Mung bean noodles and preparation method thereof

A technology for noodles and mung bean, which is applied in the field of noodle processing, can solve the problems of low nutrition and poor noodle taste, and achieve the effect of strong taste and good edible toughness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

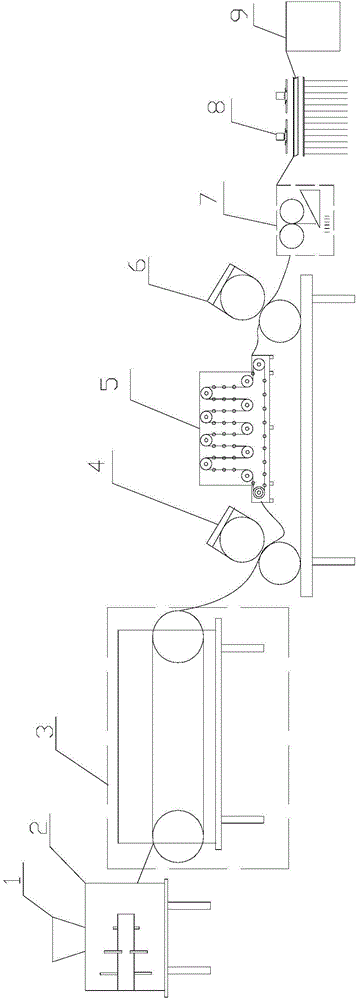

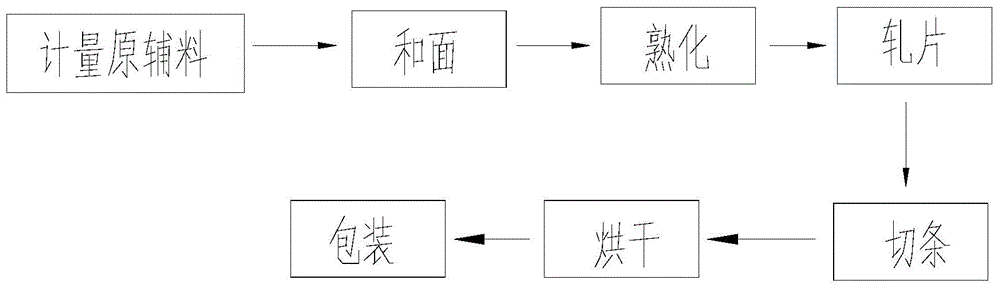

[0027] Such as figure 1 , figure 2 Shown, a kind of method for preparing mung bean noodles, comprises the following steps:

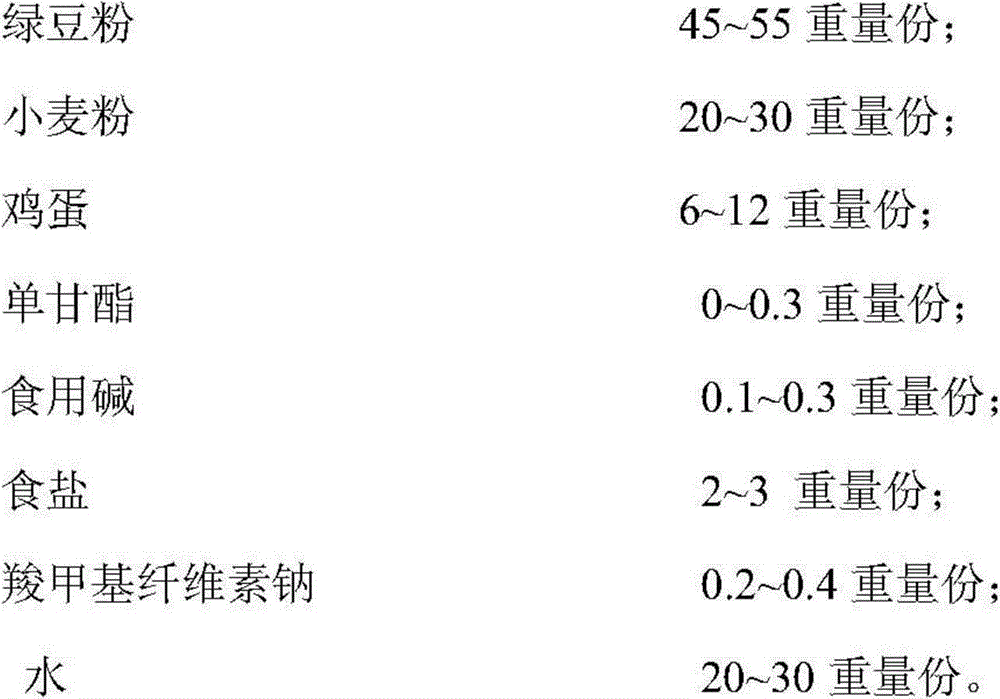

[0028] 1) Get 45 parts by weight of mung bean flour, 20 parts by weight of wheat flour, 6 parts by weight of eggs, 0.1 parts by weight of monoglyceride, 0.1 parts by weight of edible alkali, 2 parts by weight of table salt, 0.2 parts by weight of sodium carboxymethylcellulose, 20 parts by weight of Water is fed to the mixing material of the feeding device, and at 30°C, the mixed material is sent to the dough mixing device for stirring for 15 minutes, and the mixing material is kneaded into dough after stirring;

[0029] 2) The dough is transported by the conveyor belt to the compound pressing device, and rolled into a primary dough sheet, and the primary dough sheet is sent to the curing device at a temperature of 25 ° C for 10 to 15 minutes, and then sent to the continuous pressing device for binding Sheets, the thickness of the formed dough sheet is...

Embodiment 2

[0032] Such as figure 1 , figure 2 Shown, a kind of method for preparing mung bean noodles, comprises the following steps:

[0033] 1) Get 50 parts by weight of mung bean flour, 25 parts by weight of wheat flour, 9 parts by weight of eggs, 0.2 parts by weight of monoglyceride, 0.2 parts by weight of edible alkali, 2.5 parts by weight of table salt, 0.3 parts by weight of sodium carboxymethylcellulose, 25 parts by weight of Water is fed to the mixing material of the feeding device, and at 30°C, the mixed material is sent to the dough mixing device for stirring for 15 minutes, and the mixing material is kneaded into dough after stirring;

[0034] 2) The dough is transported by the conveyor belt to the compound pressing device, and rolled into a primary dough sheet, and the primary dough sheet is sent to the curing device at a temperature of 25 ° C for 10 to 15 minutes, and then sent to the continuous pressing device for binding Sheets, the thickness of the formed dough sheet ...

Embodiment 3

[0037] Such as figure 1 , figure 2 Shown, a kind of method for preparing mung bean noodles, comprises the following steps:

[0038]1) Get 55 parts by weight of mung bean flour, 30 parts by weight of wheat flour, 12 parts by weight of eggs, 0.3 parts by weight of monoglyceride, 0.3 parts by weight of edible alkali, 3 parts by weight of table salt, 0.4 parts by weight of sodium carboxymethylcellulose, 30 parts by weight of Water is fed to the mixing material of the feeding device, and at 30°C, the mixed material is sent to the dough mixing device for stirring for 15 minutes, and the mixing material is kneaded into dough after stirring;

[0039] 2) The dough is transported by the conveyor belt to the compound pressing device, and rolled into a primary dough sheet, and the primary dough sheet is sent to the curing device at a temperature of 25 ° C for 10 to 15 minutes, and then sent to the continuous pressing device for binding Sheets, the thickness of the formed dough sheet is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com