Rapid automatic bagging machine

A bagging machine, automatic technology, applied in the direction of packaging, transportation and packaging, the type of packaged items, etc., can solve the problems of slow speed, delayed work and time, and achieve the effect of accurate bagging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Further description will be made below in conjunction with the accompanying drawings.

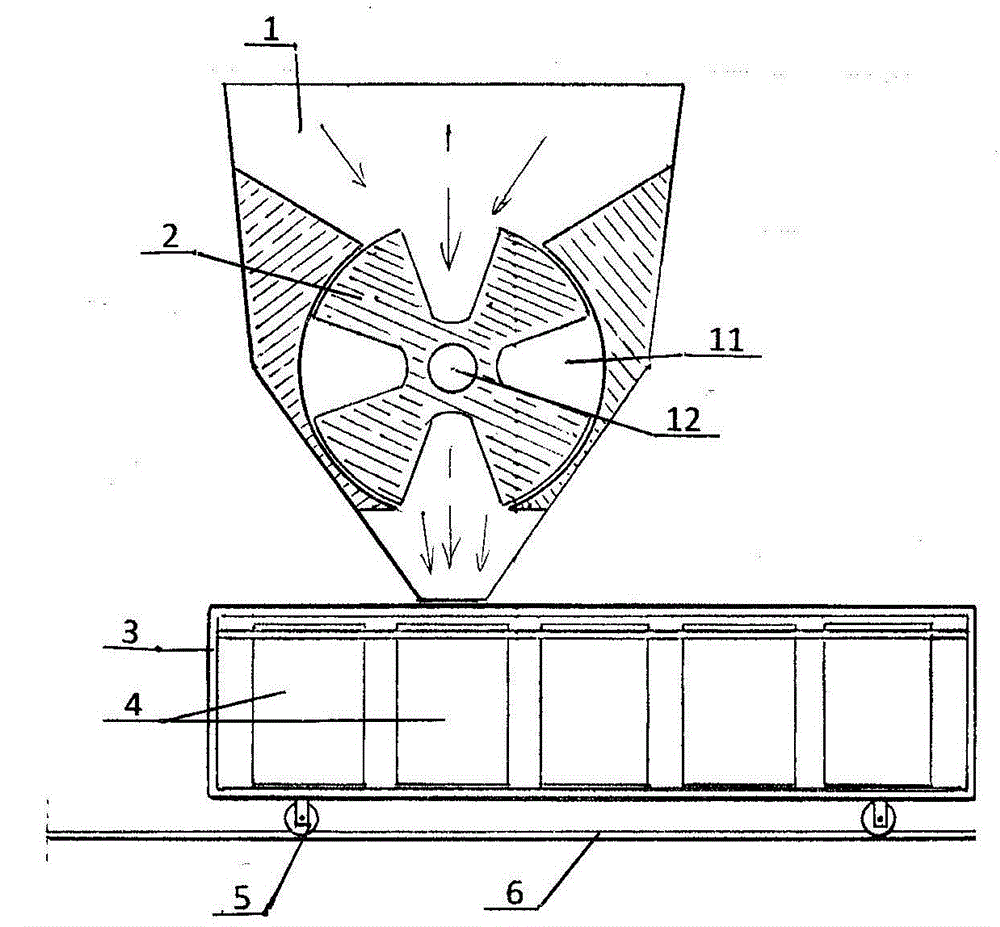

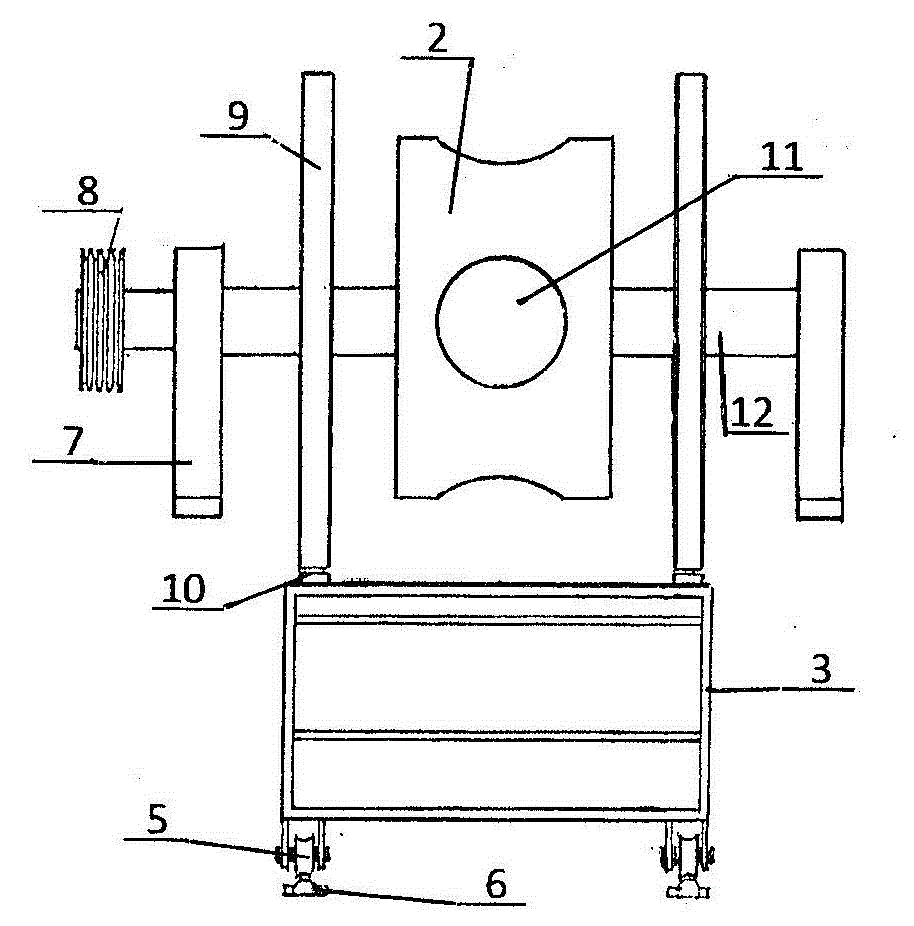

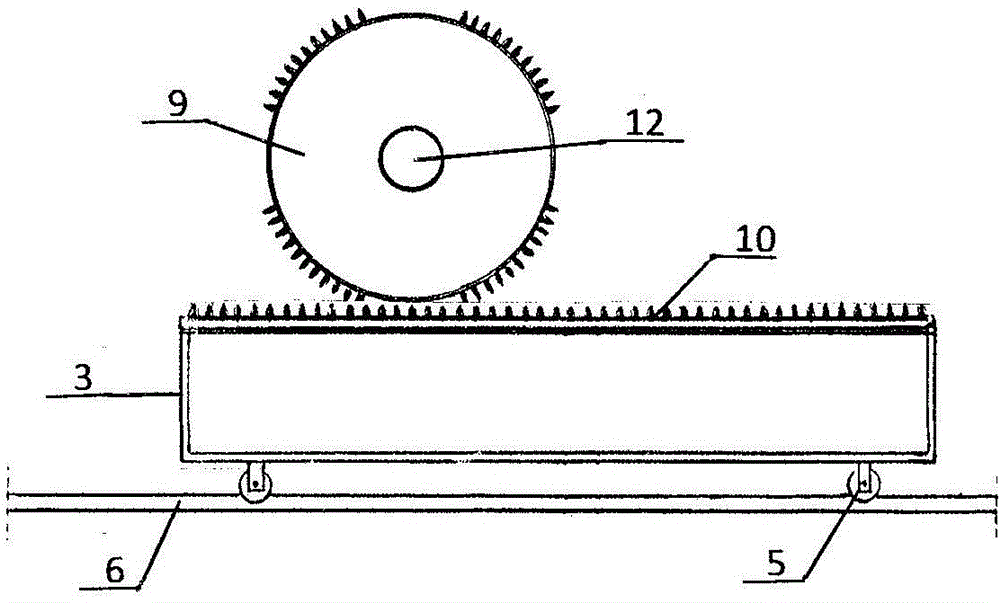

[0012] refer to Figure 1 to Figure 3 A turntable 2 is installed in the storage hopper 1, and the turntable is installed on the central transmission shaft 12. There are four frame cavities 11 around the outer edge. The lower side of the lower outlet of the storage hopper is a mobile frame 3, and multiple openings are placed in the mobile frame. The material bag 4 of the mobile rack bottom is equipped with four left and right front and rear travel wheels 5 (only two sides and one head are shown in the single figure), the travel wheels 5 slide left and right on the track 6, and the drive shaft 12 The length outside the storage hopper is equipped with two toothless gears 9 that engage and disengage with the racks 10 on the moving frame respectively. The transmission shaft 12 is supported and positioned by a bearing seat 7 with built-in bearings on the left and right sides, and its left ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com