Patents

Literature

88 results about "Teeth missing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for designing and manufacturing repair-orientated planting bone augmentation guide plate

ActiveCN107224335AReduced Boot Accuracy ImpactReduce planting riskDental implantsComputer-aided planning/modellingMissed toothPatient data

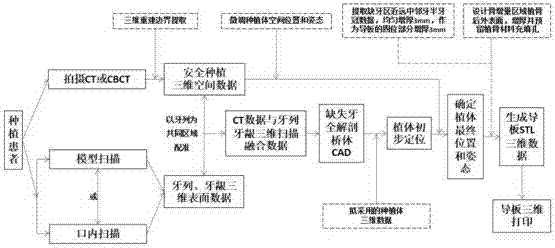

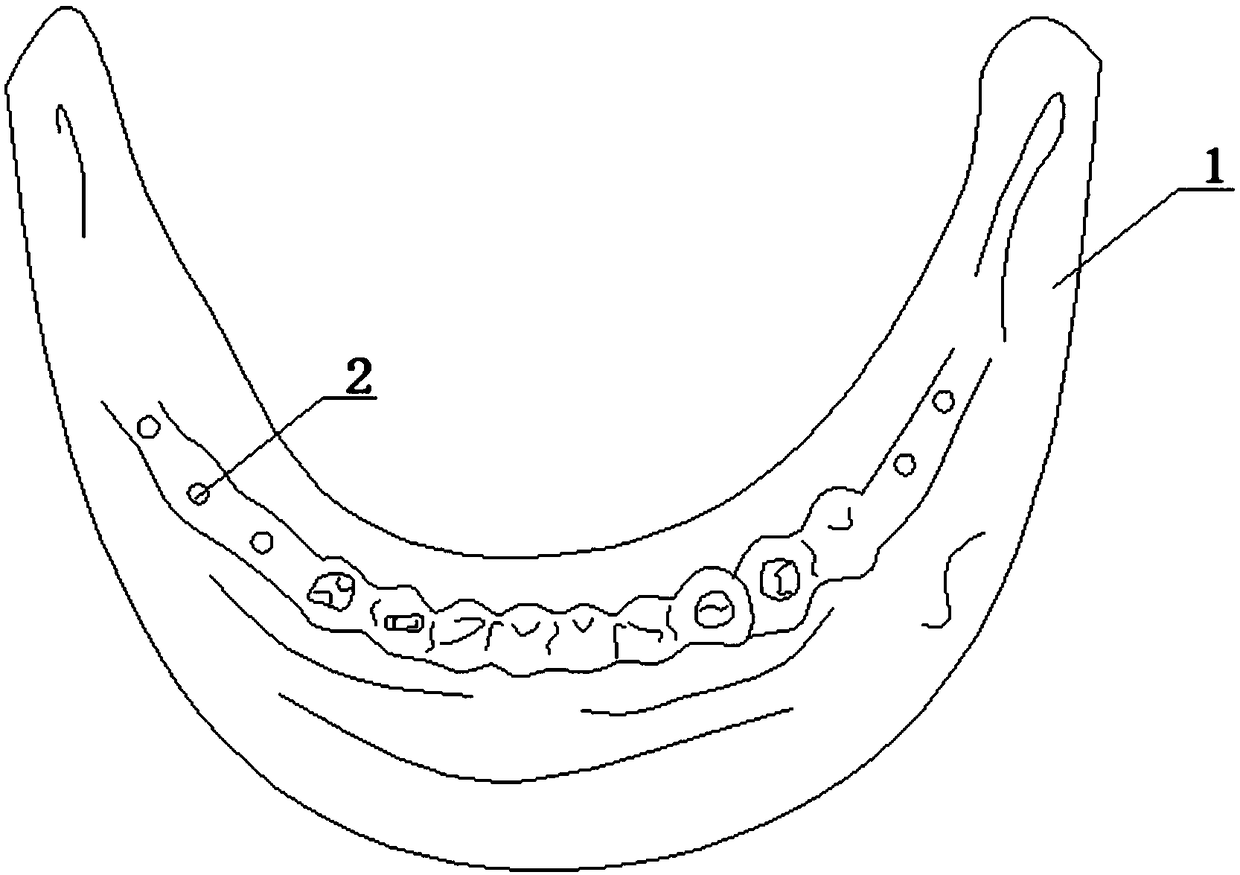

The invention relates to a method for designing and manufacturing a repair-orientated planting bone augmentation guide plate. The method comprises the following steps: shooting CT of a patient to obtain a planting three-dimensional space; carrying out intraoral three-dimensional scanning or scanning a gypsum model to obtain patient data; fusing the two parts of data; designing missing teeth and a tooth long shaft; locating an implant by using the tooth long shaft; adjusting the position and posture of the implant; extracting mesiodistal ortho-tooth half-crown data in the tooth missing region, and increasing the thickness uniformly; measuring the straight line-segment distance between the occlusal surface and the tail end of the implant body; generating a three-dimensional digital model of the planting guide plate; and designing the outer surface of the bone augmentation area after bone graft, increasing the thickness, and reserving a bone grafting material filling hole, thus completing designing and processing. According to the method provided by the invention, the mesiodistal position, the buccolingual position, the torque angle and the shaft inclination degree for oral implantation of the tooth implant can be accurately guided, the accurate bone augmentation operation is realized, the tooth planting risk is reduced, the implant amount and surface form of the allogenic bone augmentation material can be conveniently and accurately controlled, and thus the success rate of the tooth planting operation can be improved.

Owner:PEKING UNIV SCHOOL OF STOMATOLOGY

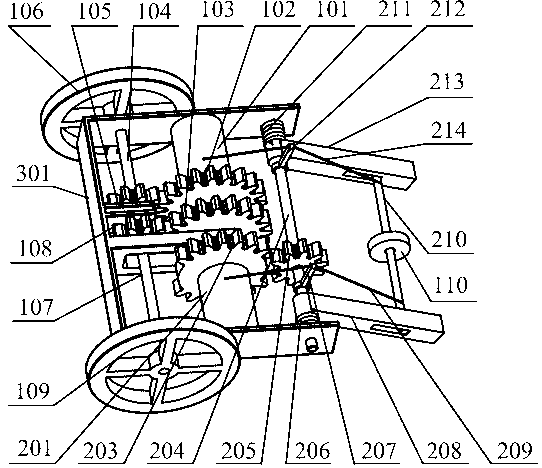

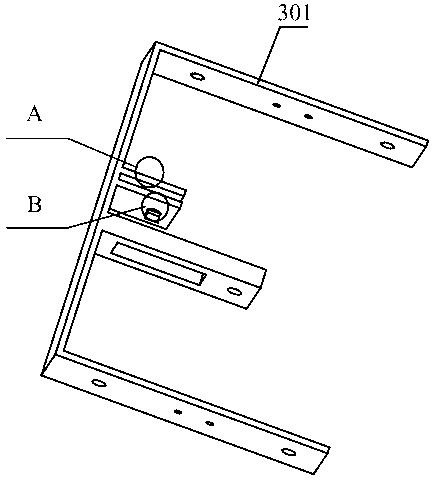

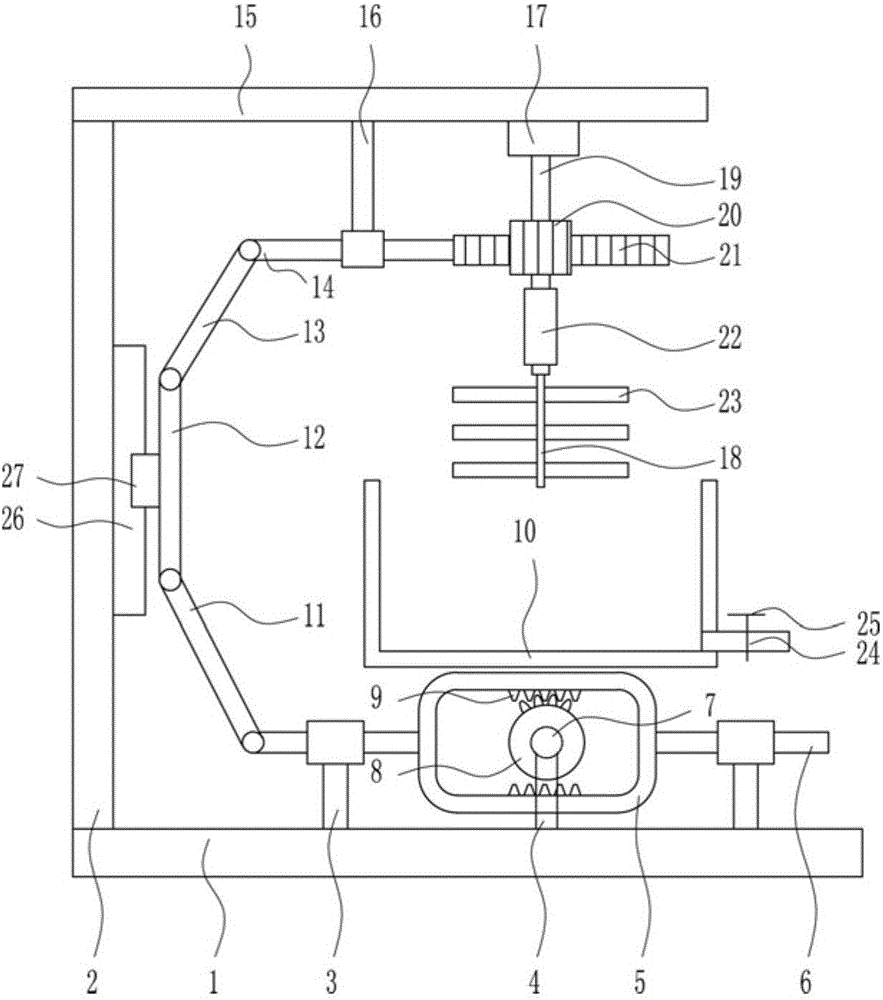

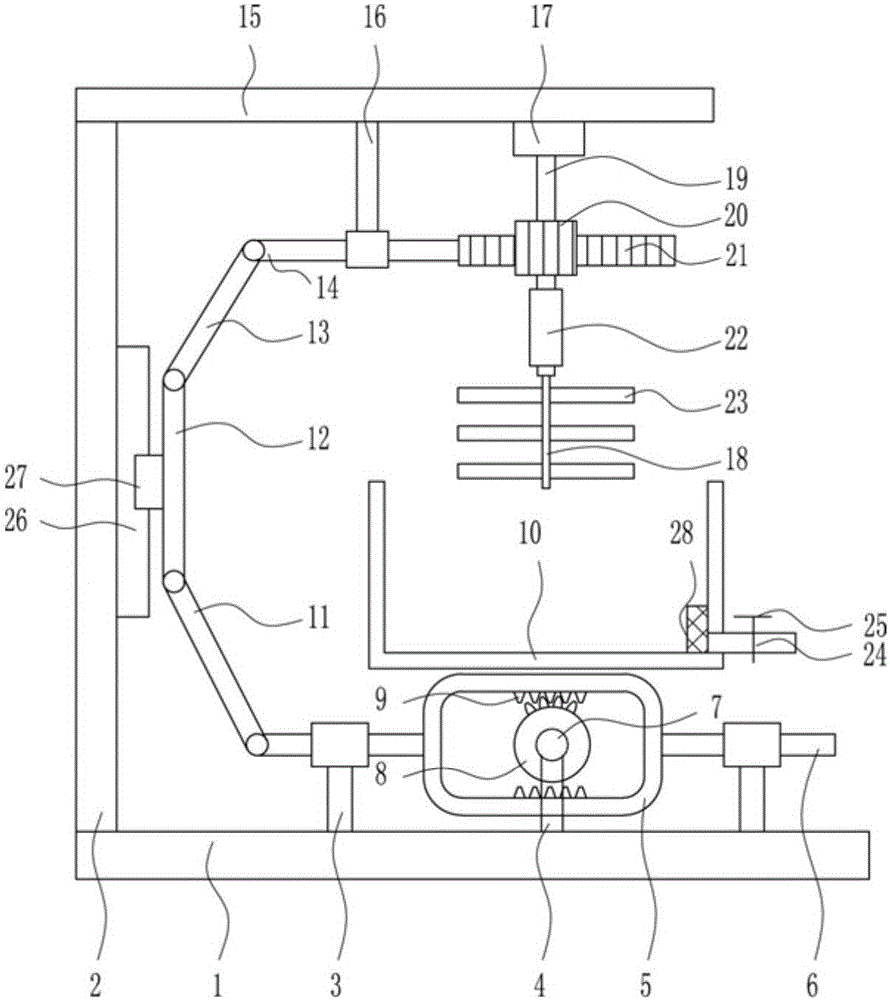

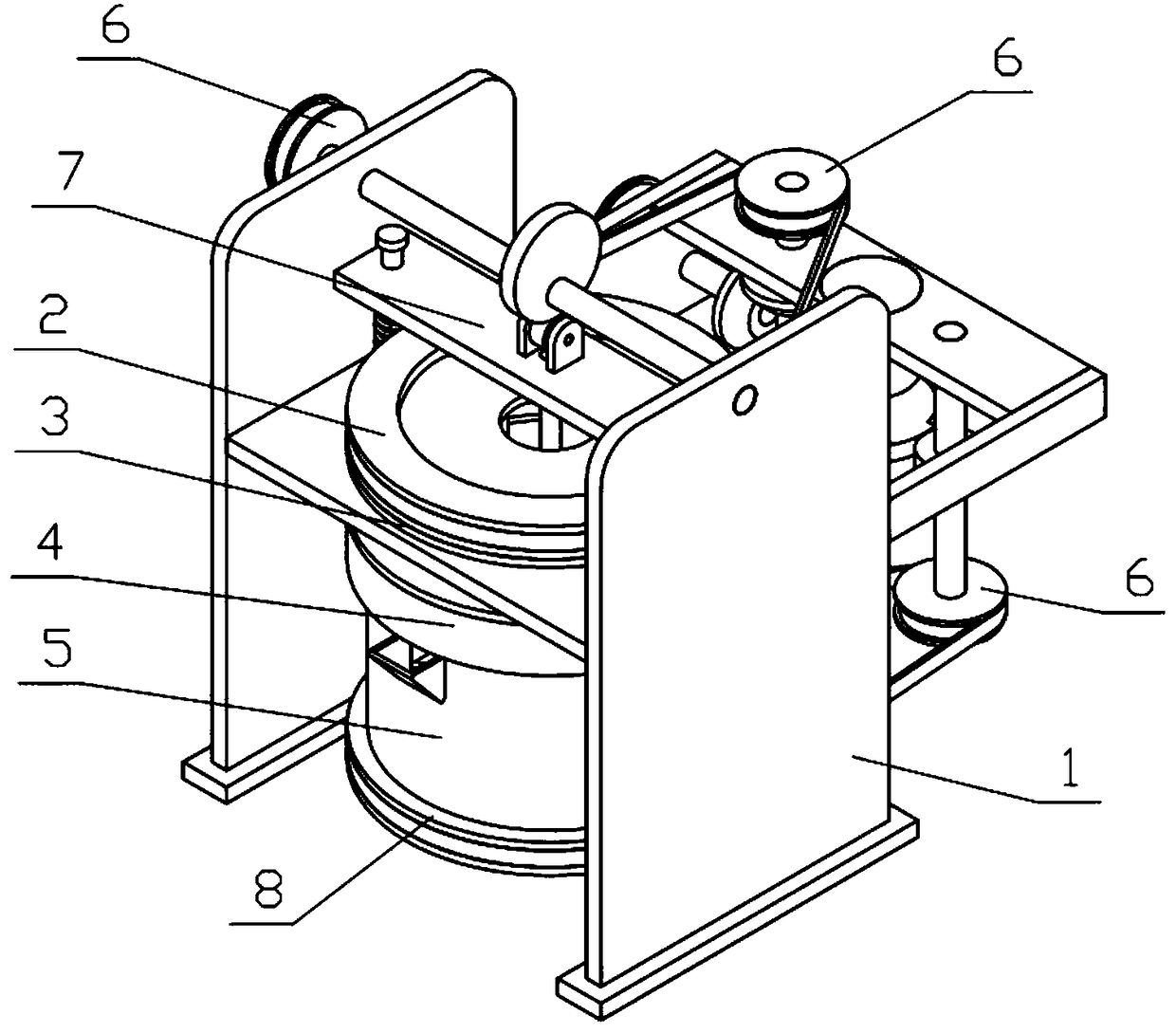

Hopping robot with wheel movement function

The invention discloses a hopping robot with a wheel movement function. The hopping robot with the wheel movement function comprises a robot body which is horizontally arranged, a wheel movement mechanism and a hopping mechanism, wherein the wheel movement mechanism is mounted in the robot body, and the hopping mechanism is mounted at an opening end of the robot body. A design of a front-back symmetric structure is used, and thus the fact that after the robot is landed, no matter the front face or the back face touches the ground, the robot can hop again is benefited, and the influence of landing turning to secondary hop is reduced; through the arc-shaped through hole structure design of protrusions with arc-shaped supporting holes arranged on the horizontal edges of the robot body, synchronous movement and asynchronous movement of two rolling wheels under the drive of a single electric motor are achieved; and by using wheel-type movement and the hopping function, the robot has multiple kinds of movement modes, by using the structure that a teeth-missing gear is meshed with a gear, instant unconstrained release of an energy storage component is achieved, and thus improvement of the hopping performance of the energy storage component is benefited. The hopping robot with the wheel movement function is taken as a moving carrier of an airborne instrument, after an airborne sensor is added to the hopping robot with the wheel movement function, the hopping robot with the wheel movement function can be used in the fields of environmental monitoring, urban counterterrorism, military reconnaissance, earthquake relief, science adventure and the like.

Owner:ZHEJIANG UNIV

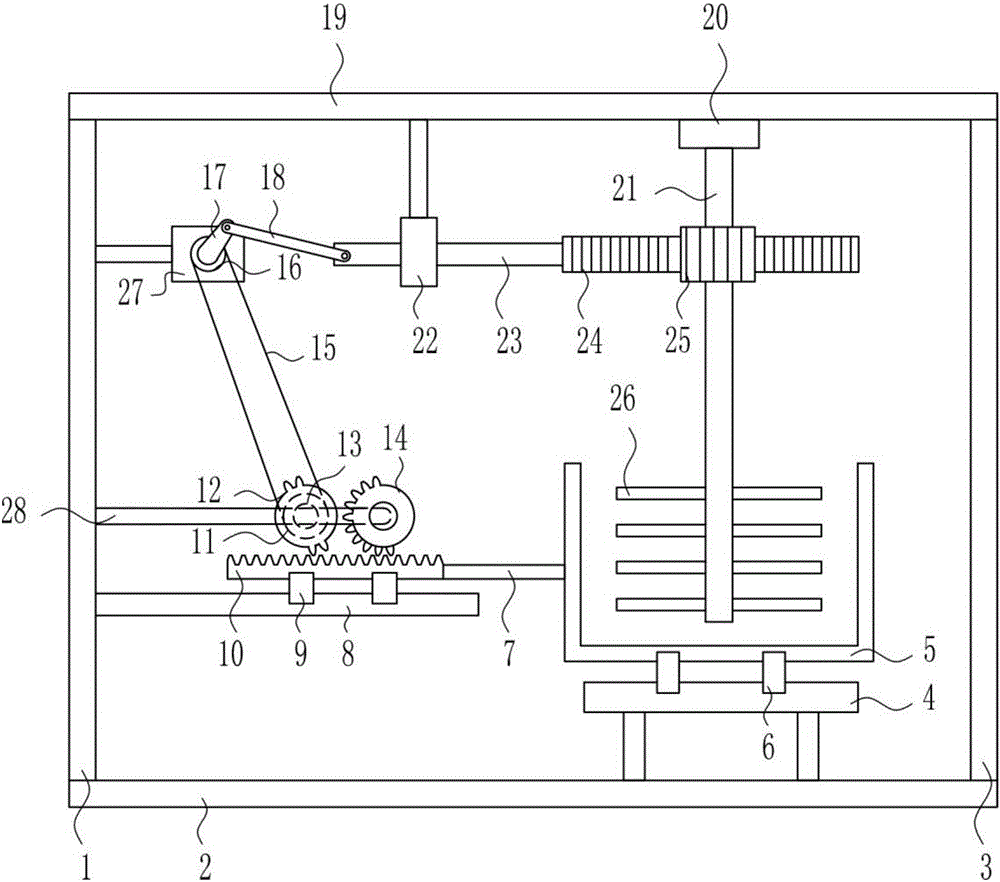

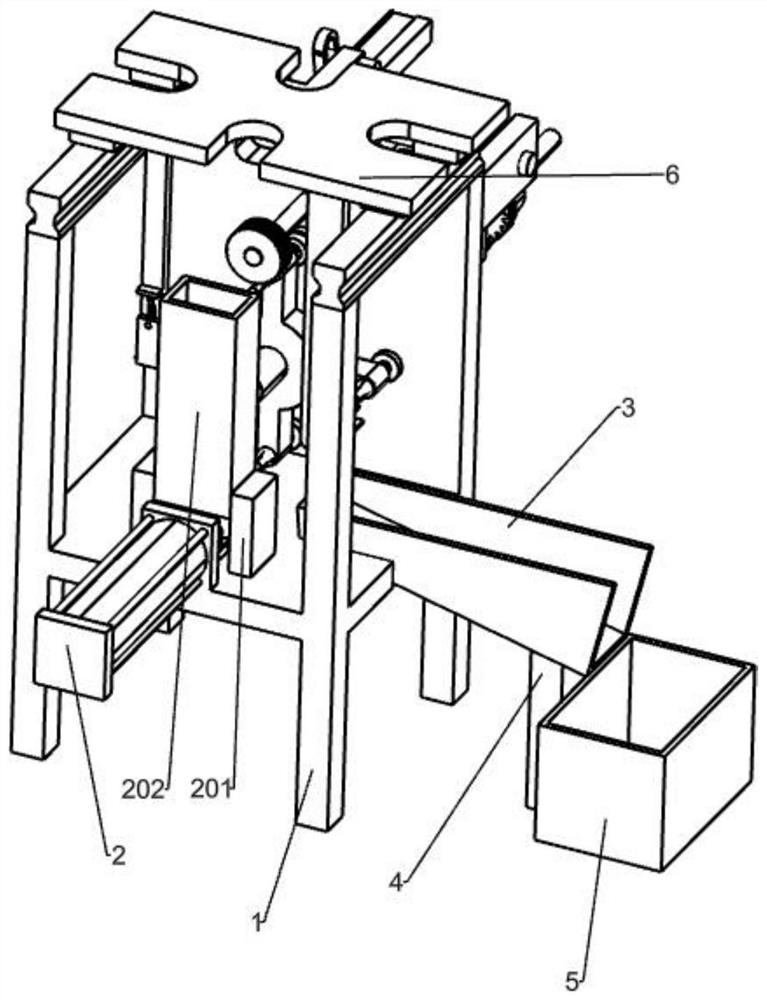

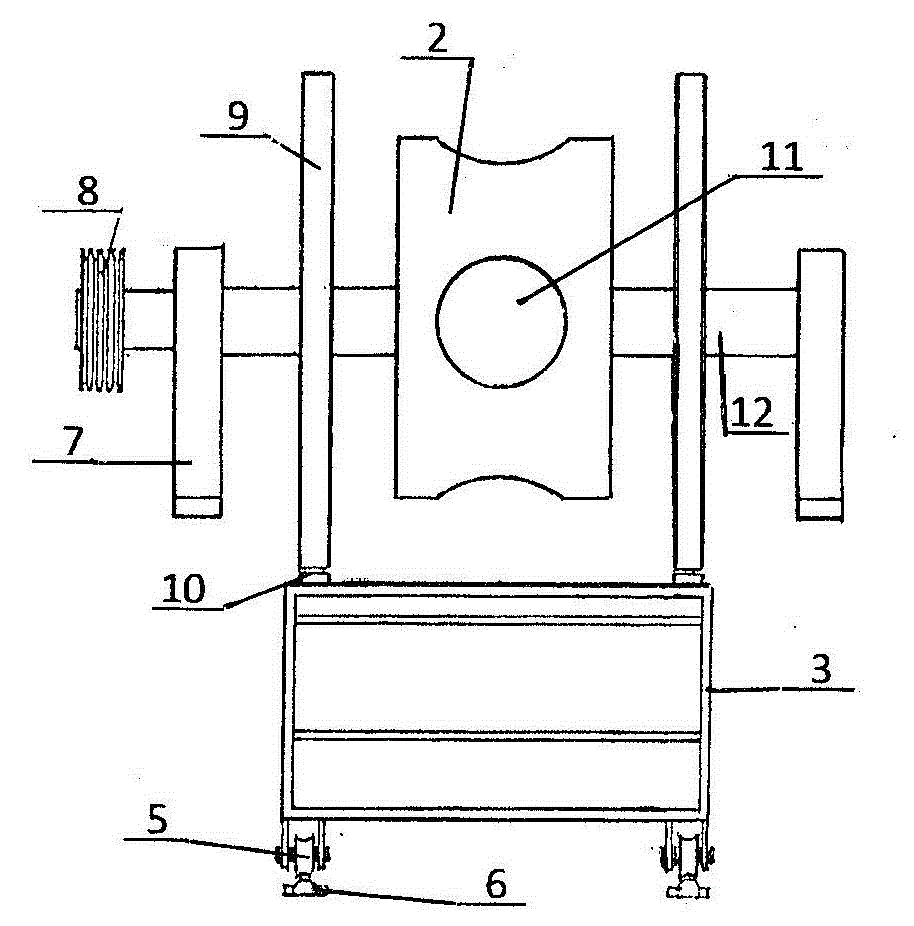

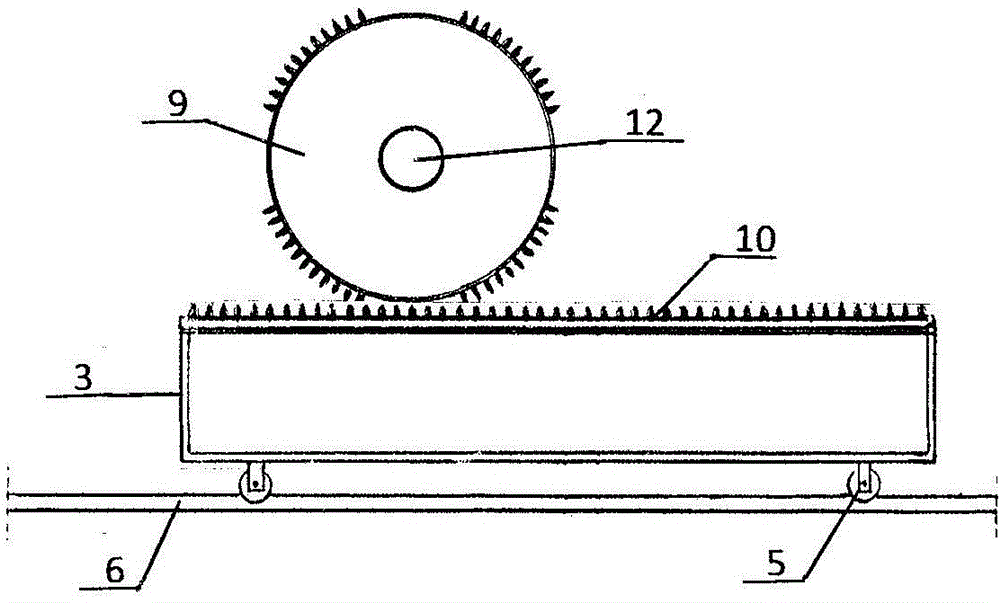

Quick mud stirring device for planting loquats

InactiveCN106215788AStir wellReduce dosageShaking/oscillating/vibrating mixersTransportation and packagingTeeth missingEngineering

The invention relates to a mud stirring device for planting loquats, in particular to a quick mud stirring device for planting loquats. Mud can be uniformly stirred by the quick mud stirring device for planting the loquats, and the quick mud stirring device is novel in structure and high in stirring speed. The quick mud stirring device for planting the loquats comprises a left frame, a bottom plate, a right frame, a first slide rail, a stirring frame, first sliders, a push rod, a second slide rail, second sliders, a second rack, a large belt pulley, a tooth-missing gear and the like. The left frame, the first slide rail and the right frame are sequentially arranged on the top of the bottom plate from the left to the right, the first sliders are slidably connected onto the first slide rail, and the stirring frame is arranged on the tops of the first sliders. The quick mud stirring device has the advantages that the mud can be uniformly stirred by the quick mud stirring device, and the quick mud stirring device is novel in structure and high in stirring speed; the mud can cover saplings of the loquats, the root systems of the saplings can be protected, transpiration of water can be reduced, and accordingly the survival rate of the loquats can be increased.

