Driving device and servo motor device

A technology of servo motor and drive device, applied in the direction of electromechanical devices, electrical components, mechanical equipment, etc., can solve problems such as assembly errors and inability to use servo motor devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

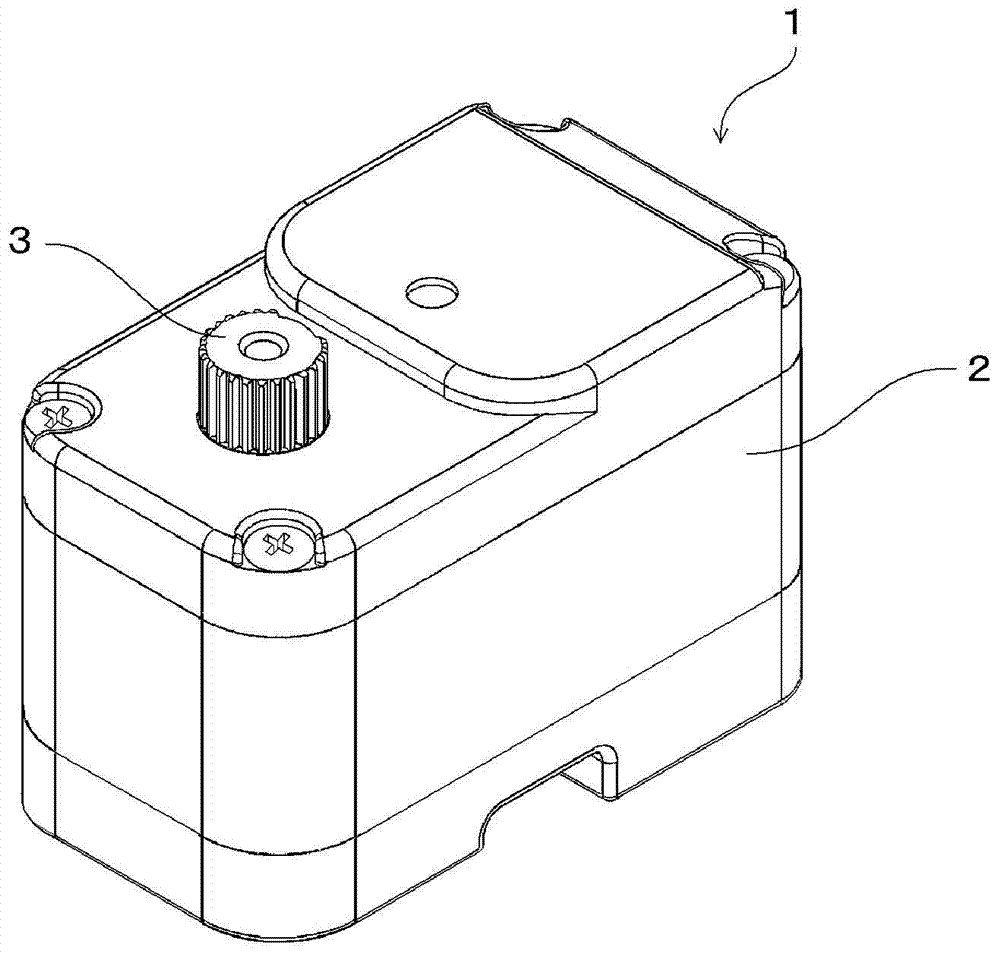

[0060] figure 1 It is a figure which shows the appearance of the casing 2 of the servomotor apparatus 1 of Example 1 of this invention.

[0061] In this figure, since the inside of the casing 2 of the servo motor device 1 is the same as that of a conventional servo motor device, description thereof will be omitted.

