Preparation device of cleaning agent of hardware galvanized tube

A technology of galvanized pipe and cleaning agent, which is applied in the direction of mixer accessories, transportation and packaging, dissolution, etc., can solve the problem of not being able to adjust the ratio of ammonium chloride and zinc chloride, and achieve good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

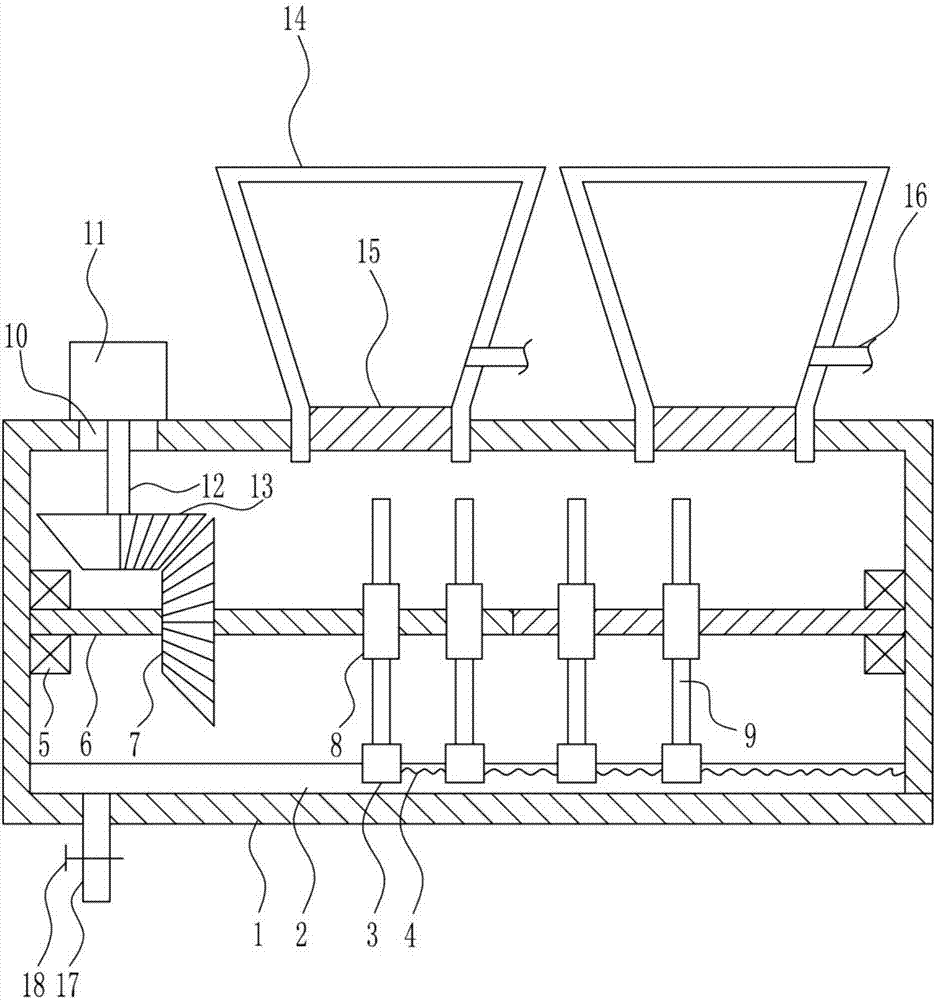

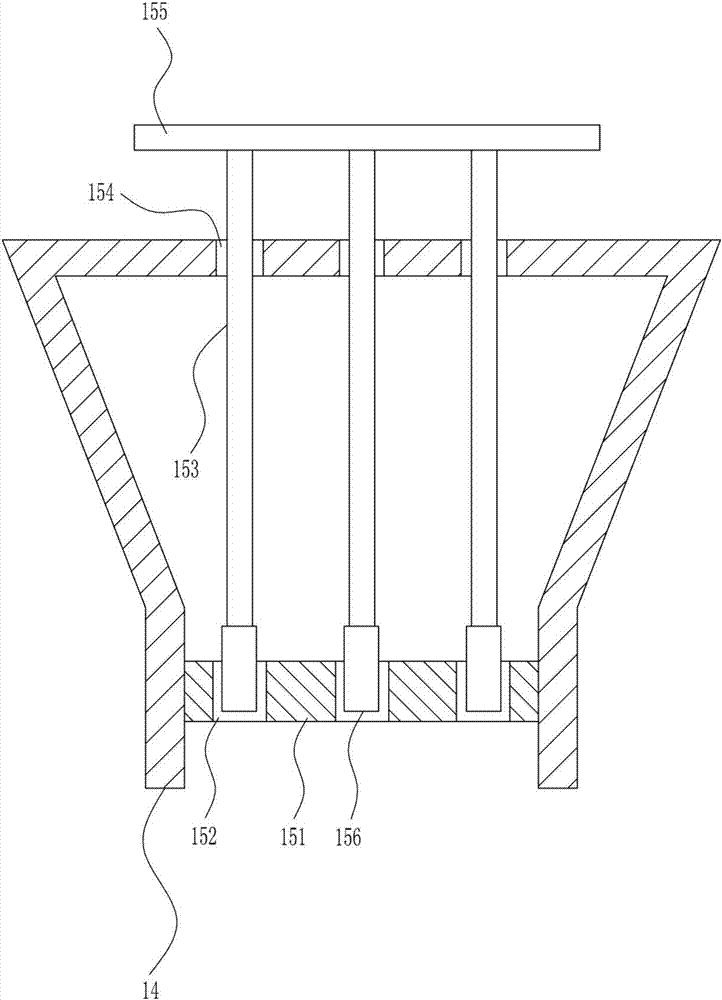

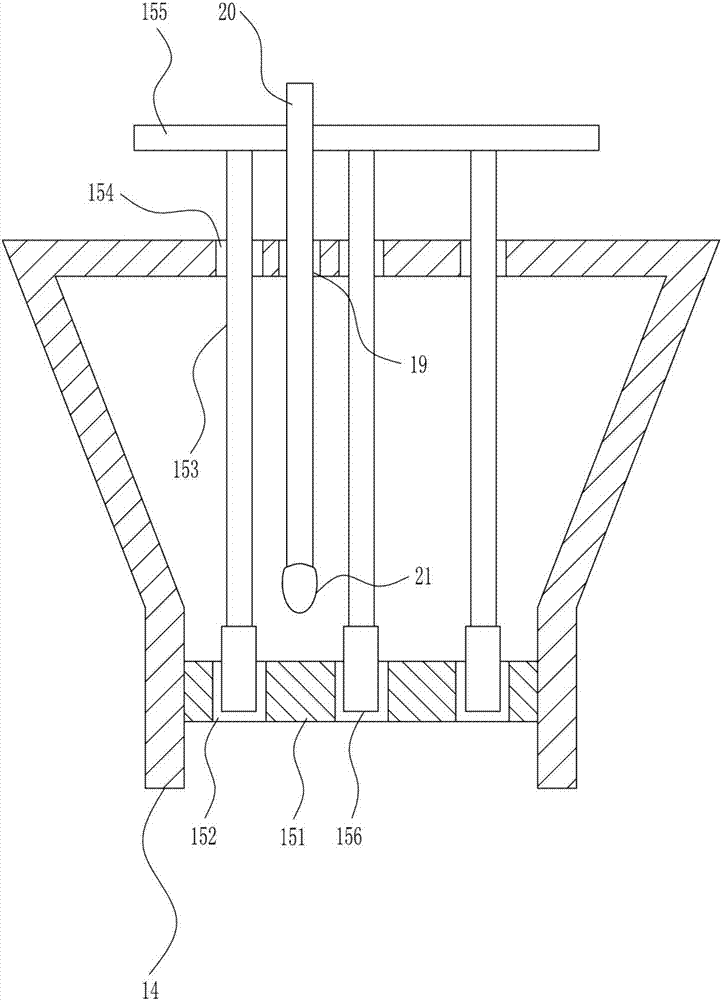

[0031] A metal galvanized pipe cleaning agent preparation device, such as Figure 1-4As shown, it includes a compounding box 1, a slide rail 2, a slider 3, a spring 4, a bearing seat 5, a screw mandrel 6, a first helical gear 7, a nut 8, a stirring rod 9, a first motor 11, a rotating rod 12, Missing tooth helical gear 13, transparent storage box 14, discharge mechanism 15, feed pipe 16, discharge pipe 17 and valve 18, slide rail 2 is connected to the inner bottom of preparation box 1, slide rail 2 is evenly connected with slide A spring 4 is connected between the block 3 and the slider 3 and between the slider 3 on the right side and the right end of the slide rail 2, a bearing seat 5 is connected to the middle of the left and right walls of the preparation box 1, and a screw rod is connected between the bearing seats 5 6. The screw rods 6 on the left and right sides are connected to each other. The thread direction of the screw rod 6 on the left side is opposite to that of th...

Embodiment 2