Owner:屏边县昌源果蔬产销专业合作社

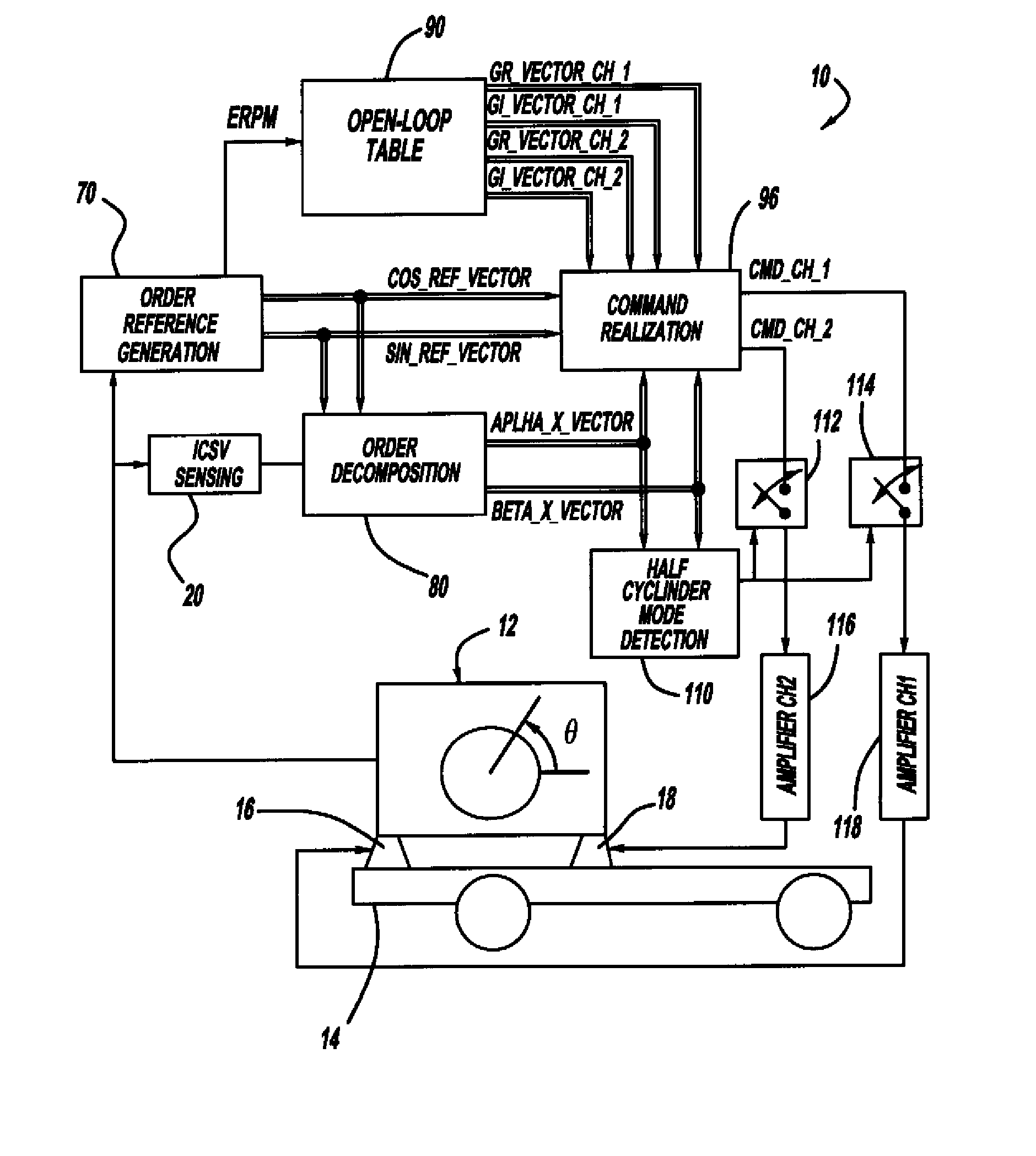

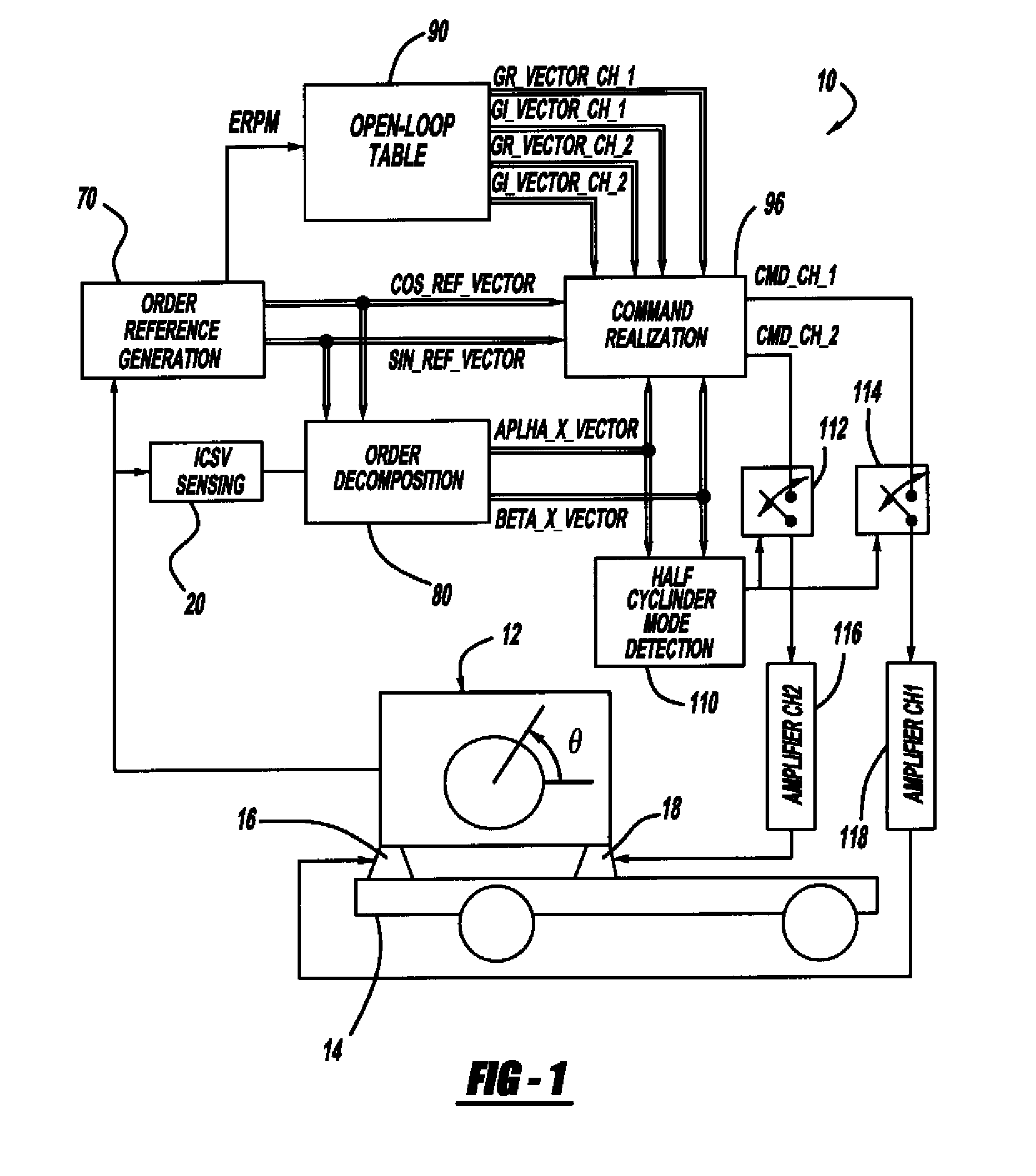

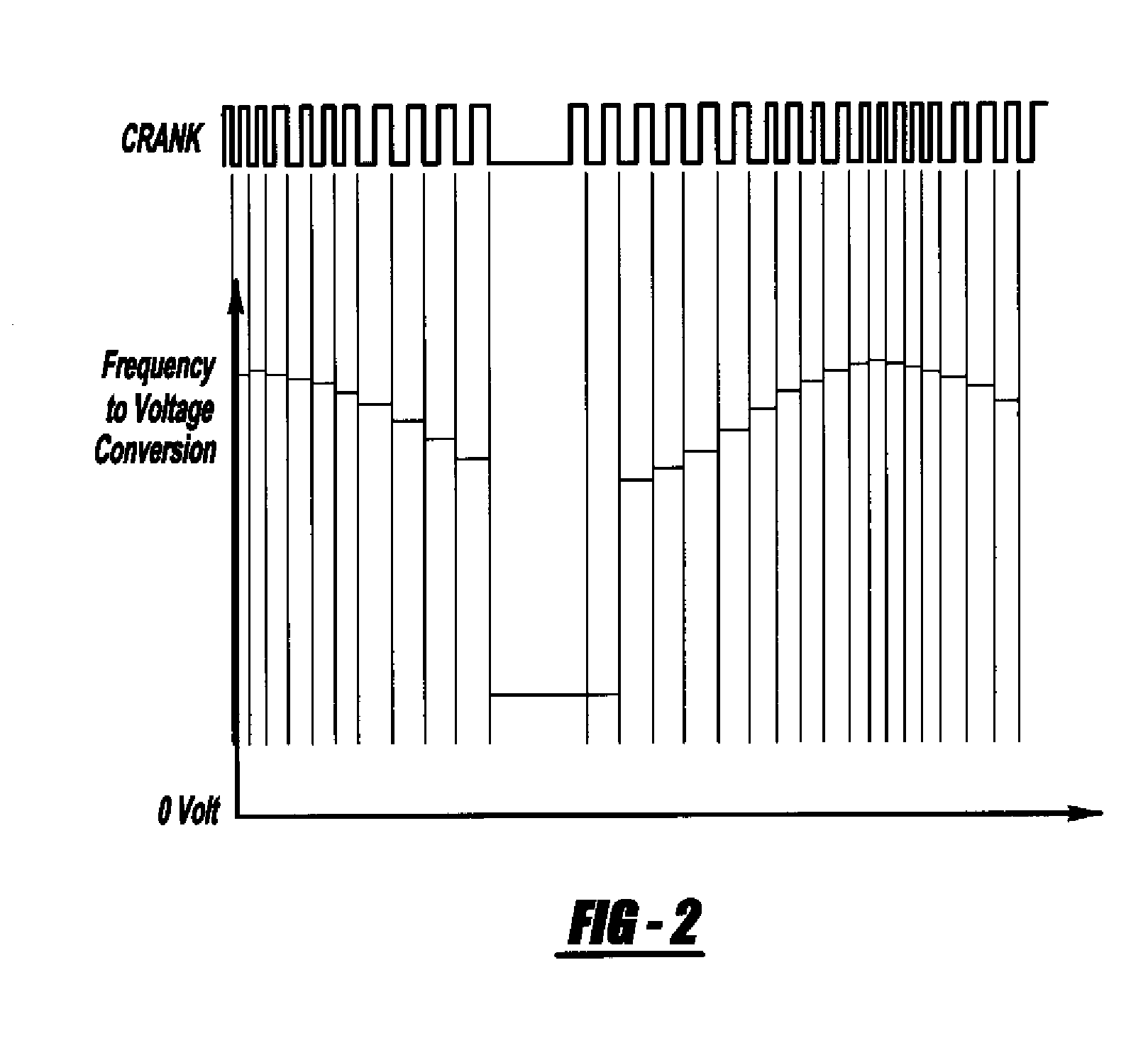

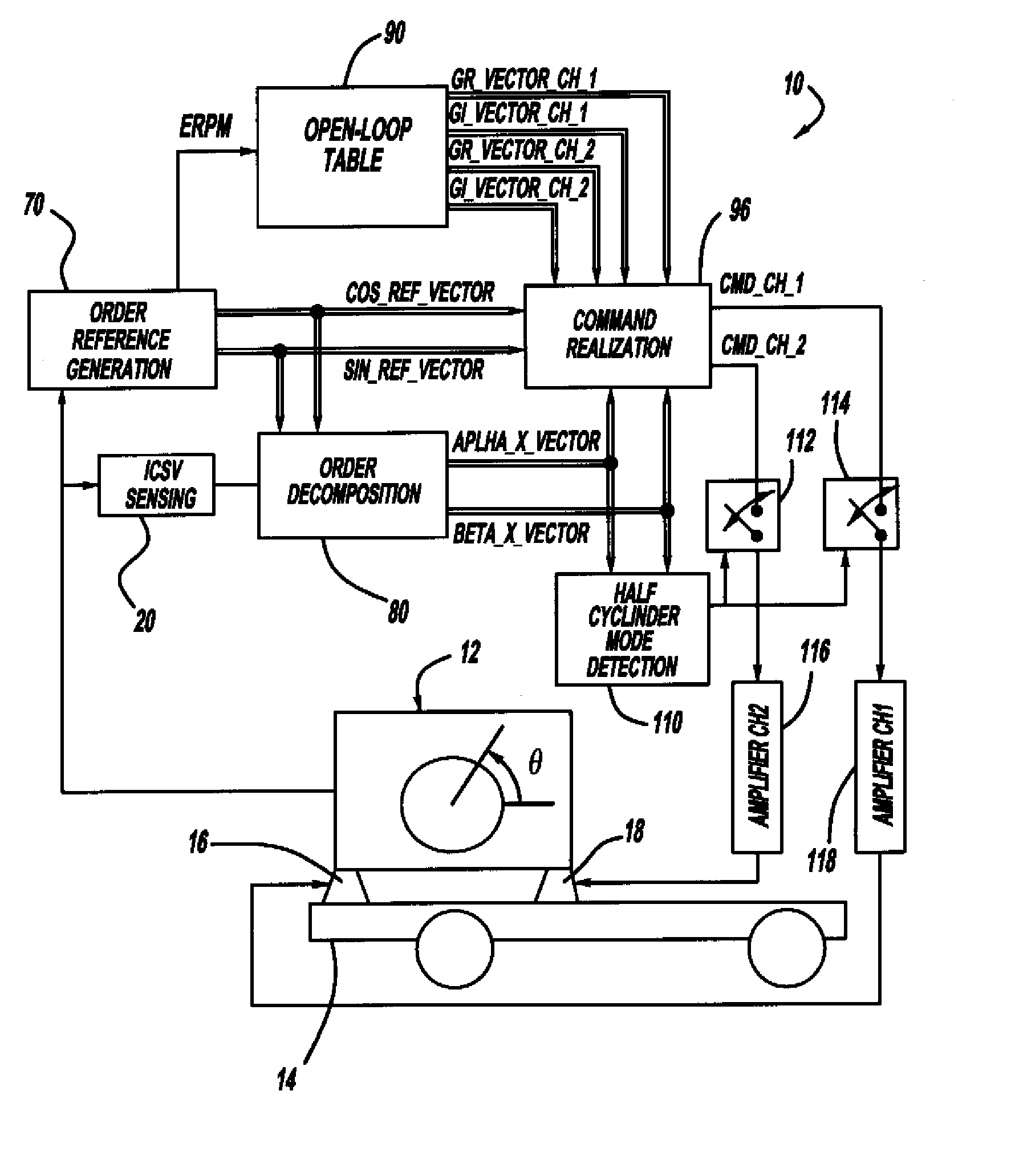

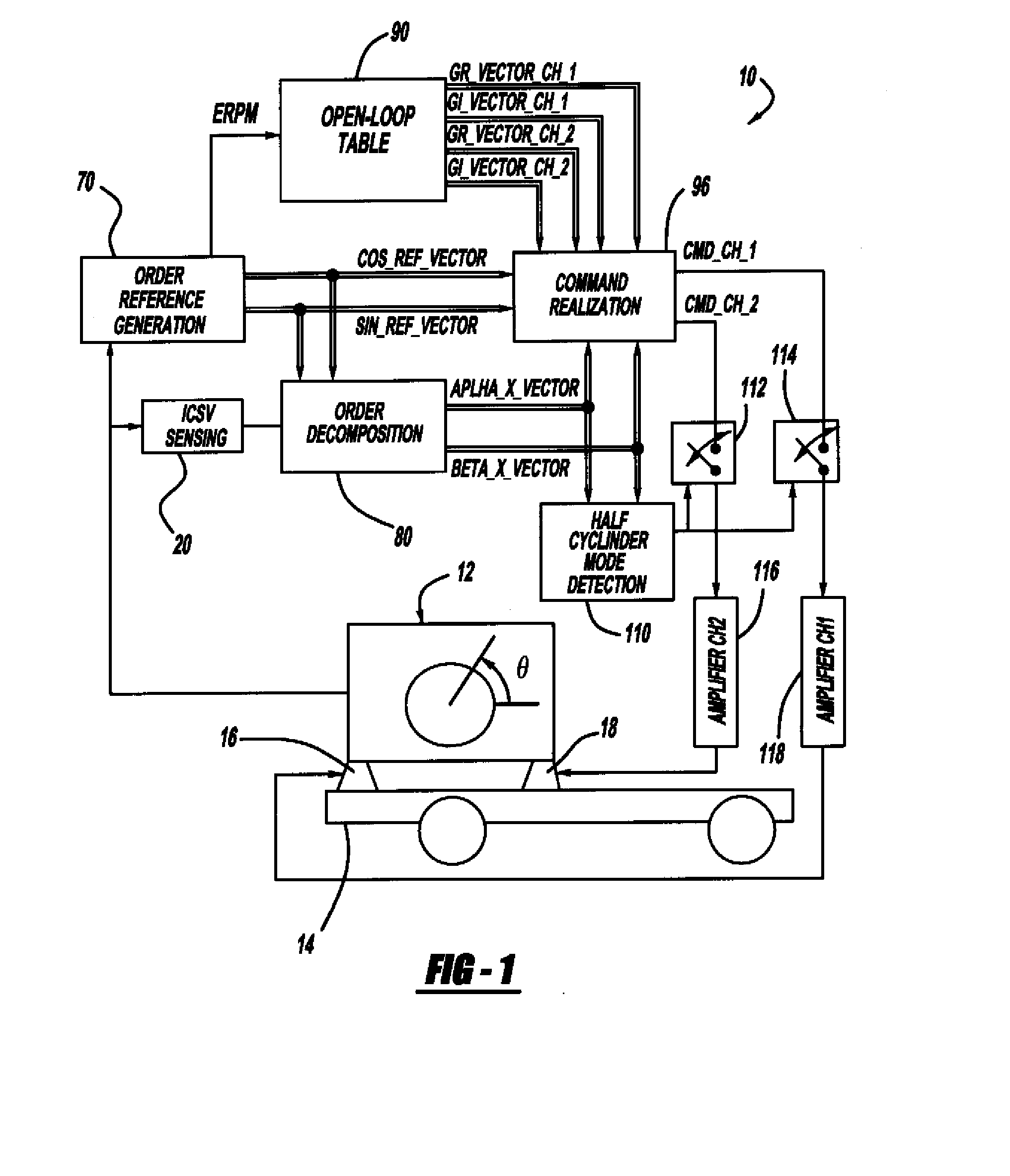

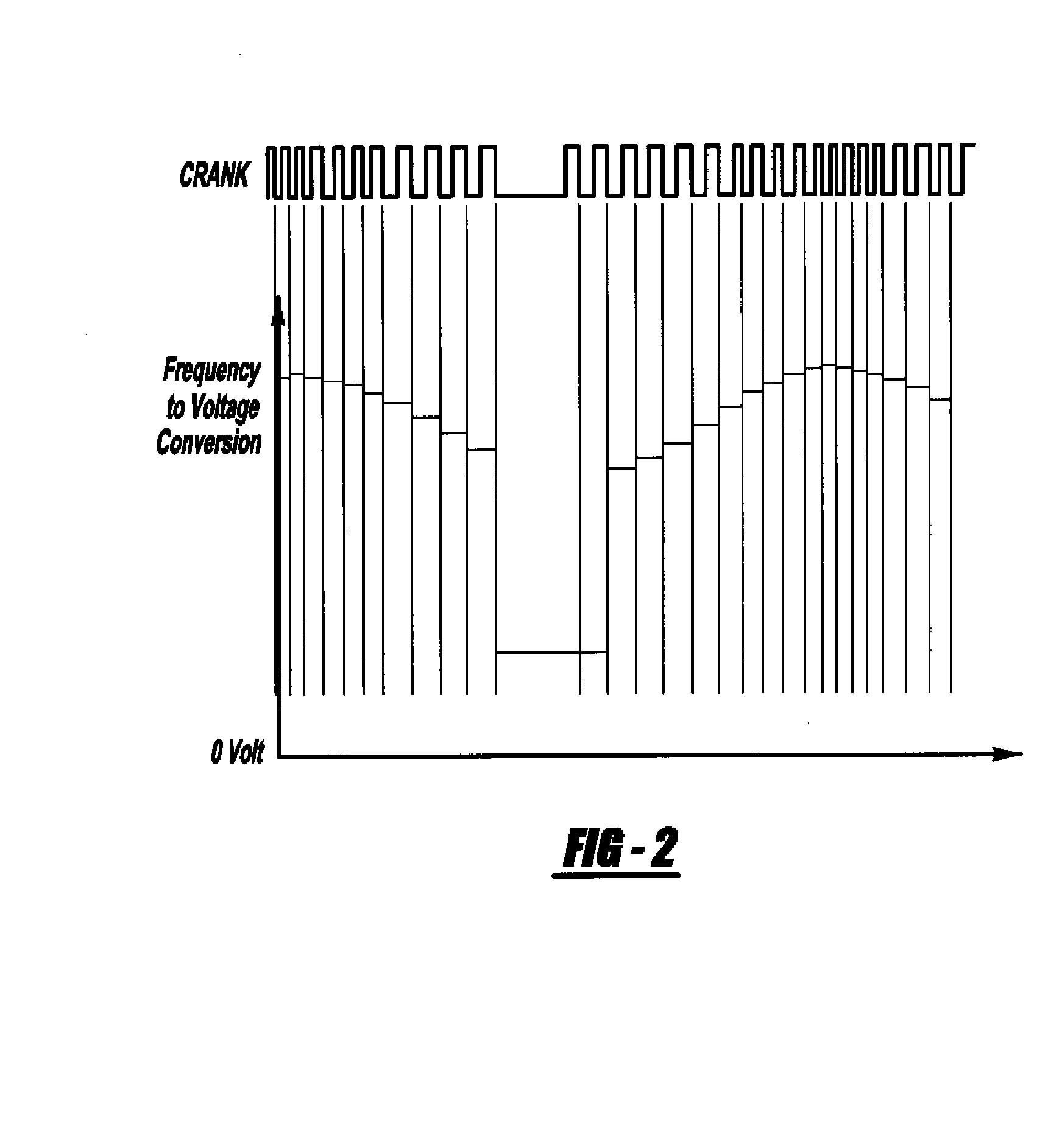

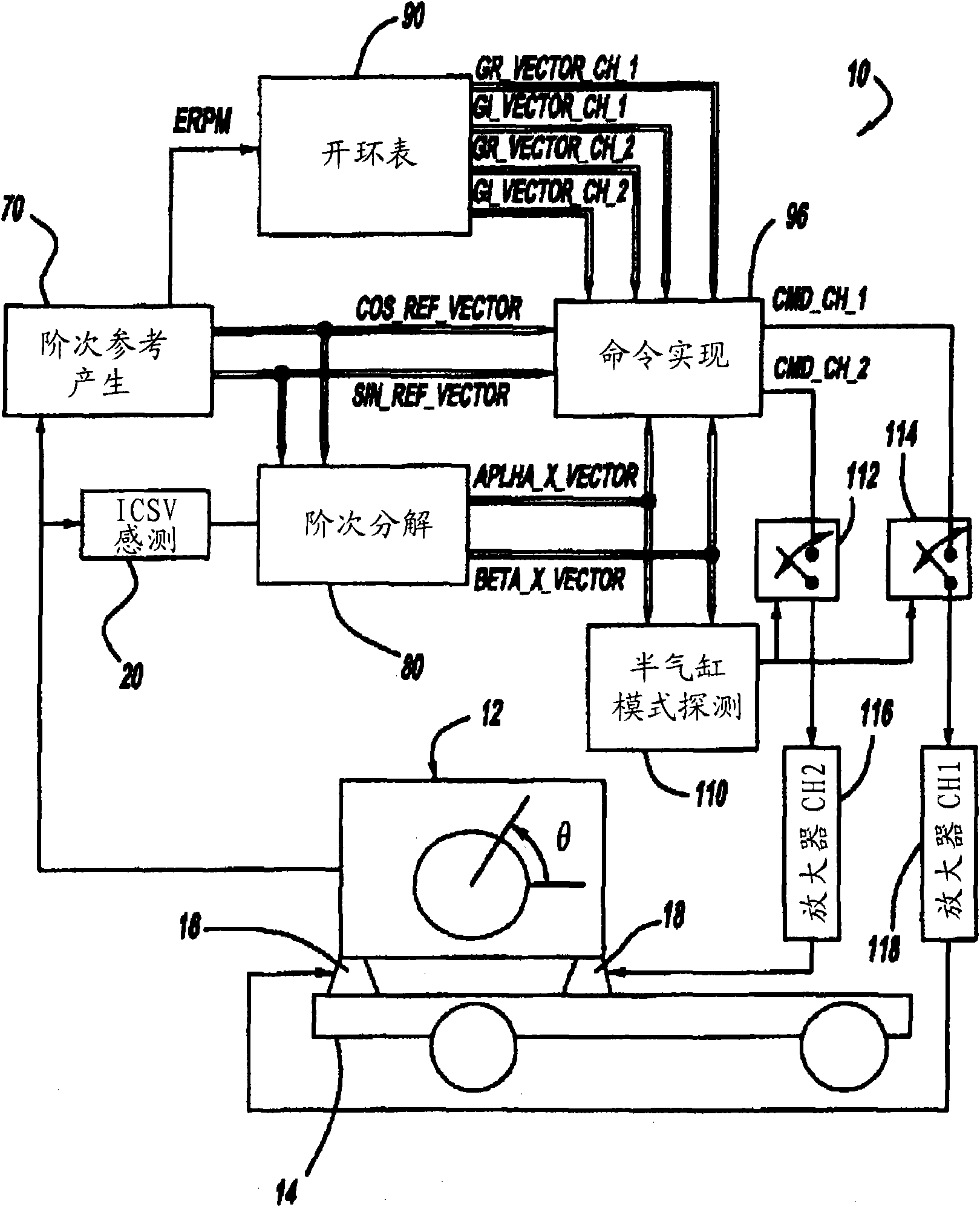

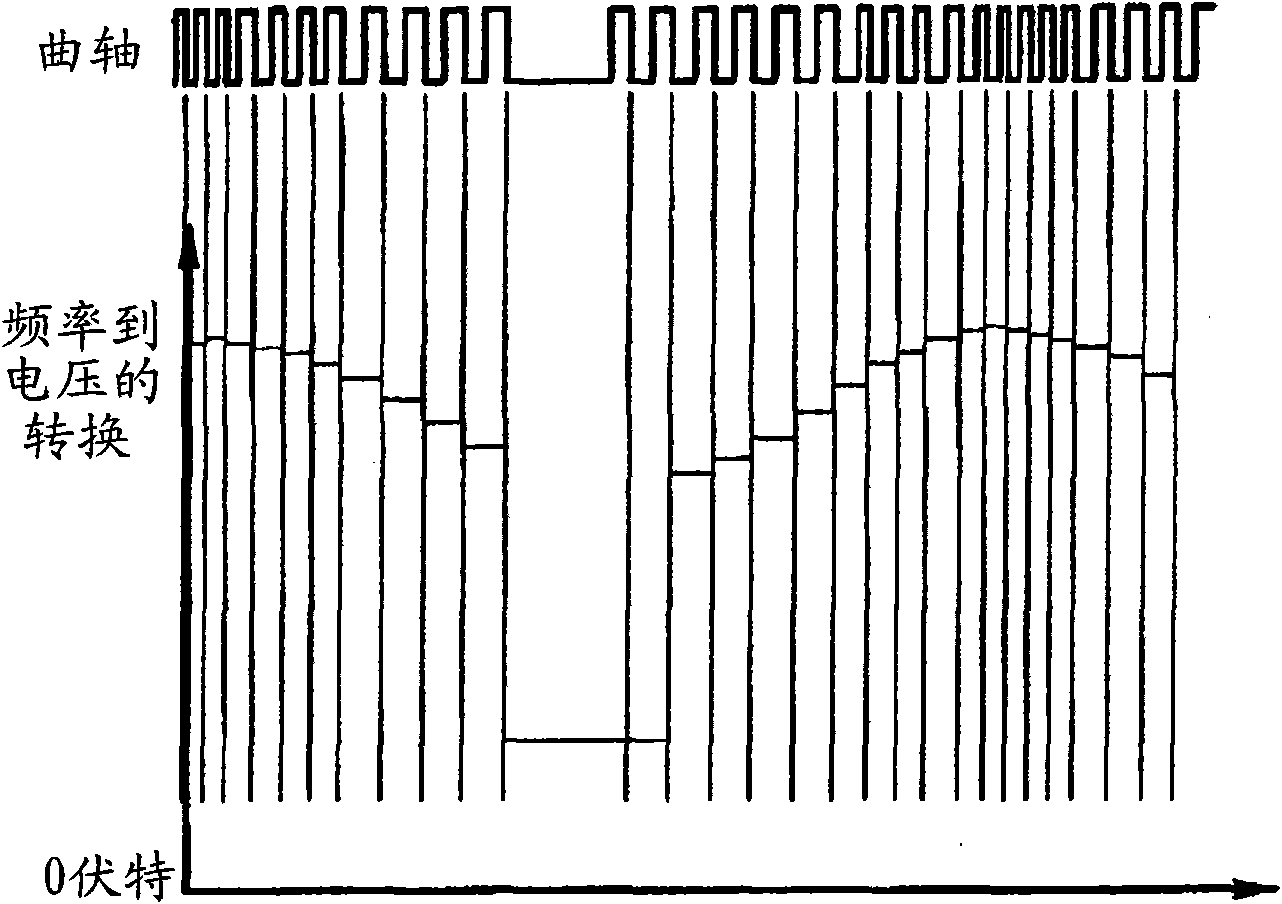

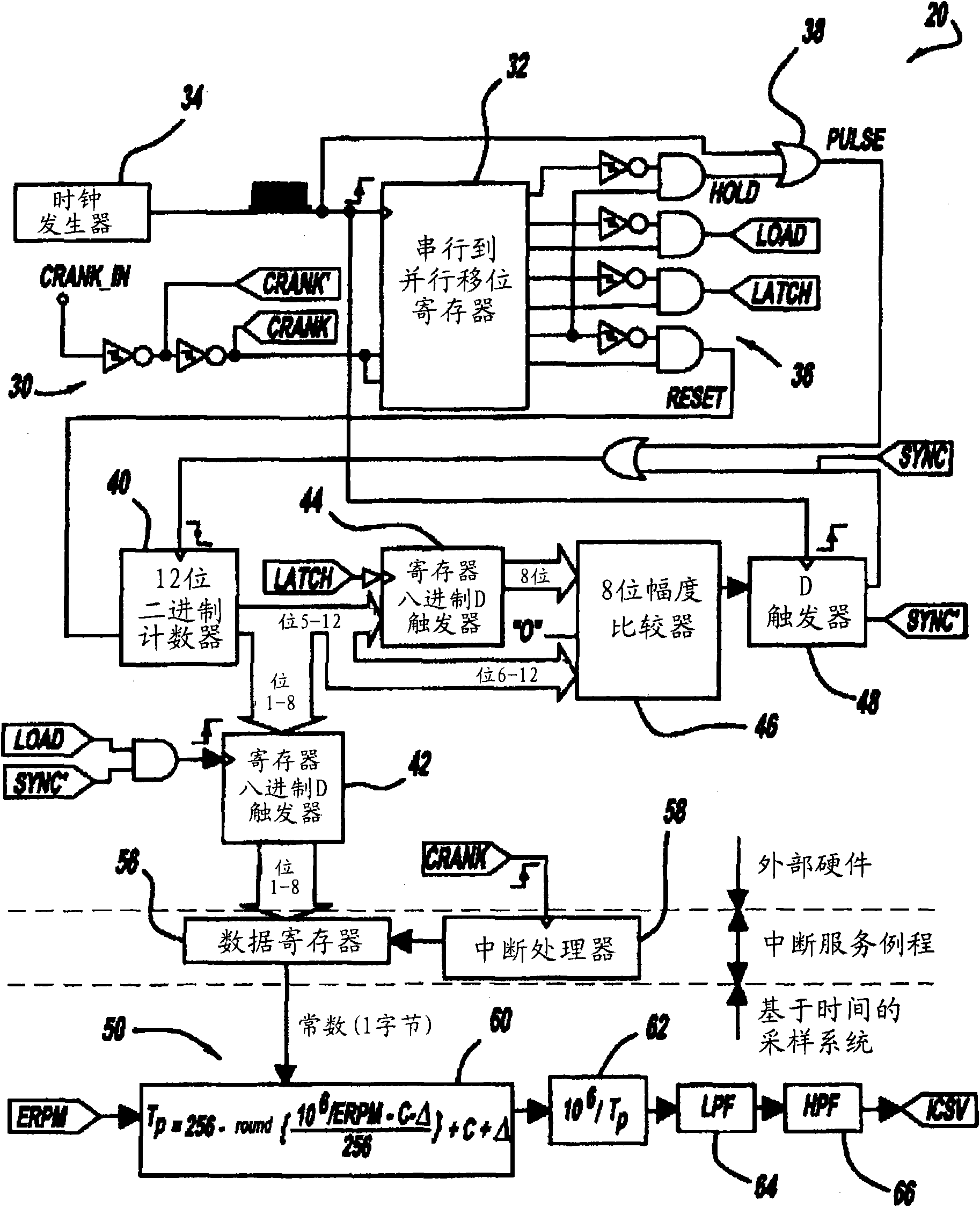

Open-loop control method for cancelling engine induced noise and vibration

An open-loop control system that provides control signals to active engine mounts to reduce or eliminate the transfer of engine vibration to a vehicle body structure, where the system uses only a crank signal from the engine as an input. The control system includes an instant crank speed variation sensing processor that receives the crank signal from the engine, where the crank signal is a pulsed signal including missing pulses as a result of teeth missing on the vehicle crank wheel. The crank speed variation sensing processor provides a measurement of the instant crank speed variation of the crank signal and minimizes an error in the measurement as a result of the missing pulses. The crank speed variation sensing processor outputs a crank speed sensing variation signal as a sine wave that identifies order content in the crank pulse signal.

