Automatic cloth cutting machine for textile

A cloth cutting machine and automatic technology, which is used in the cutting of textile materials, textiles and papermaking, etc., can solve the problems of consuming human resources, unable to automatically feed cloth, low efficiency, etc., to improve production efficiency, compact structure, and liberate manpower. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

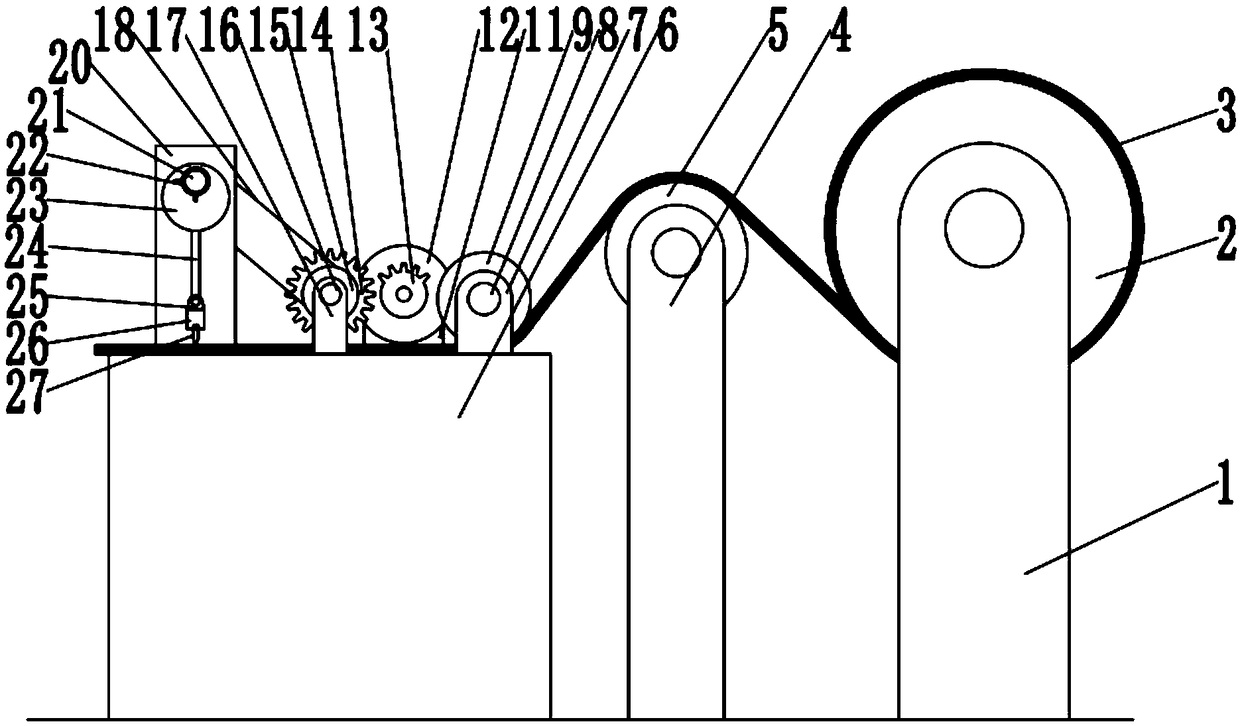

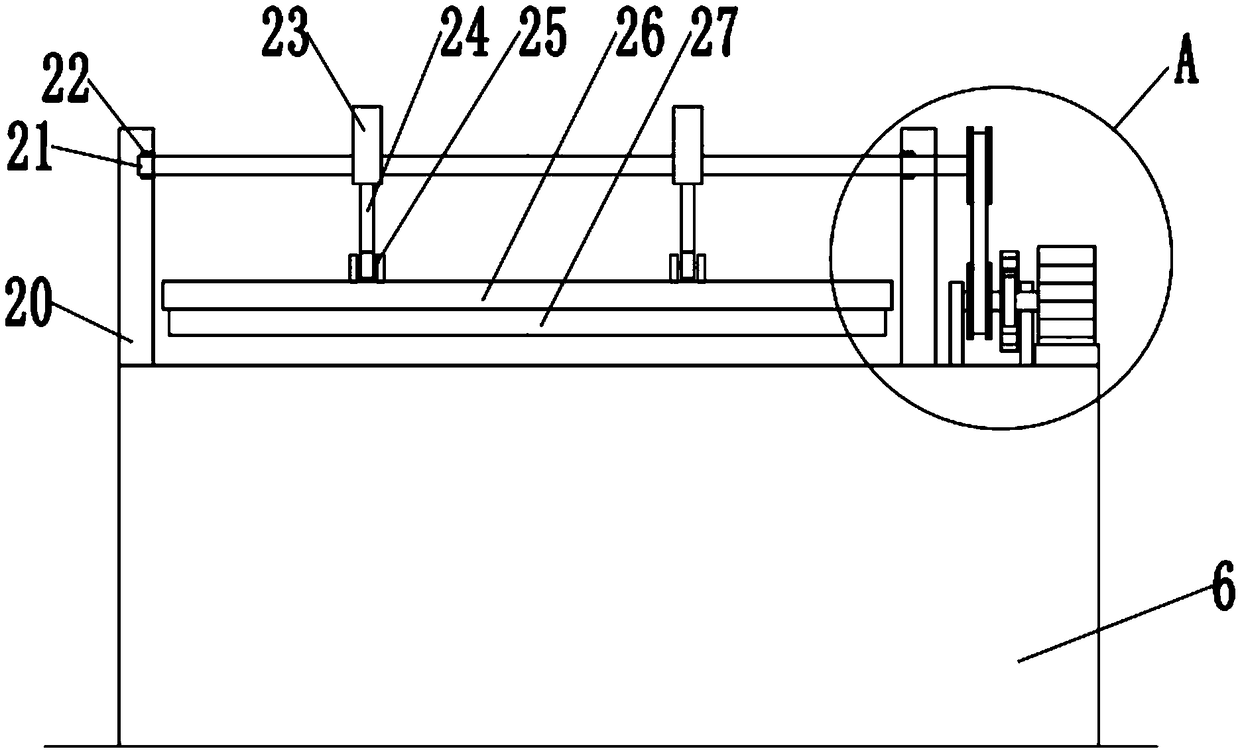

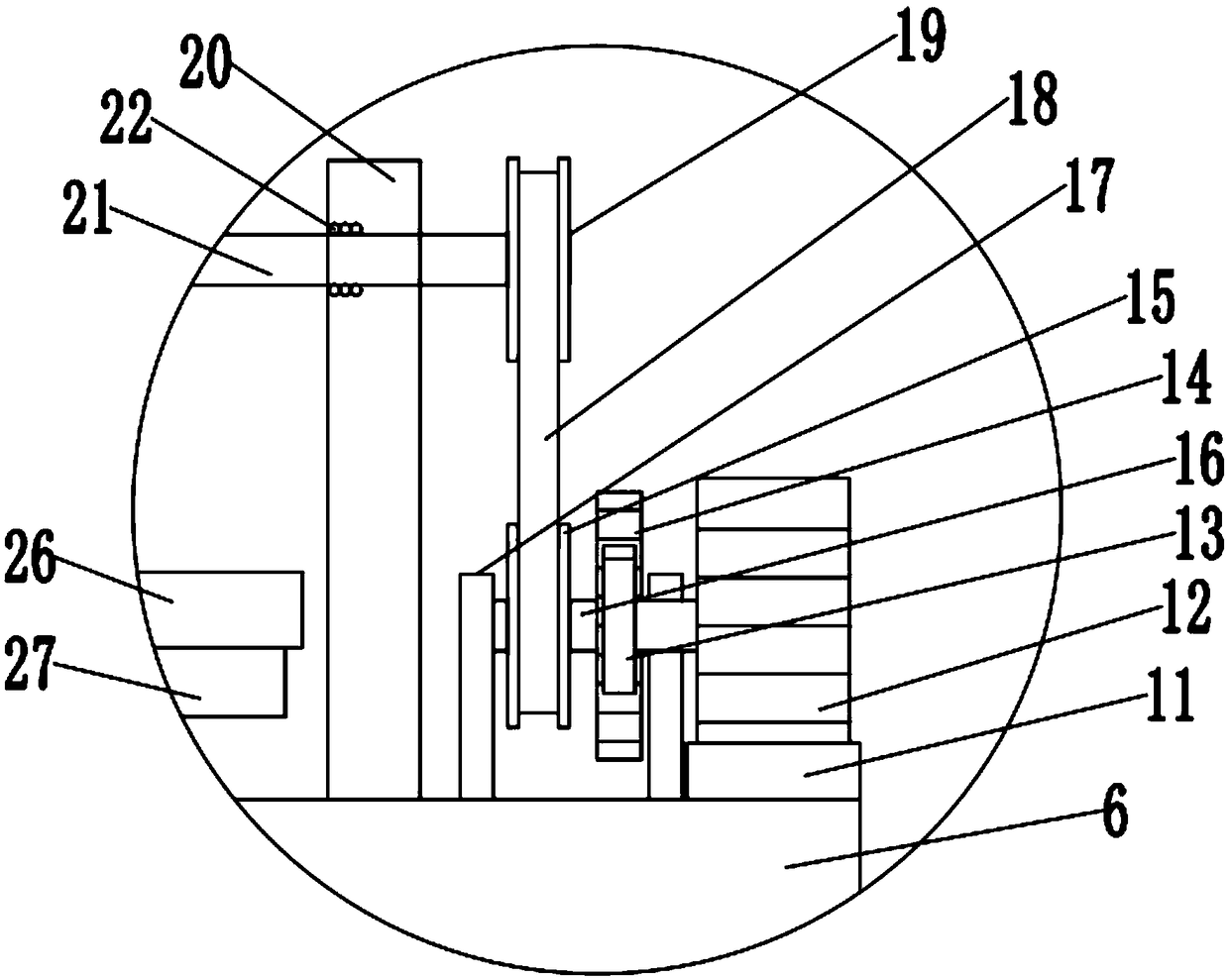

[0023] see figure 1 and figure 2 , an automatic cloth cutting machine for weaving, comprising a first support 1, the first support 1 is rotated and connected to a reel 2, and a cloth 3 is wound on the reel 2, and the cloth 3 is limited and fed by a plurality of rollers function, reach the blade 27 for cutting, the left