Patents

Literature

119 results about "Phaseolus mungo" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Vigna mungo, black gram, urad bean, urid bean, minapa pappu, mungo bean or black matpe bean (māṣa) is a bean grown in the Indian subcontinent. Like its relative, the mung bean, it has been reclassified from the Phaseolus to the Vigna genus. The product sold as black lentil is usually the whole urad bean, whereas the split bean (the interior being white) is called white lentil. It should not be confused with the much smaller true black lentil (Lens culinaris).

Appetizing dried bean curd with hawthorn and toona sinensis and preparation method thereof

The invention discloses an appetizing dried bean curd with hawthorn and toona sinensis. The appetizing dried bean curd is prepared from the following raw materials in parts by weight: 100-110 parts of soybeans, 20-30 parts of green beans, 6-8 parts of nutrition additives, 10-12 parts of oysters, 2-3 parts of lard oil, 8-9 parts of frozen tofu, 3-5 parts of five spice powder, 3-4 parts of haw slices, 6-8 parts of lotus roots, 10-12 parts of yoghourt, 3-4 parts of vinegar residues, 1-1.2 parts of tender cedrela sinensis leaves, 2-2.2 parts of paniculate microcos leaves, 1.2-2 parts of pummelo peels, 1.8-2.2 parts of sunflower discs, 1-1.3 parts of swertia mileensis grasses, 1.5-2 parts of persimmon calyx and 5-6 parts of rubus rosifolius. The dried bean curd is cool and refreshing; the added tender cedrela sinensis leaves have functions of appetizing, refreshing and dispelling wind and eliminating dampness; the pummelo peels have functions of regulating qi-flowing and eliminating phlegm, and invigorating spleen and promoting digestion; the swertia mileensis grasses have functions of clearing heat and tonifying spleen and removing heat from the lung to relieve cough; the hawthorn has the function of appetizing and helping digestion. The appetizing dried bean curd is especially suitable for being eaten before dinner to increase appetite.

Owner:JINCAIDI FOOD CO LTD

Agropolymer containing a carbohydrate and silica matrix from plants

InactiveUS6958232B2Improving water pollution controlReduce environmental pollutionSolid waste disposalContaminated soil reclamationSilica matrixCajanus