Owner:GM GLOBAL TECH OPERATIONS LLC

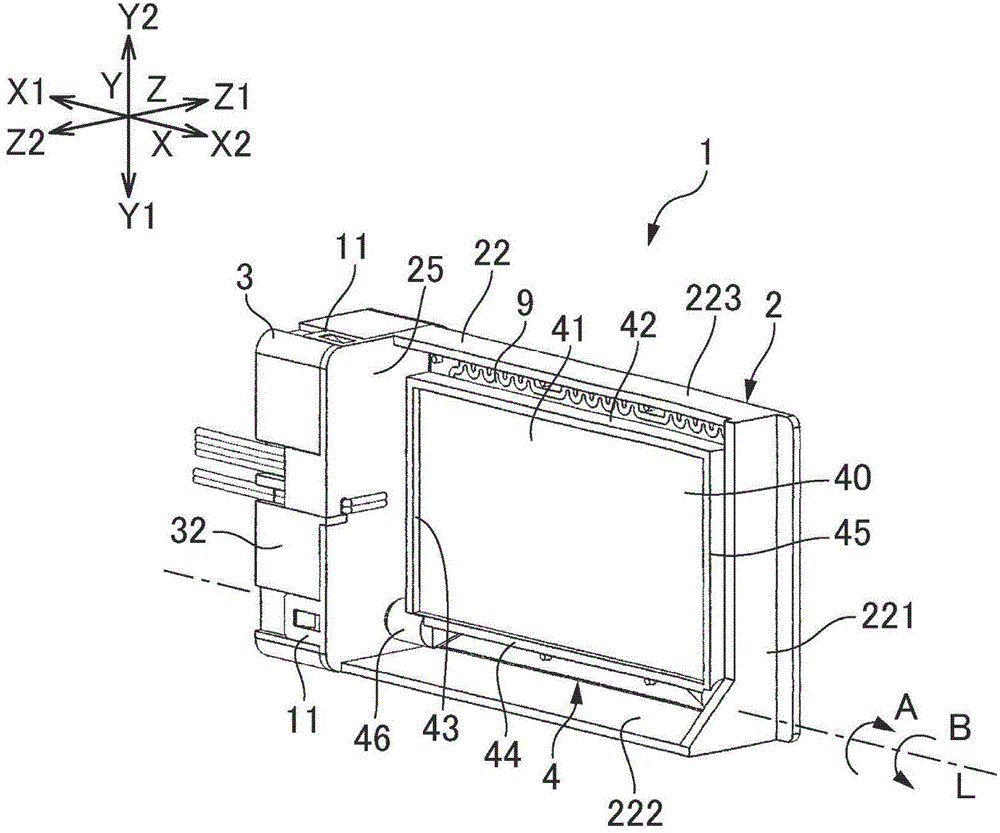

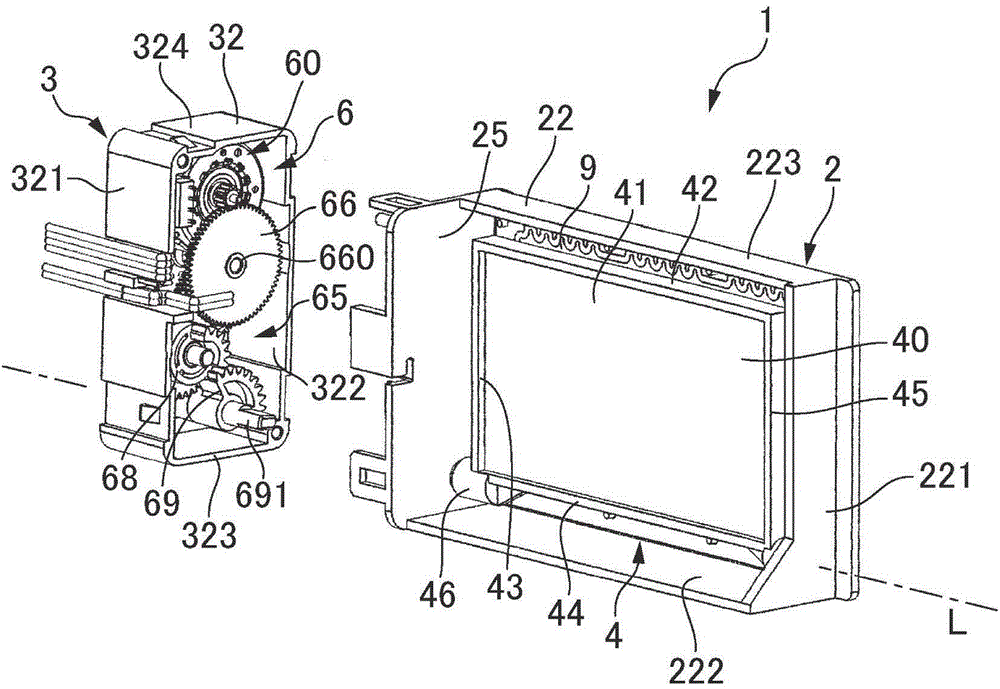

Damper apparatus

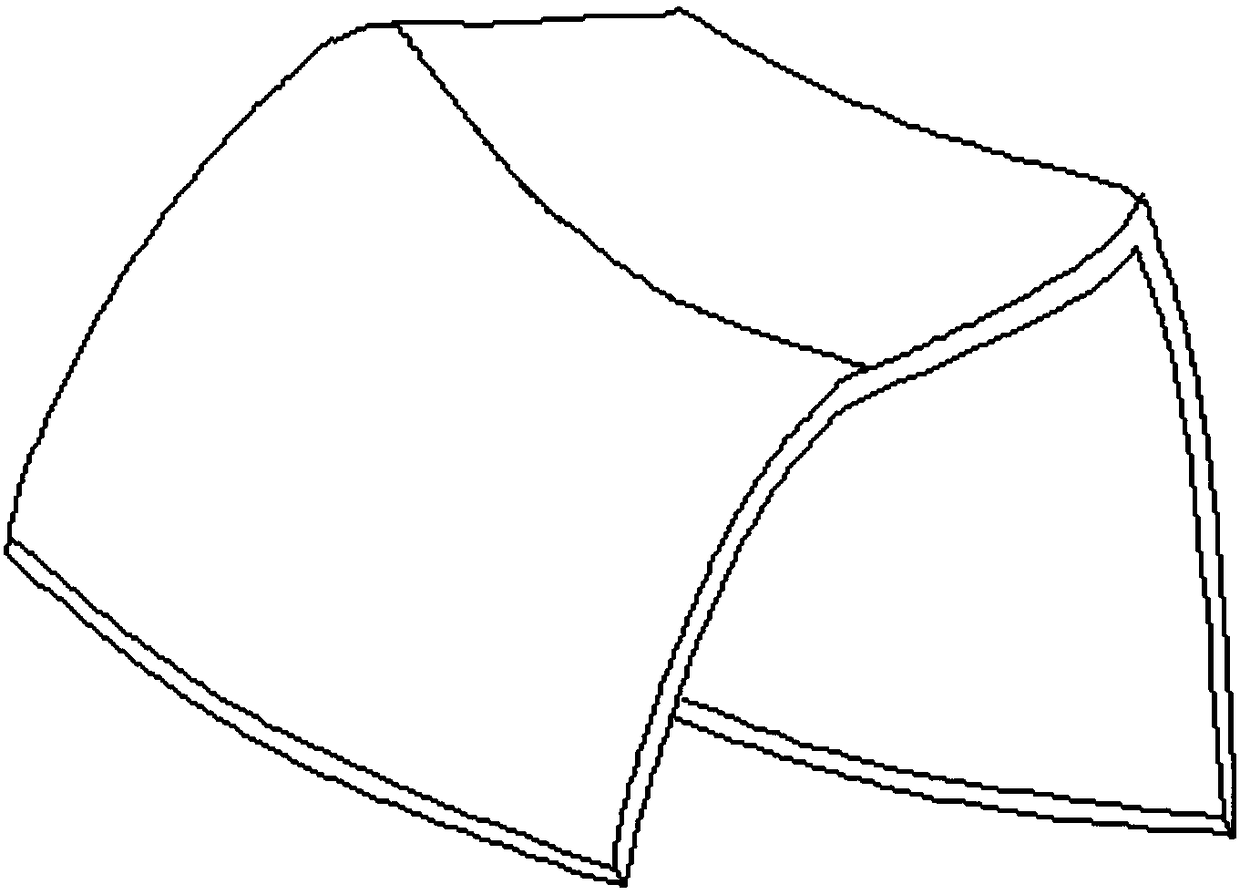

ActiveCN105042993ANot easy to shiftShock suppressionOperating means/releasing devices for valvesLighting and heating apparatusLocking mechanismTeeth missing

Provided is a damper apparatus with which it is possible to suppress abnormal sounds immediately after the locking of gears has been released. Specifically, in a first lock mechanism (81) of the damper apparatus, a first arcuate outer-peripheral part (686) peripherally adjacent to a teeth-missing gear (682) in a drive gear (68) enters a portion of a plurality of teeth (694) in which some teeth are narrowed in the axial direction to restrain a sector gear (69), the plurality of teeth (694) being meshed with the drive gear (68) in the sector gear (69). In the tooth (682c) nearest to the first arcuate outer-peripheral part (686) in the teeth-missing gear (682), the curvature of a first tooth flank (682c1) on the side opposite the first arcuate outer-peripheral part (686) is less than the curvature of a second tooth flank (682c2) on the first arcuate outer peripheral part (686) side, and the tooth (682c) has a curved surface continuous from the first tooth flank (682c1) to the second tooth flank (682c2).

