the rotor 10 .

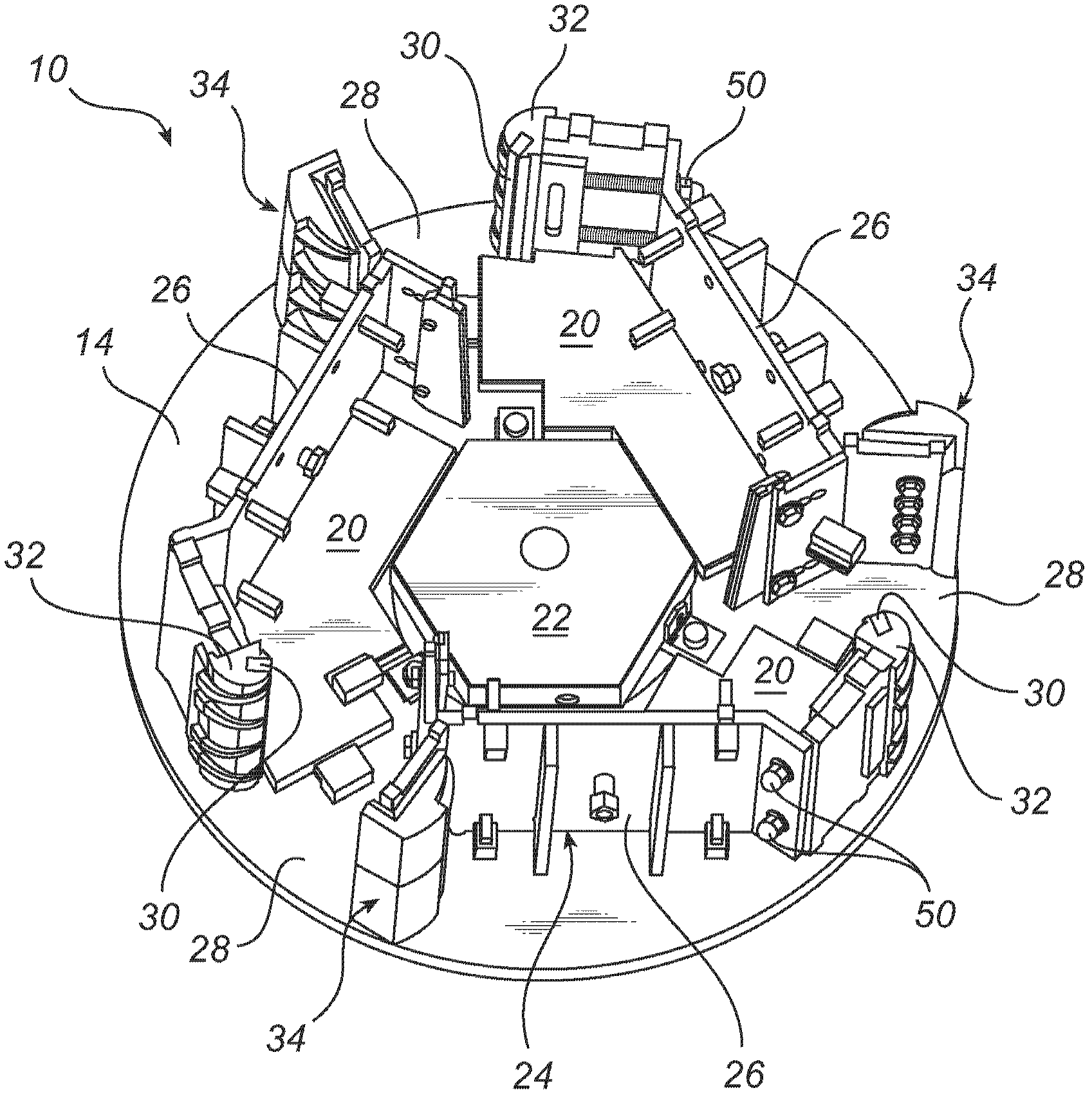

[0038] like figure 2 As shown, the lower disc 14 is protected from wear by a lower wear plate 20 . A distribution plate 22 is fastened to the center of the lower pan 14 . The distribution plate 22 distributes through the holes 18 in the upper plate 12 ( figure 1 ) and supplied materials.

