Manufacturing method of water transfer keycap for computer keyboard

A technology for computer keyboards and production methods, which is applied to circuits, electric switches, electrical components, etc., can solve the problems that patterns or patterns cannot be formed on the surface of keycaps, cannot meet the needs of consumers, and the color is monotonous, and achieve rich styles and processing Easy conditions and good overall effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

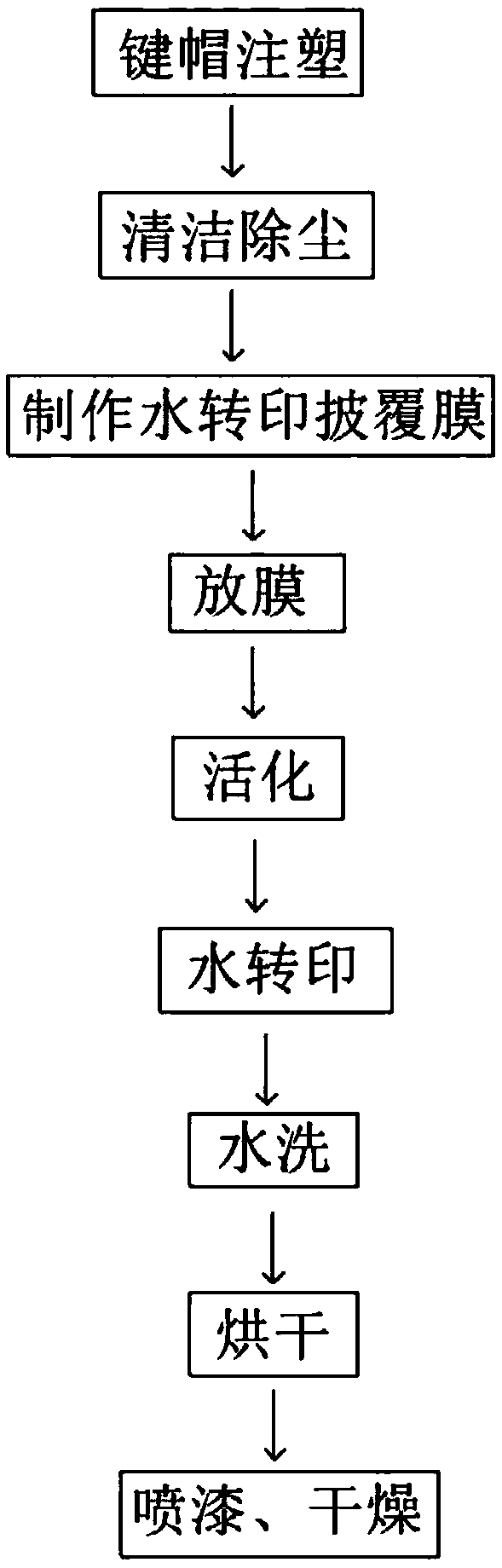

[0026] The preparation method of computer keyboard water transfer printing keycap of the present invention comprises the following steps:

[0027] Step a, take a keycap injection mold;

[0028] Step b, add PA-777C injection grade ABS raw material to SA3200Ⅱ Haitian injection molding machine, under the injection molding conditions of injection molding temperature 230°C, injection pressure 130MPa, holding pressure 70MPa, mold temperature 80°C, use key Cap injection mold carries out injection molding process, and wherein molding time is 50s, and the time of heat preservation and pressure holding is 5s, obtains key cap;

[0029] Step c, carrying out water transfer printing processing on the keycap obtained in step b, including the following sub-steps:

[0030] c1. Take a keycap fixture, fix the keycap in step b on the keycap fixture, and carry out electrostatic dust removal treatment on the keycap and the keycap fixture, so that the surface of the keycap and the keycap fixture is...

Embodiment 2

[0039] The preparation method of computer keyboard water transfer printing keycap of the present invention comprises the following steps:

[0040] Step a, take a keycap injection mold;

[0041] Step b, add PA-777C injection grade ABS raw material to SA3200Ⅱ Haitian injection molding machine, under the injection molding conditions of injection molding temperature 220°C, injection pressure 115MPa, holding pressure 65MPa, mold temperature 77.5°C, use key Cap injection mold carries out injection molding process, and wherein molding time is 45s, and the time of heat preservation and pressure holding is 4s, obtains key cap;

[0042] Step c, carrying out water transfer printing processing on the keycap obtained in step b, including the following sub-steps:

[0043] c1. Take a keycap fixture, fix the keycap in step b on the keycap fixture, and carry out electrostatic dust removal treatment on the keycap and the keycap fixture, so that the surface of the keycap and the keycap fixture ...

Embodiment 3

[0052] The preparation method of computer keyboard water transfer printing keycap of the present invention comprises the following steps:

[0053] Step a, take a keycap injection mold;

[0054] Step b, add PA-777C injection molding grade ABS raw material to SA3200Ⅱ Haitian injection molding machine, under the injection molding conditions of injection molding temperature 210°C, injection pressure 100MPa, holding pressure 60MPa, mold temperature 75°C, use key Cap injection mold carries out injection molding process, and wherein molding time is 40s, and the time of heat preservation and pressure holding is 3s, obtains key cap;

[0055] Step c, carrying out water transfer printing processing on the keycap obtained in step b, including the following sub-steps:

[0056] c1. Take a keycap fixture, fix the keycap in step b on the keycap fixture, and carry out electrostatic dust removal treatment on the keycap and the keycap fixture, so that the surface of the keycap and the keycap fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com