[0033] A metal galvanized pipe cleaning agent preparation device, such as Figure 1-4 As shown, it includes a compounding box 1, a slide rail 2, a slider 3, a spring 4, a bearing seat 5, a screw mandrel 6, a first helical gear 7, a nut 8, a stirring rod 9, a first motor 11, a rotating rod 12, Missing tooth helical gear 13, transparent storage box 14, discharge mechanism 15, feed pipe 16, discharge pipe 17 and valve 18, slide rail 2 is connected to the inner bottom of preparation box 1, slide rail 2 is evenly connected with slide A spring 4 is connected between the block 3 and the slider 3 and between the slider 3 on the right side and the right end of the slide rail 2, a bearing seat 5 is connected to the middle of the left and right walls of the preparation box 1, and a screw rod is connected between the bearing seats 5 6. The screw rods 6 on the left and right sides are connected to each other. The thread direction of the screw rod 6 on the left side is opposite to that of t...

Embodiment 3

[0036] A metal galvanized pipe cleaning agent preparation device, such as Figure 1-4 As shown, it includes a compounding box 1, a slide rail 2, a slider 3, a spring 4, a bearing seat 5, a screw mandrel 6, a first helical gear 7, a nut 8, a stirring rod 9, a first motor 11, a rotating rod 12, Missing tooth helical gear 13, transparent storage box 14, discharge mechanism 15, feed pipe 16, discharge pipe 17 and valve 18, slide rail 2 is connected to the inner bottom of preparation box 1, slide rail 2 is evenly connected with slide A spring 4 is connected between the block 3 and the slider 3 and between the slider 3 on the right side and the right end of the slide rail 2, a bearing seat 5 is connected to the middle of the left and right walls of the preparation box 1, and a screw rod is connected between the bearing seats 5 6. The screw rods 6 on the left and right sides are connected to each other. The thread direction of the screw rod 6 on the left side is opposite to that of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com