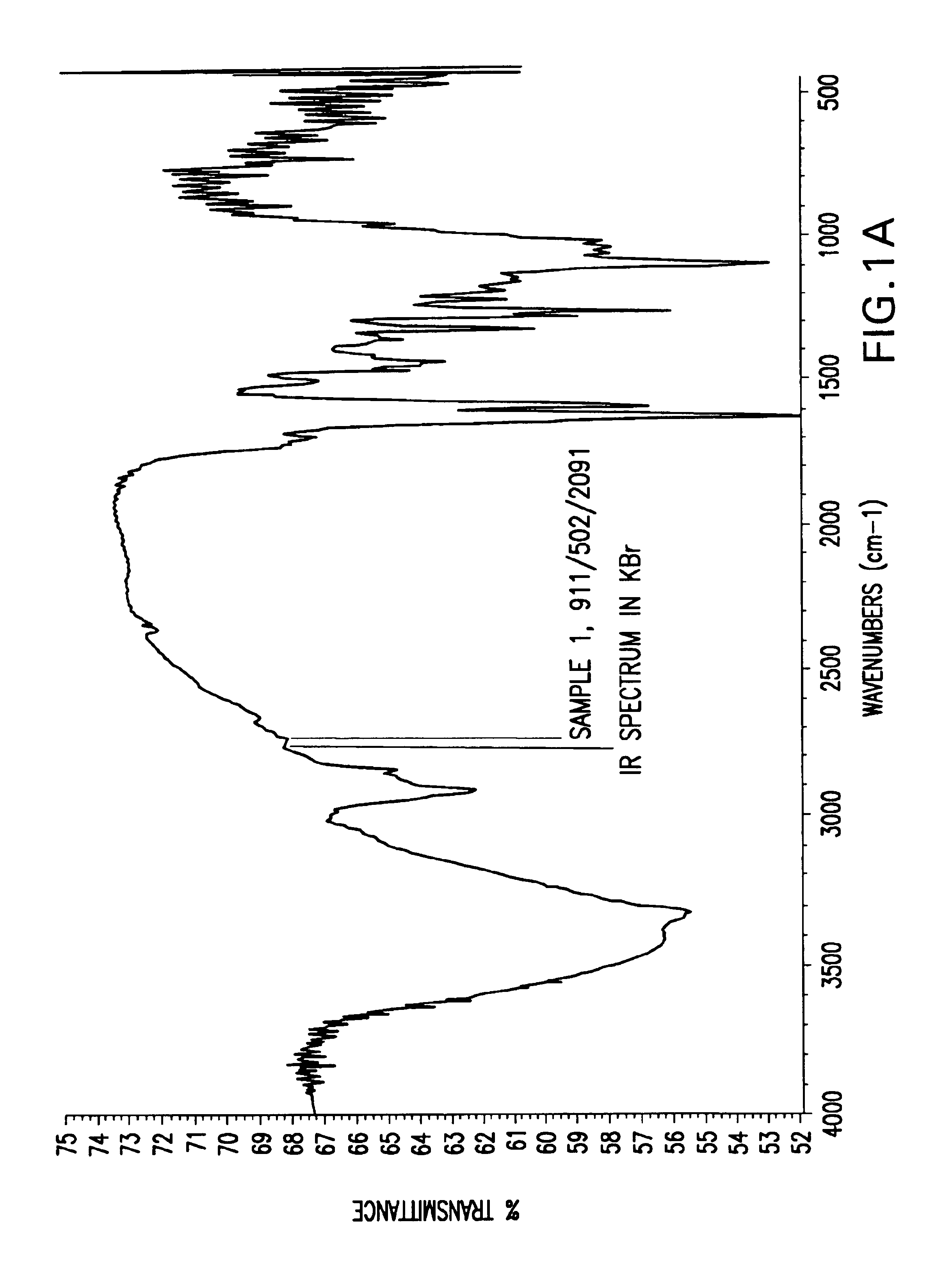

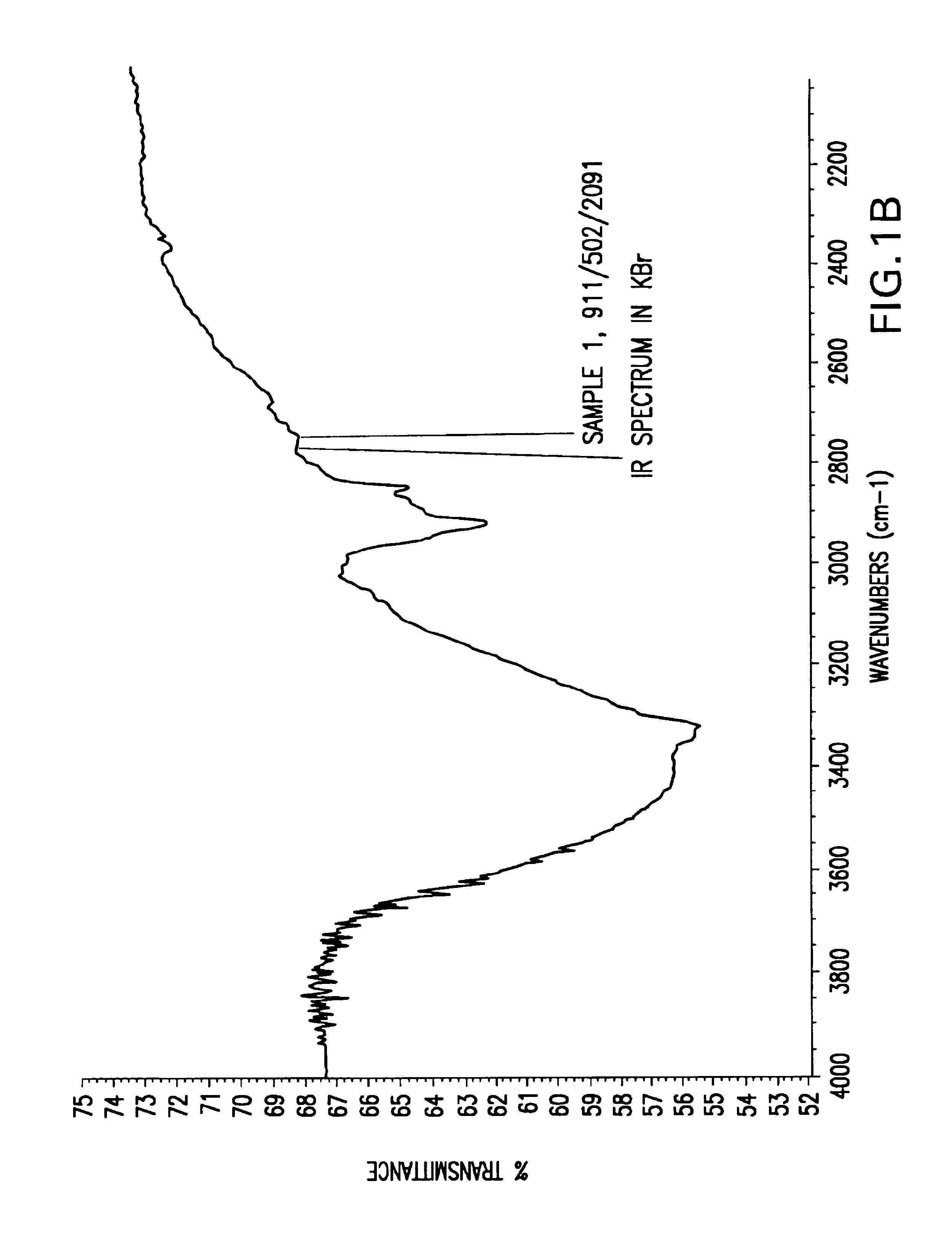

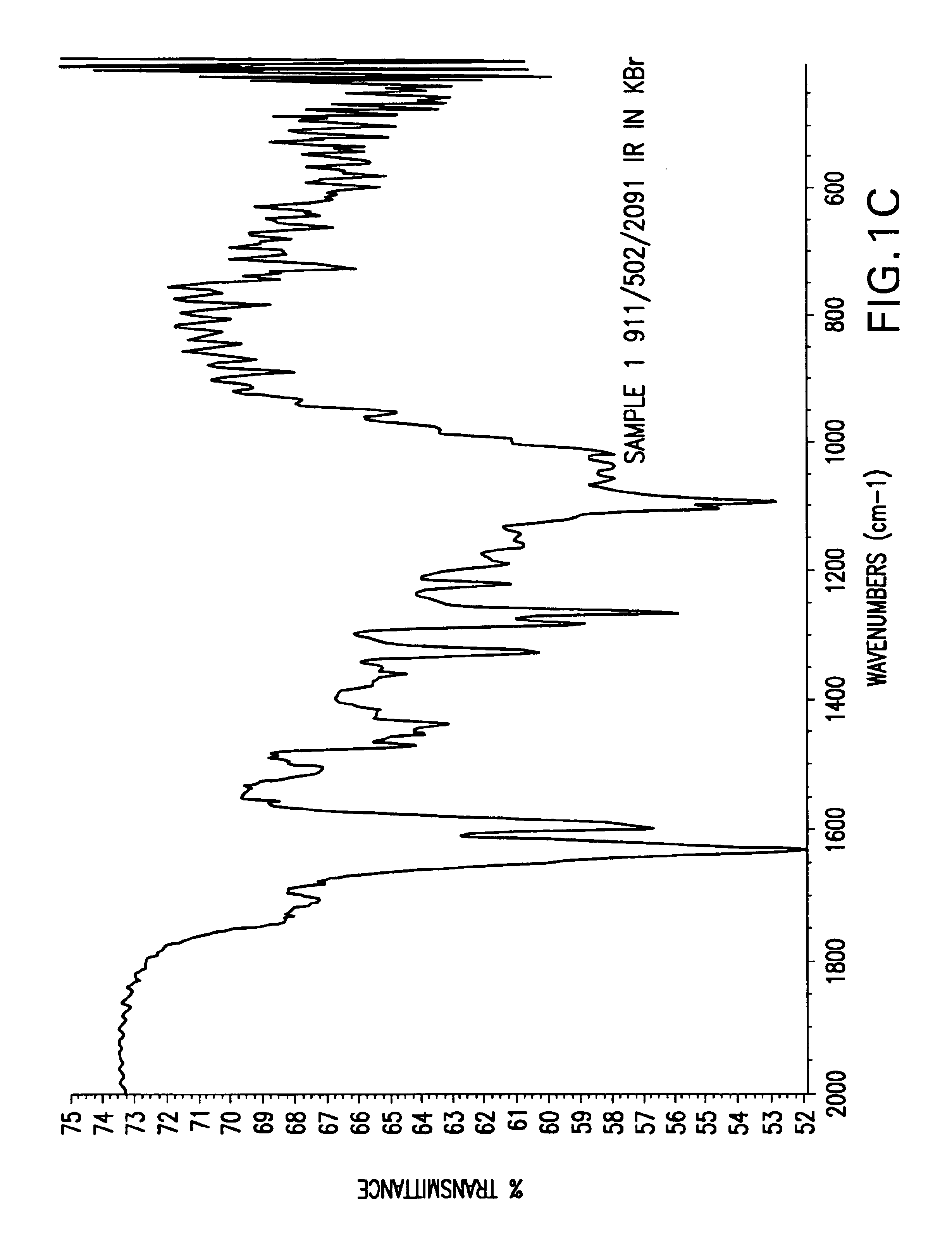

The present invention relates to novel agropolymers, which comprise a carbohydrate and / or silica matrix substantially devoid of proteins, tannins and polyphenols and which comprise metal binding reactive sites. A method of producing the agropolymers is also disclosed wherein the agropolymers are derived from plant materials such as seed coats, seed covers, husks, or hulls of various agricultural crops. The agricultural crops typically used to produce the agropolymers include Oryza sativa, Panicum miliaceum, Setaria italica, Cajanus cajan, Vigna mungo, Vigna radiata, Triticum sp., Ricinus communis, Helianthus annus, Gossypium sp., and Arachis sp. The agropolymers of the present invention are capable of purifying aqueous solutions polluted or contaminated with metals and / or ions. Thus, the present invention also discloses a method whereby agropolymers are used in the purification of contaminated water and other aqueous solutions. The agropolymers disclosed herein are useful in several industrial applications including purifying polluted drinking water or ground water.

Owner:BIJAM BIOSCI

Colorful vegetable-fruit cake

InactiveCN104068088AReduce greasy feelingBright colorDough treatmentBakery productsFruit cakeRich fruit cake

The invention discloses a colorful vegetable-fruit cake and relates to the field of foods. The colorful vegetable-fruit cake comprises, by weight, 150-250g of tomatoes, 150-250g of blueberries, 150-250g of oranges, 150-250g of grapes, 150-250g of mung beans, 45-55g of powdered milk, 55-65ml of salad oil, 15-25g of honey, 75-85g of white granulated sugar, 65-75g of self-raising flour, 150-250g of cream and 3-8 eggs. According to the colorful vegetable-fruit cake, vegetables and fruits are mixed to form the cake, the greasy taste of the cake is reduced, the cake is brightly colorful and has multiple tastes, and meanwhile, the colorful vegetable-fruit cake helps to fill in the market gap.

Owner:代兵兵

Method for preparing series food by means of triticale mixed flour

InactiveCN105558786AImprove processing qualityStrong blood sugar raising effectDough treatmentDough/pre-mixesBlood glucose increasedGluten

The invention discloses a method for preparing series food by means of triticale mixed flour. The method comprises the steps of mixing triticale flour with green bean flour according to a certain proportion to form original flour; adding a proper amount of vital gluten and / or konjaku flour to the original flour, conducting even mixing to obtain the triticale mixed flour, and making the triticale mixed flour into triticale and green bean blood glucose reduction steamed buns, triticale and green bean blood glucose reduction noodles, triticale and green bean blood glucose reduction cookies or triticale and green bean blood glucose reduction paste. Guantao triticale is taken as the main material, and the original flour obtained after triticale flour and green bean flour are mixed according to a certain proportion has a better blood glucose increase control effect compared with purer triticale flour. Meanwhile, by adding vital gluten and / or konjaku flour to the original flour, the processing quality of triticale flour is improved effectively, and products with good taste are obtained.

Owner:馆陶县科学技术局

Mutation-preventing almond tea oil

InactiveCN104222325AEasy to removeFit for consumptionFatty-oils/fats productionEdible oils/fatsGrape seedTribulus terrestris

The invention relates to mutation-preventing almond tea oil which is prepared from the following raw materials in parts by weight: 230-250 parts of camellia seeds, 50-60 parts of almond, 45-55 parts of mung beans, 40-50 parts of grape seeds, 8-10 parts of spiral seaweed, 5-7 parts of gynostemma pentaphylla, 5-6 parts of tribulus terrestris, 3-5 parts of dandelion, 6-8 parts of Chinese caterpillar fungus and the like, wherein the almond contains vitamin B17, thus the mutation-preventing almond tea oil has a mutation-preventing effect; meanwhile, in a preparation process, essences of the grape seeds and the spiral seaweed are added, thus the mutation-preventing almond tea oil has good functions of scavenging free radicals and enhancing the immunity; meanwhile, the gynostemma pentaphylla and setose thistle are added, thus the mutation-preventing almond tea oil has good functions of resisting ageing and relieving the internal heat or fever, and is suitable for being eaten by various crowds.