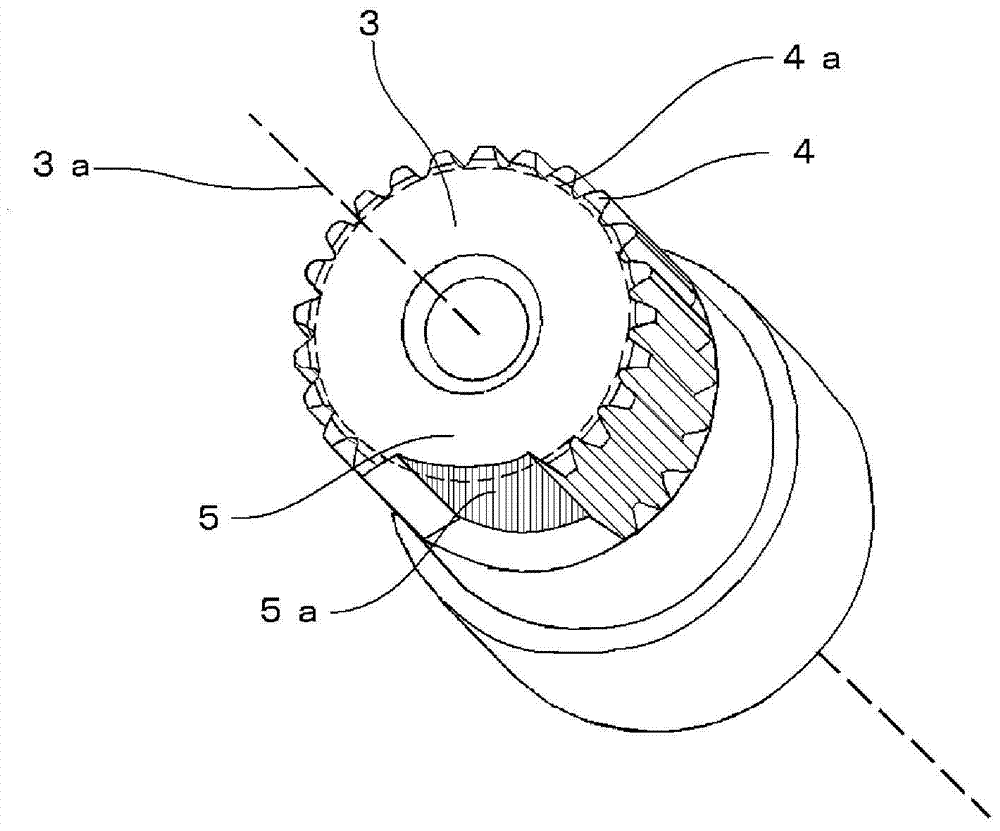

[0062] figure 2 It is a figure which removed the output shaft 3 of the servomotor apparatus 1 of Example 1 from the housing 2, and showed with a part of shape omitted.

[0063] The servo motor device 1 according to Embodiment 1 of the present invention has a rotating output shaft 3 , and a sawtooth portion 4 and a tooth-missing portion 5 are provided on a surface parallel to the rotation axis 3 a of the output shaft 3 . The output shaft 3 of the servo motor device 1 can also be an output shaft that rotates within a predetermined angle range. Furthermore, the serrated portion 4 is provided with concavities and convexities having a certain period, that is, serr...