Owner:SANKYO SEIKI MFG CO LTD

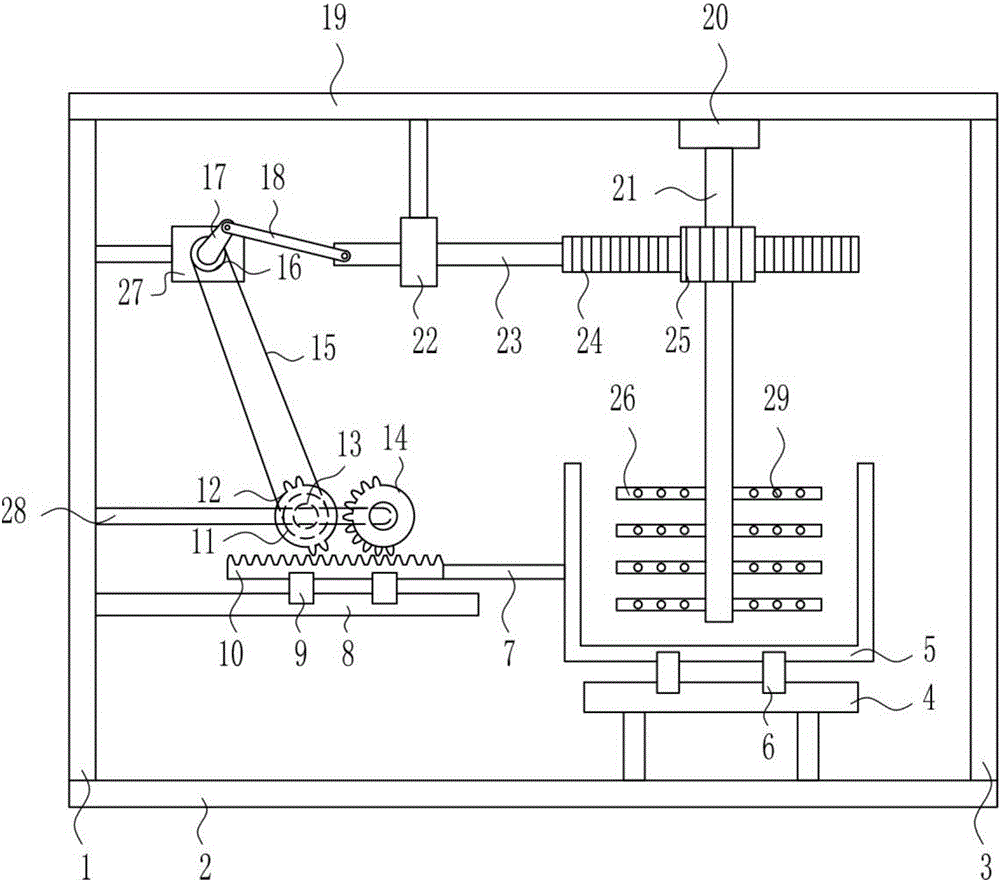

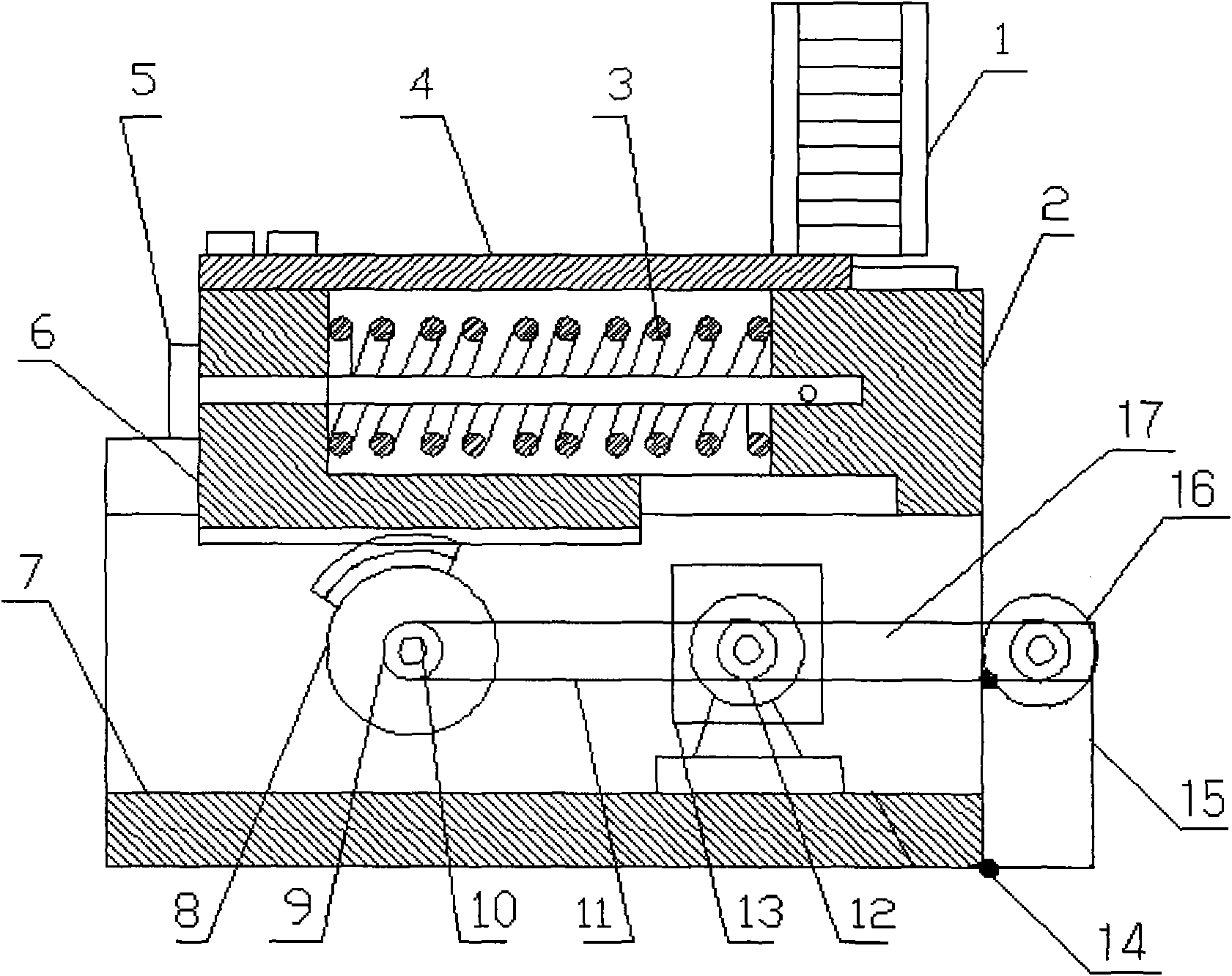

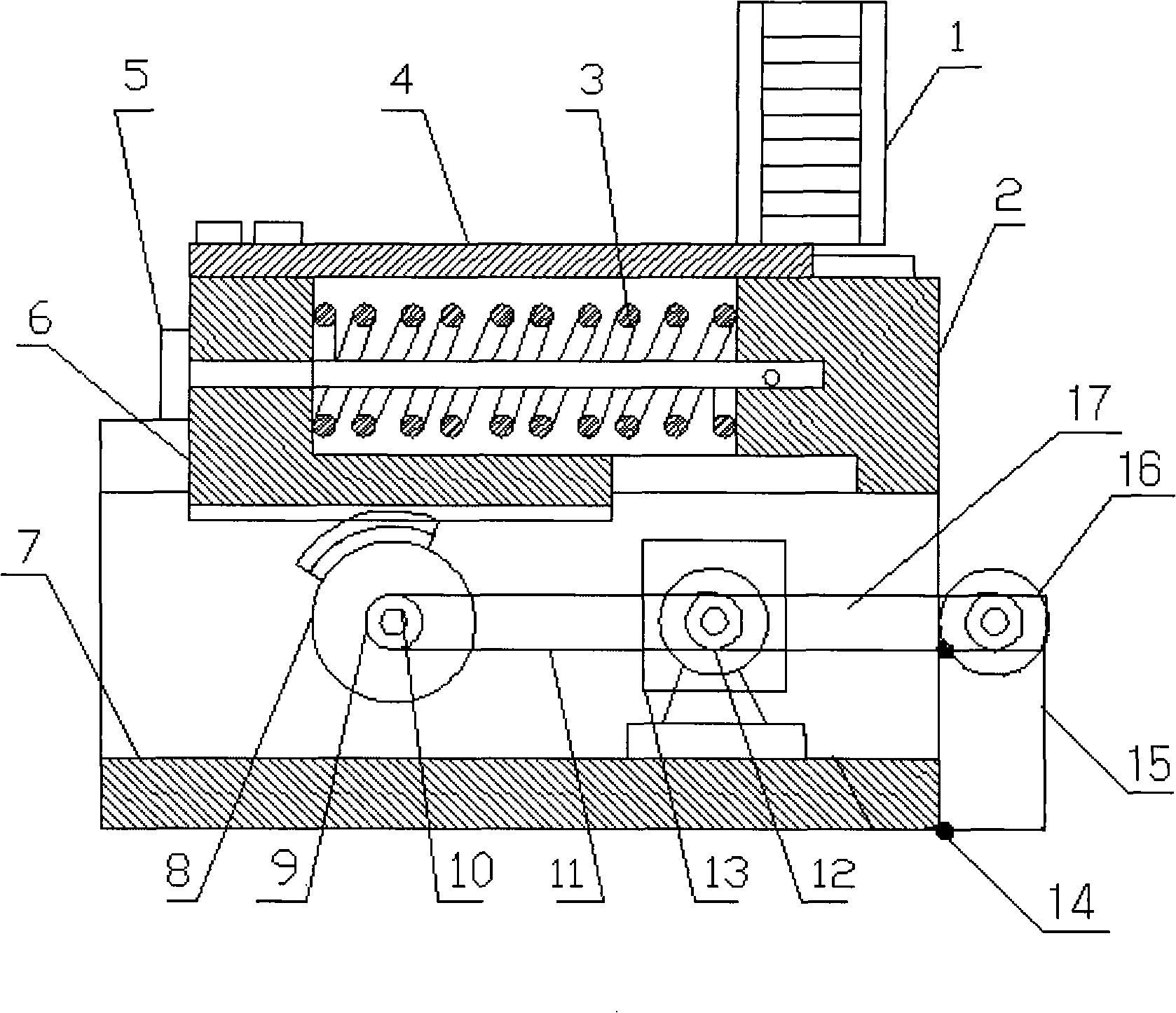

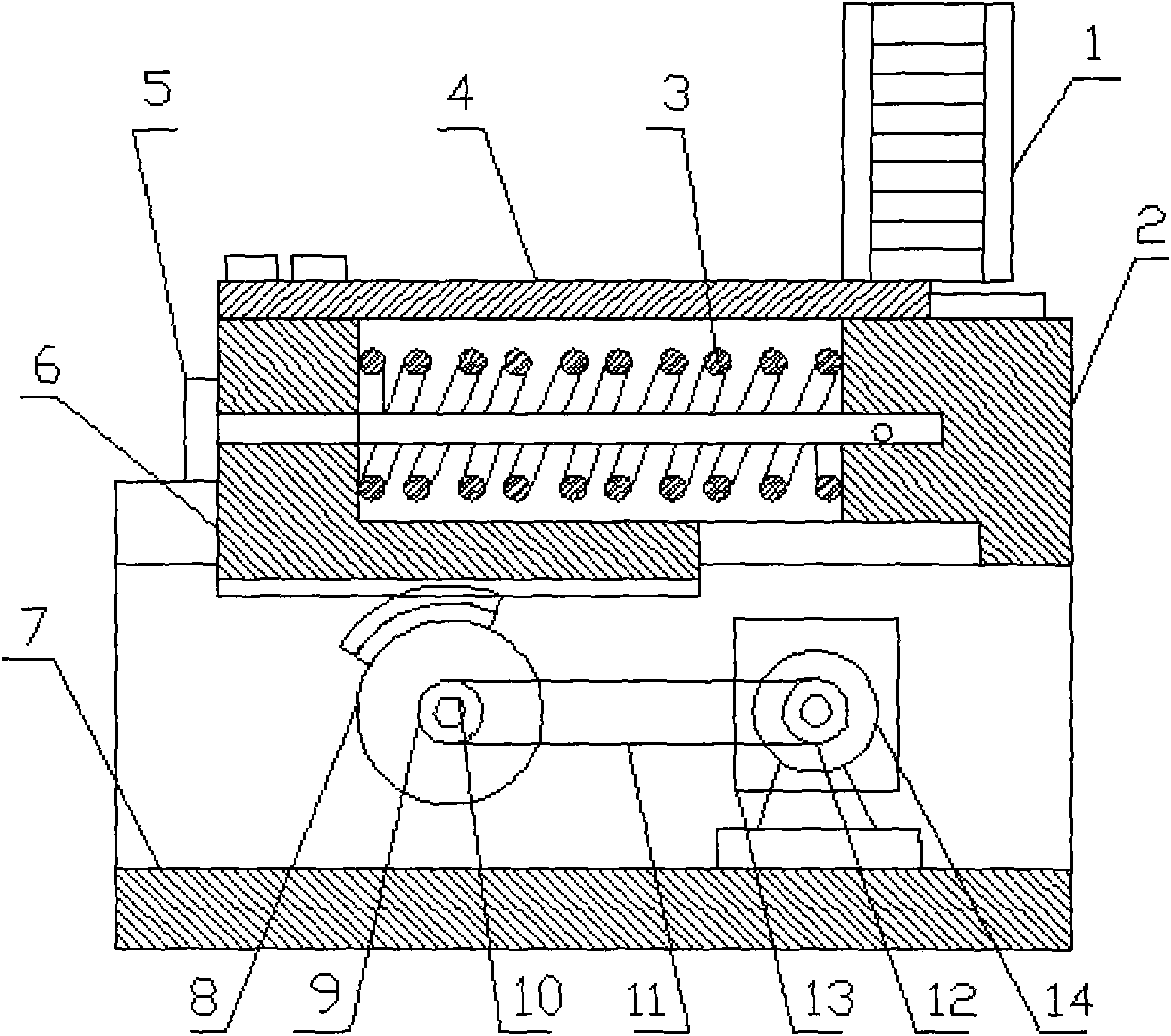

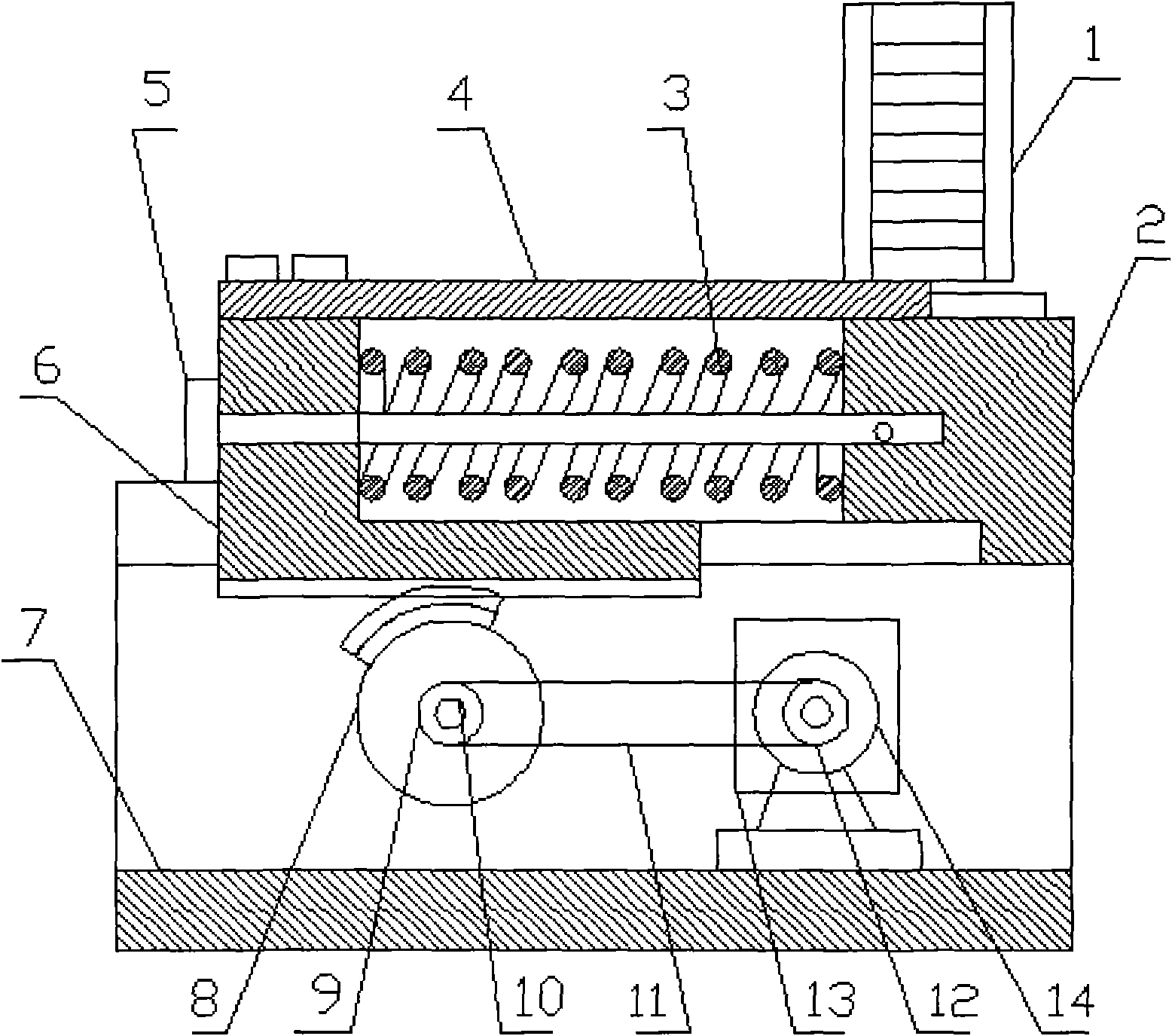

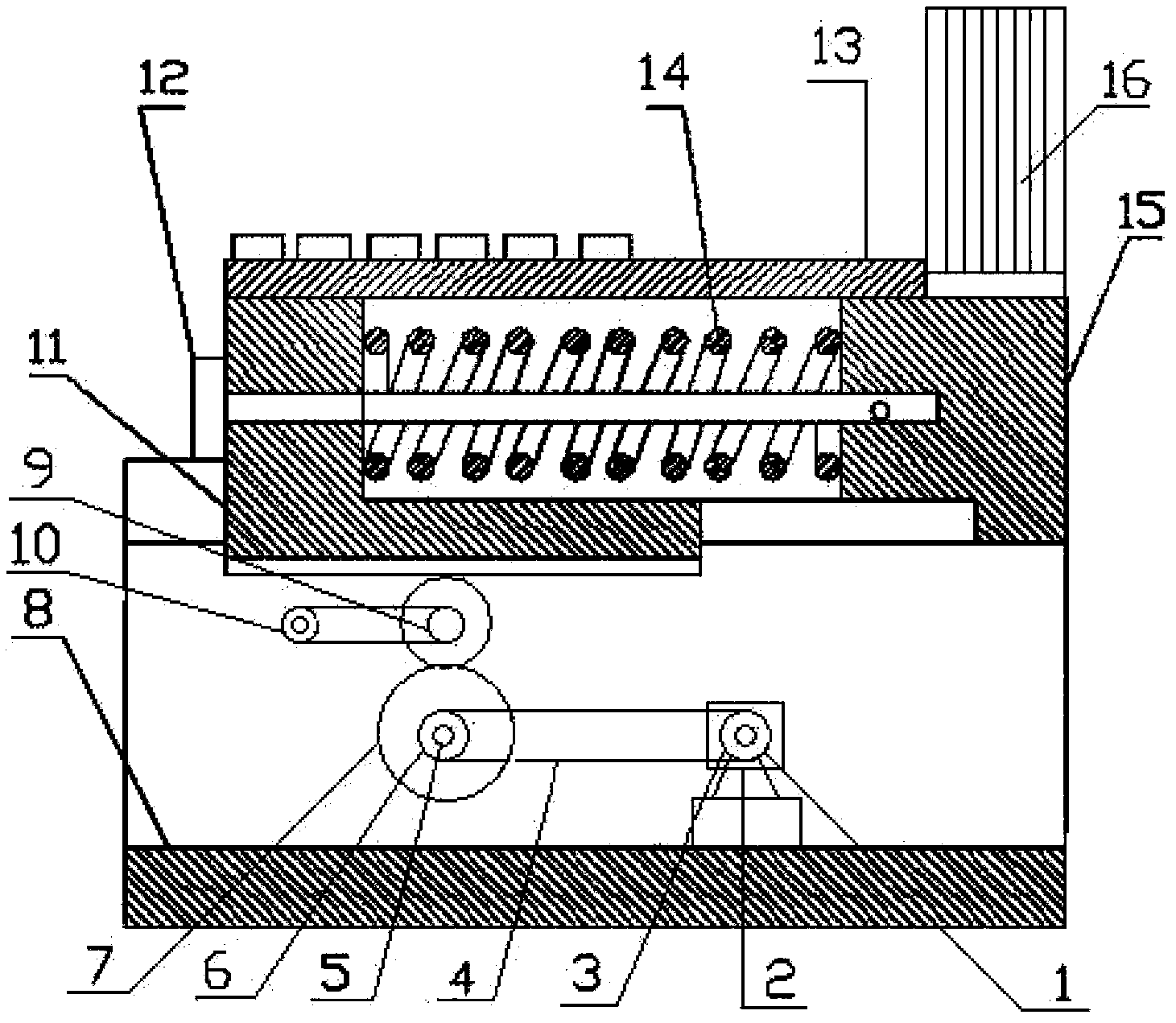

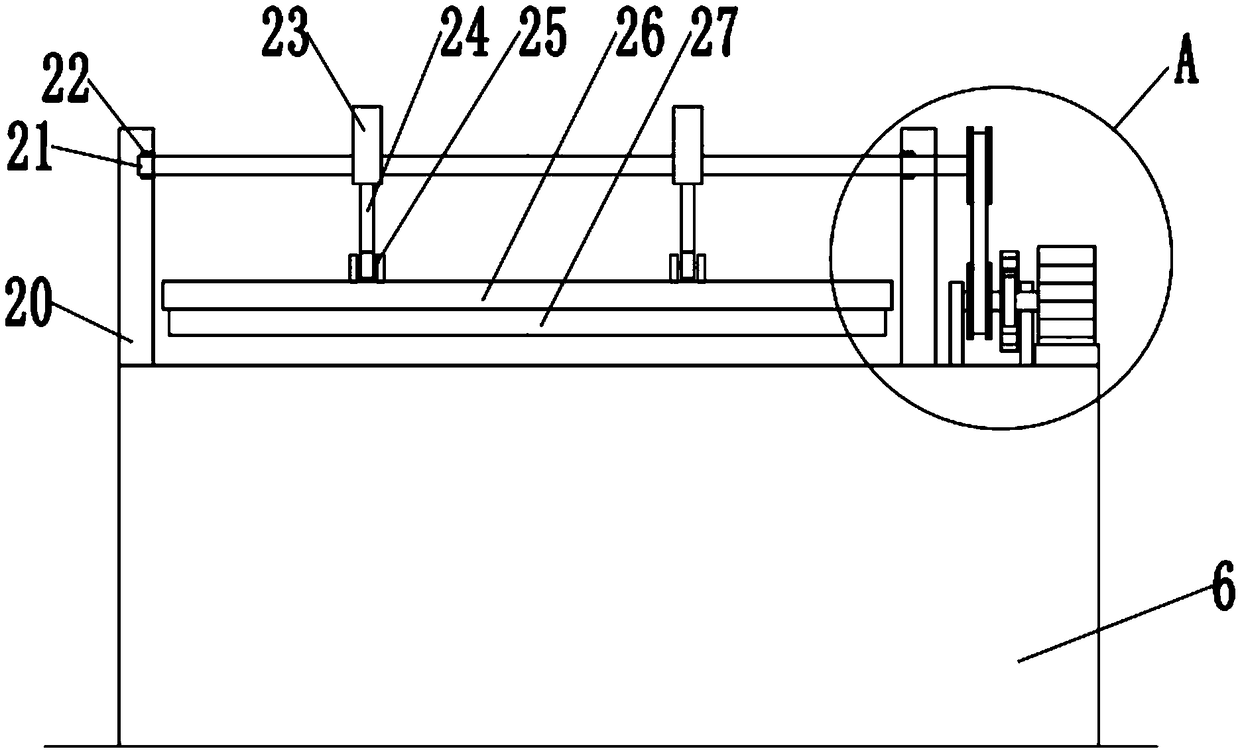

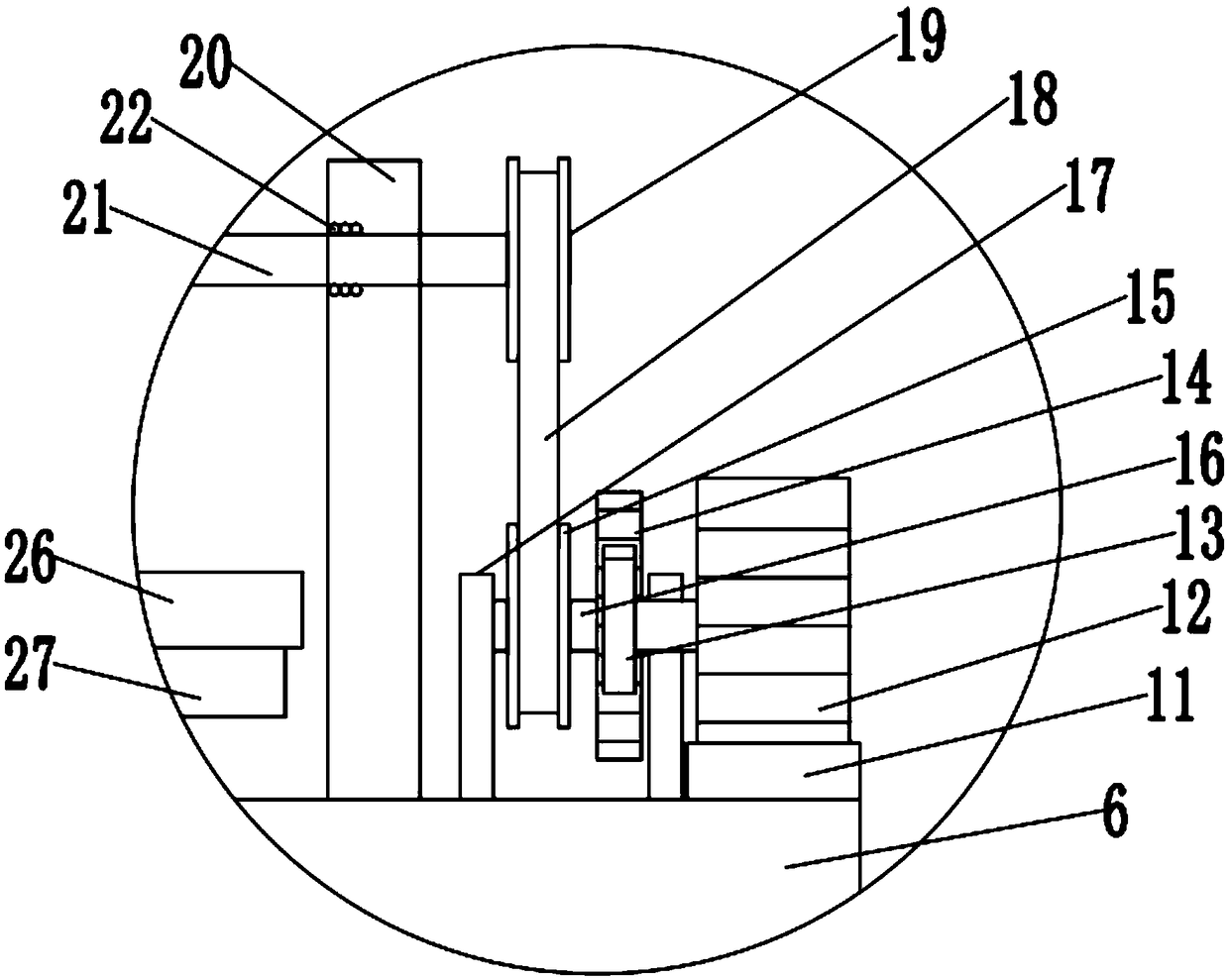

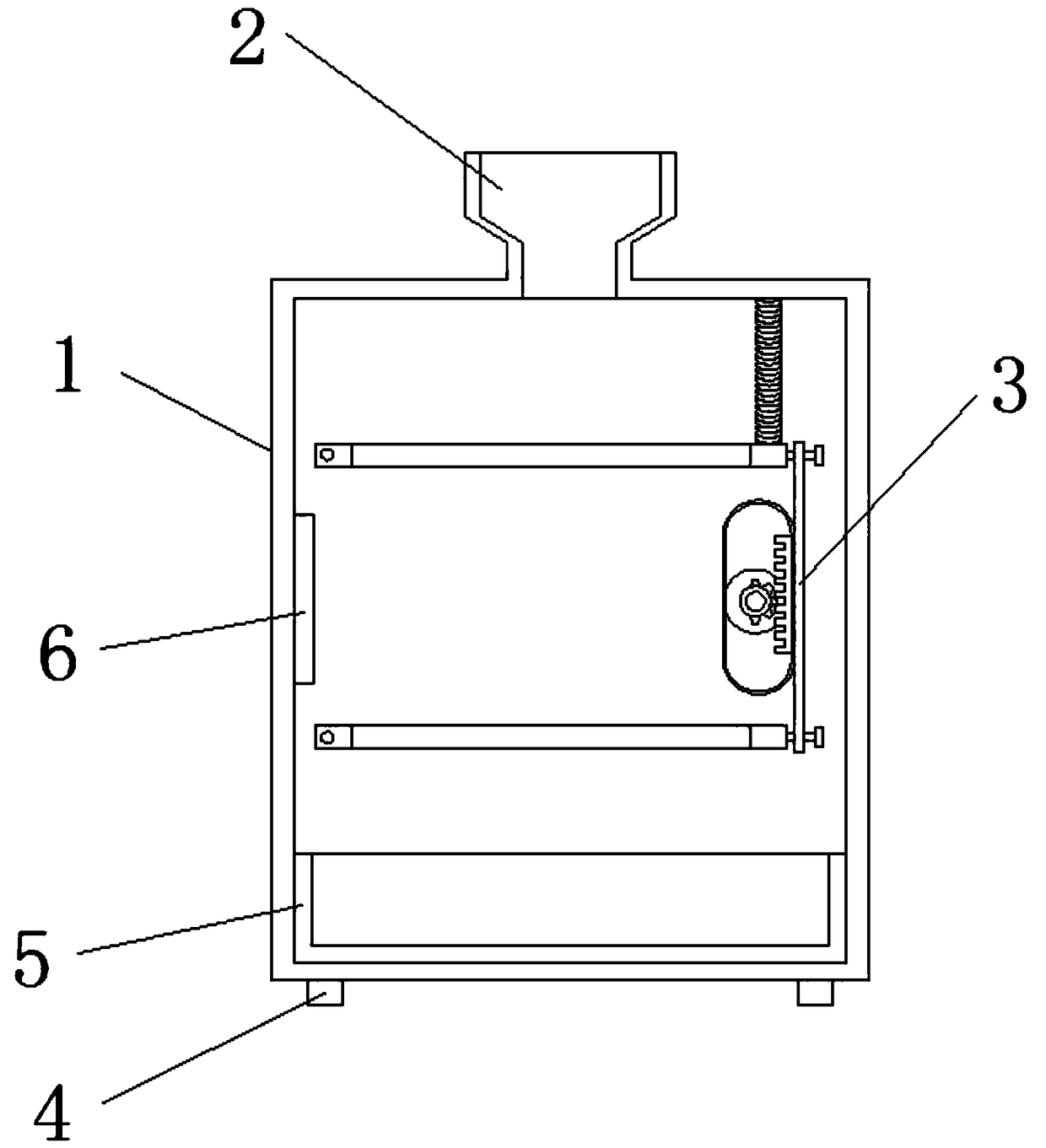

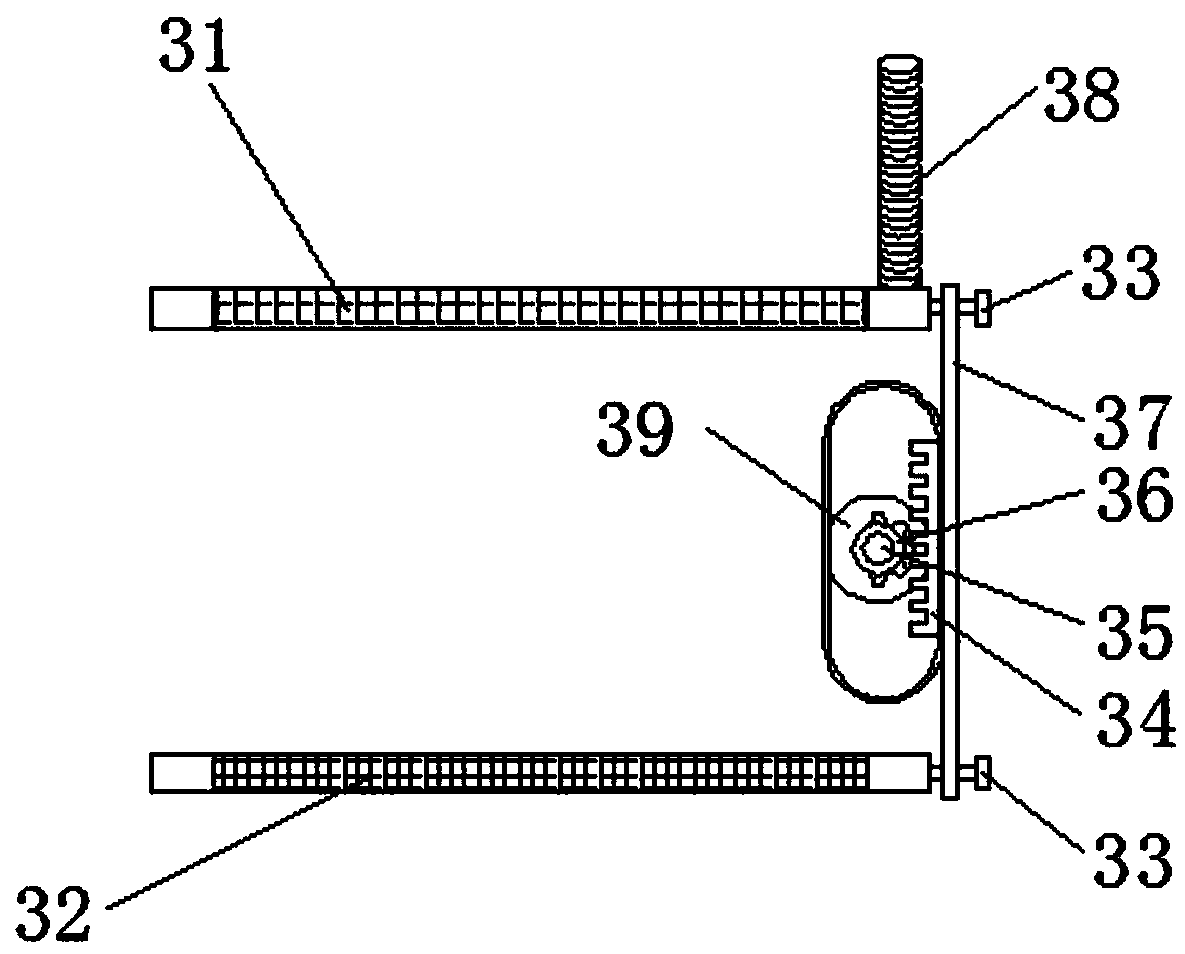

Novel electromechanical automatic feeding device

InactiveCN101844670AEasy to controlAccurate adjustment effectConveyorsConveyor partsFrequency conversionGear wheel

The invention discloses a novel electromechanical automatic feeding device. A hopper is arranged and fixed at a proper position of a hopper seat; a guide post is penetrated into a hole of a rack elbow; a return spring is sleeved on the guide post, and then a rack is arranged in a guide rail of a machine frame; the right end of the guide post is fixed on the hopper seat by using a pin or a bolt and other methods; and during assembling, the rack should be ensured to move smoothly in the guide post and the guide rail, the return spring is compressed appropriately, and a pushing plate is arranged on the feeding device. A driving shaft is arranged at a position vertical to the moving direction of the rack on the machine frame; a tooth-missed gear and a driven chain are arranged on the driving shaft; the rack is ensure to be meshed with the tooth-missed gear, and also the rack is ensured to be able to quickly and accurately reset under the action of the return spring after the meshed gears do not contact each other; and the driving parts such as a frequency conversion speed-adjusting motor, a speed changer, a driving chain wheel, a motor chain wheel, a chain, a motor chain and the like are arranged in the feeding device in turn and are fixed by fixing bolts.

Owner:郑合新

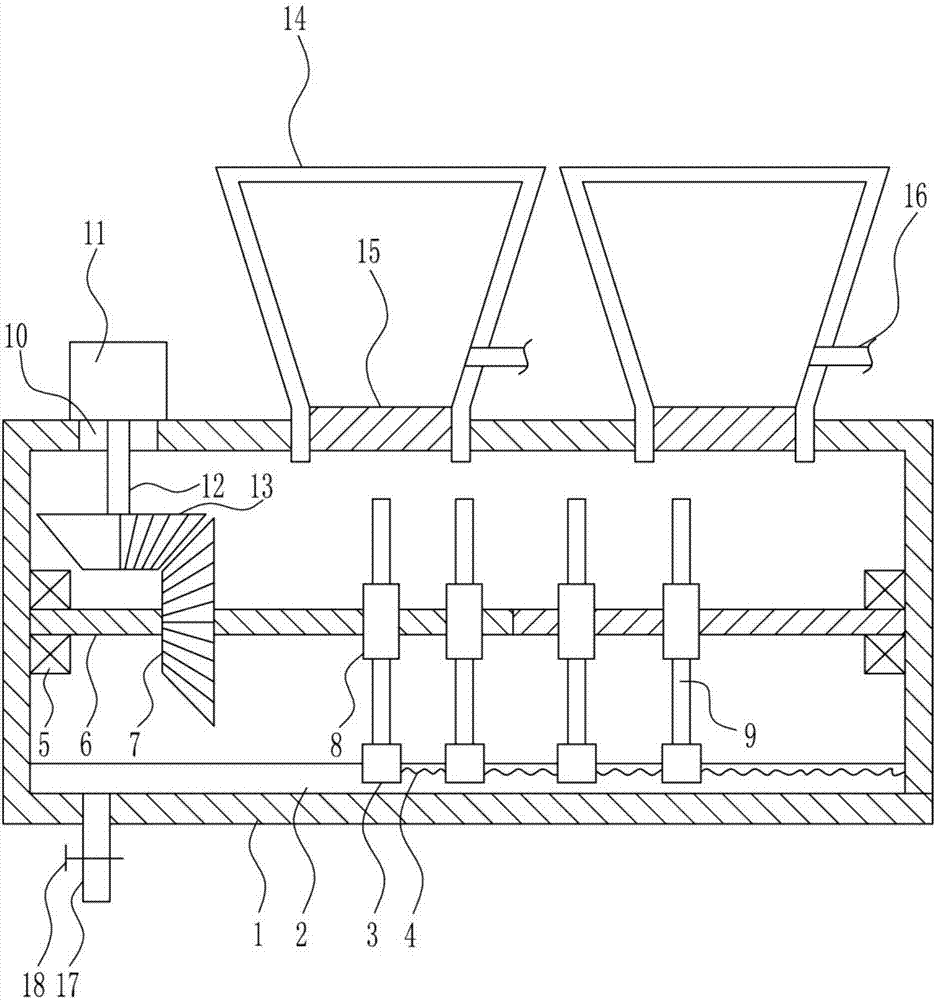

Energy-saving efficient cleaning device for aluminum scrap recovery

The invention relates to a cleaning device for aluminum scrap recovery, in particular to an energy-saving efficient cleaning device for aluminum scrap recovery. By the adoption of the energy-saving efficient cleaning device for aluminum scrap recovery, the technical purposes of simple structure, energy saving and high cleaning efficiency are achieved. For achieving the technical purposes, the energy-saving efficient cleaning device for aluminum scrap recovery comprises a bottom plate, a left frame, first guide sleeves, a supporting rod, a movable frame, a first movable rod, a motor, a tooth-missing gear, a first rack, a cleaning pool, a first connecting rod, a second connecting rod, a third connecting rod, a second movable rod, a top plate, a second guide sleeve, a bearing seat, a stirring rod, a rotary shaft, a cylindrical gear, a second rack, an electric push rod, blades, a water outlet pipe and an electric control valve. The first guide sleeves are symmetrically arranged on the right side of the top of the bottom plate. The first movable rod is mounted on the first guide sleeves. By the adoption of the energy-saving efficient cleaning device for aluminum scrap recovery, the effects of simple in structure, energy saving, and high cleaning efficiency are achieved.

Owner:沅陵县向华电子科技有限公司

Canned fruit processing equipment

ActiveCN111844217AEasy loadingEasy to processVegetable peelingMetal working apparatusCanned fruitTeeth missing

The invention relates to the field of food processing, in particular to canned fruit processing equipment. According to the technical scheme, the canned fruit processing equipment comprises a bracketand a moving mechanism, wherein a pushing mechanism is installed on the bracket, a discharging hopper is embedded on the side, away from the pushing mechanism, of the bracket, a pillar is installed atthe bottom of the discharging hopper, and a collection box is placed on the ground of the lower side of the discharging hopper; the moving mechanism is installed at the top of the bracket, a tooth missing gear is arranged on the moving mechanism, a rotating shaft V is rotatably arranged on the side, close to the tooth missing gear, of the bracket, a spur gear is installed on the rotating shaft V,and the spur gear is matched with the tooth missing gear. According to the equipment, fruit can be inserted on a fixing rod through the pushing mechanism, so that the fruit can be convenient to feed,and through the moving mechanism, a cutting knife can move backwards to peel the fruit, so that the fruit can be convenient to process.