Owner:YUEXI GUANGSHENG TEA OIL CO LTD

Dried bean curd mixed with multiple beans and preparation method of dried bean curd mixed

InactiveCN103734354AMeeting nutritional needsPromote absorptionCheese manufactureFood scienceBiotechnologyAdditive ingredient

The invention discloses dried bean curd mixed with multiple beans and a preparation method of the dried bean curd. The dried bean curd comprises the following raw materials in parts by weight: 70-80 parts of black beans, 30-40 parts of soybeans, 30-40 parts of green beans, 15-25 parts of red beans, 4-6 parts of coconuts, 4-5 parts of carambola, 6-8 parts of carrots, 3-5 parts of bean curd stick, 2-4 parts of dandelion, 2-4 parts of ginkgo leaves, 2-4 parts of Arundina chinensis, 1-3 parts of cassia twig, 2-3 parts of tuckahoe, 1-2 parts of Pseudostellaria heterophylla, 3-5 parts of trichosanthes palmate, 4-5 parts of Artemisia halodendron, 2-4 parts of fructus trichosanthis leaves, 1-3 parts of Indian nightshade root and 2-3 parts of fortune loosestrife herb. By mixing multiple beans, the dried bean curd is rich in amino acid, protein and vitamin and can meet nutritional requirements of a human body; the dried bean curd is supplemented with Chinese herbal medicines, fruits and vegetables, and the preparation method is special, namely raw materials are extracted by virtue of methods of enzymolysis, water extraction and the like, so that nutritional ingredients of the raw materials are easy to release and can be conveniently absorbed by the human body.

Owner:WUHU ZHONGLU IND

Dried shrimp meat floss containing vegetable protein

The invention provides a dried shrimp meat floss containing vegetable protein, comprising the following raw materials by weight: 200 to 230 parts of shrimp meat, 30 to 40 parts of soya bean, 20 to 30 parts of mung bean, 30 to 40 parts of japonica rice, 10 to 20 parts of the seed of Job's tears, 4 to 5 parts of Galium aparine L., 4 to 5 parts of common bletilla, 3 to 4 parts of mulberry leaf, 3 to 4 parts of unprocessed rehmannia root, 3 to 4 parts of galagal rhizome, 4 to 5 parts of glossy ganoderma, 3 to 4 parts of red sage root, 3 to 4 parts of lotus plumule, 2 to 3 parts of sesame leaf, 3 to 4 parts of Chinese dwarf cherry leaf, 10 to 15 parts of green tea, 50 to 70 parts of rice wine, 20 to 30 parts of curry powder, 5 to 10 parts of minced ginger, 20 to 40 parts of salt, 20 to 30 parts of soy, 10 to 50 parts of white sugar, a proper amount of olive oil and a proper amount of water. According to the invention, the dried shrimp meat floss is rich in animal protein and vegetable protein, can be easily absorbed by a human body and has rich nutrients and delicate taste; cereals are especially added, so the contents of starch and dietary fiber in the floss are increased; extracts of medicinal traditional Chinese medicinal materials like Galium aparine L. and common bletilla with cold dispelling, pain relieving and beauty fostering effects are added; thus, the dried shrimp meat floss is especially applicable to females and ideal health food for females.

Owner:HEFEI FULAIDUO FOOD

Laying hen feed containing cinnamomum camphora seeds

InactiveCN103621770AAvoid coldPrevent diarrheaFood processingAnimal feeding stuffHordeum vulgareBroad beans

The invention relates to the technical field of feeds, and in particular relates to a laying hen feed containing cinnamomum camphora seeds. The feed is prepared from the following raw materials in percentage by weight: 50-60 percent of corns, 25-30 percent of barley, 12-18 percent of corn straw, 6-8 percent of green beans, 10-12 percent of rye, 15-18 percent of wheat bran, 10-12 percent of brown rice, 20-25 percent of bean pulp, 8-10 percent of corn distillers grains, 1-2 percent of diatomaceous earth, 1-2 percent of shell powder, 2-3 percent of yellow mealworm dry powder, 1-2 percent of duck blood meal, 1-2 percent of chicken bone meal, 3-4 percent of groundnut stem, 3-4 percent of houttuynia cordata, 3-4 percent of broad bean leaf, 1-2 percent of cinnamomum camphora seeds, a proper amount of table salt and 0.2-0.5 percent of a phagostimulant. In the laying hen feed provided by the invention, the cinnamomum camphora seeds are added particularly, so that the laying hen feed has the effects of expelling wind, removing cold, relieving exterior syndrome and bringing down fever, and can effectively prevent diseases such as cold, dysentery and the like of laying hens, reduce the incidence probability of chicken flocks and ensure normal egg laying of the laying hens.

Owner:铜陵市银树生态养殖有限责任公司

Peach flower powder soybean milk and preparation method thereof

InactiveCN102948488AReduce cholesterolPromote excretionMilk substitutesFood scienceBiotechnologyBees honey

The invention discloses peach flower powder soybean milk and a preparation method thereof. The peach flower powder soybean milk is made by the following raw materials in parts by weight: 10-25 parts of peach flower powder, 5-15 parts of mung bean, 400-600 parts of water, 100-120 parts of soya bean, 20-40 parts of corn and 20-40 parts of bee honey. The preparation method comprises the following steps of 1) taking 5-15 parts of mung bean, 100-120 parts of soya bean and 20-40 parts of corn, adding 400-600 parts of water, putting the mung bean, the soya bean, the corn and the water into a mixer for pulping, filtering, and obtaining mixed juice; and 2) adding 10-25 parts of peach flower powder into the obtained mixed juice, boiling in low flame after the peach flower powder is mixed uniformly, and then adding 20-40 parts of bee honey after the mixture is cooled, thus obtaining the peach flower powder soybean milk by mixing the bee honey uniformly. The preparation method of the peach flower powder soybean milk, disclosed by the invention, is simple, the nutritional value is high, no chemical additive exists, the taste is delicious, and the peach flower powder soybean milk is one green and delicious healthy drink.

Owner:李文德

Green bean curd processing technology

The invention discloses a green bean curd processing technology. The green bean curd is processed by using green beans and soybeans as raw materials, wherein the green beans and the soybeans account for 50 percent respectively. The technology comprises the following steps of: soaking the green beans and the soybeans into clean water in an amount which is 5 times weight of the green beans and the soybeans at normal temperature, wherein the green beans are soaked for 12 to 15 hours and the soybeans are soaked for 8 to 10 hours so that the green beans and the soybeans fully absorb water and are swollen, and the green beans and the soybeans are soaked till the green beans and the soybeans can be broken off by hand and foam is not produced; grinding the green beans and the soybeans together with the soaking water, wherein the pulping granularity is 120 to 150 meshes; timely filtering the ground milk with residue, separating the soybean milk and the soybean residue, and repeatedly flushing with warm water for over three times to filter out soybean milk; quickly heating and boiling for 5 to 6 minutes; when the soybean milk is cooled to the temperature of between 75 and 85 DEG C, solidifying the soybean milk by using gluconate-sigma-lactone; and quickly filling the solidified soybean milk into a box and squeezing after 5 to 8 minutes, performing block division, and thus obtaining the green bean curd. The technology has the advantages that: by adding the green beans, the bean curd has the mouthfeel of the green beans, also has the color and the aroma of the green beans and is a new-style bean curd with compressive color, aroma and taste.

Owner:石爱军

Mung bean cake and preparation method of mung bean cake

InactiveCN103843858AHeat-clearing and detoxifyingWith blood pressure loweringDough treatmentBakery productsCooking & bakingVegetable oil

The invention discloses mung bean cake and a preparation method of the mung bean cake. The mung bean cake is prepared from the following ingredients in percentage by weight: oil skin comprises the following ingredients in percentage by weight: 40 to 50 percent of low-gluten flour, 20 to 30 percent of water, 10 to 18 percent of vegetable oil and 10 to 20 percent of lotus leaf powder; crust skin comprises the following ingredients in percentage by weight: 50 to 60 percent of low-gluten flour and 30 to 55 percent of vegetable oil; stuffing comprises the following ingredients in percentage by weight: 30 to 40 percent of mung bean, 30 to 40 percent of glucose powder, 1 to 2 percent of water and 25 to 35 percent of butter. The preparation method comprises the steps that the low-gluten flour, the water, the vegetable oil and the lotus leaf powder are taken and are uniformly stirred, the water content is controlled to be 5 to 6 percent, and the oil skin is prepared; the low-gluten flour and the vegetable oil are taken and are uniformly stirred, and the crust skin is prepared; the mung bean is taken and cleaned, the water is added, the mung bean is boiled out, is uniformly stirred and is poured into a pan, the butter and the glucose powder are added, and the mixture is boiled into the stuffing by soft fire; the oil skin and the crust skin are respectively cut into a plurality of identical small blocks, then, the crust skin is placed on the oil skin and is rolled to be longer, and next, the rolling up is carried out; each small block is taken and is flattened by pressing and is rolled into a round shape, the stuffing is taken and wrapped, and the blank is put into a baking oven for to be baked, and the mung bean cake disclosed by the invention is obtained.