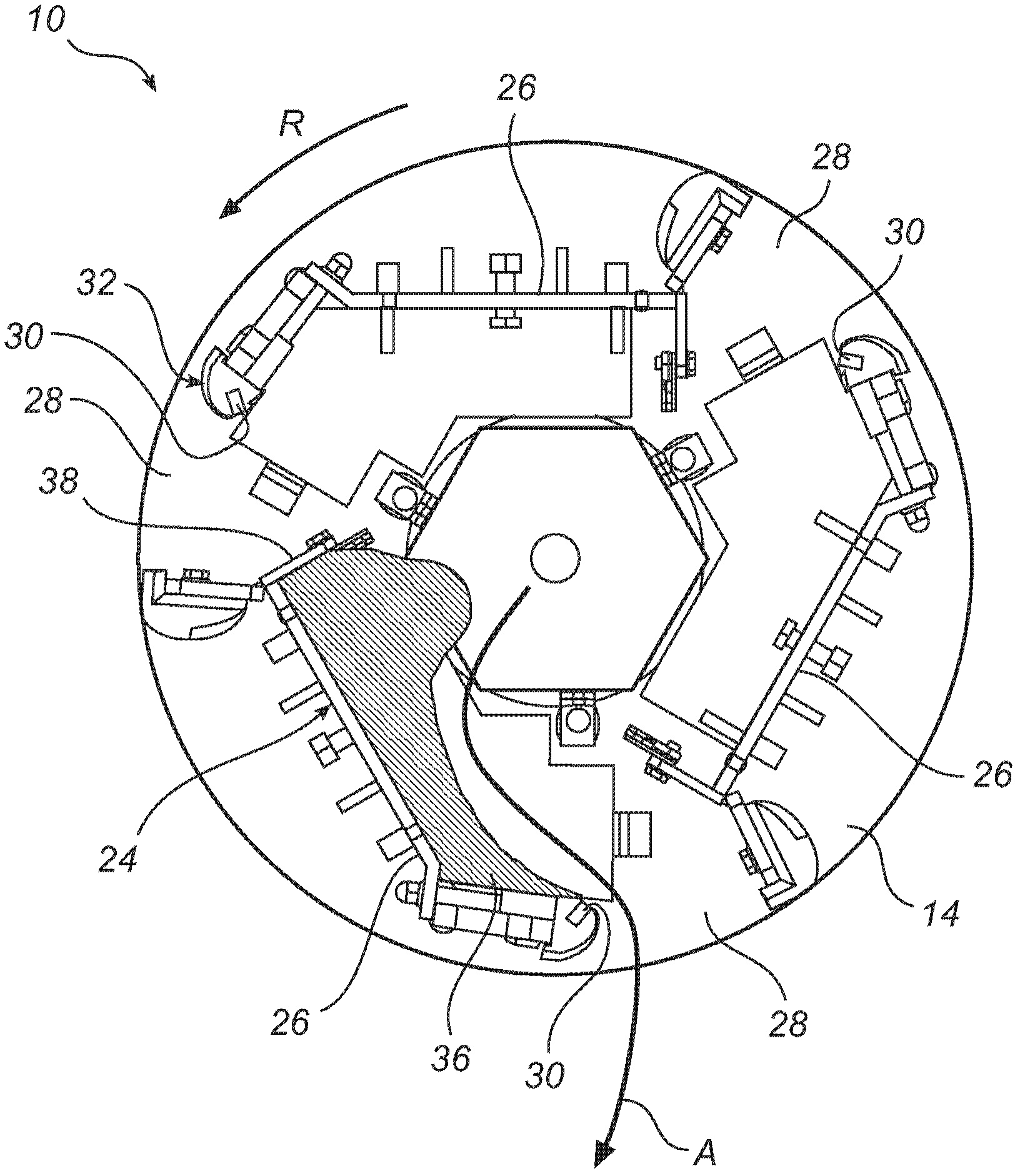

[0039] The upper disk 12 and the lower disk 14 are separated and held together by a vertical rotor wall 24 which is divided into three separate wall sections 26 . The gaps between the wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com