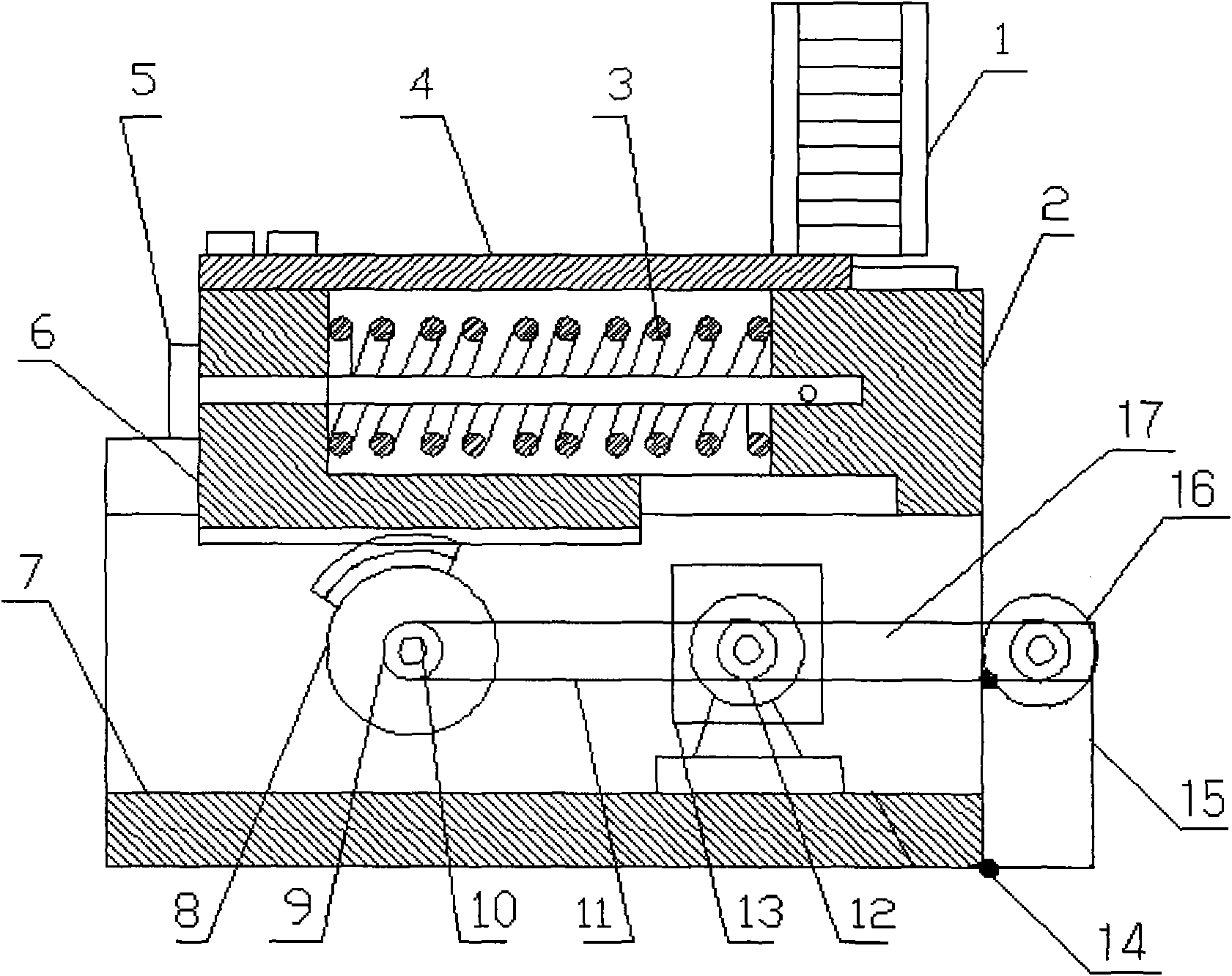

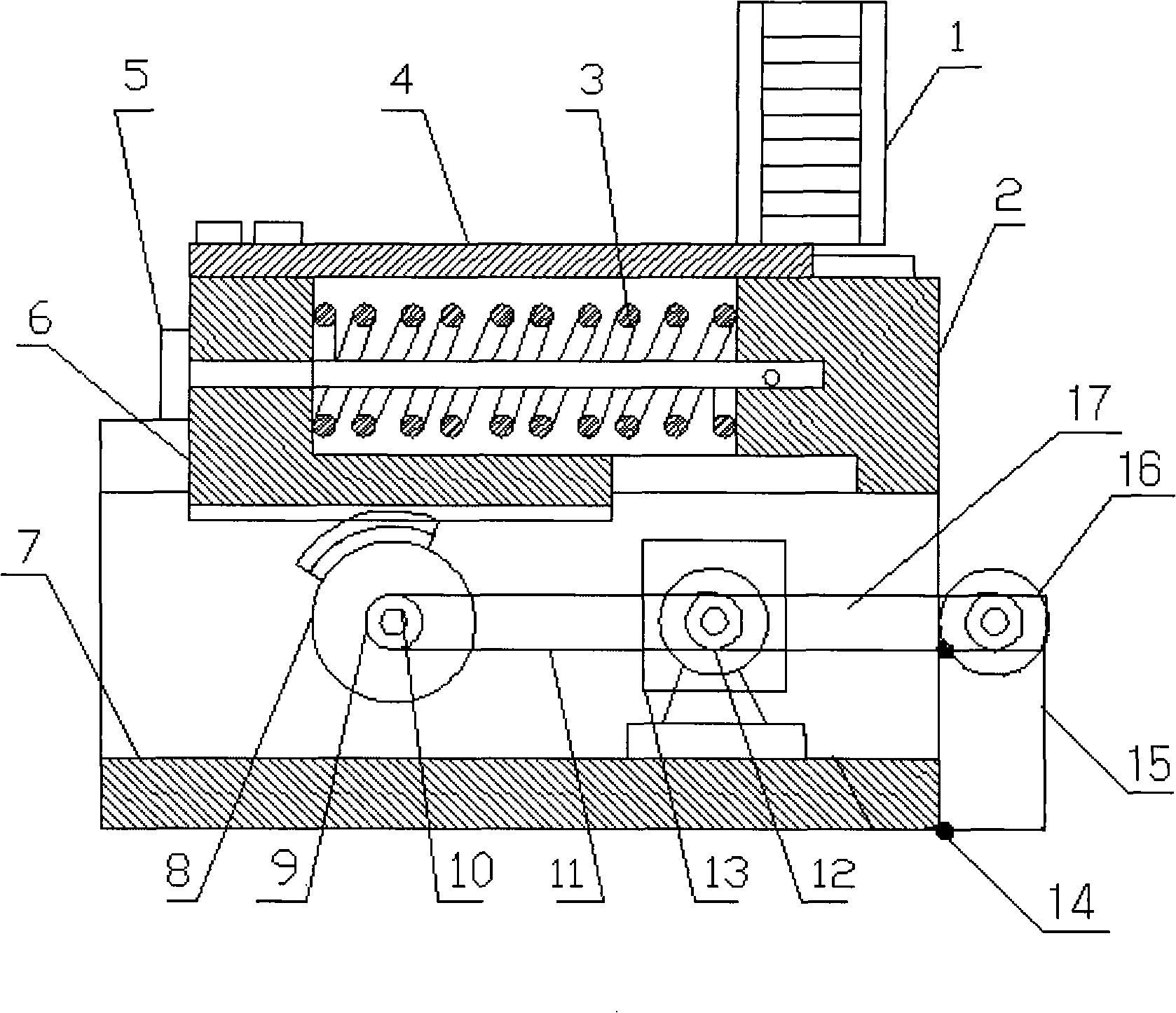

Novel electromechanical automatic feeding device

A feeding device, electromechanical technology, applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of high labor intensity, poor interchangeability, complex structure, etc., to achieve precise control and adjustment, easy production matching, and structural simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The specific embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0009] Install and fix the hopper (1) on the appropriate position of the hopper seat (2), insert the guide post (5) into the hole of the elbow part of the rack (6), and at the same time put the return spring (3) on the guide post ( 5) on the top, then install the rack (6) into the guide rail a of the frame (7), and at the same time fix the right end of the guide post (5) on the hopper seat (2) with pins or screws or other methods, during assembly It should be ensured that the rack moves smoothly in the guide post (5) and guide rail a, and the return spring (3) should be properly compressed. In the above cases, the pusher plate (4) can be installed. Drive shaft (10) is installed on the place where frame (7) is perpendicular to the direction of motion of rack (6), and tooth-missing gear (8) and passive chain (9) are installed on drive shaft (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com