Owner:俞华

Natural coarse-cereal quick-frozen sweet dumplings

The invention discloses a production manner for novel quick-frozen sweet dumplings, and the production manner belongs to the technical field of food processing. The production manner comprises: getting seven groups of the following raw materials: 50 parts-300 parts of glutinous rice flour, 50 parts-300 parts of red bean (milled into a powder), 50 parts-300 parts of soybean (milled into a powder), 50 parts-400 parts of corn (milled into a powder), 50 parts-500 parts of black rice (milled into a powder), 10 parts-500 parts of pumpkin or carrot (juiced), and 50 parts-500 parts of tomato (juiced), and respectively adding proper amount of water, stirring uniformly and kneading to form dough, so as to form seven sweet dumpling base materials with different colors, adding different kinds of stuffing into each sweet dumpling base materials, so as to prepare various sweet dumplings, and refrigerating at a temperature of 0 DEG C or less. The natural coarse-cereal quick-frozen sweet dumplings have various different nutrients and colors, and provide more selections according to different hobbies and habits of people.

Owner:马玉梅

Mung bean chocolate crackling and production method thereof

InactiveCN106376693ASweet tasteFull of nutritionMilk preparationFrozen sweetsButter cocoaMonoglyceride

The invention relates to mung bean chocolate crackling and relates to a production method of the mung bean chocolate crackling, and belongs to the technical field of food ingredients. The mung bean chocolate crackling comprises the following raw materials, by weight part, 50-70 parts of white sugar, 100-160 parts of palm oil, 20-60 parts of cocoa butter, 10-30 parts of cocoa liquor, 0-10 parts of a cocoa butter substitute, 10-40 parts of coconut oil, 30-100 parts of mung bean powder, 0.05-0.3 part of monoglyceride of fatty acid, 0.01-0.2 part of polyglyceryl fatty ester, 0.5-2 parts of phosphatide, 0.05-0.2 part of salt, and 0.01-0.3 part of essence. The mung bean chocolate crackling tastes delicious and sweet, is abundant in nutrients and bright in color, and has natural fragrance of mung beans. The mung bean chocolate crackling is reasonable in nutrient composition and diversified in taste. The production process is simplified.

Owner:中卫市金帝冷冻食品有限责任公司

Gluten-free panicum miliaceum flour sandwich steamed cake and making method thereof

ActiveCN105231116AFull of nutritionGood processing characteristicsSugar food ingredientsFood ingredient as foaming agentVegetable oilVitamin C

The invention discloses a gluten-free panicum miliaceum flour sandwich steamed cake, which is prepared from the following raw materials by weight: 90-120 parts of panicum miliaceum flour, 20-40 parts of mung bean, 220-250 parts of fresh egg, 5-15 parts of agave syrup, 3-8 parts of baking powder, 0.05-2 parts of vitamin C, 1-2 parts of salt, 3-5 parts of white vinegar, and 2-5 parts of edible vegetable oil. The making method includes: mixing fresh egg, agave syrup and salt evenly, conducting stirring till the salt is completely dissolved, then adding white vinegar to obtain original egg liquid, and then conducting whipping at a speed of 800rpm for 10-15min to obtain whole egg paste; adding premixed powder into the prepared whole egg paste, and stirring the materials evenly to obtain cake paste; and then putting the cake paste into a mold and conducting steaming to obtain the finished product. The gluten-free panicum miliaceum flour sandwich steamed cake provided by the invention is not only suitable for general population to eat, but also is suitable for diabetic patients and celiac disease patients, enriches the panicum miliaceum product variety, and promotes the improvement of human dietary fiber structure.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

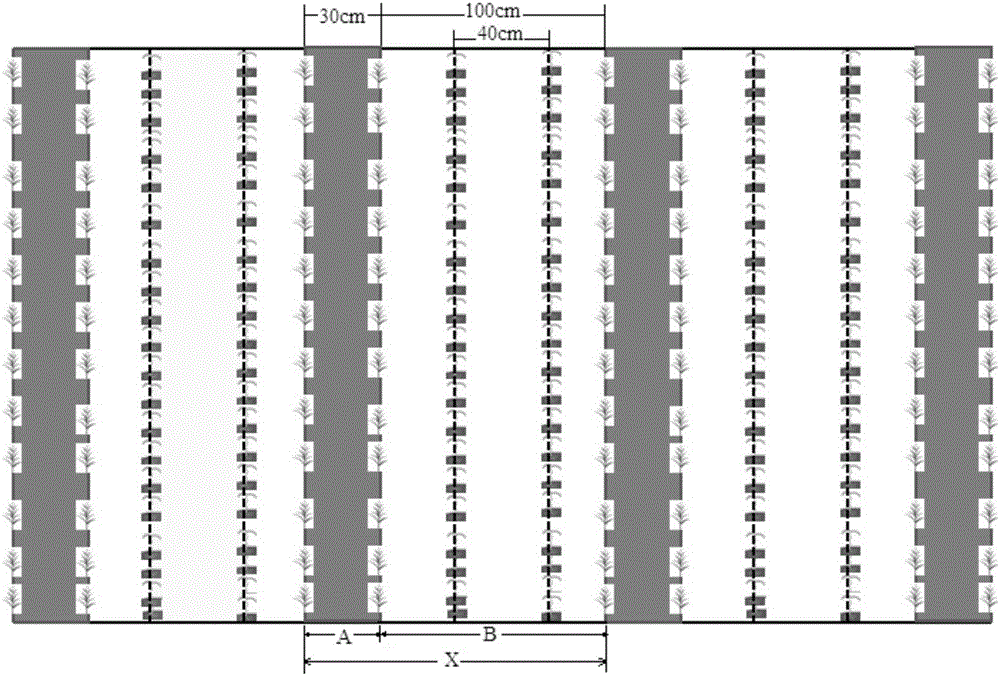

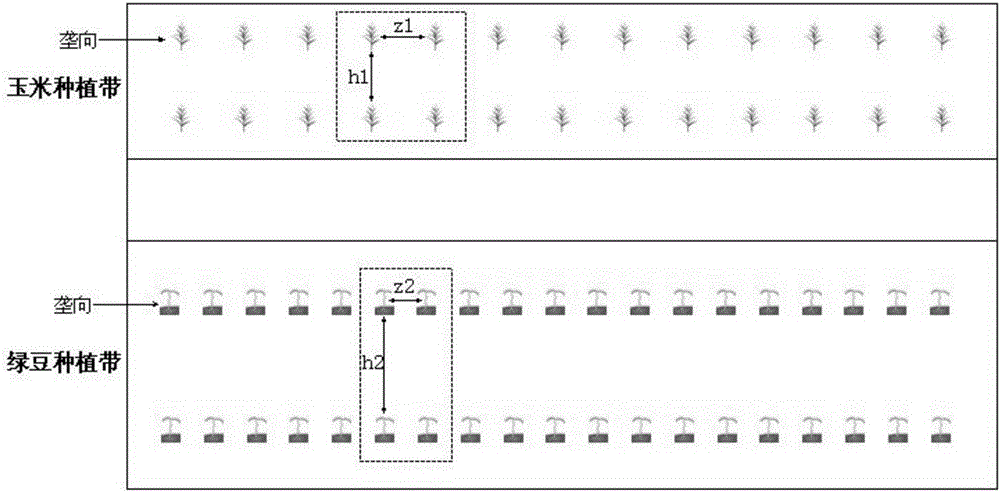

Corn and mung bean intercropping cultivation method

ActiveCN105210652AField layout optimizationReduce occlusionCultivating equipmentsPlant cultivationHectarePhaseolus mungo

The invention relates to a corn and mung bean cultivation method, in particular to a corn and mung bean intercropping cultivation method. The method aims at solving the problems that in an existing corn and mung bean planting method, utilization of light and heat recourses is insufficient, consumption of soil nutrient elements is unbalanced, the crop yield is low, and economical benefits are poor. The method includes the steps of fine soil preparation, good variety selection, rational close planting, field layout of the corn and mung bean cultivation method, scientific field management and timely harvest. According to the method, a traditional small-row-spacing planting mode is changed into a wide-and-narrow row planting cultivation mode, the row spacing of corn in narrow rows is 30 cm, two rows of mung beans are planted in the middle of each wide row, layout of the crops in the field is optimized, and the horizontal layout of wide-narrow-wide alternative distribution is formed. The mung bean yield can be increased by 1000-13000 kilograms per hectare without reducing the corn yield, and the yield and benefit of the crops per unit area are significantly increased. The method is applied to the field of crop planting.

