Energy-saving environment-friendly industrial waste gas treatment device

An industrial waste gas, energy saving and environmental protection technology, applied in the direction of dispersed particle separation, chemical instruments and methods, separation methods, etc., can solve the problem of inability to remove organic and harmful gases in industrial waste gas, and achieve the effect of improving purification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0041]Before explaining the specific implementation, in order to avoid repetitive language, it is explained that the following "fixed connection" can be: fixed by bolt connection, welding and rivet connection, etc. Those skilled in the art can choose different connections according to different application scenarios. The fixed connection method, the main purpose is to fix the two parts.

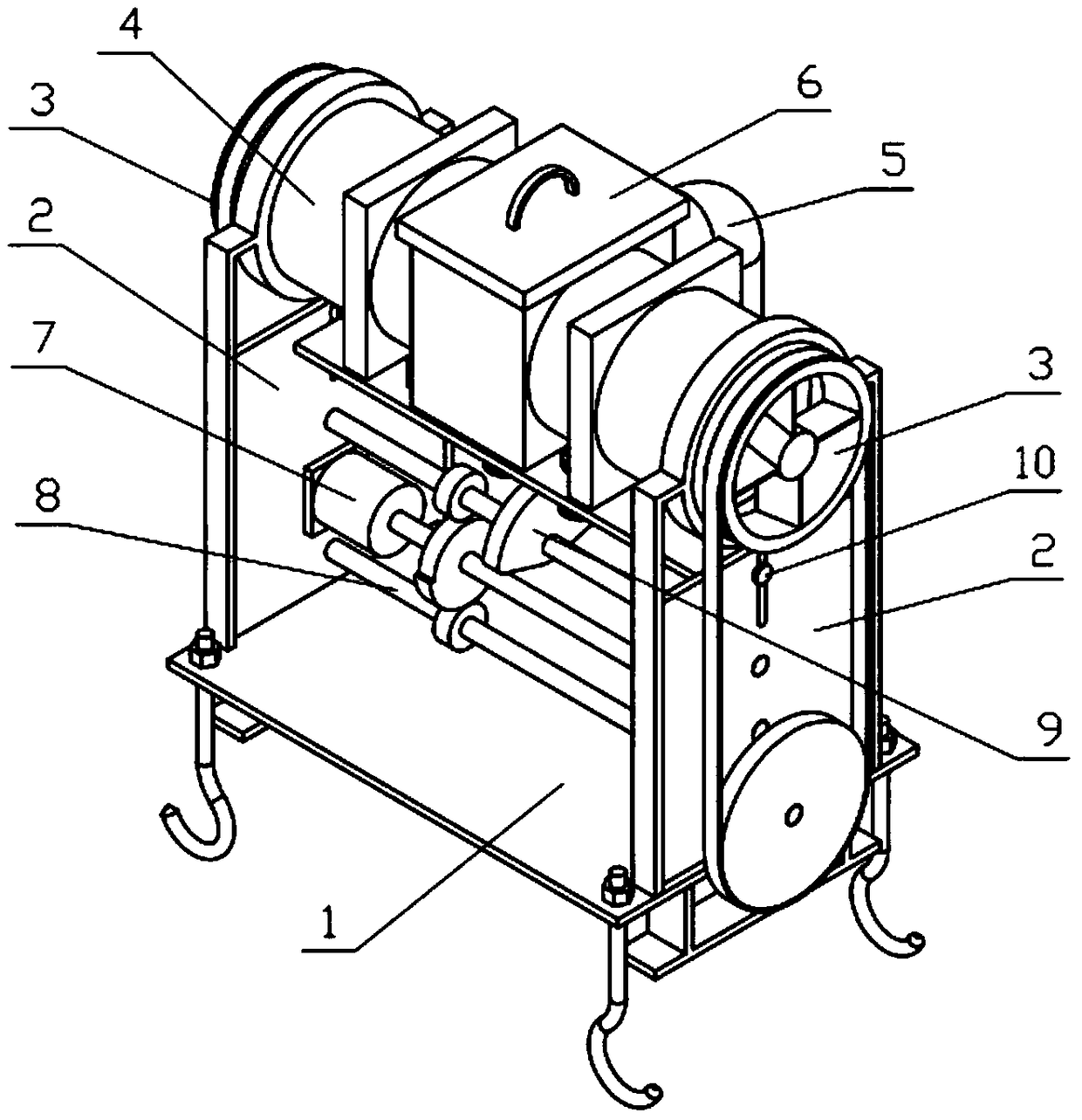

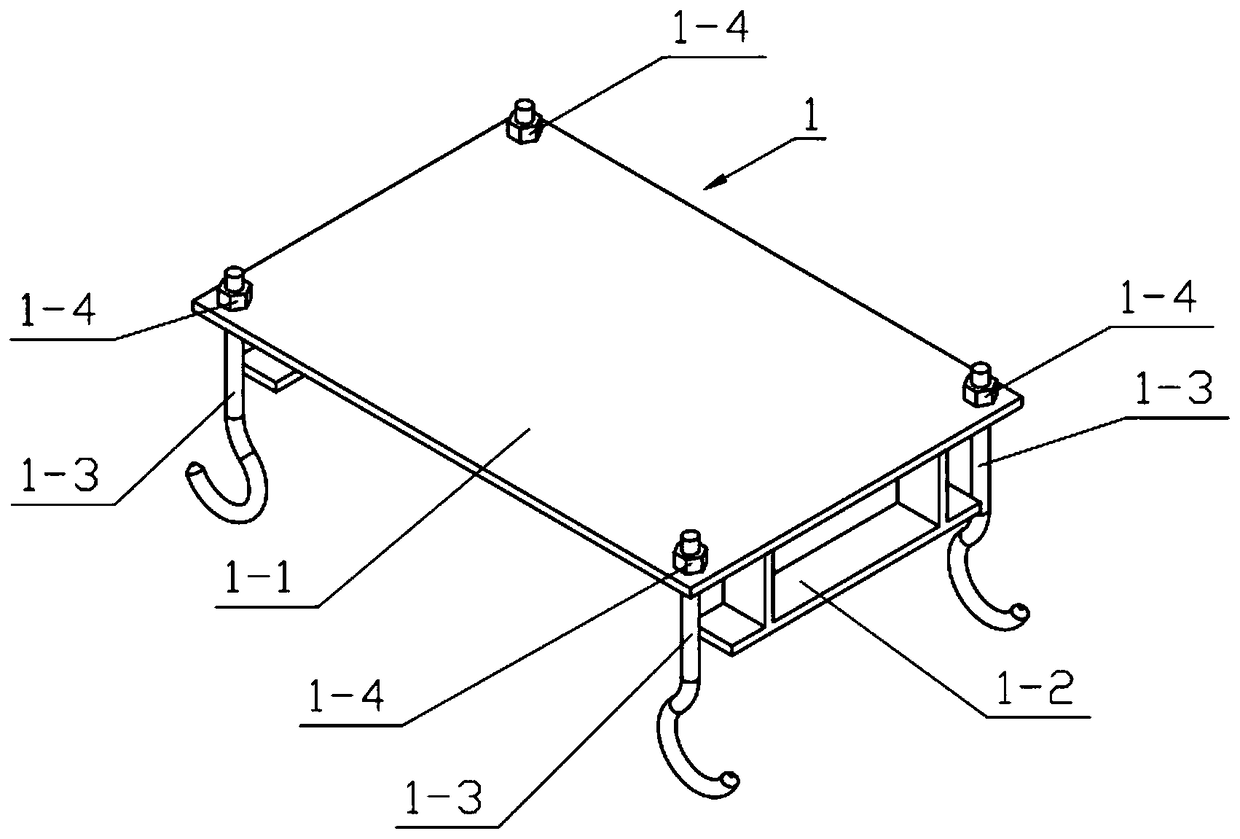

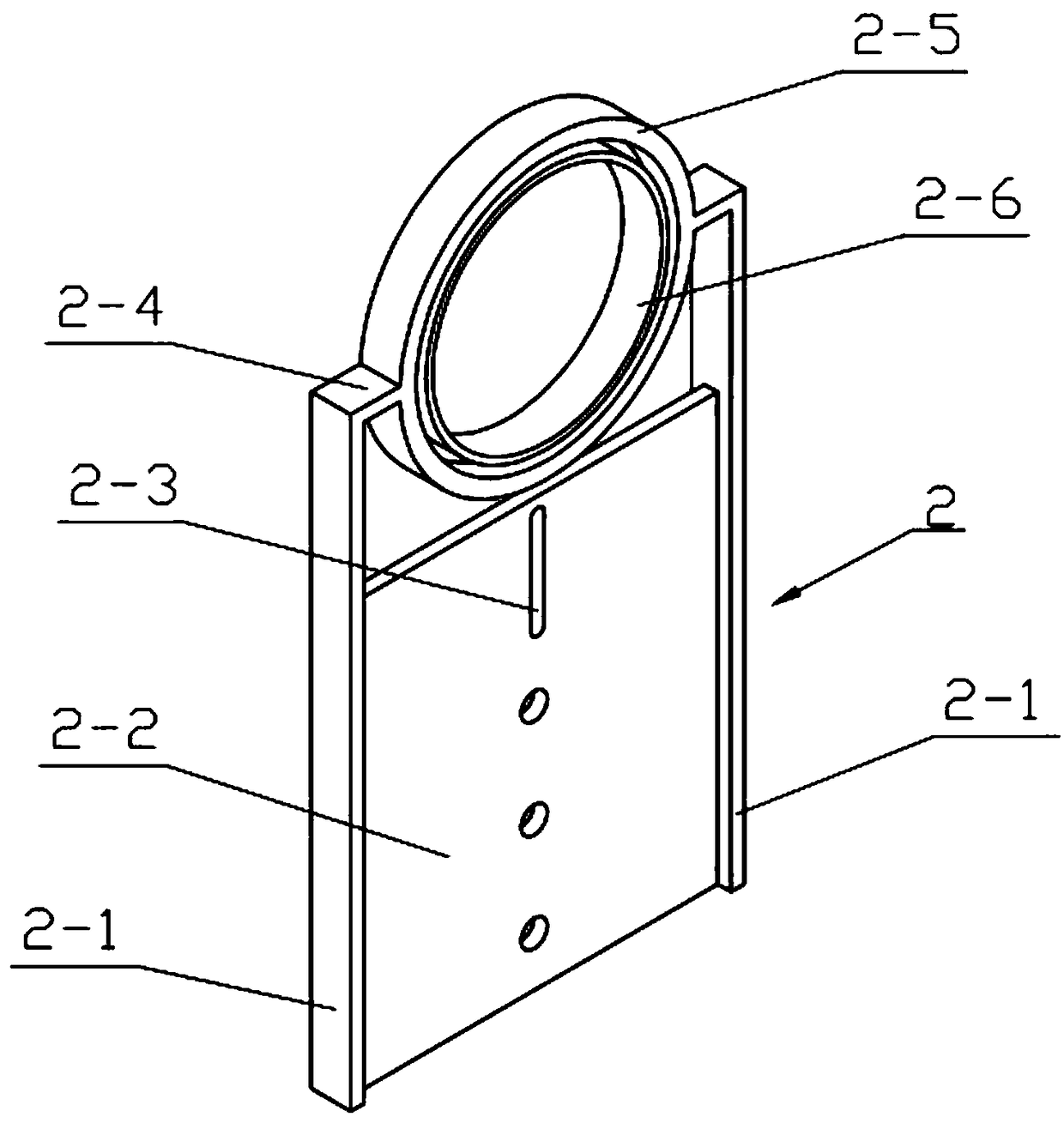

[0042] Combine below Figure 1-14 Describe this embodiment, an energy-saving and environment-friendly industrial waste gas treatment device, including a bottom bracket 1, a support bracket 2, a fan 3, a catalytic cylinder 4, a heat supply pipe 5, a catalyst box 6, a power mechanism 7, a transmission mechanism 8, and a pushing mechanism 9 and the closing mechanism 10, the intermittent operation of the transmission mechanism 8 and the pushing mechanism 9 can be realized through the toothless gear 7-2 provided on the power mechanism 7. When the transmission mechanism 8 works and moves, it drives...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com