Owner:砀山县胜华罐头食品有限公司

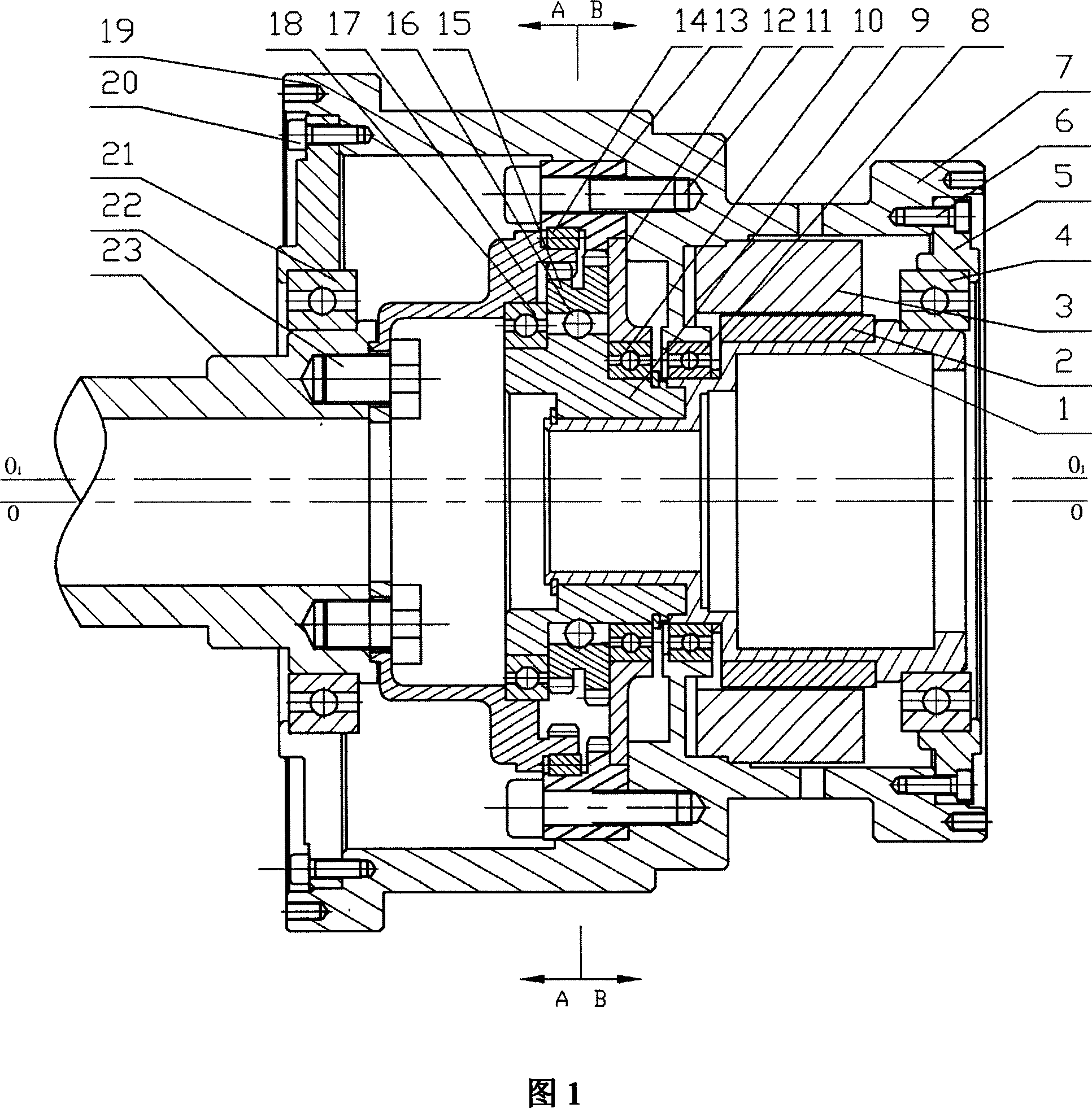

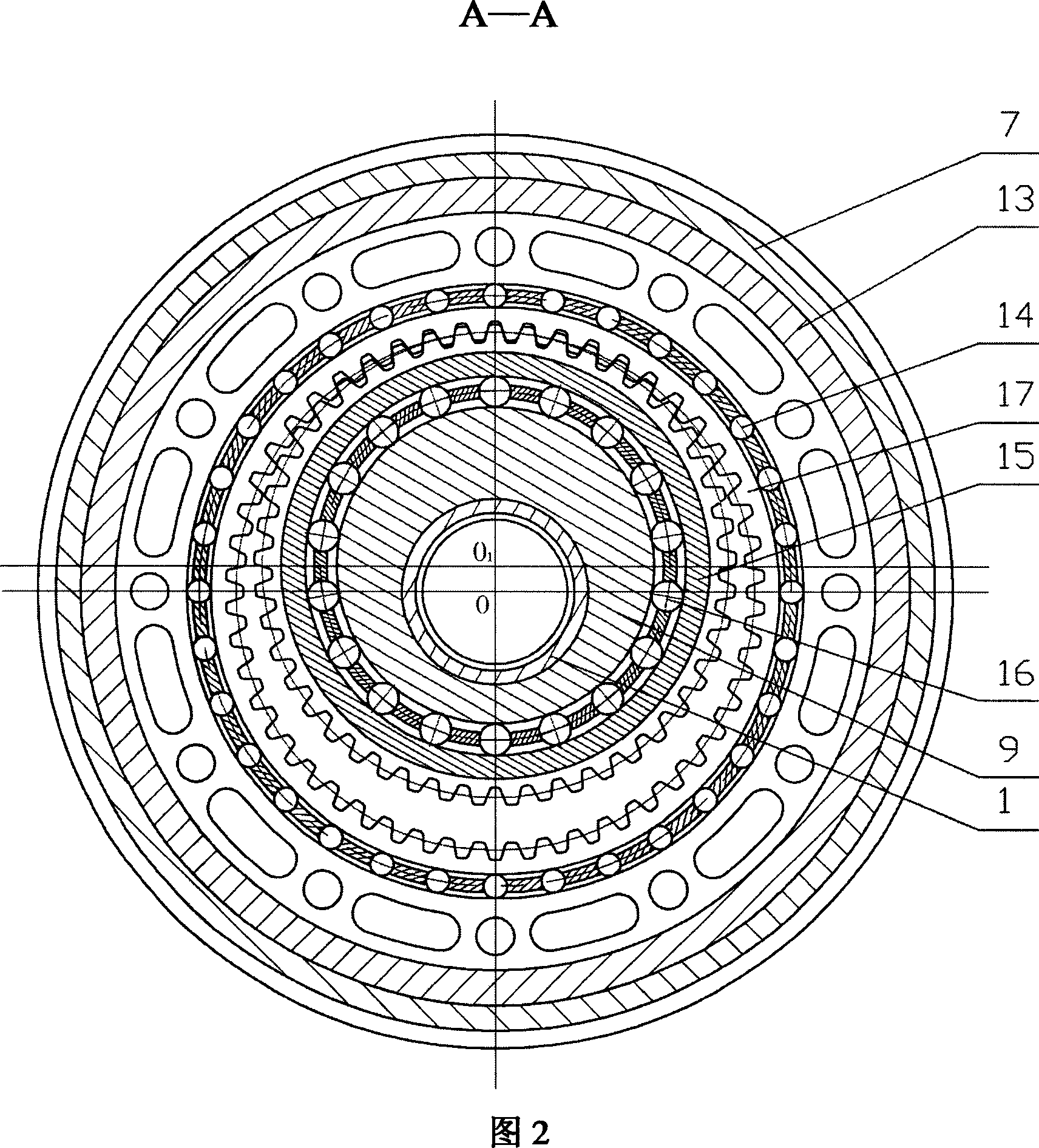

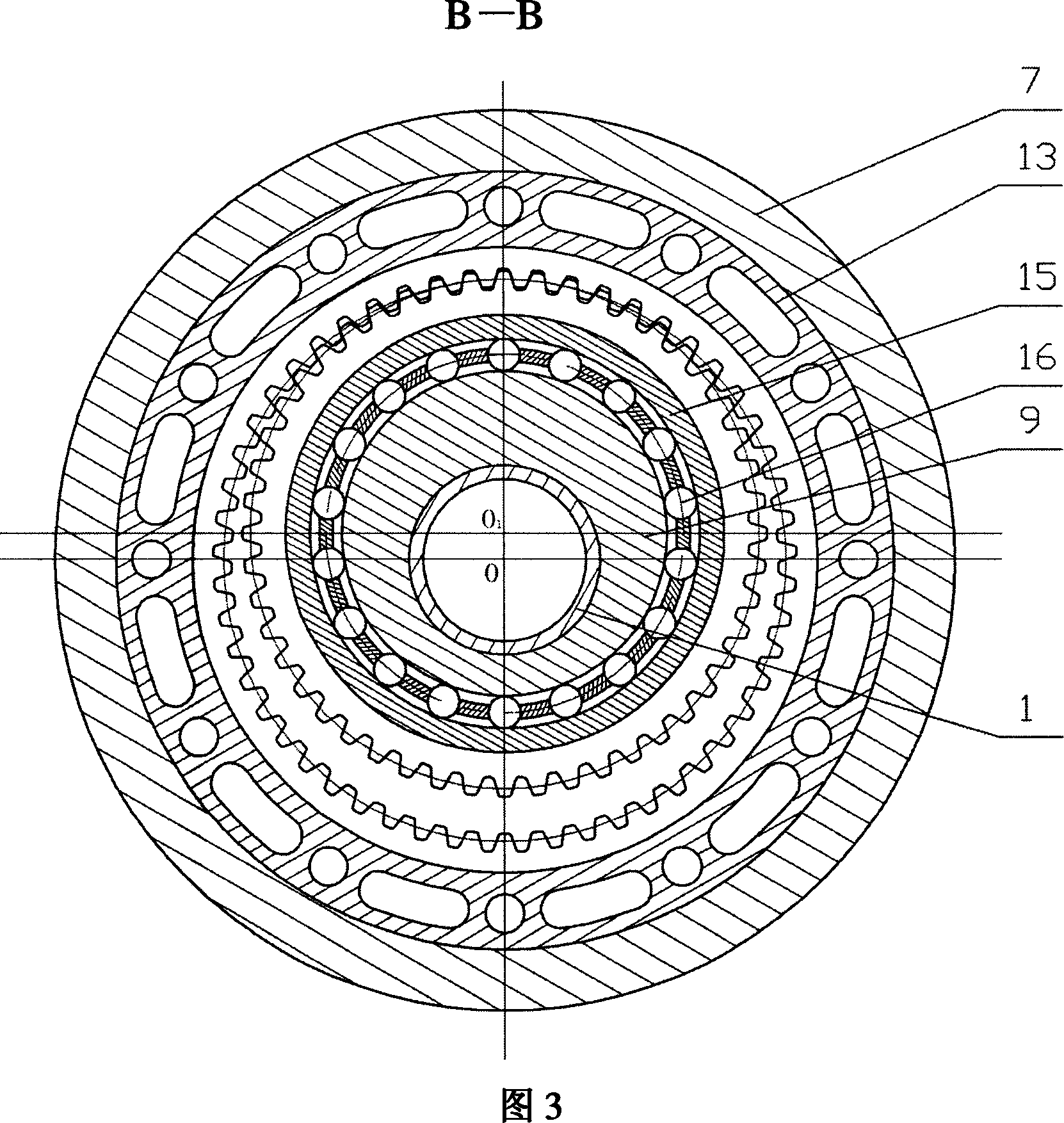

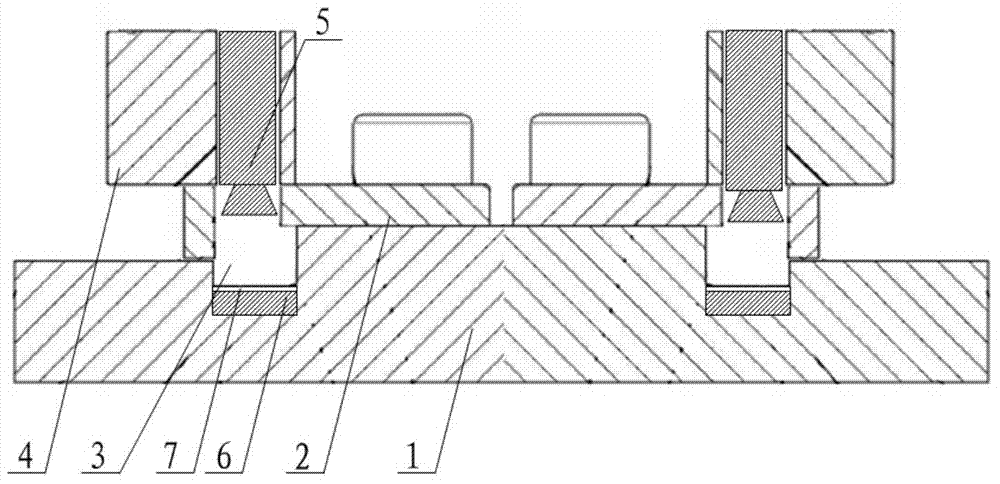

Solid lubrication precision wave filtering driving device

InactiveCN101042180AHigh precisionReduce energy consumptionGearingVacuum evaporation coatingWear resistantTeeth missing

It relates to a solid lubrication fine wave filter drive device. It integrates the design of the decelerator component, output drive mechanism and servo generator to ensure the precision drive on structural basis. The input dual gear can cause offset rotation through the offset cam, generating two teeth missing differential drive by the teething part of the fixed gear and the output gear. It has arc slot rolling movement channel and installed with bearing on the offset cam. The drive sub teething surface is coated with energy absorbing, noise reducing, wear resistant solid lubricant film with proper resilience to get rid of the stiffness of the structure. It has high precision, reliability, durability, big toque, low energy consumption, light weight.

Owner:CHONGQING UNIV

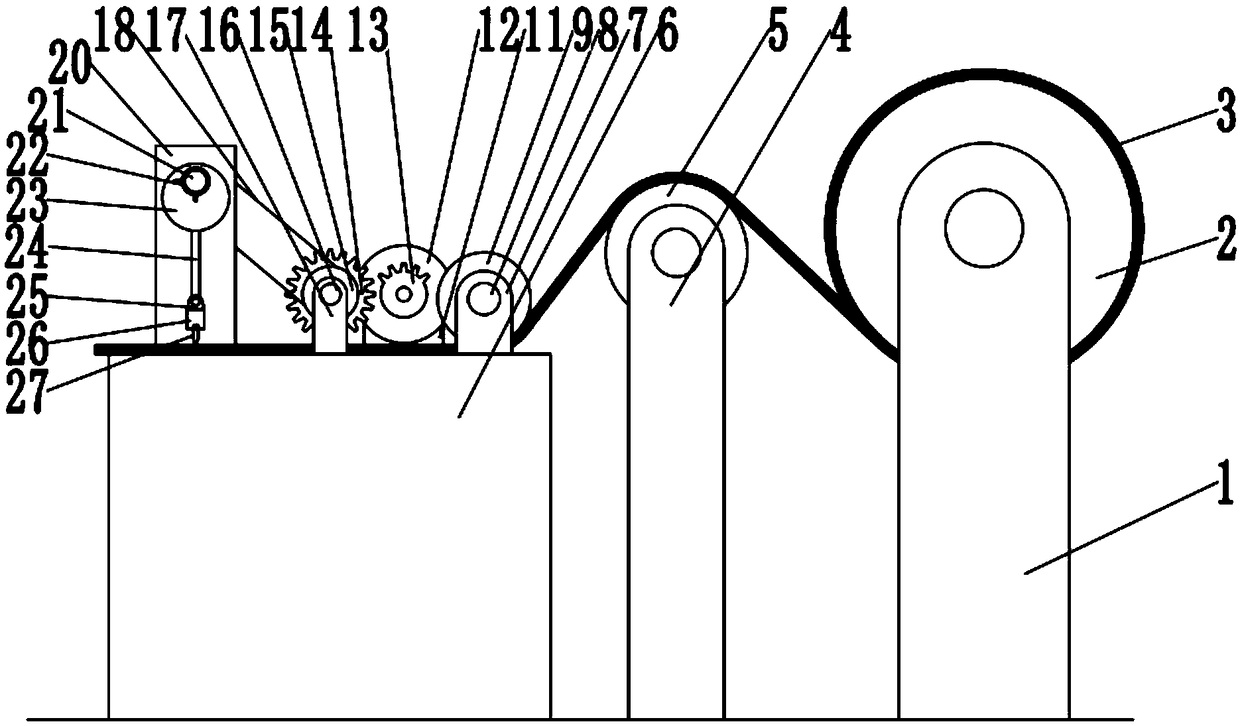

Novel automatic feeder

InactiveCN101844671AEasy to controlAccurate adjustment effectConveyorsLoading/unloadingGear wheelTeeth missing

The invention discloses a novel automatic feeder. A hopper is fixedly arranged at a proper position of a hopper base; a guide post is inserted into a hole of a rack bend part; an offsetting spring is sleeved on the guide post simultaneously; and a rack is arranged in a guide rail of a frame. Meanwhile, the right end of the guide post is fixed on the hopper base by a pin or screw; in the assembly, the smooth movement of the rack in the guide post and the guide rail is guaranteed; the offsetting spring is properly compressed simultaneously; and a material pushing plate is arranged under the conditions. A transmission shaft is arranged at a part where the moving direction of the frame is vertical to that of the rack; a teeth-missing gear and a driven chain are arranged on the transmission shaft in turn; the reliable engagement between the rack and the teeth-missing gear is guaranteed; meanwhile, after the engaged teeth are disengaged from contact, the rack can be rapidly and accurately reset under the action of the offsetting spring. A frequency conversion speed regulating motor, a driving chain wheel of the speed reducer and chains, and other transmission components are arranged.

Owner:郑合新

Open-Loop Control Method for Cancelling Engine Induced Noise and Vibration

InactiveUS20090133949A1Reduce and eliminate transferMinimizes error measurementAnalogue computers for vehiclesElectric propulsion mountingLoop controlControl signal

An open-loop control system that provides control signals to active engine mounts to reduce or eliminate the transfer of engine vibration to a vehicle body structure, where the system uses only a crank signal from the engine as an input. The control system includes an instant crank speed variation sensing processor that receives the crank signal from the engine, where the crank signal is a pulsed signal including missing pulses as a result of teeth missing on the vehicle crank wheel. The crank speed variation sensing processor provides a measurement of the instant crank speed variation of the crank signal and minimizes an error in the measurement as a result of the missing pulses. The crank speed variation sensing processor outputs a crank speed sensing variation signal as a sine wave that identifies order content in the crank pulse signal.

Owner:GM GLOBAL TECH OPERATIONS LLC

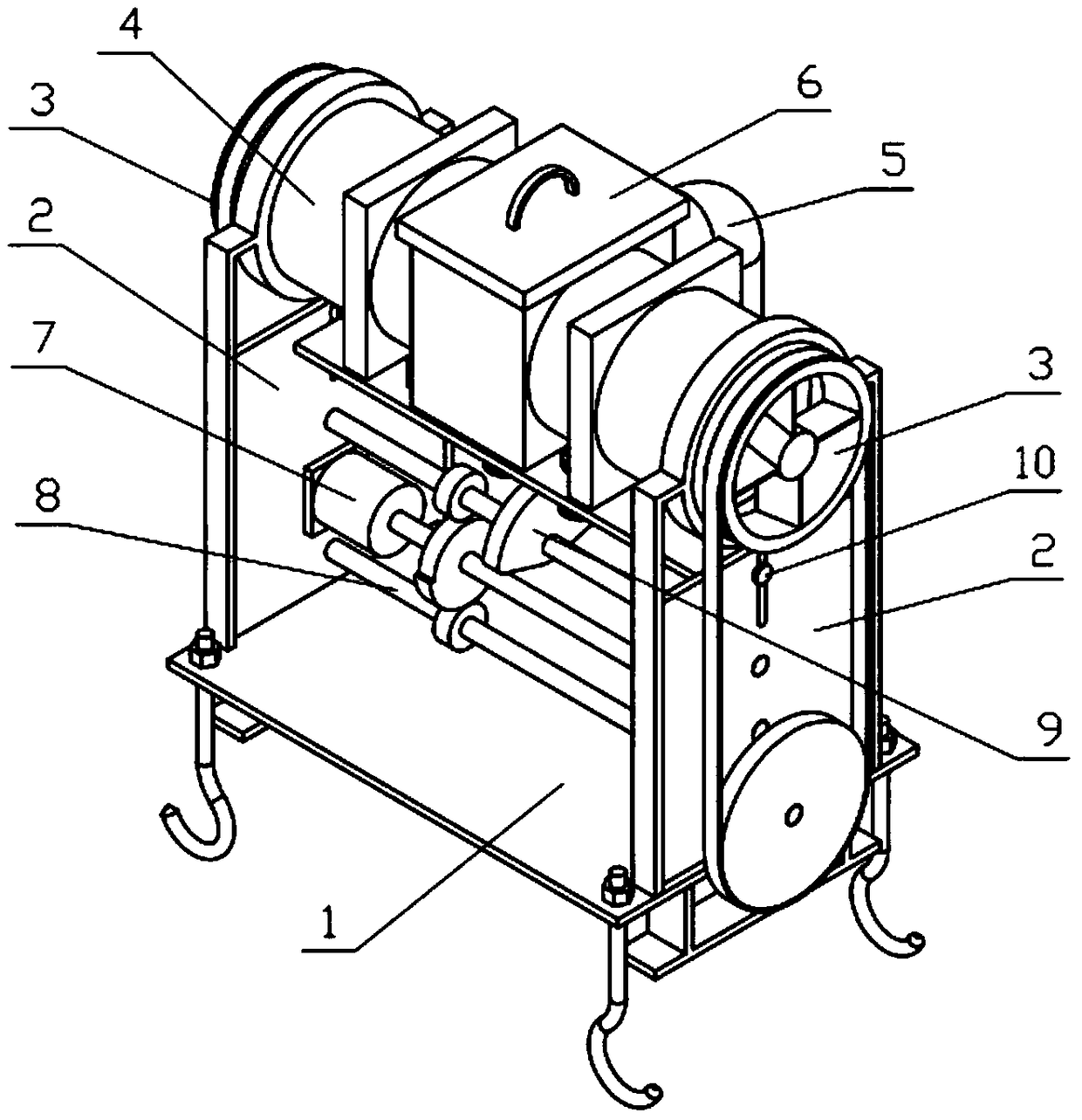

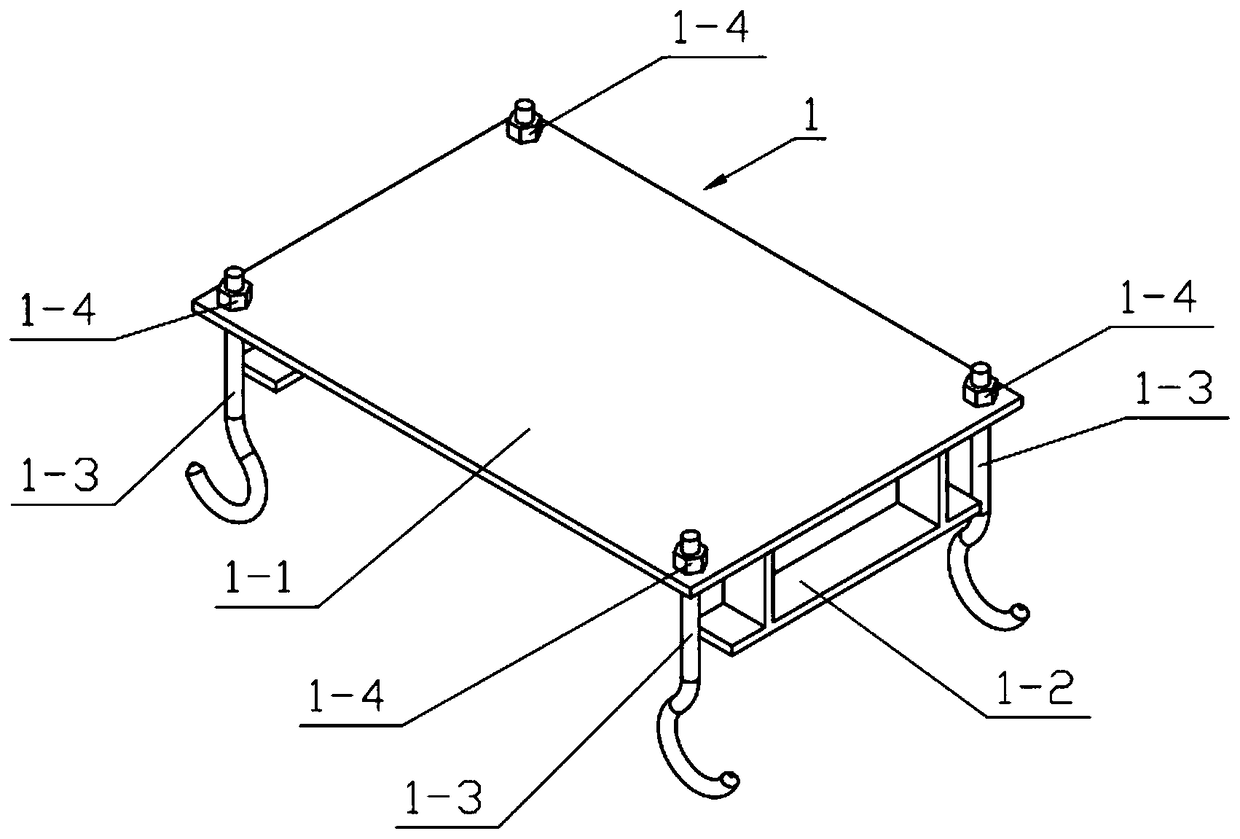

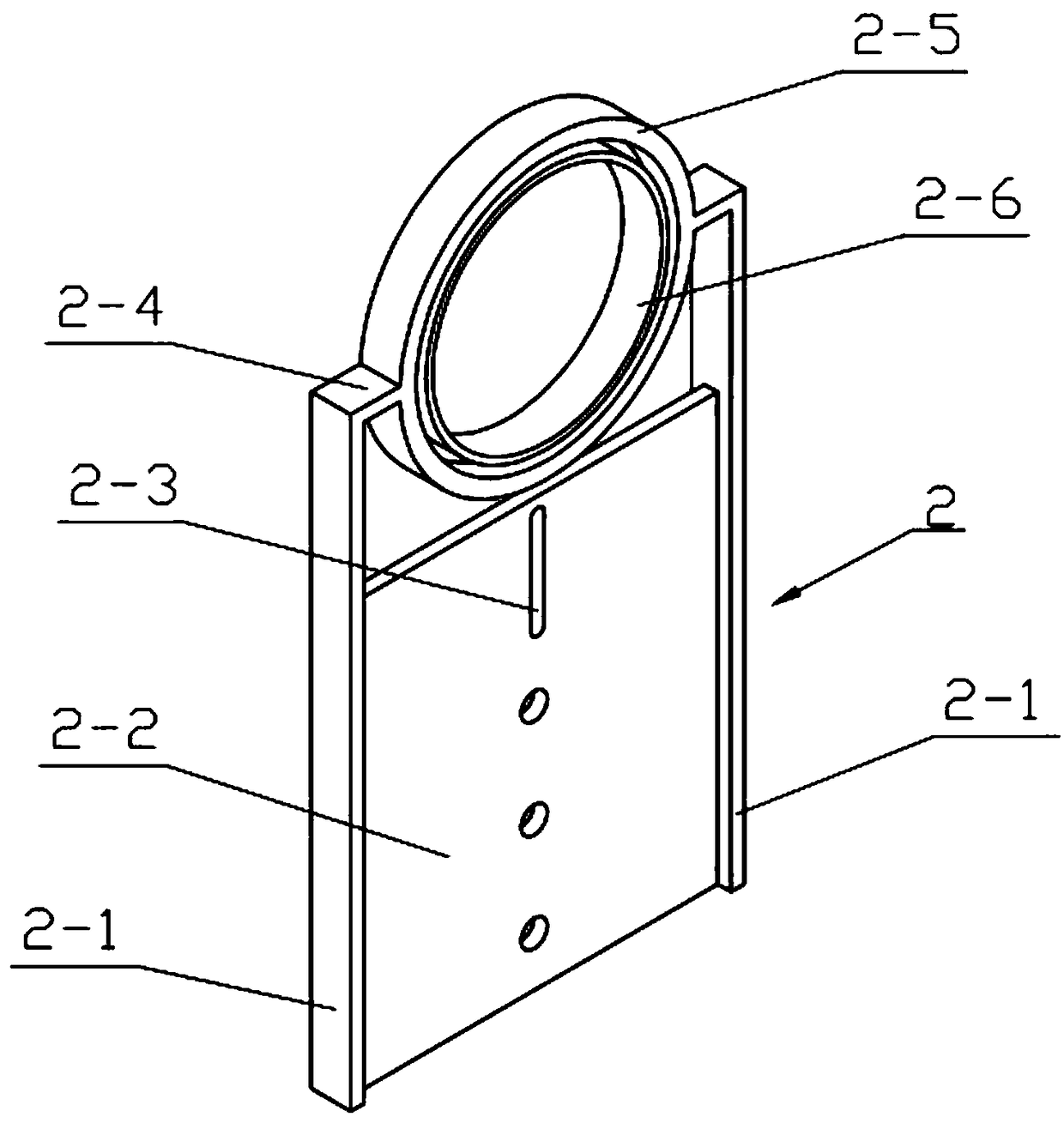

Energy-saving environment-friendly industrial waste gas treatment device

ActiveCN109046012AImprove purification efficiencyDispersed particle separationTeeth missingEnvironmental engineering

The invention relates to exhaust gas treatment devices and more particular relates to an energy-saving environment-friendly industrial waste gas treatment device. The energy-saving environment-friendly industrial waste gas treatment device comprises a bottom bracket, a supporting bracket, fans, a catalyzing tube, a heating pipe, a catalyst box, a power mechanism, a transmission mechanism, a pushing mechanism and a closing mechanism. Intermittent working of the transmission mechanism and the pushing mechanism can be achieved through a tooth-missing gear arranged on the power mechanism; when thetransmission mechanism works and moves, two fans are driven to suck industrial waste gases into the catalyzing tube, and the catalyst box is heated through being heated by the heating pipe so as to accelerate a reaction between a catalyst in the catalyst box and organic gases in the industrial waste gases; when the pushing mechanism works, two closing grooves are closed, a closed space is formedin the catalyzing tube, the catalyst in the catalyst box and the organic gases in the industrial waste gases have time for a full reaction, the organic gases in the industrial waste gases are thoroughly oxidated, and the purification efficiency of the industrial waste gases is increased.

Owner:广东水之源环保科技有限公司

Rapid automatic bagging machine

The invention discloses a rapid automatic bagging machine which is rapid, saves labor and is accurate in measurement. According to the technical scheme, the rapid automatic bagging machine is characterized in that a horizontal cylindrical rotary disc is installed in a storage hopper; a plurality of frame cavities are arranged on the outer edge peripheral line of the rotary disc; the outer edges of the left and right sides of the rotary disc are close to the inner side of the storage hopper; a loading bag is installed on a movable frame below a lower discharging port of the storage hopper; a transmission shaft in the center of the rotating disc is provided with a transmission wheel or a manual rotary disc and a tooth-missing gear; blanks as many as the frame cavities on the outer edge peripheral line of the rotary disc are reserved on the outer edge of the gear, and teeth on the tooth-missing gear are engaged with teeth on a rack on the movable frame below the tooth-missing gear. According to the acting principle, during rotation of the rotary disc, the frame cavities are loaded with materials when moving upwards and unloads the materials into the loading bag when moving downwards, at that time, the blanks on the tooth-missing gear are opposite to the rack, and the movable frame stops. Afterwards, engagement of the gear and the rack is carried out movably and alternately.

Owner:HEZE ZHONGHEJIANYUAN BIOLOGY TECH CO LTD

Two-way cooling type fan

ActiveCN105370604AStable and effective air coolingEfficient air coolingPump installationsNon-positive displacement fluid enginesTeeth missingDrive motor

The invention relates to a two-way cooling type fan which mainly comprises a chassis base, wherein the right side of the chassis base is hinged with a movable rack; a drive motor is fixedly mounted on the movable rack; the motor is connected with a main rotary shaft; the front end of the main rotary shaft is provided with a fan; a shaft sleeve which is welded on the movable rack is connected on the main rotary shaft in a sleeving mode; the left end of the shaft sleeve is hinged with a long connecting rod; the left end of the long connecting rod is fixedly connected with a rack; the lower end of the rack is provided with a front base table for mounting the rack in a horizontal direction in a sliding mode; a gear I is engaged on the rack; a gear II which is coaxial with the gear I is arranged behind the gear I; the upper end of the gear II is engaged with a teeth-missing gear; the lower end of the gear II is engaged with a teeth-missing ring; a gear III and the teeth-missing ring are jointly connected with a main mandrel on axe positions; and the main mandrel is connected with a transposition motor. The two-way cooling type fan can be used for sequentially controlling the fan to deflect leftward, deflect rightward and stop respectively, so that effect of carrying out air cooling on two pieces of processing machinery is achieved. The two-way cooling type fan can be used for remarkably improving air-cooling efficiency.