Owner:NORTHEAST INST OF GEOGRAPHY & AGRIECOLOGY C A S

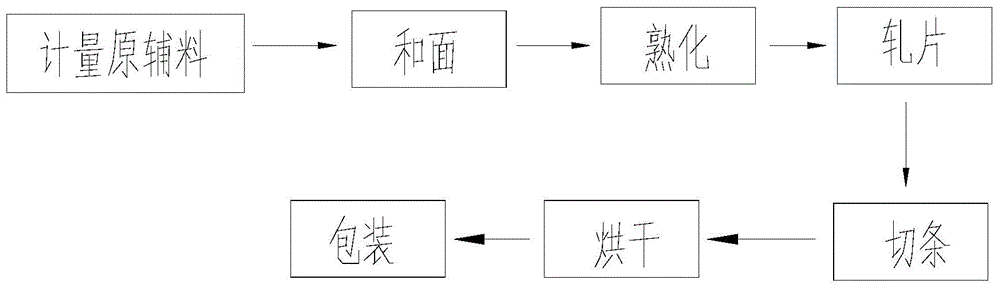

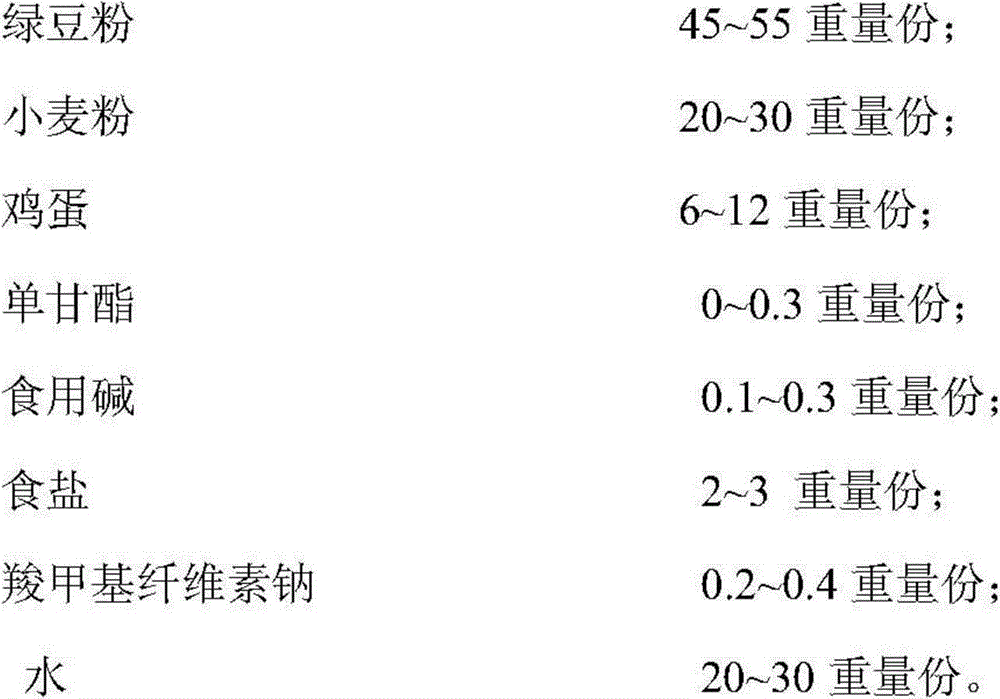

Mung bean noodles and preparation method thereof

InactiveCN105614257AMaintain nutrientsReasonable ratioFood preparationCarboxymethyl celluloseMonoglyceride

The invention provides mung bean noodles and a preparation method thereof, and solves the problem that the mouth feel of the noodles is poor, and the nutrient value is low. The mung bean noodles are prepared from the following raw materials in parts by weight: 45-55 parts of mung bean powder, 20-30 parts of wheat flour, 6-12 parts of eggs, 0-0.3 part of monoglycerides, 0.1-0.3 part of dietary alkali, 2-3 parts of table salt, 0.2-0.4 part of sodium carboxymethyl cellulose and 20-30 parts of water. According to the mung bean noodles and the preparation method thereof disclosed by the invention, the mung bean powder is used as the raw materials, main and auxiliary materials are added to be in a reasonable compounding ratio, and a curing device is additionally arranged in the production technology; rollers in n-shaped arrangement are arranged in the curing device, so that dough sheets are sufficiently fermented by the curing device; crude starch in the mung bean noodles is converted into alpha starch easy to absorb, and after the crude starch is cured, the mouth feel is chewy, the edible toughness is good, and the nutrient components of mung beans are maintained; the mung bean noodles are lubricious and refreshing, and have the efficacies of clearing heat, removing toxicity, benefiting and invigorating premordial energy, adjusting five internal organs, preventing diseases and health caring.

Owner:青岛君盛食品股份有限公司

Red date candy

The invention relates to a red date candy, and is characterized in that the red date candy is prepared by mixing white granulated sugar, granular red date flesh and a seasoning solution and then boiling into a solid finished product with the water content of 1%-5% in a container with small fire, and the weight ratio of the white granulated sugar, the red date flesh and the seasoning solution is 1:0.15:400, wherein the seasoning solution comprises the following raw materials in parts by weight: 30 parts of mint leaves, 5 parts of radix bupleuri, 2 parts of reed rhizome, 2 parts of buddleja officinalis, 0.5 part of radix et rhizoma thalictri, 50 parts of mung bean, 60 parts of saccharina japonica, 5 parts of coix chinensis, 2 parts of raw radix rehmanniae, 0.5 part of radix gentianae macrophyllae, 2 parts of poria cocos, 2 parts of phyllanthus urinaria, 2 parts of dried ginger, and 1000 parts of water. The seasoning solution is obtained by adding the above raw materials into water, soaking with the water temperature of 2 DEG C above zero for 30 days and then filtering out a solid part. The red date candy is quite good in mouthfeel, is fresh, savoury and mellow, and also has the functions of tonifying spleen, reducing blood lipid, eliminating free radicals in a body, improving eyesight, preventing cancer and caring health.

Owner:李美纯

Waxberry and red bean bread

InactiveCN103598284AFull of nutritionGood for healthDough treatmentBakery productsBiotechnologyApple peel

Disclosed is a waxberry and red bean bread. The waxberry and red bean bread is composed of the following components including, by weight part, 300-320 parts of flour, 4-5 parts of yeast powder, 3-4 parts of baking soda, 45-50 parts of waxberries, 45-50 parts of green plums, 50-60 parts of red beans, 20-30 parts of mung beans, 7-8 parts of rose, 8-10 parts of sweet osmanthus, 5-6 parts of sterculia scaphigera, 6-7 parts of honeysuckle, 6-7 parts of rhizoma phramgitis, 4-5 parts of apple peel, 6-7 parts of pearl, 4-5 parts of calcium fruit leaves, 4-5 parts of shepherd's purse flower, 12-15 parts of distiller's yeast, 60-70 parts of lemon juice and water as balance. The waxberry and red bean bread is rich in nutrient and can provide multiple vitamins and proteins by adding food materials such as the waxberries and the red beans, and has good health care effects by adding extractives of TCM (traditional Chinese medicine) materials such as the sterculia scaphigera, thereby being beneficial to human health.

Owner:鲁奎

Rose and ass meat ham sausage

InactiveCN103519199AFit for consumptionHas beauty benefitsNatural extract food ingredientsFood ingredient functionsBiotechnologyBlack tea

The invention discloses a rose and ass meat ham sausage which consists of the following raw materials in parts by weight: 160-180 parts of ass meat, 100-120 parts of starch, 35-40 parts of rose, 20-30 parts of lily, 30-40 parts of coix seed, 50-60 parts of black rice, 30-35 parts of mung bean, 20-25 parts of black tea, 5-6 parts of Chinese angelica, 5-6 parts of bird's nest, 4-5 parts of polygonum multiflorum, 4-5 parts of saussurea involucrate, 4-5 parts of radix paeoniae alba, 3-4 parts of watermelon leaf, 3-4 parts of juncus effusus, 20-50 parts of edible salt, 20-30 parts of black pepper, 130-150 parts of sesame oil and a proper amount of water. With the ass meat as the raw material and by adding the rose and lily extract, the rose and ass meat ham sausage disclosed by the invention is fragrant and pleasant with certain beautifying function; meanwhile, by specially adding the extracts of the traditional Chinese medicines for replenishing qi and tonifying blood such as Chinese angelica and bird's nest, the beautifying function of the rose and ass meat ham sausage is increased; and the rose and ass meat ham sausage is particularly suitable for the women caring about beauty, and has a distinctive delicious taste.