Embodiment 2

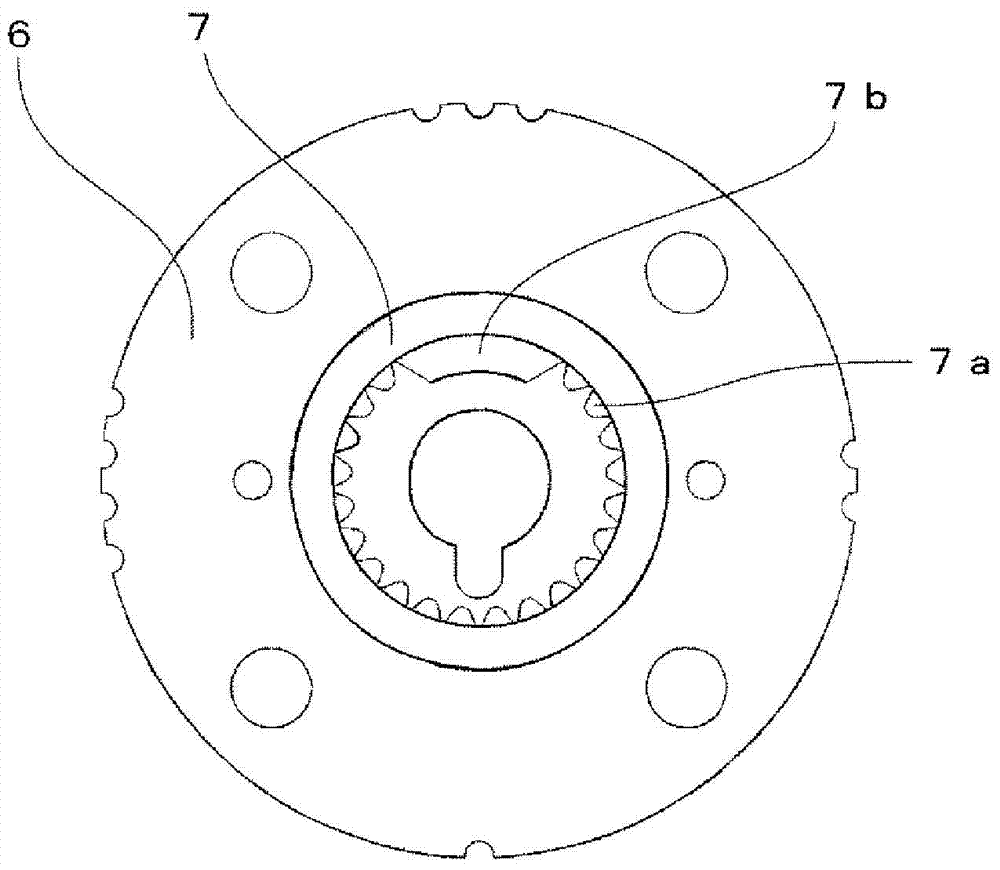

[0080] Image 6 It is a figure which removed the output shaft 13 of the servomotor apparatus which concerns on Example 2 of this invention from a housing, and showed a part shape abbreviate|omitted. Since the structure of the servo motor device other than the output shaft 13 is the same as that of the first embodiment, description thereof will be omitted.

[0081] A plurality of, for example, three sawtooth portions 14a, 14b and a plurality of, for example, three tooth-missing portions 15 are provided on a surface parallel to the rotation axis of the output shaft 13 of the servo motor device.

[0082] The output shaft 13 can be fitted with a dedicated servo shim having a fitting portion not shown that fits at a specific position to form a drive device.

[0083] At this time, if the serrated parts 14a, 14b and the tooth-missing part 15 are evenly divided, even if it is a dedicated servo pad, the installation position of the servo pad will not be specified. The zigzag portions...

Embodiment 3

[0087] Figure 7 It is a figure which removed the output shaft 30 of the servomotor apparatus of Example 3 of this invention from a housing, and a part shape is abbreviate|omitted and shown. Since the structure of the servo motor device other than the output shaft 30 is the same as that of the first embodiment, description thereof will be omitted.

[0088] The output shaft 30 is provided with a missing-tooth portion position display portion for displaying the missing-tooth portion 32 as a mark 33 . The installation of the servo horn becomes easier by providing the mark 33 . In addition, like the other embodiments, the drive device is constituted by the servo motor device of the third embodiment and the servo shim attached to the output shaft 30 at a specific position.

[0089] The mark 33 is for emphasizing the missing tooth part 32 with respect to the upper surface 31 of the output shaft 30, and is provided so that the upper surface part of the tooth missing part 32 may be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com