Owner:ANHUI PULUN INTELLIGENT EQUIP CO LTD

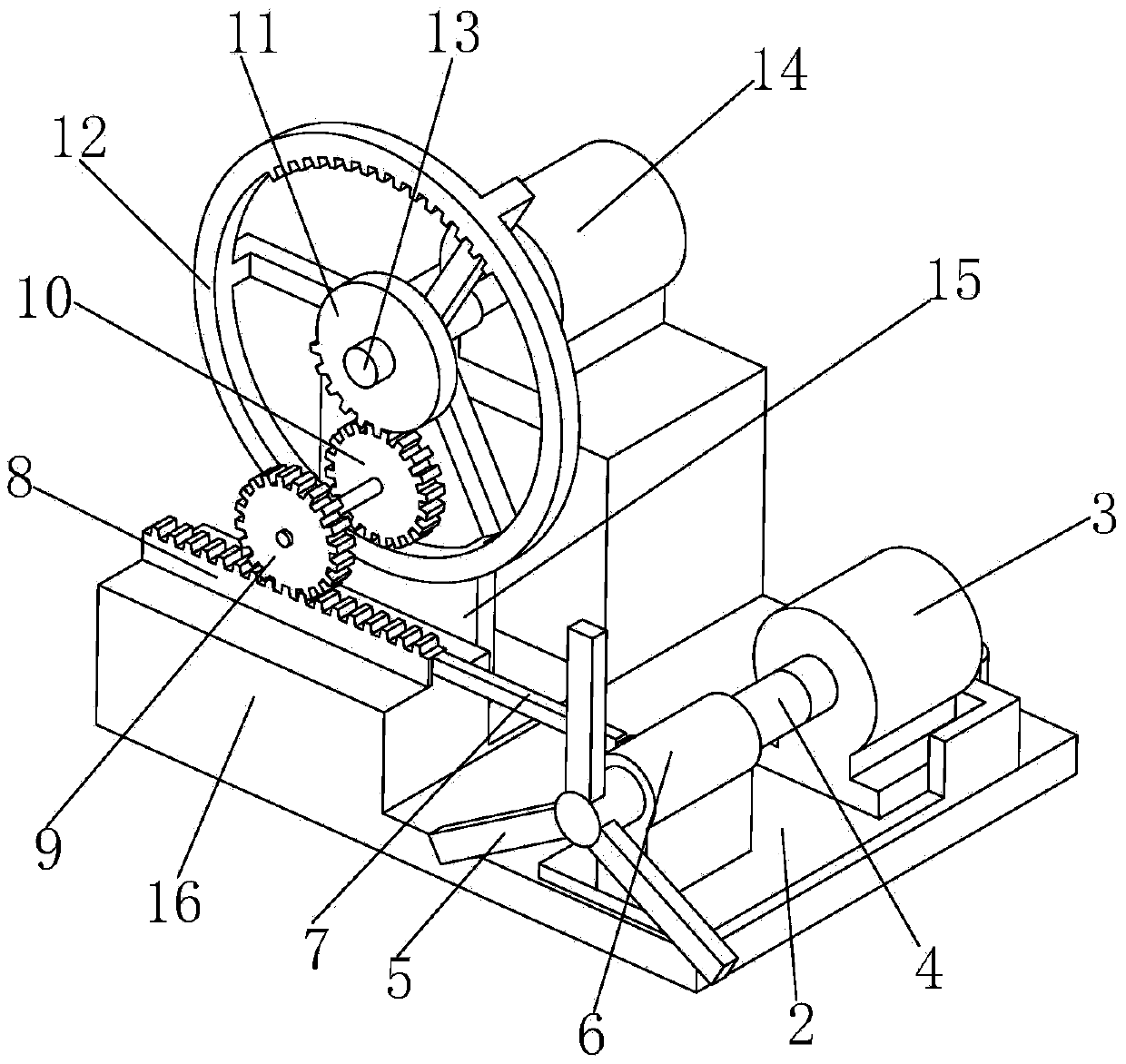

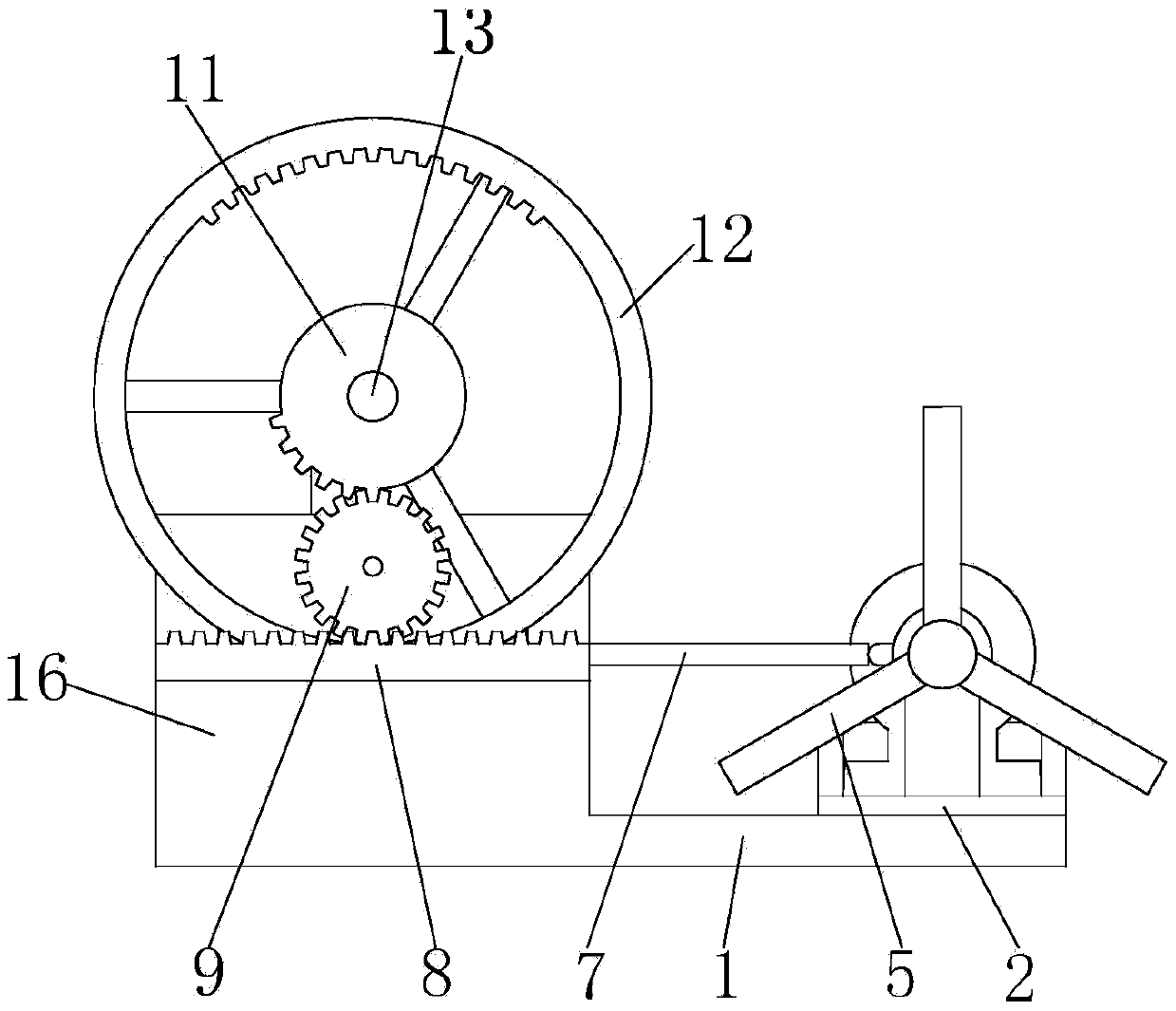

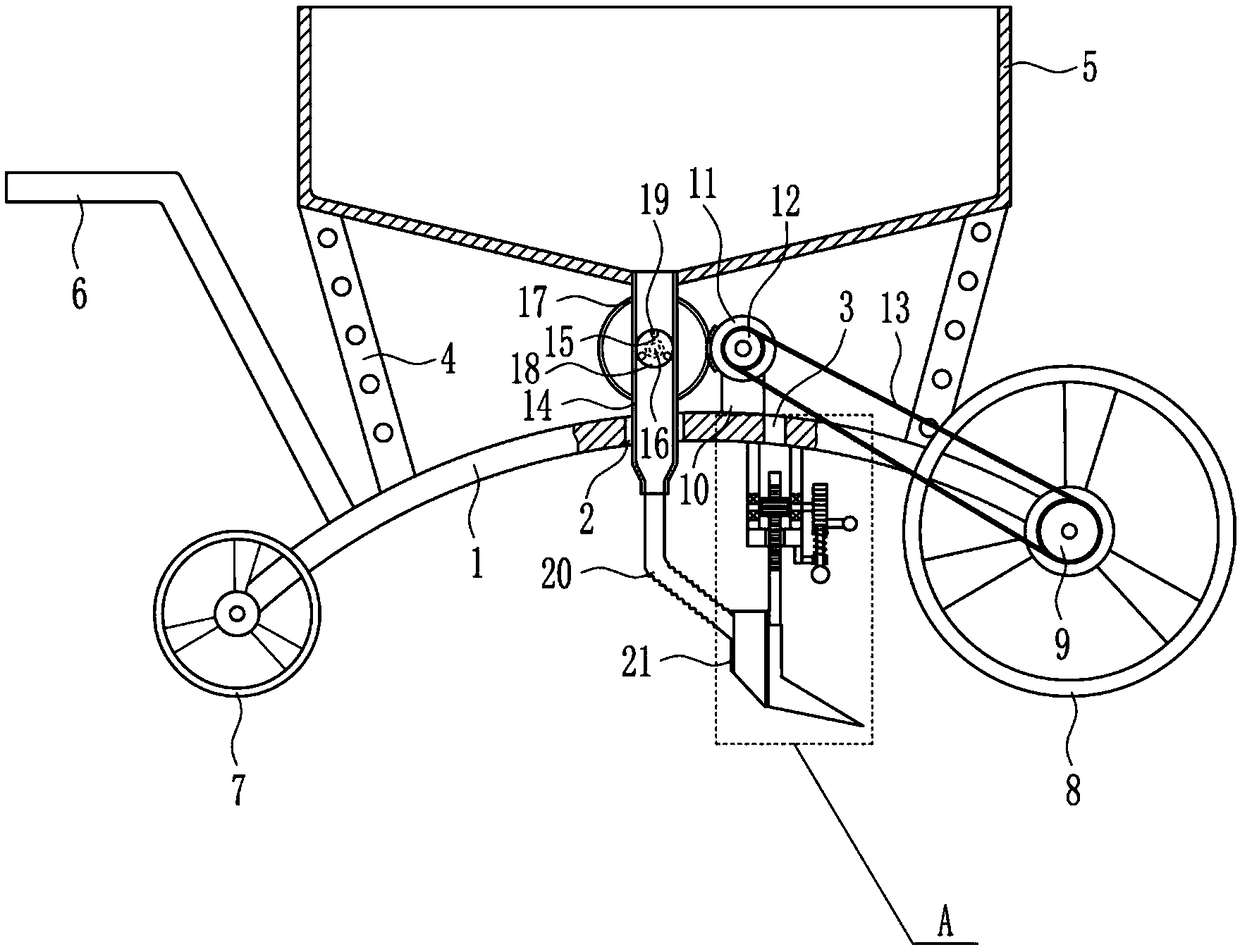

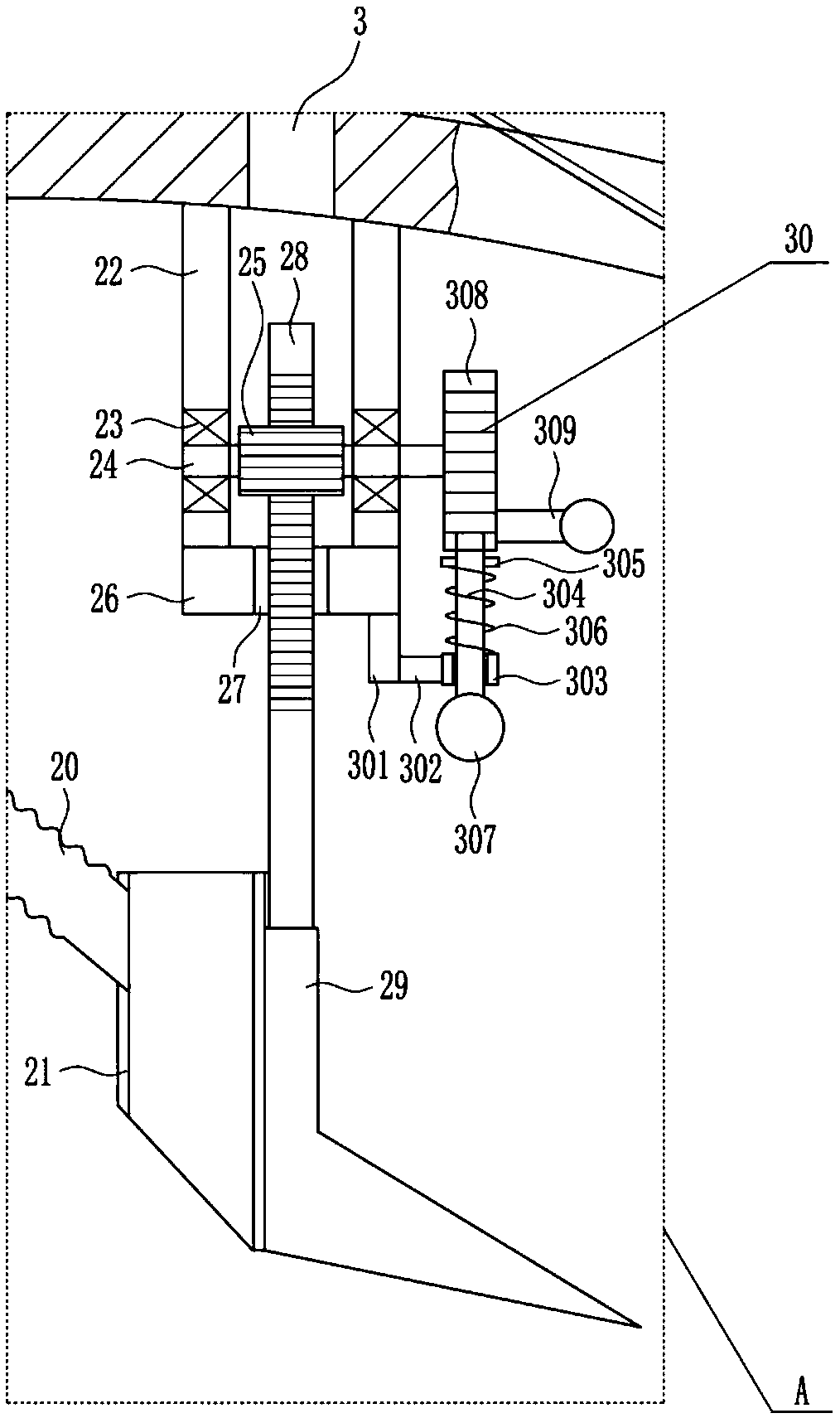

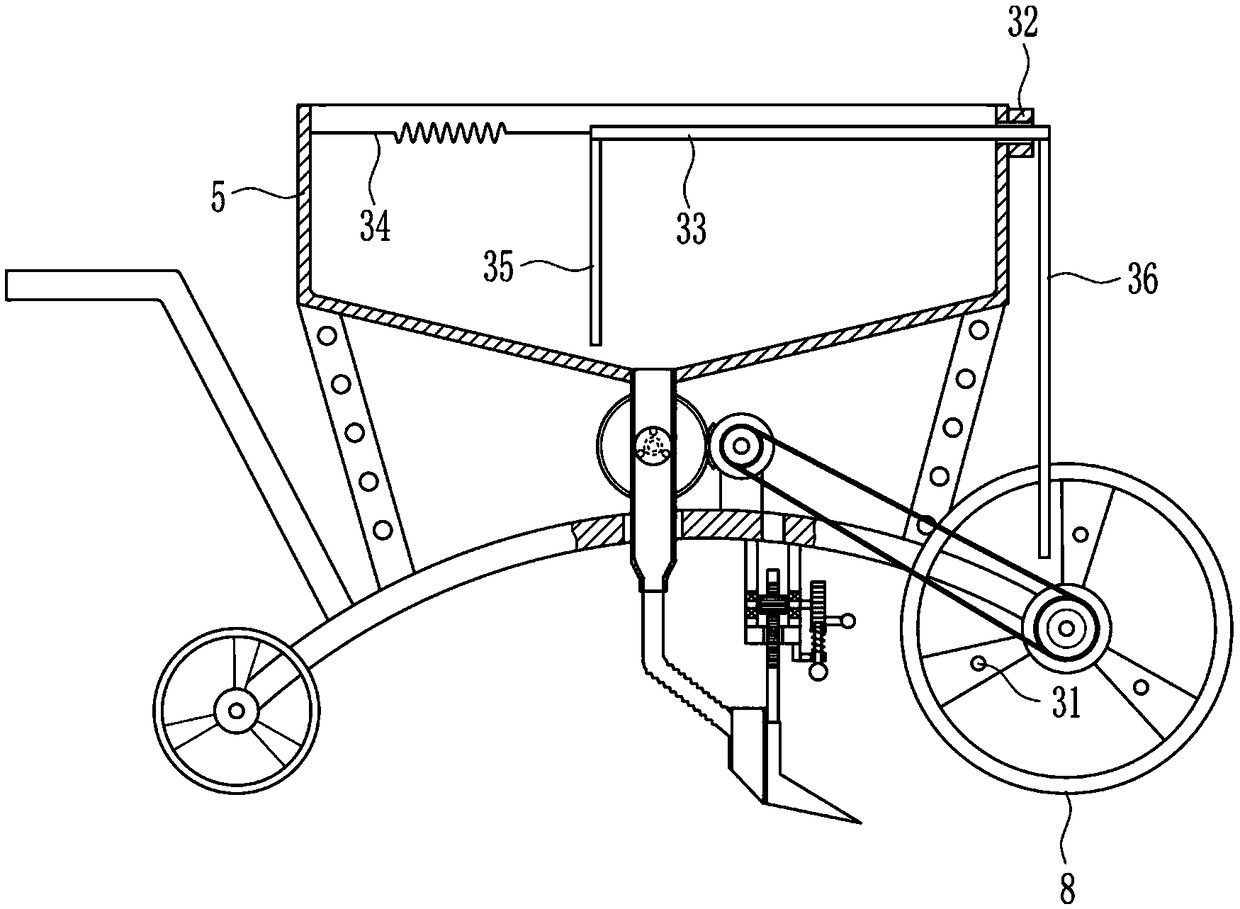

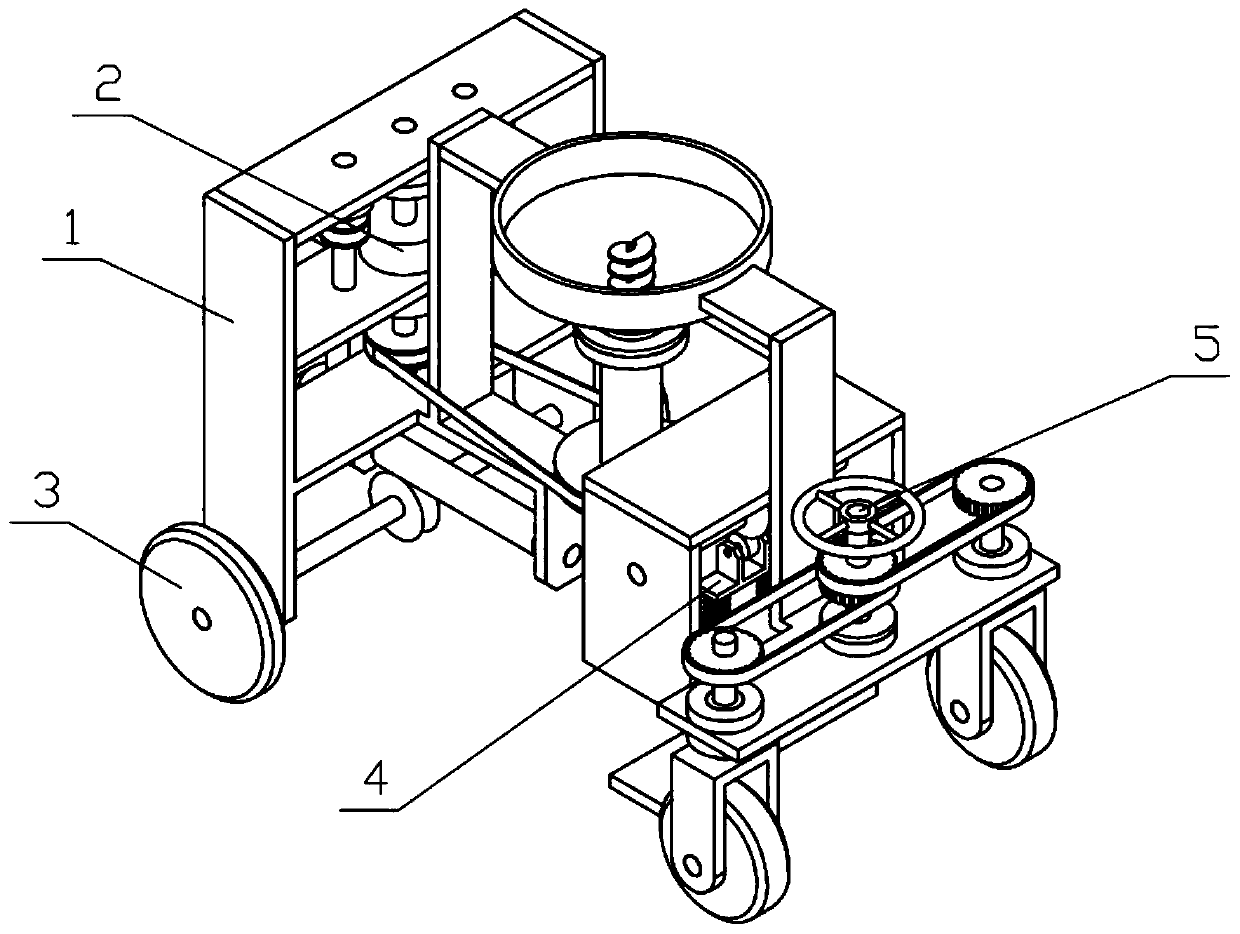

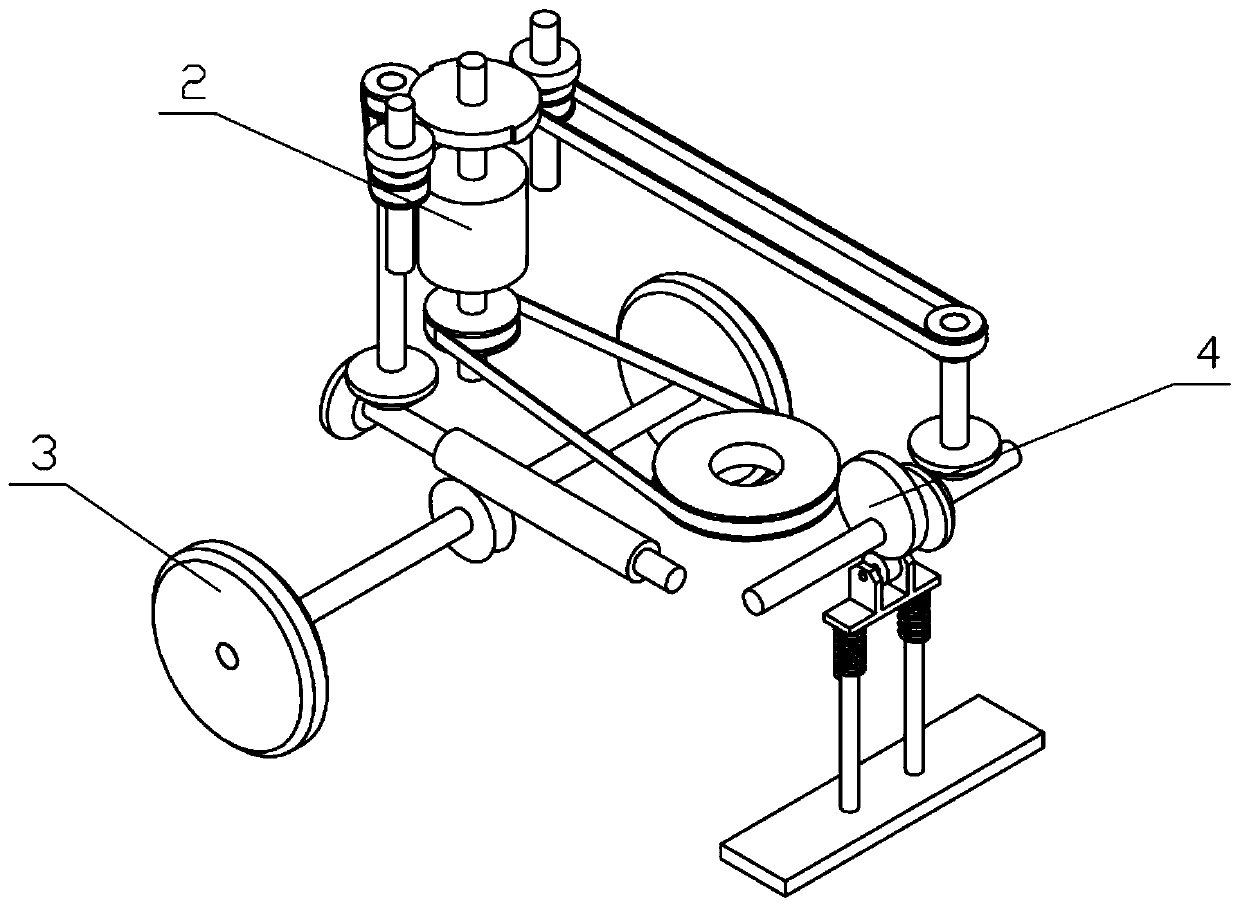

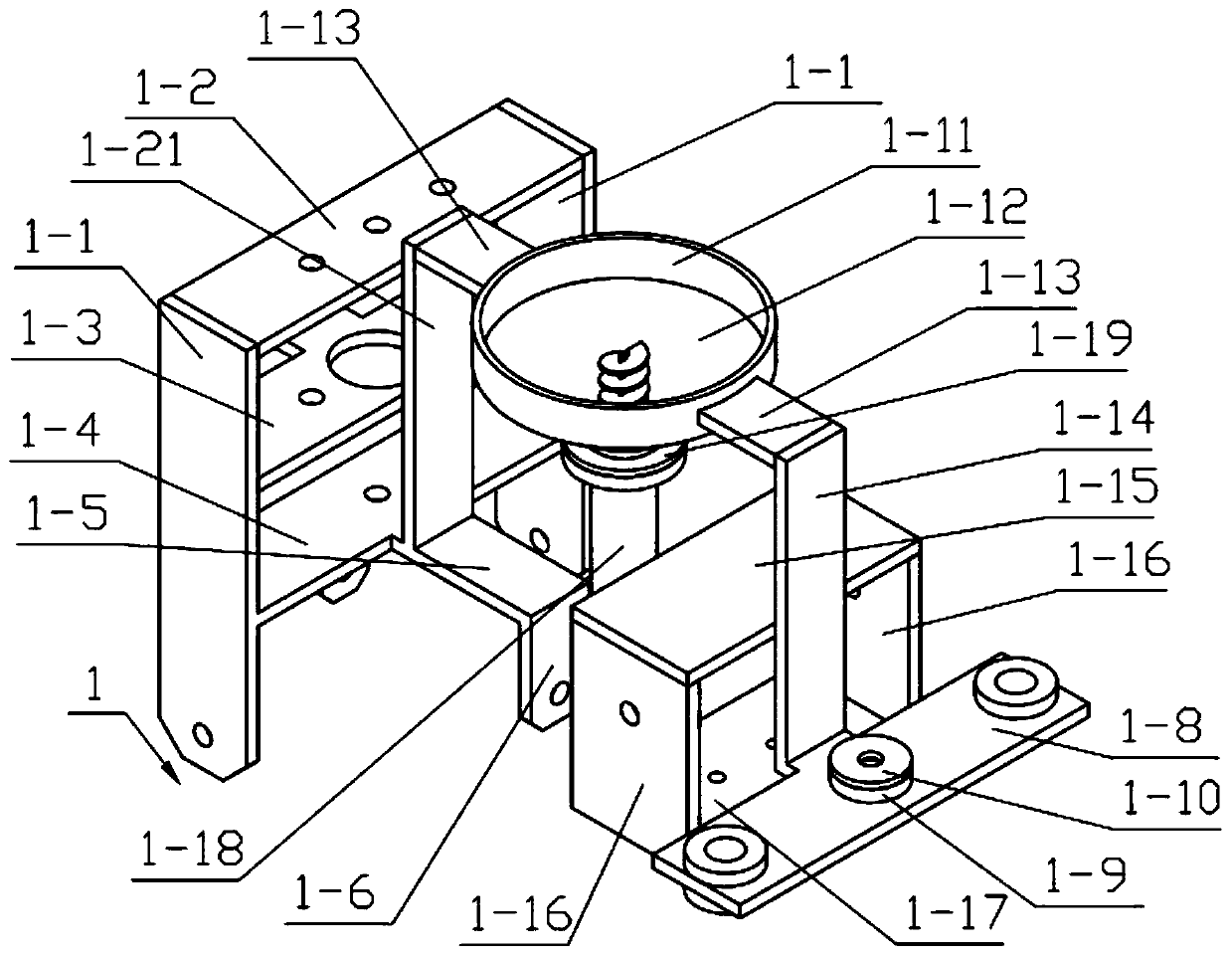

Manual mung bean dibbling machine

ActiveCN108811609APrevent movementPrevent rotationPlantingFurrow making/coveringTeeth missingWater storage tank

The invention belongs to the technical field of agricultural planting machinery and in particular relates to a manual mung bean dibbling machine. Aiming at solving the technical problems, the invention provides the manual mung bean dibbling machine which can reduce the labor intensity and can improve the dibbling efficiency. According to the technical scheme, the manual mung bean dibbling machinecomprises a support, supporting plates, a water storage tank, a handle, a first vehicle wheel, a second vehicle wheel, a first belt wheel, a mounting plate, a tooth-missing gear, a second belt wheel,a flat belt and the like, wherein a through a hole is formed in the middle of the support; a first guide hole is formed in the support at the right side of the through hole; the two supporting platesare connected at the top of the support and the water storage tank is connected between the tops of the two supporting plates. According to the manual mung bean dibbling machine provided by the invention, a shovel plate is rightward driven to move rightward; the shovel plate moves rightwards and a groove can be formed on the land; a round block rotates intermittently and intermittent dibbling canbe realized, so that manual grooving is not needed and manual dibbling is not needed, and furthermore, the labor intensity can be reduced and the dibbling efficiency can be improved; a pulling block moves rightward and mud can be leveled, so that mung beans can be covered with the soil.

Owner:周应发

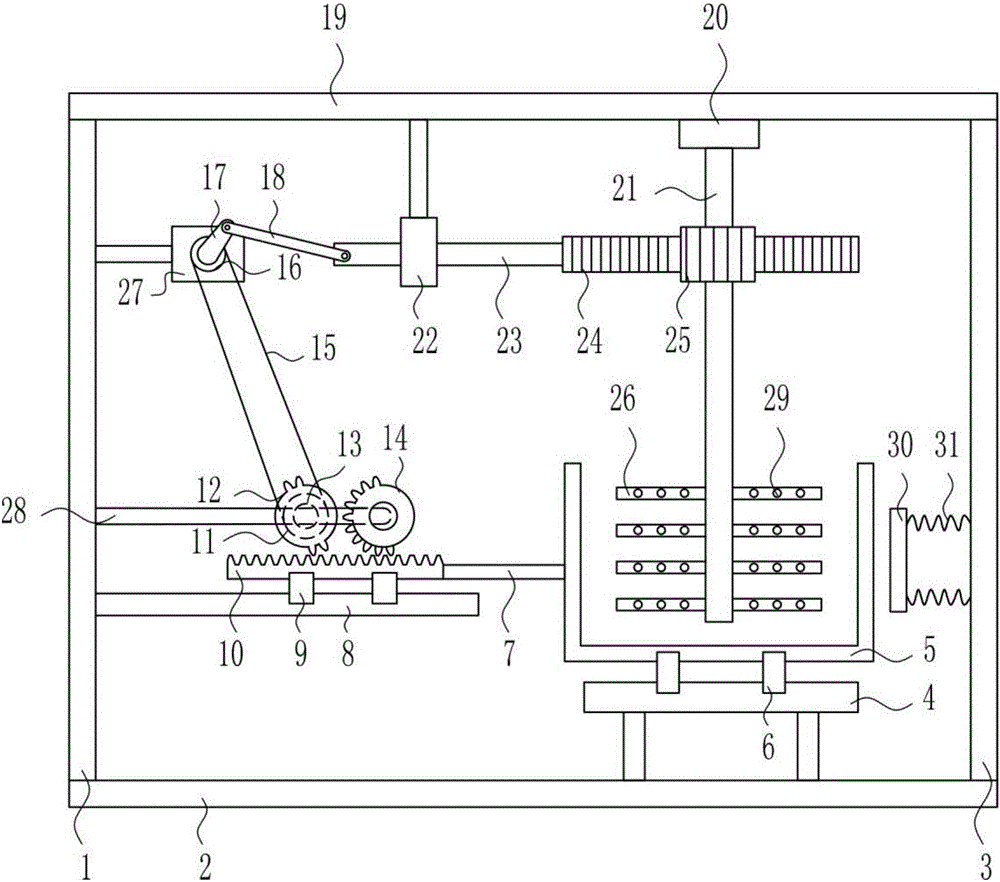

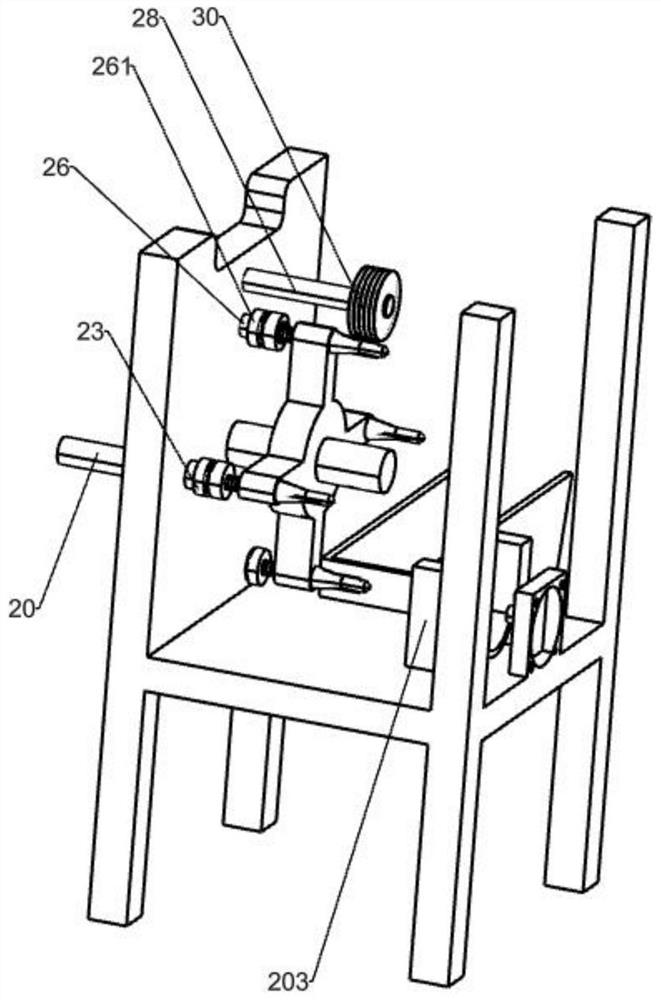

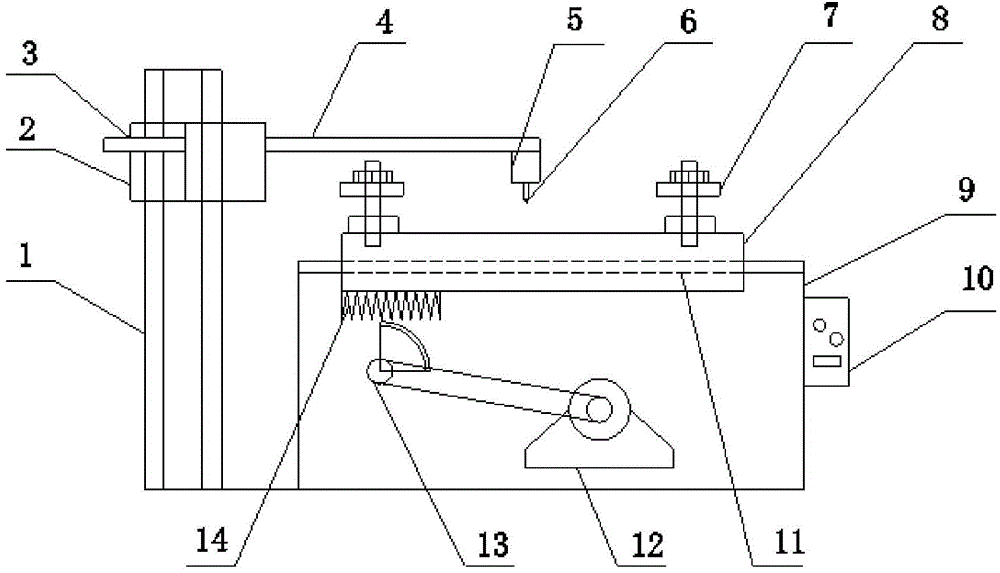

Workpiece punching device

InactiveCN104923830AAvoid displacementControl to move left and rightAutomatic control devicesFeeding apparatusPunchingTeeth missing

The invention discloses a workpiece punching device which comprises a support, a vertical slide block, a circular rod, a first electric motor, a threaded drill bit, a fixing device, a working table, a machine frame, a control device and a second electric motor. The support is arranged on the left side of the machine frame. The vertical slide block is installed on the support and provided with a transverse slide block. The circular rod is installed on the transverse slide block. The second electric motor is arranged on the circular rod. The working table is installed on the machine frame through a guide rail. The fixing device is installed on the working table. A tooth-missing gear corresponding to a gear groove is arranged on the machine frame. The control device is electrically connected with the first electric motor and the second electric motor through input, and therefore the procedures of the working table and the threaded drill bit can be effectively distributed without disorder; due to the fixing device, it is effectively avoided that when displacement happens to a workpiece in the punching process, deviation happens during punching.