Owner:重庆市荣昌区丰诺农业综合开发有限公司

Mung bean mask powder

InactiveCN104248599AExcellent heat clearing and detoxificationHas anti-inflammatory and anti-acne effectsCosmetic preparationsToilet preparationsWaxBiotechnology

The invention relates to a mung bean mask, which is characterized by comprising the following materials by weight: 20-30 parts of mung bean powder, 15-20 parts of deep-sea mud, 10-18 parts of coix seed powder, 8-15 parts of oat powder, 6-8 parts of mint, 10-12 parts of silkworm larva, 10-12 parts of white peony root, 10-12 parts of bletilla striata, 10-18 parts of wax gourd seed, 17-22 parts of seaweed, and 30-40 parts of kaolin. The mung bean powder is prepared by grinding mung bean and sieving with a 200 mesh sieve, the coix seed powder is prepared by grinding coix seed and sieving with a 200 mesh sieve, and the oat powder is prepared by grinding oat and sieving with a 200 mesh sieve. The mung bean mask has anti-inflammatory anti-acne, spot-removing and whitening effects, can be used for a long term, and is free of side effect.

Owner:QINGDAO UNITED INNOVATION TECHN SERVICES PLATFORM

Rice noodles containing mung bean powder

InactiveCN103652591AReasonable matching of raw materialsFull of nutritionFood shapingFood preparationTreatment feverPhaseolus mungo

The invention relates to rice noodles in food, in particular to rice noodles containing mung bean powder. The rice noodles are characterized by comprising raw materials in parts by weight as follows: 10-15 parts of mung beans, 5-10 parts of rice, 5-10 parts of millet and 5-10 parts of lotus root powder. According to the rice noodles containing the mung bean powder, the raw materials are reasonably matched, the nutrition is rich, mechanical processing is facilitated, the taste is good during eating, and particularly, the rice noodles contain more mung bean powder and has the efficacy of bringing down various fevers, resolving hundred toxins, clearing away heat, removing dampness, relieving internal heat or fever, protecting the liver, relieving heat and alleviating water retention.