side of the first support 1 is provided with a second support 4, the second support 4 is rotated and connected to the first roller 5, and the top of the first roller 5 is slidingly connected to the cloth 3 to ensure The cloth 3 is spread out and is in a tense state. The left side of the second support 4 is provided with a processing table 6, and the top of the processing table 6 is fixedly connected with a fixed frame 20, a fourth support 17, a motor seat 11 and a third Bearing 7, the third bearing 7 rotates and connects with the first rotating shaft 8, and the first rotating shaft 8 is fixedly connected with the second roller 9 outside, and the second roller ...

Embodiment 2

[0026] see Figure 5 , this embodiment is improved on the basis of Embodiment 1, the left side of the outer wall of the processing table 6 is fixedly connected to the triangular bracket 31, the triangular bracket 31 is fixedly connected to the fifth support 30, and the fifth support 30 is rotatably connected to the third roller 28. The surface of the third roller 28 is provided with a rubber ring 29, and the three brackets 31 can make the cloth 3 fall neatly for subsequent processes. The rubber ring 29 on the surface of the third roller 28 can make the cut cloth 3 slide down without affecting Subsequent cropping.

[0027] In the present invention, during use, the reel 2 is installed in the first support 1, and the cloth 3 is drawn out so that it passes through the first roller 5 and the second roller 9 to control the rotation of the motor 9 and drive the tooth-missing gear 13 to rotate. When the toothed gear 13 meshes with the first gear 10, it drives the second roller 9 to r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com