Owner:张伟飞

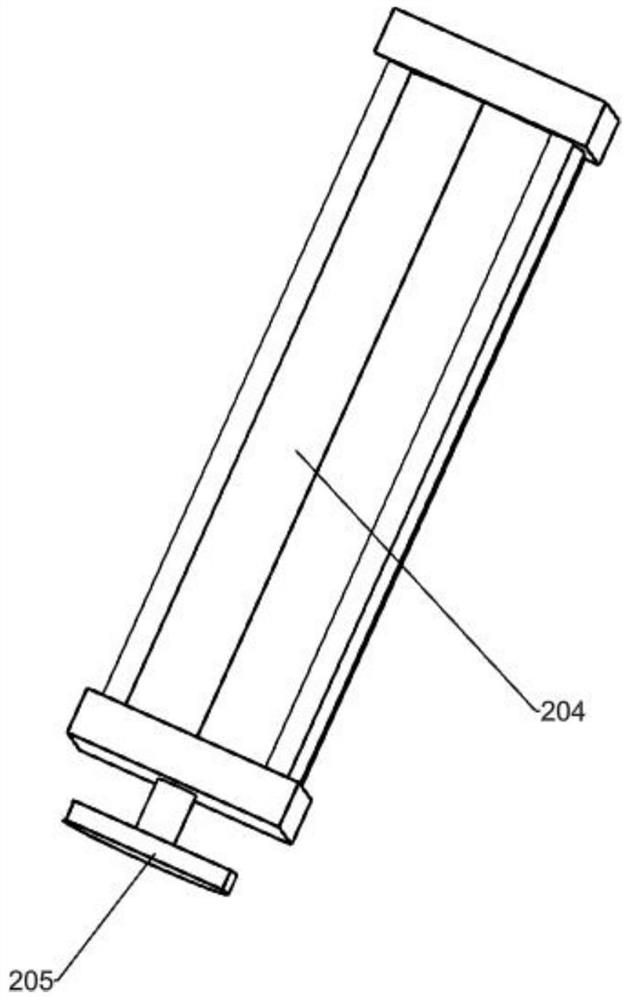

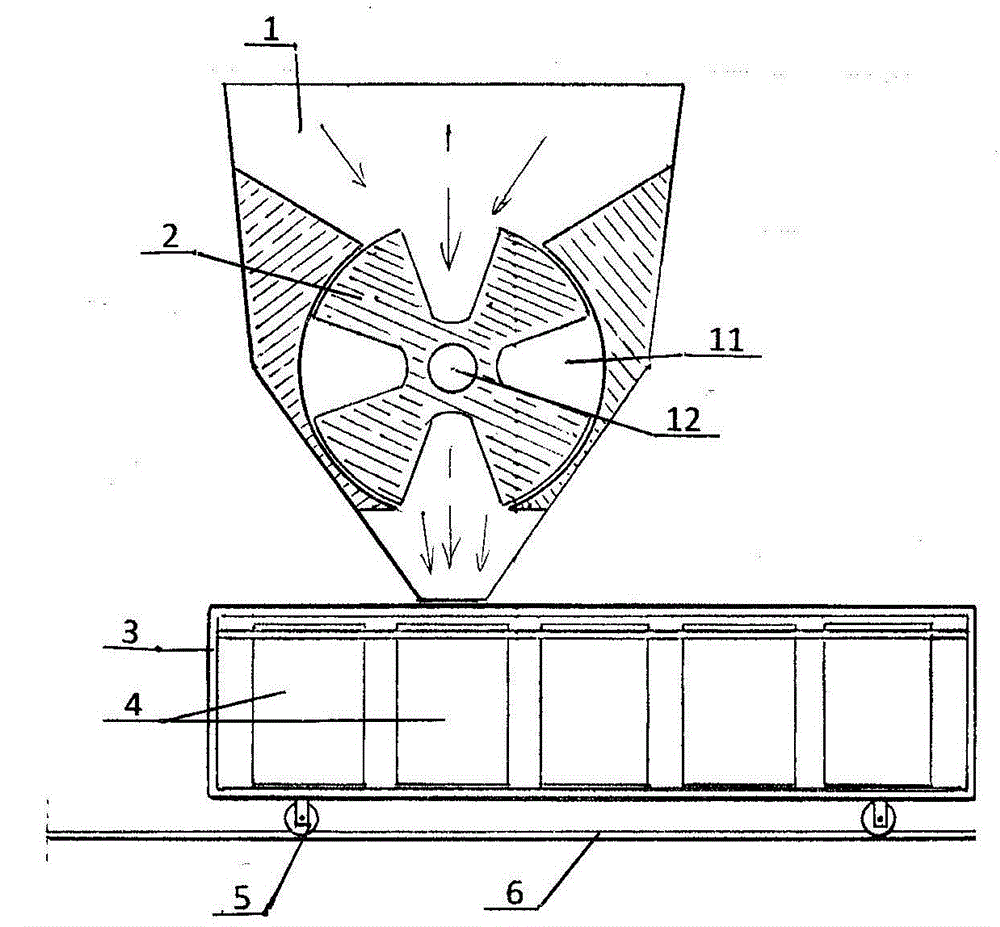

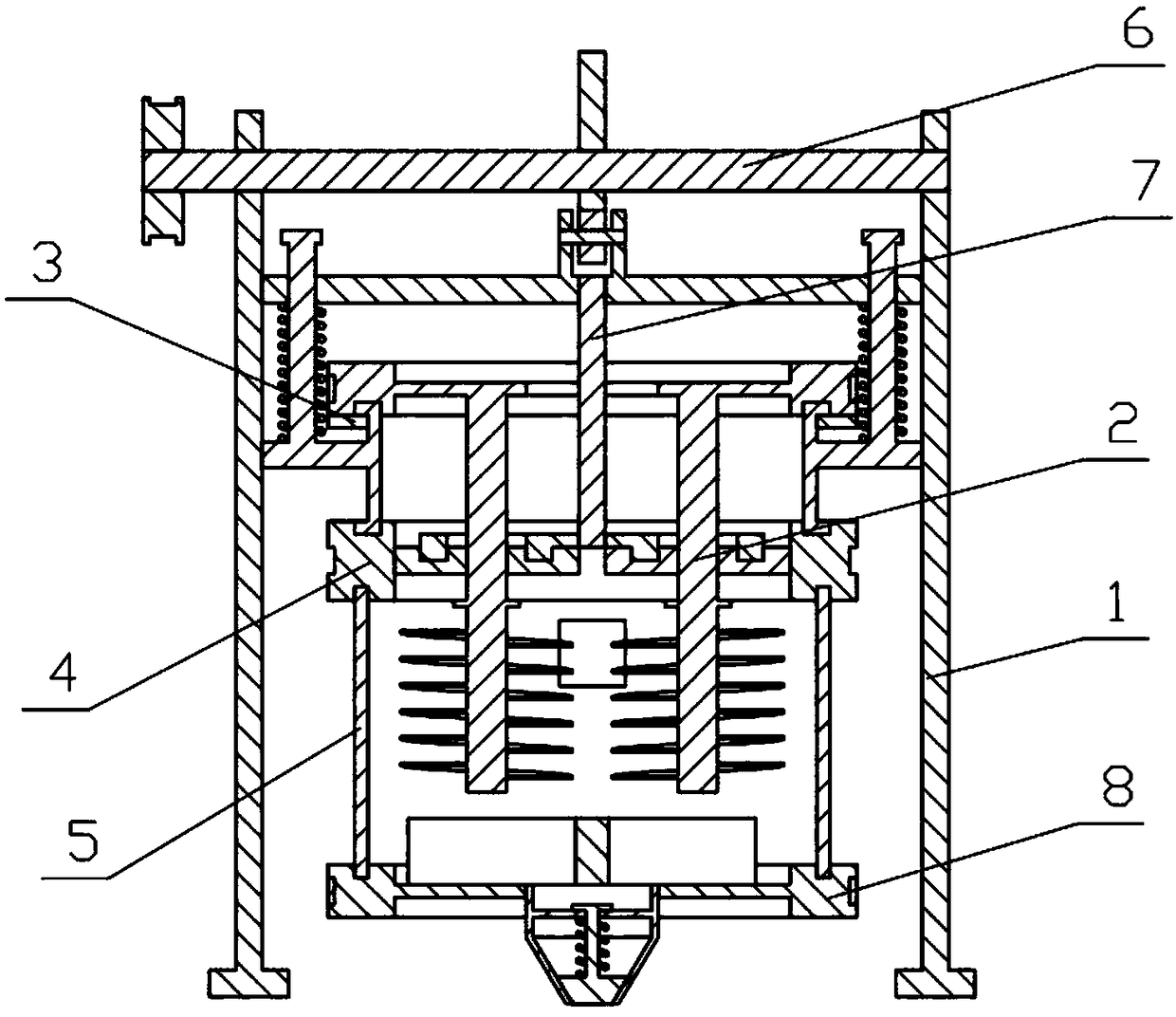

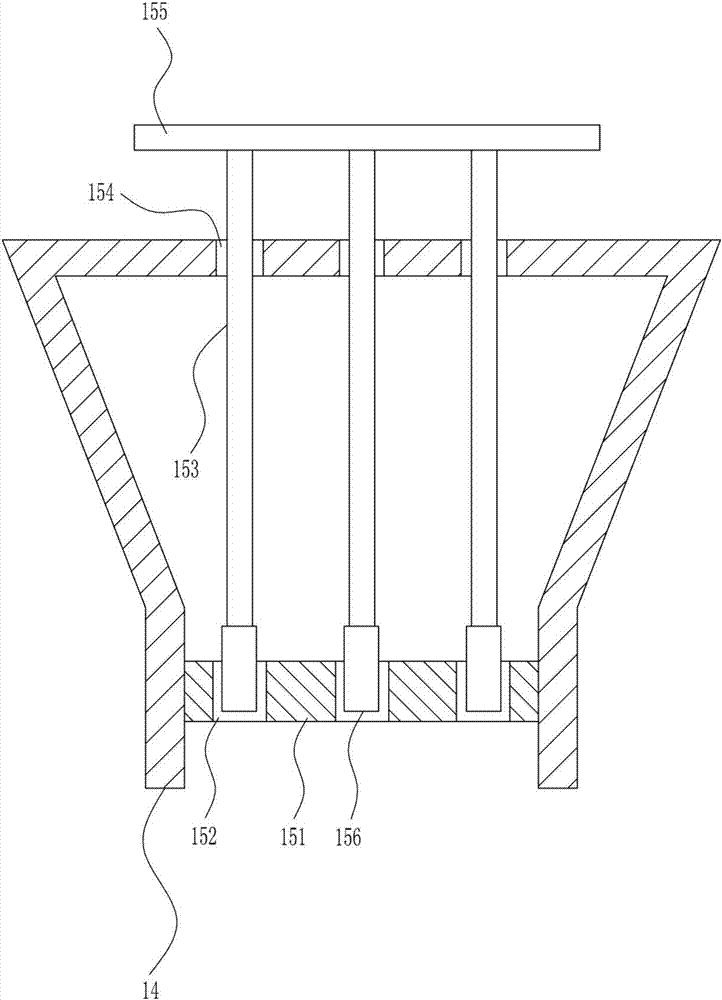

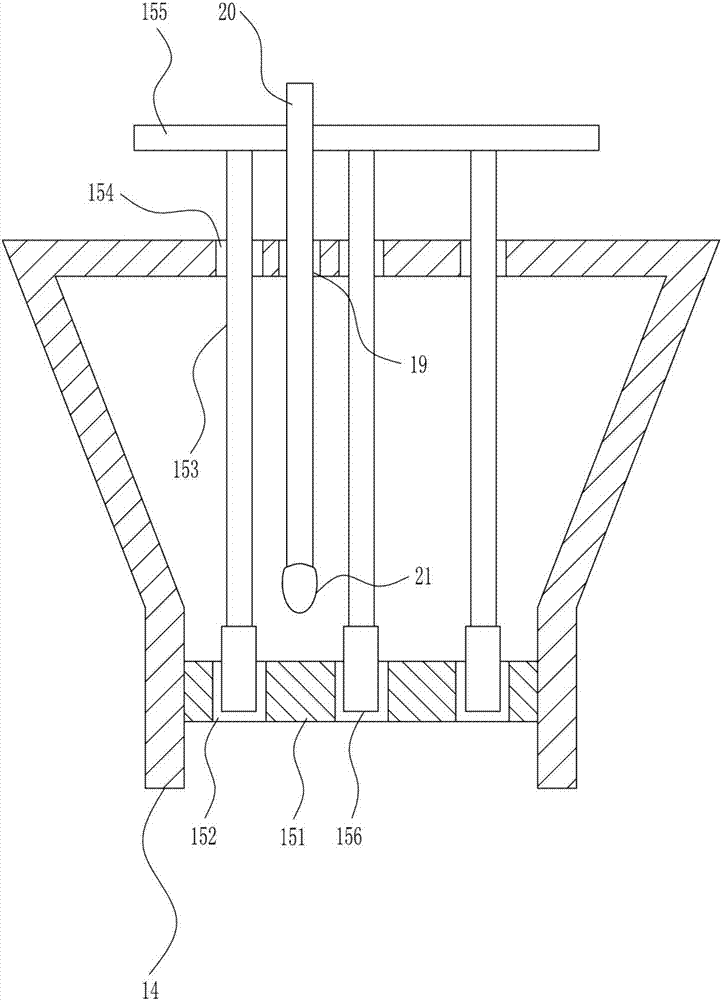

Power ultrasonic-assisted feeding device for soil remediation device

InactiveCN109772866AMeet the needs of useContaminated soil reclamationIntermittent motionUltrasonic assisted

The invention relates to a feeding device, and more particularly to a power ultrasonic-assisted feeding device for a soil remediation device. The feeding device comprises an overall bracket, a power mechanism, a moving mechanism and an extrusion mechanism. A motor moves intermittently through a teeth missing gear, a power gear I and a power gear II of the moving mechanism; when the teeth missing gear and the power gear I are in engaging transmission, the teeth missing gear and the power gear II exit the engaging transmission; the power gear I rotates to drive the moving mechanism to move, themoving mechanism drives the device to move, the power gear II rotates to drive the extrusion mechanism to move, the extrusion mechanism extrudes soil through an ultrasonic extrusion plate, the ultrasonic extrusion plate emits ultrasonic waves to oscillate the soil, a feeding pulley is driven by the motor to drive a feeding threaded body in a feeding rotating tube to rotate, the soil in a conical storage bucket is transported to the ground, and the device is controlled by a steering mechanism to steer so as to meet more usage requirements.

Owner:HEILONGJIANG LANDE ULTRASONIC TECH CO LTD

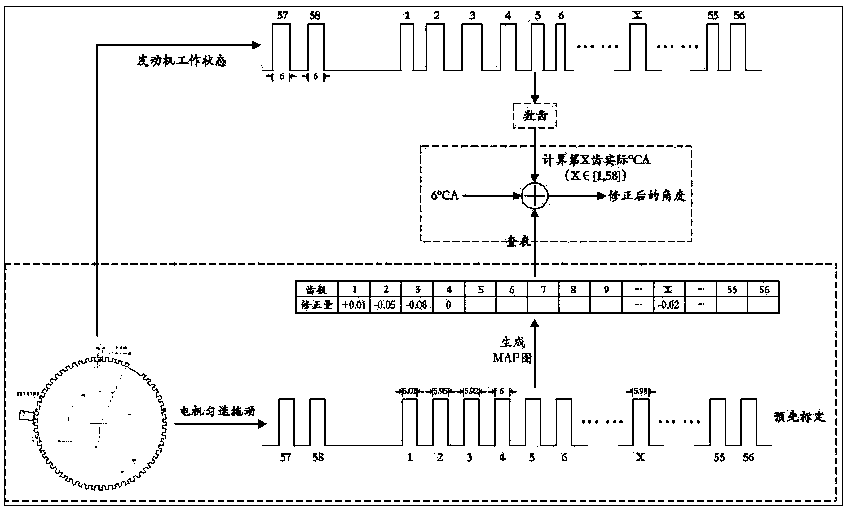

Method for modifying flywheel ring gear tooth profile error

InactiveCN103993968AEasy to controlSolve the spray angleElectrical controlMachines/enginesTeeth missingTransducer

The invention relates to a method for modifying the flywheel ring gear tooth profile error. The method comprises the following steps that firstly, a flywheel ring gear is dragged through a motor at a constant speed, a revolution speed transducer is used for collecting tooth profile signals of a gear ring, and an oscilloscope is used for recording the tooth profile signals of the gear ring; secondly, under constant-speed revolution, for a gear ring with 2-60 teeth, the pulse width of each tooth profile should be 6o CA under the ideal state, a first tooth is calibrated from a tooth missing signal, and error values of all teeth are recorded to form a MAP graph; thirdly, an engine is in an online working state, the teeth begin to be counted after it is detected that the gear ring lacks the teeth, and ejecting preparation is carried out; fourthly, all errors of the teeth are modified based on 6o CA obtained under the ideal state and the error values which correspond to the tooth numbers and are inquired in the MAP graph obtained in the second step, and the actual angles of the teeth are output after the operation for ejection control. The method can effectively solve the ejection angle and ejection width errors caused by the tooth profile errors, and the angle of the engine can be controlled more accurately.

Owner:CHINA NORTH ENGINE INST TIANJIN

Open-loop control method for cancelling engine induced noise and vibration

Owner:GM GLOBAL TECH OPERATIONS LLC

Mechanical automatic feeding mechanism

Provided is a mechanical automatic feeding mechanism. A transmission guiding column penetrates into a hole of a rack. The rack is arranged in a guiding way of a machine frame. A reset spring is arranged on the transmission guiding column in a sleeved mode. A hopper base is connected to the right end of the transmission guiding column. A feeding plate and a feeding hopper are arranged on the hopper base. A frequency-changing speed-adjusting motor is arranged on the machine frame. A speed adjuster, a driving chain and a chain are arranged on the frequency-changing speed-adjusting motor. A transmission shaft is connected to one end of the chain. The transmission shaft is connected with a driven chain and a tooth-missing gear which is connected with a roller shaft. The roller shaft is connected with a roller which is connected with the transmission guiding column.

Owner:XUZHOU CONTENT TRANSMISSION TECH

Secondary grinding device for ceramic slurry

The invention relates to a grinding device, in particular to a secondary grinding device for ceramic slurry. A whole machine support, a grinding mechanism, a rotating baffle, a fixed wheel, a grindingbarrel, a power mechanism, an overturning mechanism and a stirring mechanism are included; power of a motor can be graded through a tooth missing gear, a power gear I and a power gear II arranged onthe power mechanism; when the power gear I rotates, a power belt wheel 1 drives the grinding mechanism to rotate, and ceramic slurry in the grinding barrel is ground; while the grinding mechanism rotates, power cone teeth drive a pushing cam to move, and the pushing cam pushes the overturning mechanism to extrude a compression spring I to move; the overturning mechanism pushes a grinding gear to slide on a connection key; the grinding gear drives a grinding spiral body to move up and down so that the ceramic slurry can be overturned; and the grinding spiral body overturns when performing grinding, and when the power gear II rotates, the stirring mechanism works so that the ceramic slurry in the grinding barrel can be stirred.

Owner:佛山迪骏自动化科技有限公司

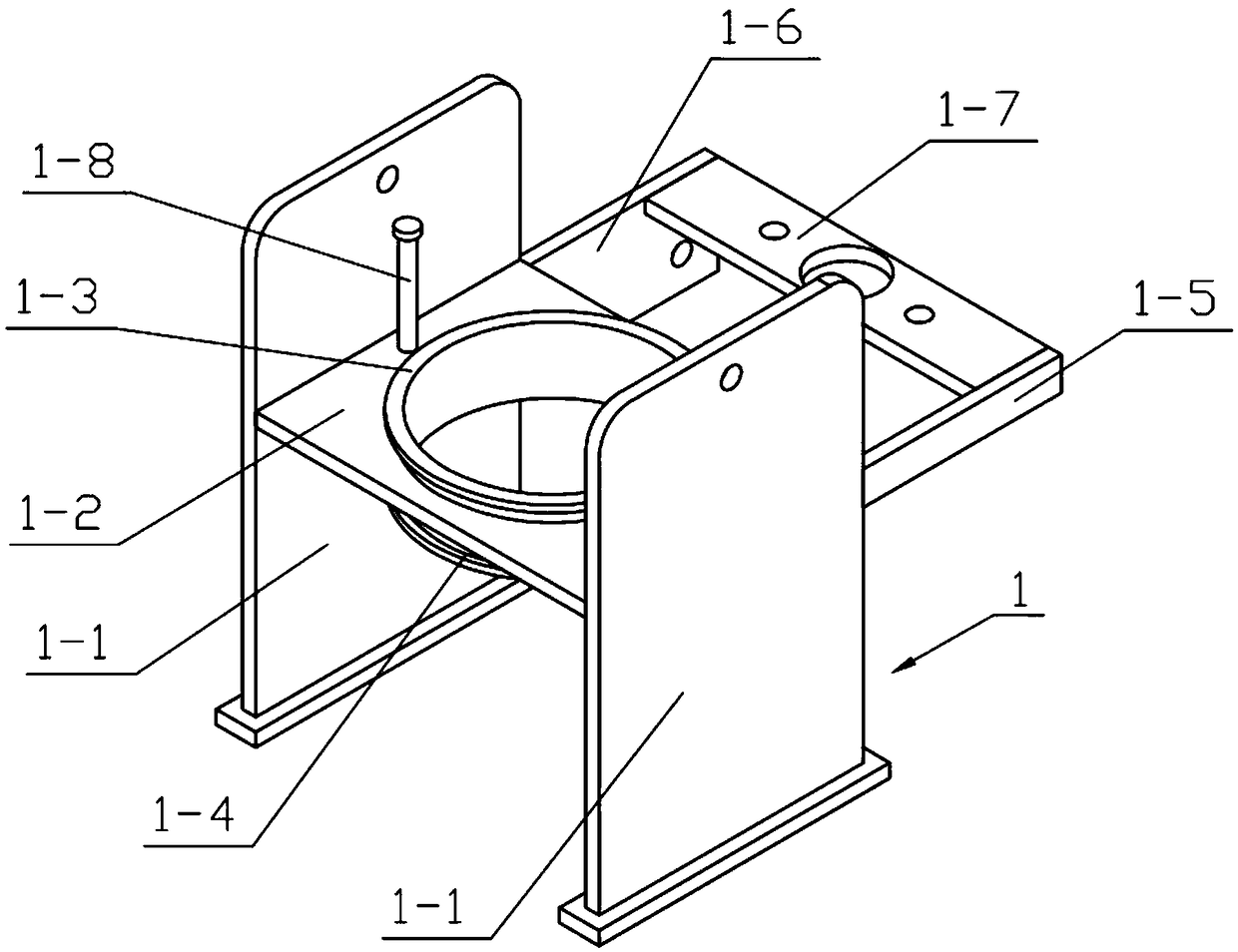

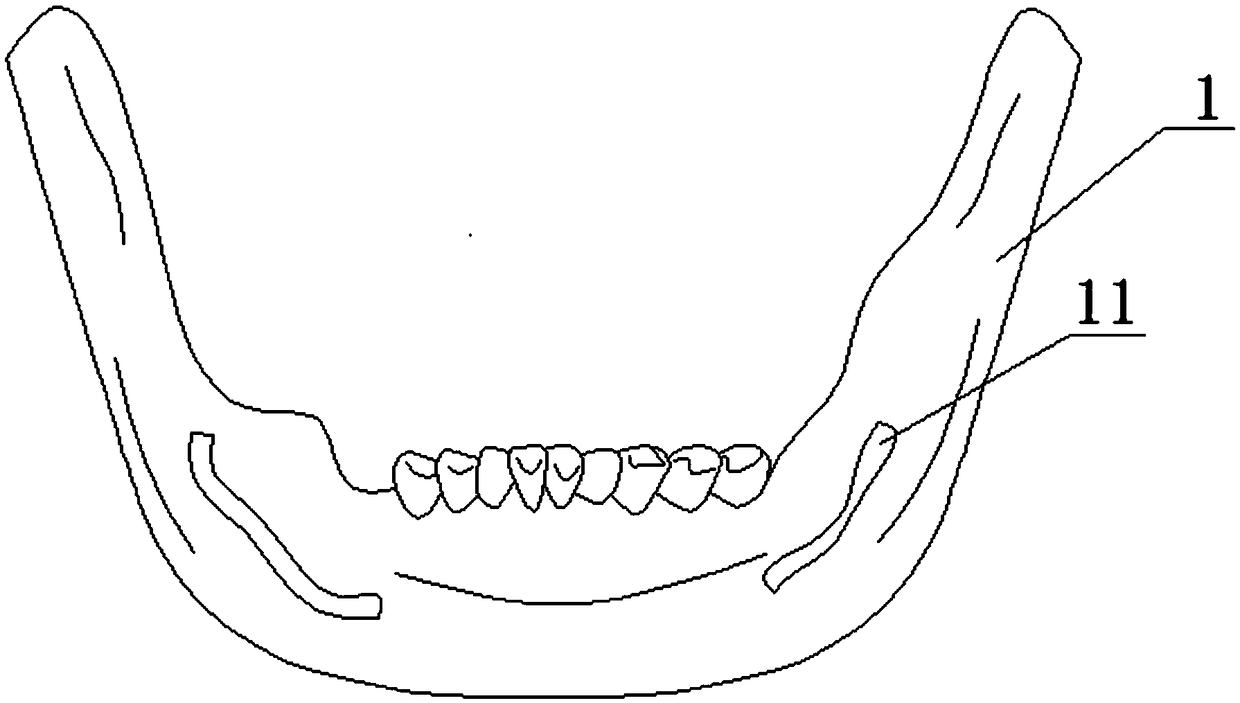

A bone surface anchoring type dental implant design method with a topological optimization structure and an implant

PendingCN109446738AGood mechanical propertiesReduce financial burdenDental implantsDesign optimisation/simulationAnatomical structuresImplantation Site

A bone surface anchoring type dental implant design method with a topological optimization structure comprises the following steps of (1) obtaining an oral maxillofacial CT image of a patient, and using the medical image processing software for reconstructing a three-dimensional model of a mandible of the patient, wherein the reconstructed model further comprises a mandibular nerve canal anatomical structure; 2) measuring and evaluating a tooth missing condition and a bone mass condition of an implant implanting part in medical image processing software, determining a position of a repairing base station, and formulating a comprehensive repairing scheme; determining the position and form of the implant, implanting a traditional cylindrical or conical dental implant at a position with sufficient or insufficient bone mass; and designing the bone surface anchoring type implant at the position where the serious bone mass is insufficient. The invention provides the bone surface anchoring type dental implant design method with the topological optimization structure and an implant. The implant is different from a traditional subperiosteal implant and a root-shaped implant, and the bone increment operation is not needed.

Owner:ZHEJIANG UNIV OF TECH

Automatic zipper machine

InactiveCN104738907AImprove reliabilityImprove stabilitySlide fastenersOptical detectionTeeth missingEngineering

The invention discloses an automatic zipper machine with an automatic zipper tooth missing detection device and belongs to the field of mechanical equipment. The automatic zipper tooth missing detection device comprises a base and a connecting plate arranged on the base; the end surface of the base facing to the connecting plate is provided with a zipper channel, an infrared emitter is arranged above the zipper channel, and an infrared sensor corresponding to the infrared emitter is arranged under the zipper channel. The traditional rolling ball detection is replaced with the infrared emitter; the reliability and stability of detection are improved, and the automatic zipper machine is adaptive to tooth missing detection of various zippers and is adaptive to various zipper production companies; the structure is simple, the detecting process is free of manual operation, and the detecting efficiency is improved greatly; a transparent protecting layer is arranged above the infrared sensor and is capable of protecting the infrared sensor better; since the height of the infrared emitter on a support can be adjusted vertically, the device can be adaptive to tooth missing detection of various zippers.