Owner:李琴

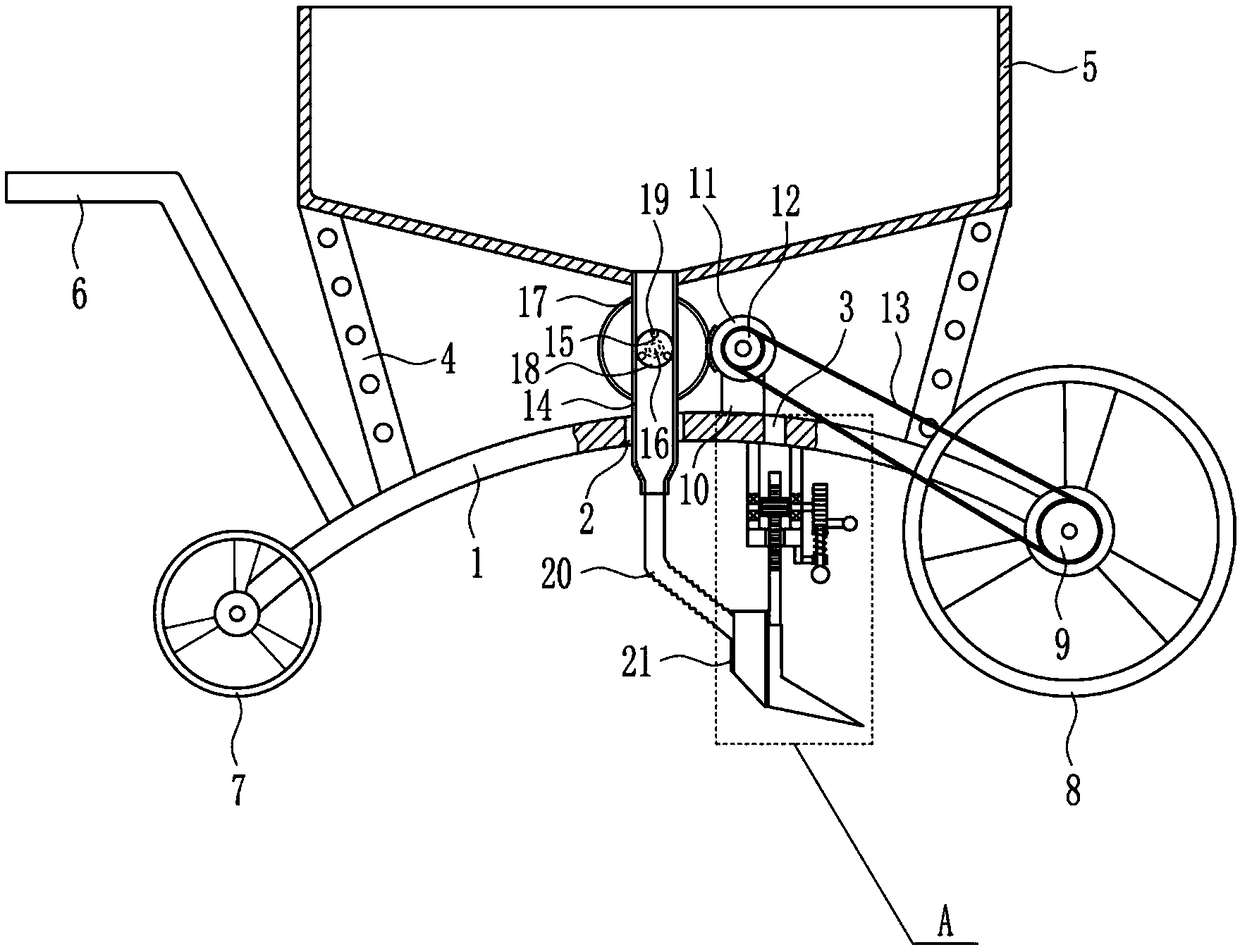

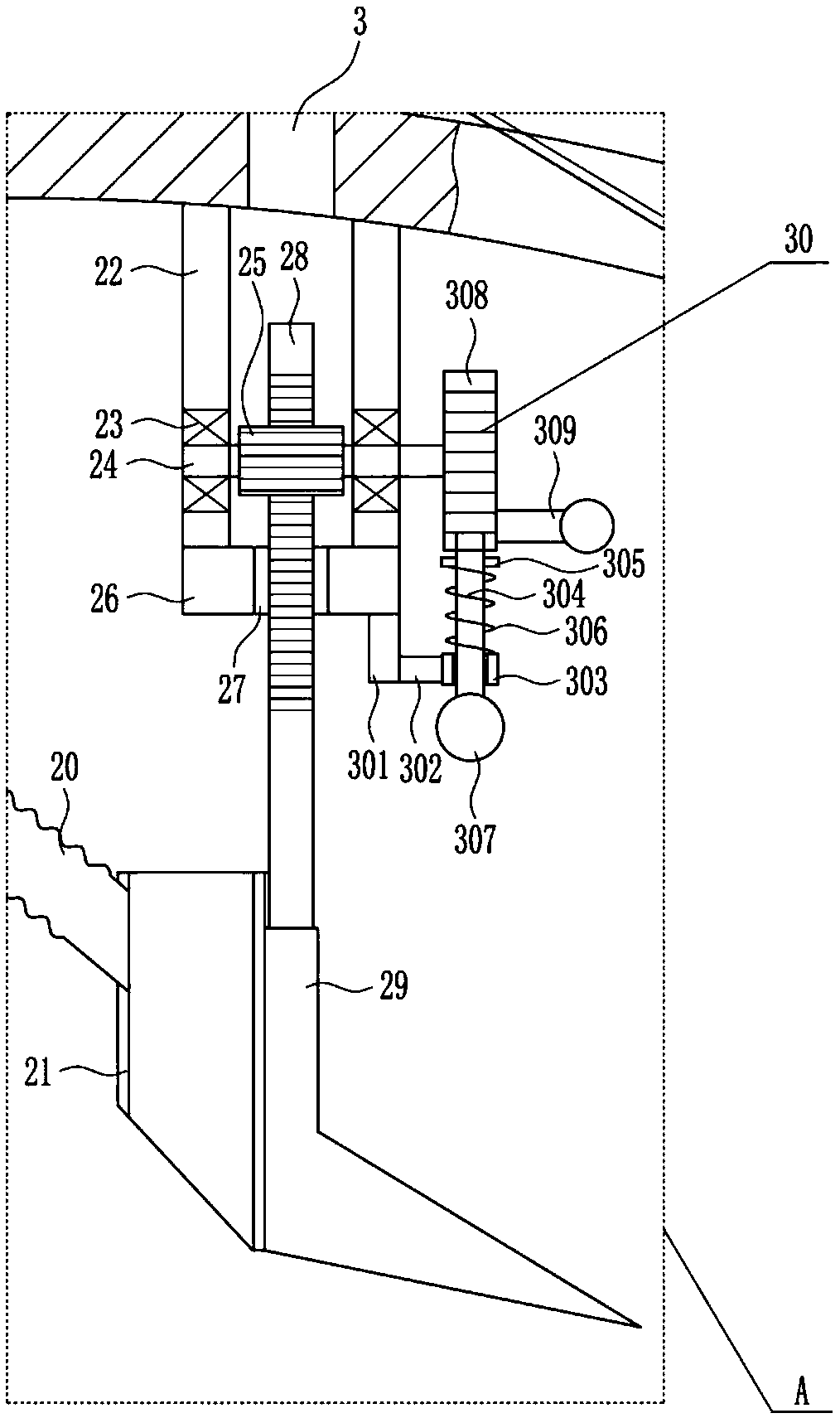

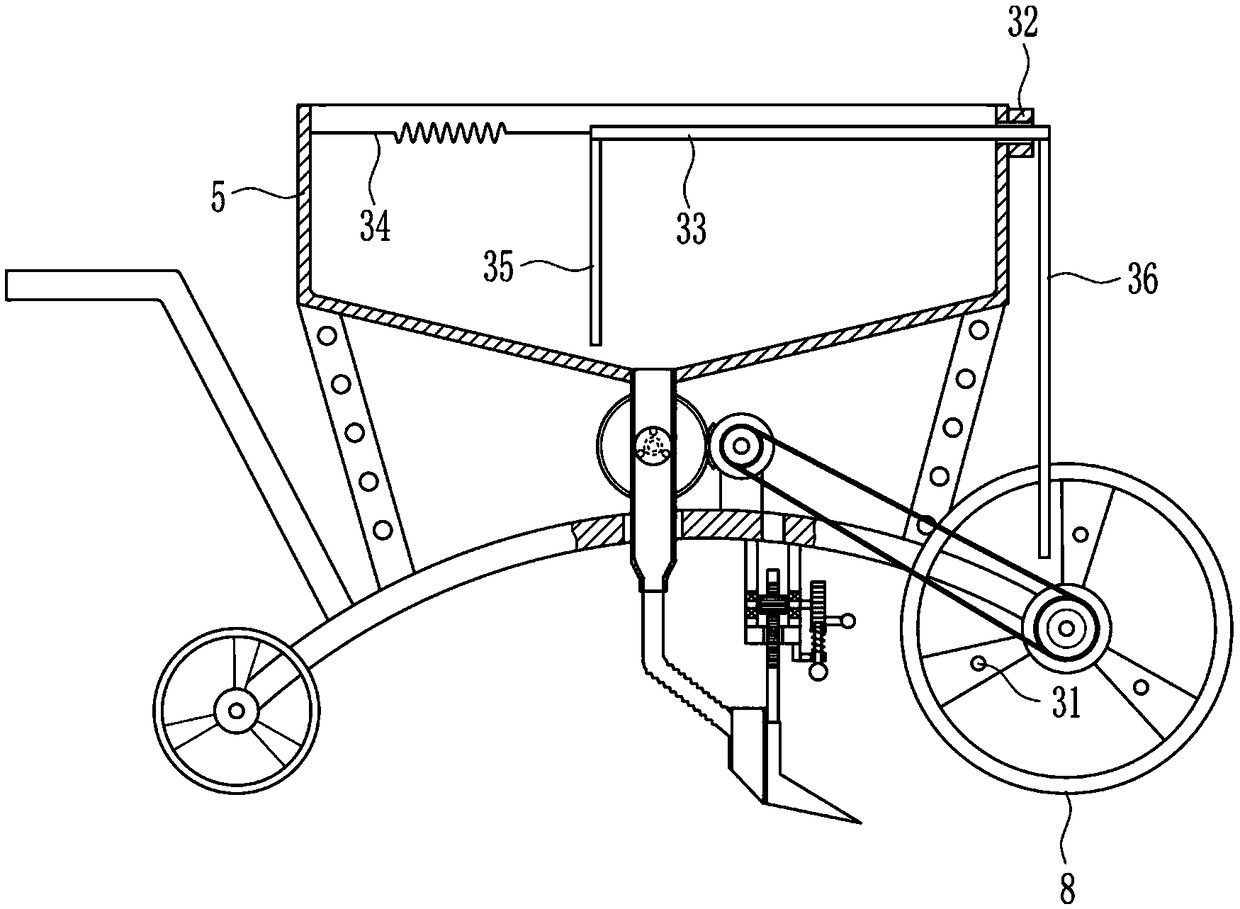

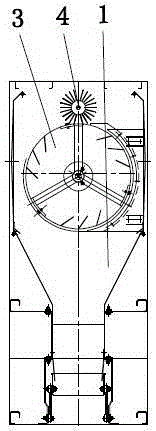

Manual mung bean dibbling machine

ActiveCN108811609APrevent movementPrevent rotationPlantingFurrow making/coveringTeeth missingWater storage tank

The invention belongs to the technical field of agricultural planting machinery and in particular relates to a manual mung bean dibbling machine. Aiming at solving the technical problems, the invention provides the manual mung bean dibbling machine which can reduce the labor intensity and can improve the dibbling efficiency. According to the technical scheme, the manual mung bean dibbling machinecomprises a support, supporting plates, a water storage tank, a handle, a first vehicle wheel, a second vehicle wheel, a first belt wheel, a mounting plate, a tooth-missing gear, a second belt wheel,a flat belt and the like, wherein a through a hole is formed in the middle of the support; a first guide hole is formed in the support at the right side of the through hole; the two supporting platesare connected at the top of the support and the water storage tank is connected between the tops of the two supporting plates. According to the manual mung bean dibbling machine provided by the invention, a shovel plate is rightward driven to move rightward; the shovel plate moves rightwards and a groove can be formed on the land; a round block rotates intermittently and intermittent dibbling canbe realized, so that manual grooving is not needed and manual dibbling is not needed, and furthermore, the labor intensity can be reduced and the dibbling efficiency can be improved; a pulling block moves rightward and mud can be leveled, so that mung beans can be covered with the soil.

Owner:周应发

Red barnyard grass and millet paste

InactiveCN103039795ANutritious and comprehensiveReasonable collocationFood preparationHuman bodyOlder people

The invention relates to red barnyard grass and millet paste which comprises the following raw materials in parts by weight: 60-80 parts of red barnyard grass, 10-30 parts of glutinous rice, 5-20 parts of millet and 5-20 parts of mung bean. The raw materials are matched, baked till the raw material are well cooked, and then crushed to form powder with the mesh size of above 120 meshes. A nutritious food produced by adopting the technical formula has the advantages of abundant and comprehensive nutrition, reasonable matching, capability of relatively comprehensively meeting the needs of human bodies for various nutrients and convenience for eating, and is particularly suitable for old people and children. The red barnyard grass and millet paste is also suitable for general population.

Owner:ZUNYI JUNHUIYUAN FOOD ENG

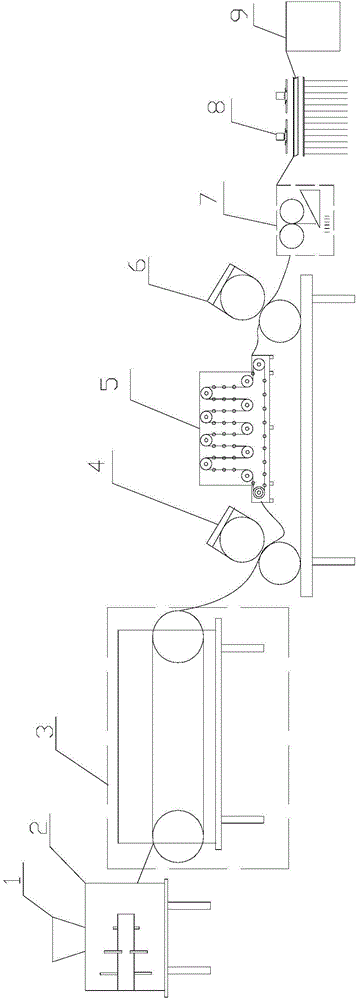

Preparation method of mung bean vermicelli

InactiveCN102187979AGreat tasteFull of nutritionFood shapingFood preparationDigestionPhaseolus mungo

The invention discloses a preparation method of a mung bean vermicelli. The method comprises the following steps: (1) extracting starch; (2) suppressing a vermicelli. Processing steps of the method in the invention are simple and easy for operation, and the prepared mung bean vermicelli is about 6mm in diameter, well tasted, abundant in nutrition and beneficial to digestion. In addition, the mung bean vermicelli has good boil-resistance and the effects of clearing heat, detoxifying and beautifying, etc.

Owner:HUZHOU DINGLIANFANG FOOD

Mung bean instant noodle and preparation method thereof

InactiveCN105901511AEasy to synthesizeGuaranteed muscleFood dryingFood ingredient functionsVillosa choctawensisMixed materials

The invention relates to mung bean instant noodle. The mung bean instant noodle comprises, by weight, 8-12 parts of soybean, 16-24 parts of mung bean, 24-36 parts of rice, 4-6 parts of peanut, 4-6 parts of apricot kernel, 12-18 parts of caraway, 4-6 parts of sweet potato powder, 8-12 parts of kidney bean and 20-30 parts of water. The preparation method comprises the following steps: crushing or cutting up the raw materials for later use; immersing rice, soybean, mung bean, kidney bean and caraway in clear water to obtain mixed materials; adding sweet potato powder, peanut, apricot kernel and the mixed materials into water and grinding to a pulpous state so as to obtain mixed pulp; layering and baking the mixed pulp to obtain matured dough layers; stacking the matured dough layers, sealing and storing until the matured dough layers are softened, and cutting into strips to obtain the mung bean instant noodle.

Owner:杨江东

Yogurt-green bean-fish meat sauce

InactiveCN103689532AFit for consumptionHigh in proteinFood preparationMonosodium glutamateBiotechnology

The invention relates to a yogurt-green bean-fish meat sauce, which comprises the following raw materials, by weight, 280-300 parts of bean paste, 60-80 parts of yogurt, 30-40 parts of fish meat, 20-30 parts of green bean, 65-75 parts of lemon vinegar, 10-15 parts of woodear powder, 5-10 parts of coffee, 5-10 parts of chicken juice, 20-25 parts of glutinous rice, 4-5 parts of violet, 5-6 parts of conmon verbena herb, 4-5 parts of rosemary, 4-5 parts of coix lacryma-jobi, 4-5 parts of roselle calyx, 5-6 parts of blaeberry, 4-5 parts of edible bird nest, 3-4 parts of finelydivided phtheirospermum root, 2-3 parts of ramose scouring rush herb, 20-30 parts of gravy salt, 10-15 parts of monosodium glutamate, 40-50 parts of soybean oil, and a proper amount of water. According to the yogurt-green bean-fish meat sauce, fish meat and green bean are adopted as the main raw material, such that the protein content is high, and the protein can be complemented; and extracts of violet, conmon verbena herb, rosemary, coix lacryma-jobi and the like are added, such that effects of fatigue elimination, throat moistening, heat clearing, detoxification, face nourishing and spot removing are provided, and the yogurt-green bean-fish meat sauce is suitable for people easily with excessive internal heat.

Owner:ANHUI MEDIF FOOD

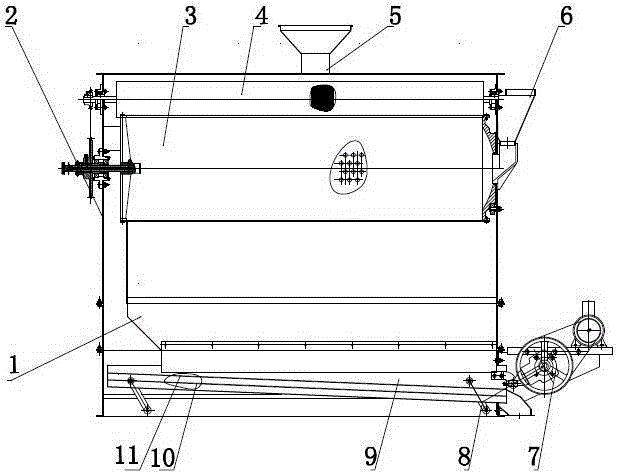

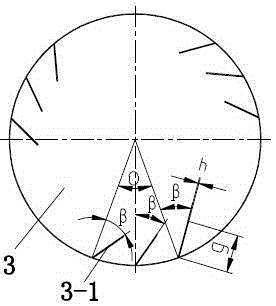

Mung bean peeling machine

The invention relates to a mung bean peeling machine, and belongs to the technical field of agricultural machinery. The machine comprises a feeding hopper mounted at the top of a rack. A horizontal peeling roller supported on the rack is arranged below the feeding hopper. A vibration separating sieve supported on the rack is arranged below the peeling roller. One side of the vibration separating sieve is provided with a discharging port. The peeling roller is provided with circular holes which are distributed at intervals. The diameter of each circular hole is 0.1-0.3mm less than the diameter of the sieve pore of a grading mung bean sieve. Shoveling plates are arranged at intervals in the peeling roller. Each shoveling plate inclines towards the rotation direction. A circumferential angle being 35-50 degrees is formed between each shoveling plate and the inner wall of the peeling roller. A horizontal sieve cleaning brush roller which rotates reversely is arranged on the outer side of the peeling roller. The brush roller is provided with bristles which are circumferentially arranged at intervals and extend radially, and the bristles arranged in the axial direction are corresponding to the circular holes. By employing the machine, a blocking phenomenon can be avoided, and mung beans can be timely output after being peeled, so that the milled rice rate, the head rice yield and the production efficiency of the mung bean peeling machine can be improved.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

Purple potato liver-protecting dumplings

The invention discloses purple potato liver-protecting dumplings which are prepared from the following raw materials in parts by weight: 40 to 50 parts of purple potato, 10 to 13 parts of mung beans, 35 to 45 parts of high gluten flour, 5 to 10 parts of papaya powder, 2 to 4 parts of green tea powder, 2 to 3 parts of circium japonicum, 2 to 3 parts of herba violae, 2 to 3 parts of American ginseng, 2 to 4 parts of lycium barbarum, 3 to 4 parts of lily, 1 to 2 parts of pseudo-ginseng, 1 to 2 parts of lotus leaves, 1 to 2 parts of lophatherum gracile, 1 to 2 parts of Chinese chestnut leaves, 1 to 2 parts of hance brandisia herb, 2 to 3 parts of fragrant-flowered garlic and 1 to 2 parts of condensed milk. Dumpling wrappers are formed by kneading a dough by using a Chinese herbal medicine extracting liquid instead of water, so that the single taste of the wrappers is improved; the nutritive value is also improved. In addition, the mung beans have the function of protecting the liver and the kidney; the papaya, the lily, the lycium barbarum, the American ginseng and the like also have the function of protecting the liver. Thus, the purple potato liver-protecting dumplings are especially suitable for people enjoying the drinking and having poor liver functions.

Owner:安徽鑫河清真牛羊肉加工有限公司

Preparation method of instant mung bean

InactiveCN104770681AAvoid churnHigh quality and stableFood preparationActive componentPhaseolus mungo

The invention discloses a preparation method of instant mung bean. A continuous preparation device is adopted and comprises a washing and soaking tank, a boiling and aging tank, and a hot-wind drying tank, and the three tanks are connected in sequence. The preparation method comprises the following steps: (1) washing mung bean by water, and then soaking mung bean in water; (2) steaming the mung bean by water steam under a normal pressure for 90 to 100 minutes so as to fully cook the mung bean or boiling the mung bean in water under a normal pressure for 50 to 80 minutes to fully cook the mung bean; (3) drying the mung bean by hot wind to reduce the water content of mung bean to 10-15% so as to obtain the instant mung bean. Through the steps of pretreatment, aging, and drying, the mung bean starch structure is in a pre-gelatinization state; at the same time, the pretreatment, aging, and drying are optimized so as to preserve the active components and nutrients of mung bean and prevent loss of nutrients and active components during the processing process; the instant mung bean can be softened and eaten after being boiled in water for several minutes, the mung bean is intact, and the mung beans will not be stuck together.

Owner:ZHEJIANG UNIV

Edible mushroom flavored chili sauce not likely to cause internal heat and preparation method thereof

The invention provides edible mushroom flavored chili sauce not likely to cause internal heat and a preparation method thereof. The edible mushroom flavored chili sauce is prepared from 100-200 partsof dried chili, 100-200 parts of plant oil, 1,500-2,000 parts of edible mushrooms, 10-20 parts of mung beans, 30-40 parts of dandelion, 30-40 parts of tea leaves, 5-10 parts of processed sesame and 0.1-0.5 part of additives. An enzymolysis method is adopted for processing edible mushrooms, dandelion and tea leaves, the usable components are kept to the maximum degree, and on the condition that nocorrosion remover is added, the preservation time is long; the dandelion and the tea leaves have the effect of removing internal heat, the sesame and the mung beans are adopted as a flavor blending agent, a flavoring agent and laxative, and meanwhile internal heat can be helped to be removed; the chili sauce is abundant in nutrient, small in side effect, good in taste and not likely to cause internal heat, and edible crowds are added.

Owner:SHANDONG HONGDA FOOD CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com