Owner:常熟市给力拉链设备有限公司

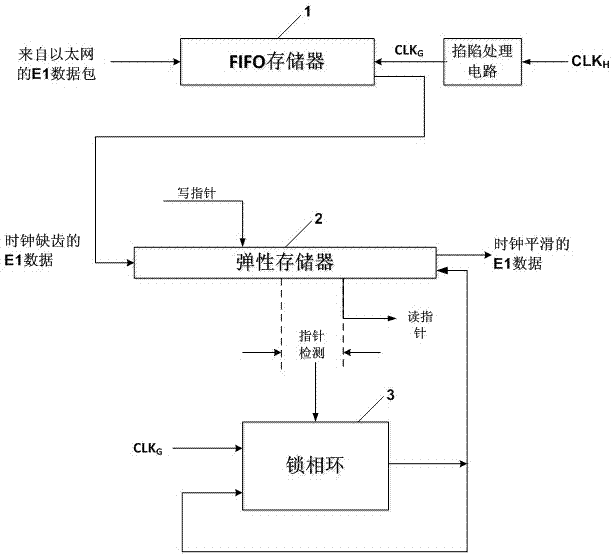

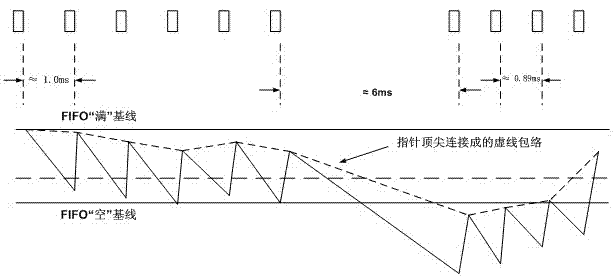

Clock recovery method and device for transmitting EI signals based on Ethernet

ActiveCN103795521AReduce driftGood roaming performanceSynchronising arrangementNetwork packetTeeth missing

The invention relates to a clock recovery method for transmitting EI signals based on the Ethernet. The clock recovery method includes the steps that an EI data package coming from the Ethernet is stored in an FIFO memorizer and buffered, the data package is read through a tooth missing clock CLKG, and EI data of clock tooth missing are output by the FIFO memorizer; the EI data of clock tooth missing are stored in an elastic memorizer, a phase-locked loop outputs synchronizing signals to the elastic memorizer, meanwhile output of the phase-locked loop is input as feedback, the phase-locked loop controls the output clock frequency of the elastic memorizer by monitoring difference between a reading pointer and a writing pointer of the elastic memorizer, if the difference between the reading pointer and the writing pointer is larger than a set value, the clock frequency of the output of the phase-locked loop is reduced, otherwise, the clock frequency of the output of the phase-locked loop is increased, and the elastic memorizer outputs the EI data with clock smoothed. The invention further discloses a clock recovery device for transmitting the EI signals based on the Ethernet. A clock is recovered with two-level buffering adjustment to reduce phase position diffuse movement, smooth missed teeth and recover the clock meeting the related ITU-TG. 823 requirements; a good diffuse movement performance index can be achieved without changing a frame structure.

Owner:HUAXIAO PRECISION SUZHOU

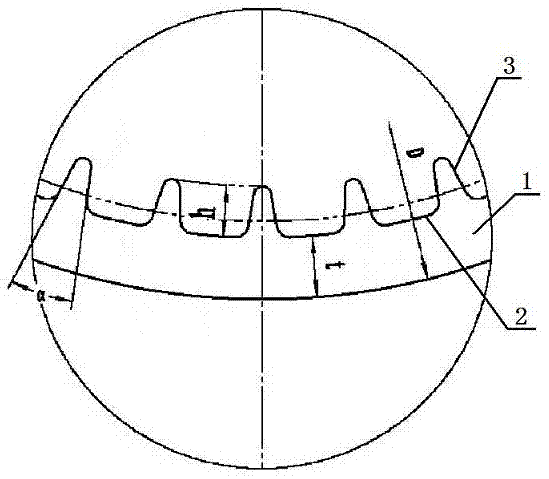

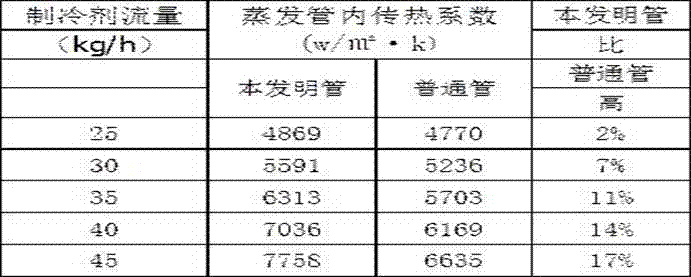

High-efficient inner screw copper tube

PendingCN107990778AEasy to moveHigh strengthHeat exchanger casingsTubular elementsTeeth missingEngineering

Owner:GOLDEN DRAGON PRECISE COPPER TUBE GROUP

Automatic cloth cutting machine for textile

InactiveCN108951088ACompact structureHigh degree of automationSevering textilesTeeth missingEngineering

The invention relates to a textile device, in particular to an automatic cloth cutting machine for textile. The machine comprises a fourth support seat, a motor seat and a processing table, the top ofthe processing table is fixedly connected with a third support seat, the third support seat is internally rotatably connected with a first rotating shaft, the rear end of the first rotating shaft isfixedly connected to a first gear, the top of the motor seat is fixedly connected to a motor, a motor output shaft is fixedly connected to a teeth missing gear, a fourth support seat is internally rotatably connected to a second rotating shaft, the second rotating shaft is fixedly connected to a second gear, a first belt pulley is disposed on the front side of the second gear, a belt is disposed outside the first belt pulley, and a second belt pulley is connected to the other end of the belt. The machine is applicable to a textile operation assembly line, through the meshing action between theteeth missing gear and the two gears, the automatic feeding and cutting action of cloths are completed, and the lifting of blades is completed under the action of the restoring force of a torsion spring. The machine has the advantages of compact structure and high degree of automation, can automatically complete the feeding and cutting action of the cloths, liberates manpower, saves costs and significantly increases production efficiency.

Owner:曾俊杰

Separating machine

The invention relates to a separating machine. The separating machine comprises a box body, a feeding bin, an air compressor, an upper screen, a lower screen, pin shafts, a rack, a rotating shaft, a tooth-missing gear, a connecting rod, a limiting spring, a motor and a material collecting groove, wherein the feeding bin is arranged at the top end surface of the box body, the material collecting groove is formed in the bottom end surface of the interior of the box body, the air compressor is arranged at the left end surface of the interior of the box body, the upper screen and the lower screenare rotationally connected to the interior of the box body, the rack is connected in the box body in a sliding mode, the connecting rod is fixedly arranged at the right end of the rack, the two ends of the connecting rod are movably connected to the pin shafts, the tooth-missing gear is arranged on the rotating shaft, the rotating shaft is fixedly connected with the output end of the motor, the upper screen is connected to the top end surface of the box body through the limiting spring, and the tooth groove of the tooth-missing gear is meshed with the tooth groove of the rack. By the design, the two screens are driven to rotate in a reciprocating mode through the cooperation of an incomplete gear mechanism and the limiting spring, impurities are enabled to roll on the screens, and the problem that the impurities cannot be screened due to stacking is solved.

Owner:安徽省阜阳市海泉粮油工业股份有限公司

Preparation device of cleaning agent of hardware galvanized tube

InactiveCN107138084AGood effectVolume controlShaking/oscillating/vibrating mixersTransportation and packagingTeeth missingChloride

Owner:车秋玲

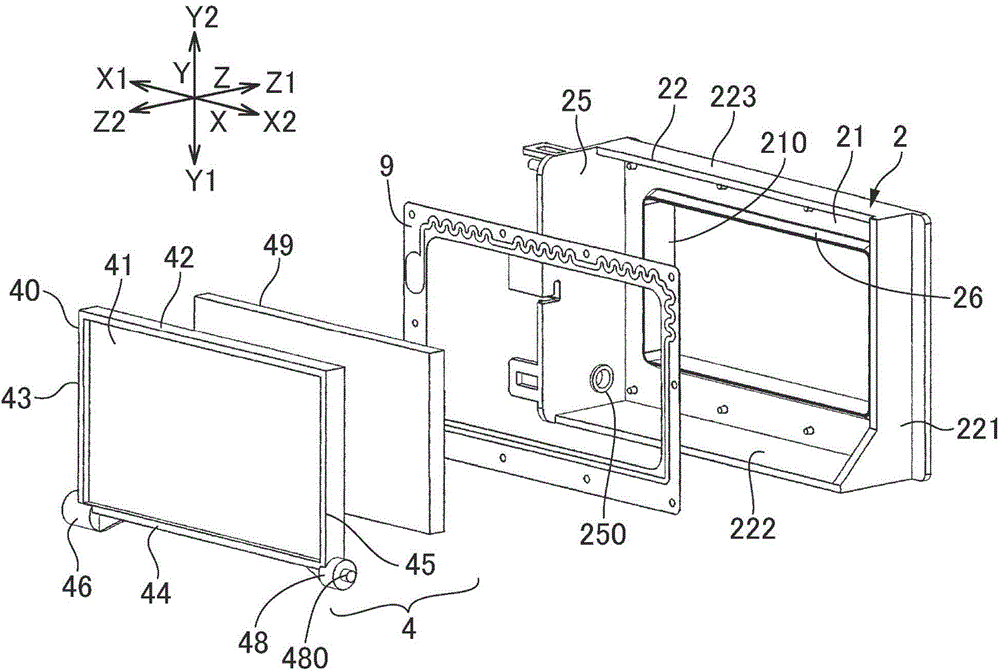

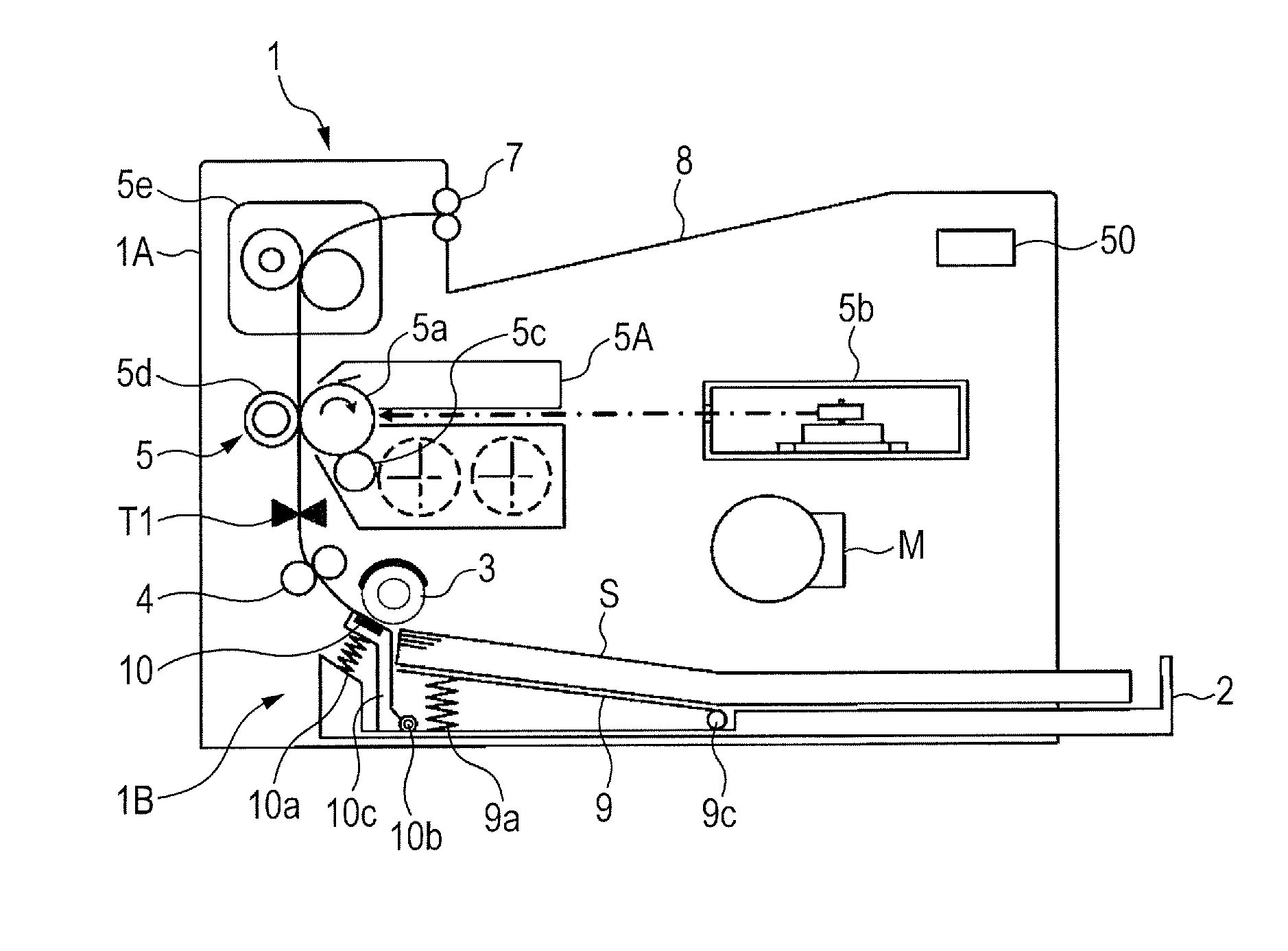

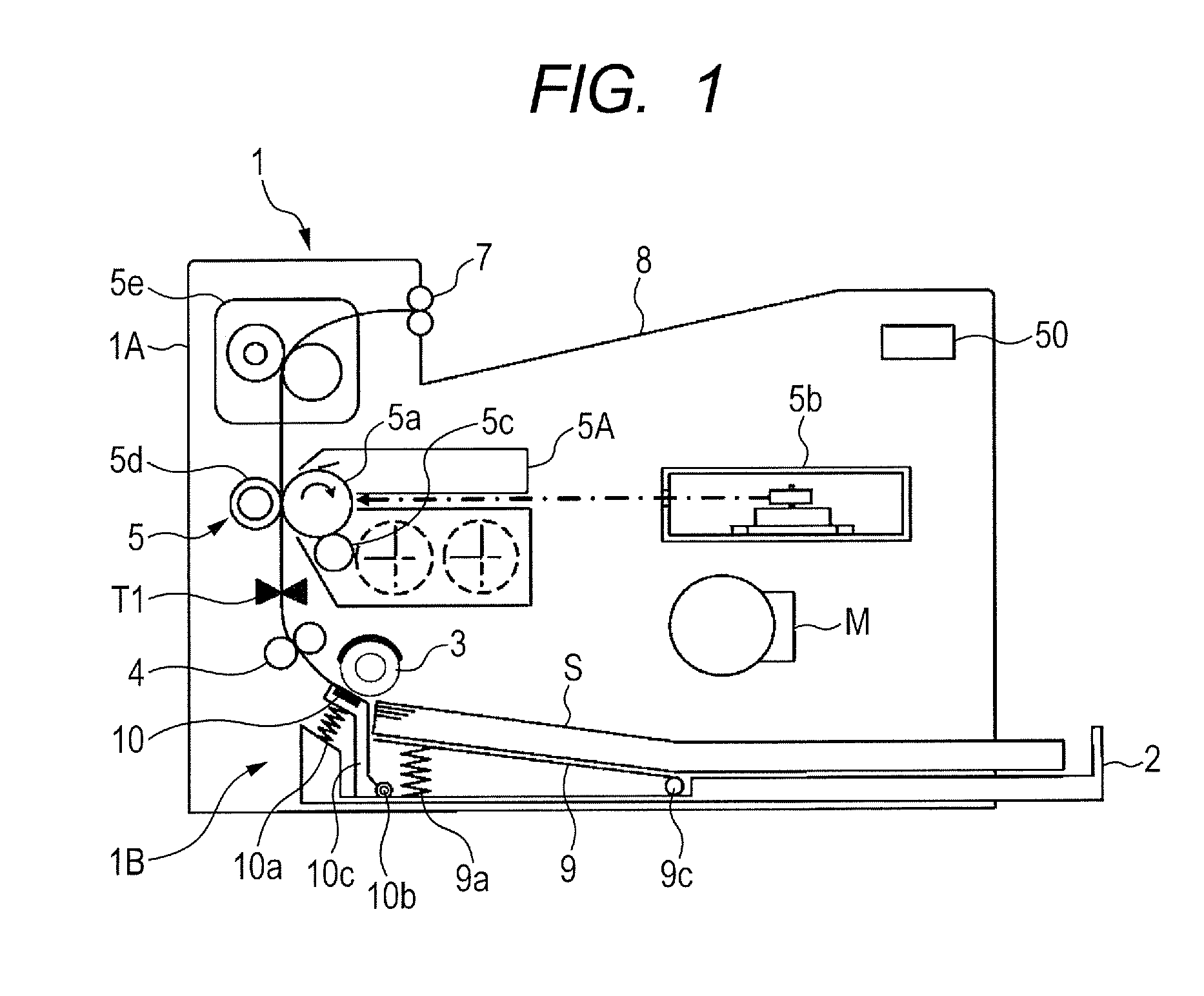

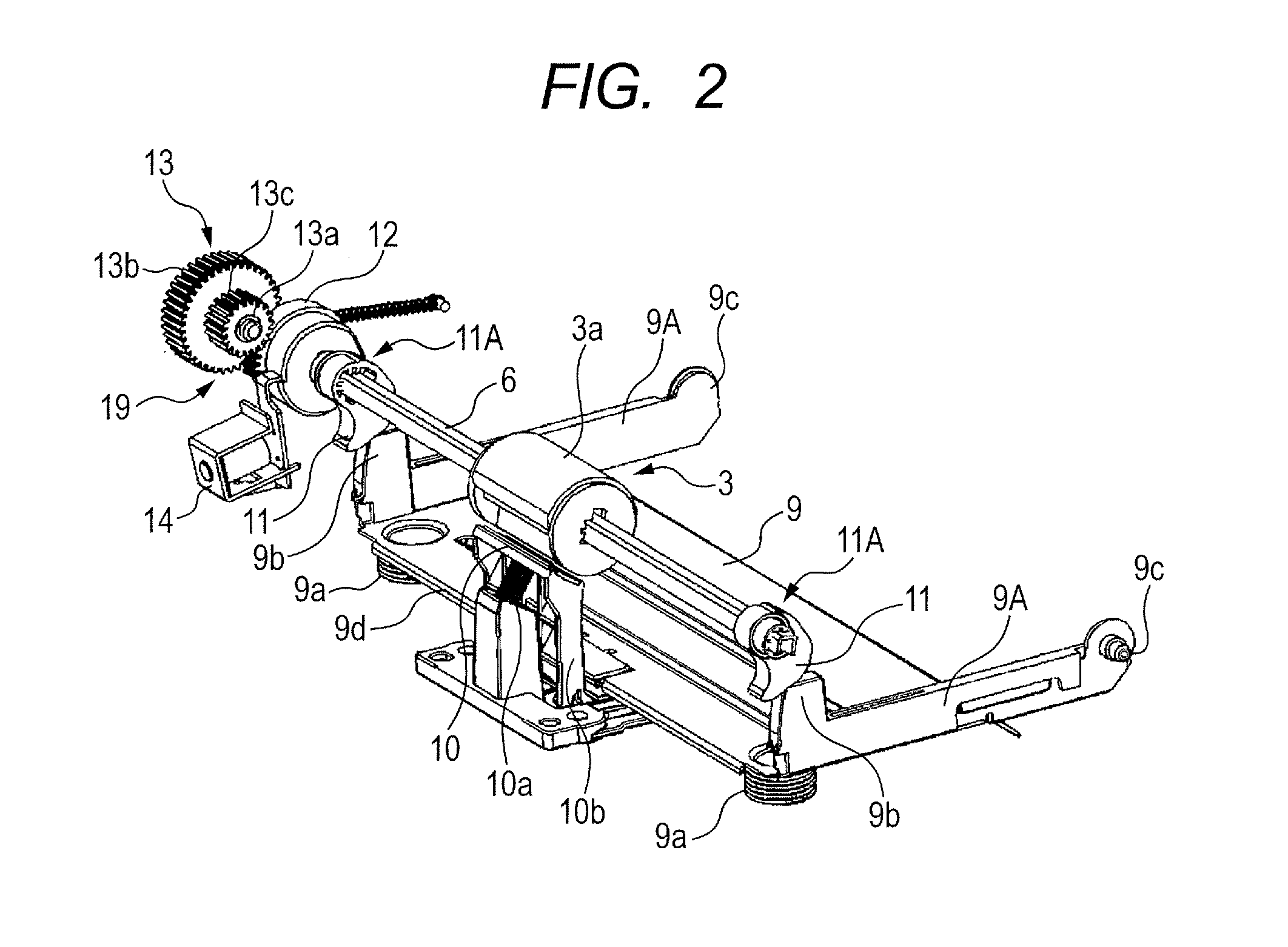

Sheet feeding apparatus and image forming apparatus

A variable speed unit is driven by a drive unit to make a tooth-missing large gear of a sheet feed tooth-missing stage gear mesh with a small gear of an input stage gear rotating at a constant speed, to then rotate a rotating shaft of the feeding roller and a cam at a first speed to lift an intermediate plate. If a sheet stacked on the intermediate plate is pressed against the feeding roller, the variable speed unit makes a large gear of the input stage gear and a tooth-missing small gear of the sheet feed tooth-missing stage gear mesh with each other, so that the rotating shaft of the feeding roller is rotated at a second speed faster than the first speed to rotate the feeding roller at a fast speed.

Owner:CANON KK

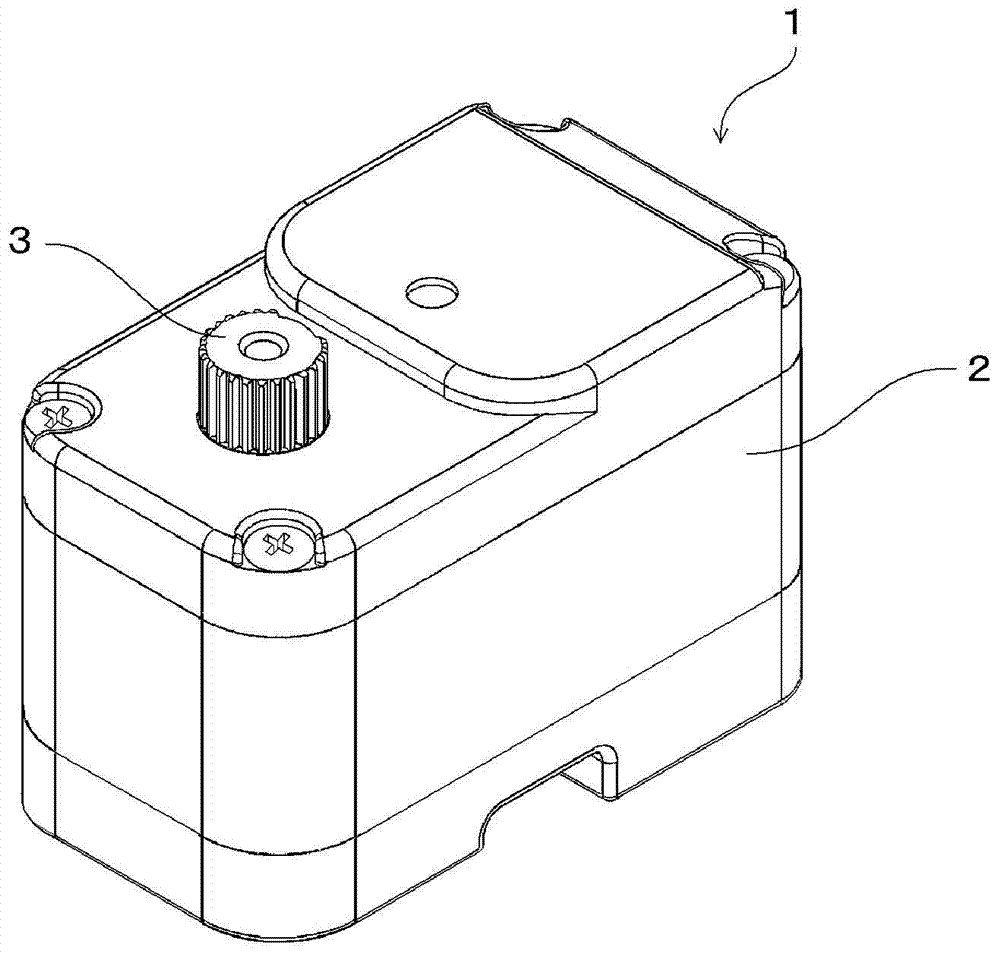

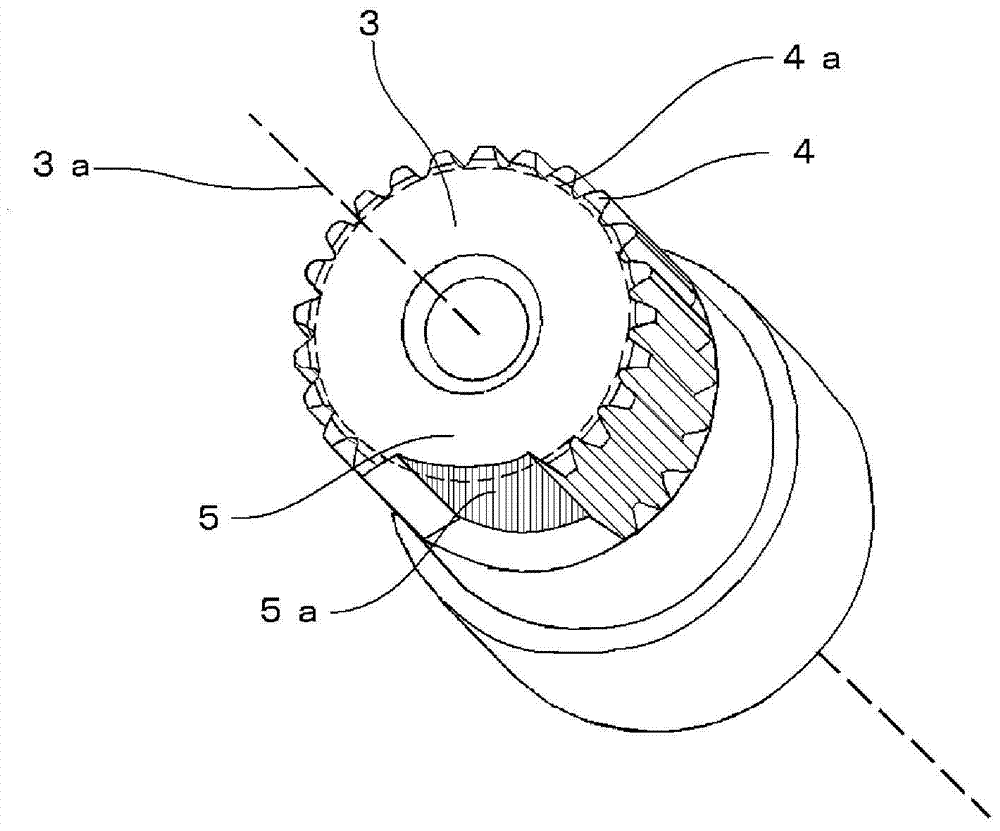

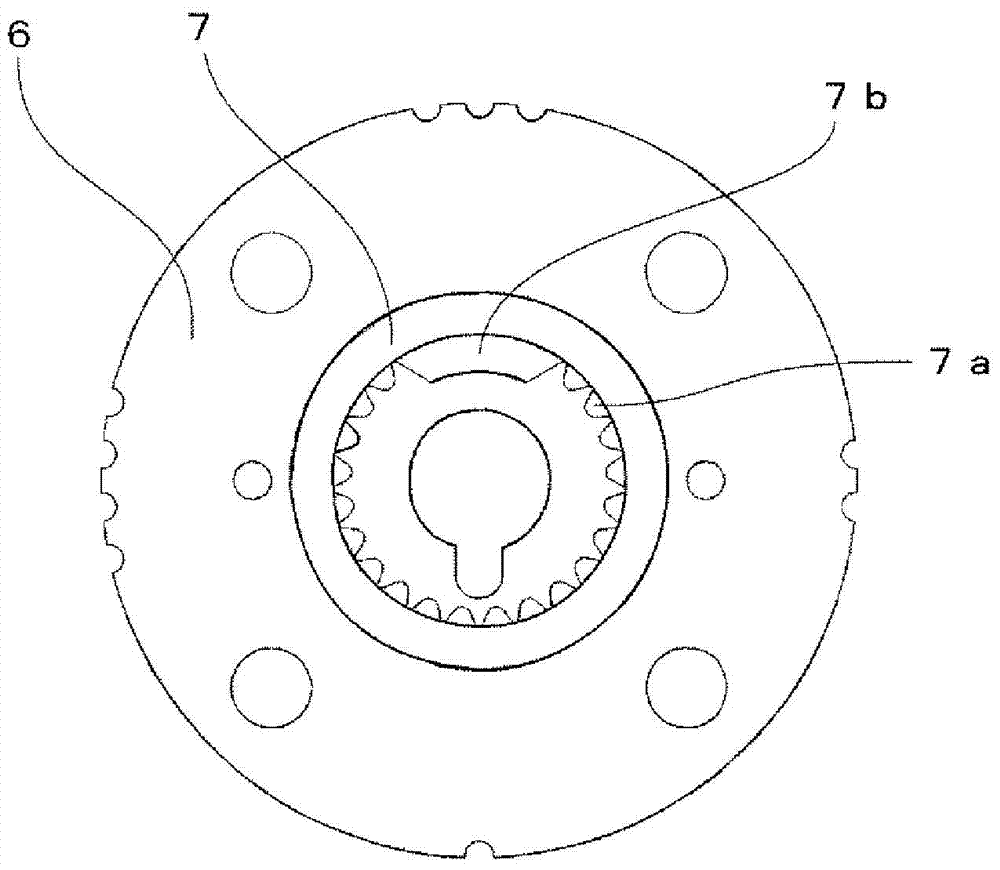

Driving device and servo motor device

The invention provides a driving device and a servo motor device. An output shaft (3) of a servo motor device is provided with a zigzag-shaped part (4) and a teeth-missing part (5). The zigzag-shaped part (4) is provided with concave parts and convex parts periodically. The length of the teeth-missing part (5) from a rotating shaft (3a) to the teeth-missing part (5) is shorter than the length from the rotating shaft (3a) to a root circle (4a) of the zigzag-shaped part (4). By adopting the structure, the special servo gasket irons embedded with the special position of the output shaft (3) and the conventional servo gasket irons disposed at any angles and positions on the output shaft (3) can be disposed on the output shaft (3).

Owner:FUTABA CORPORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com