Power ultrasonic-assisted feeding device for soil remediation device

A technology of soil remediation and ultrasound, applied in the restoration of contaminated soil, etc., can solve the problems of inability to remediate soil and large-scale feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

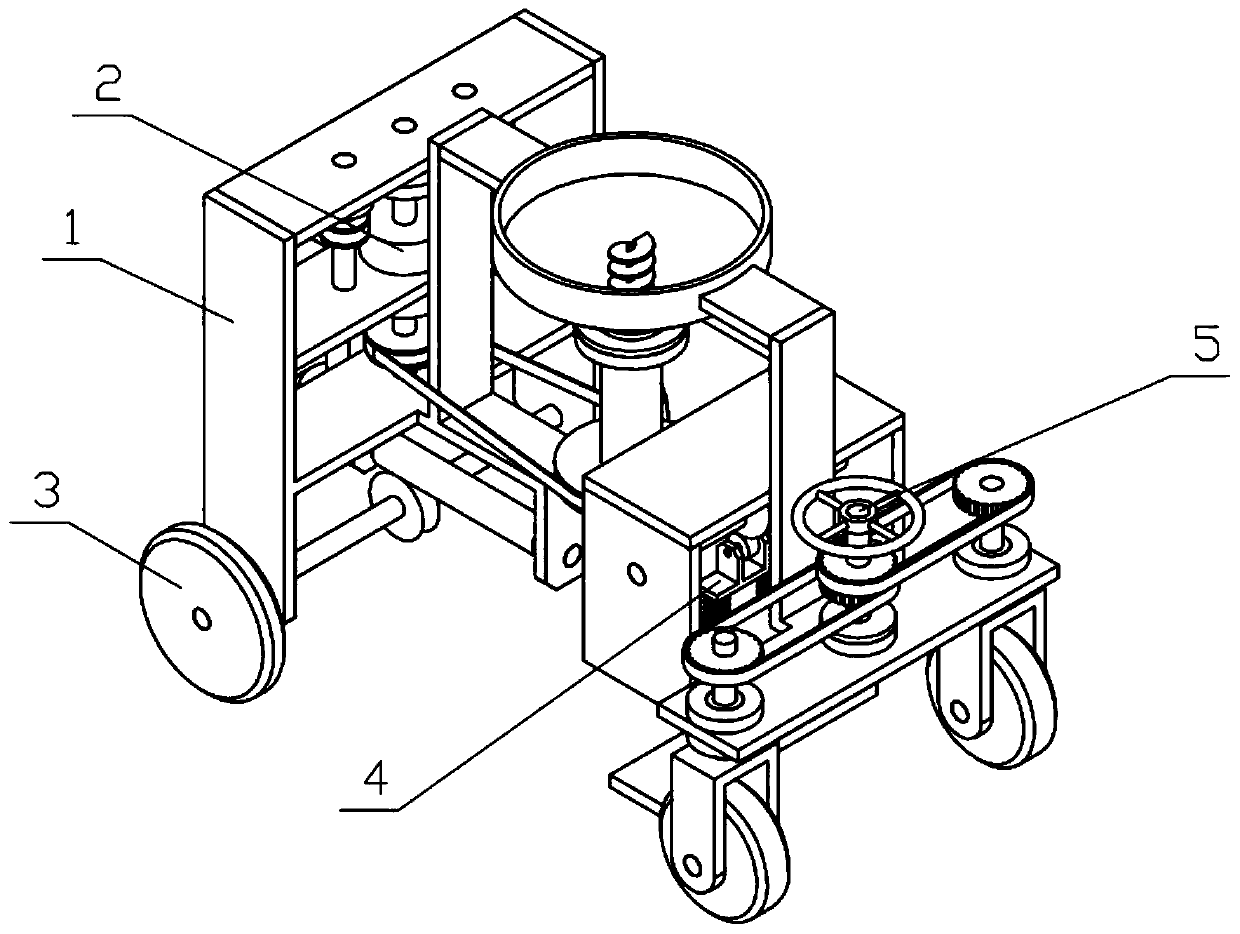

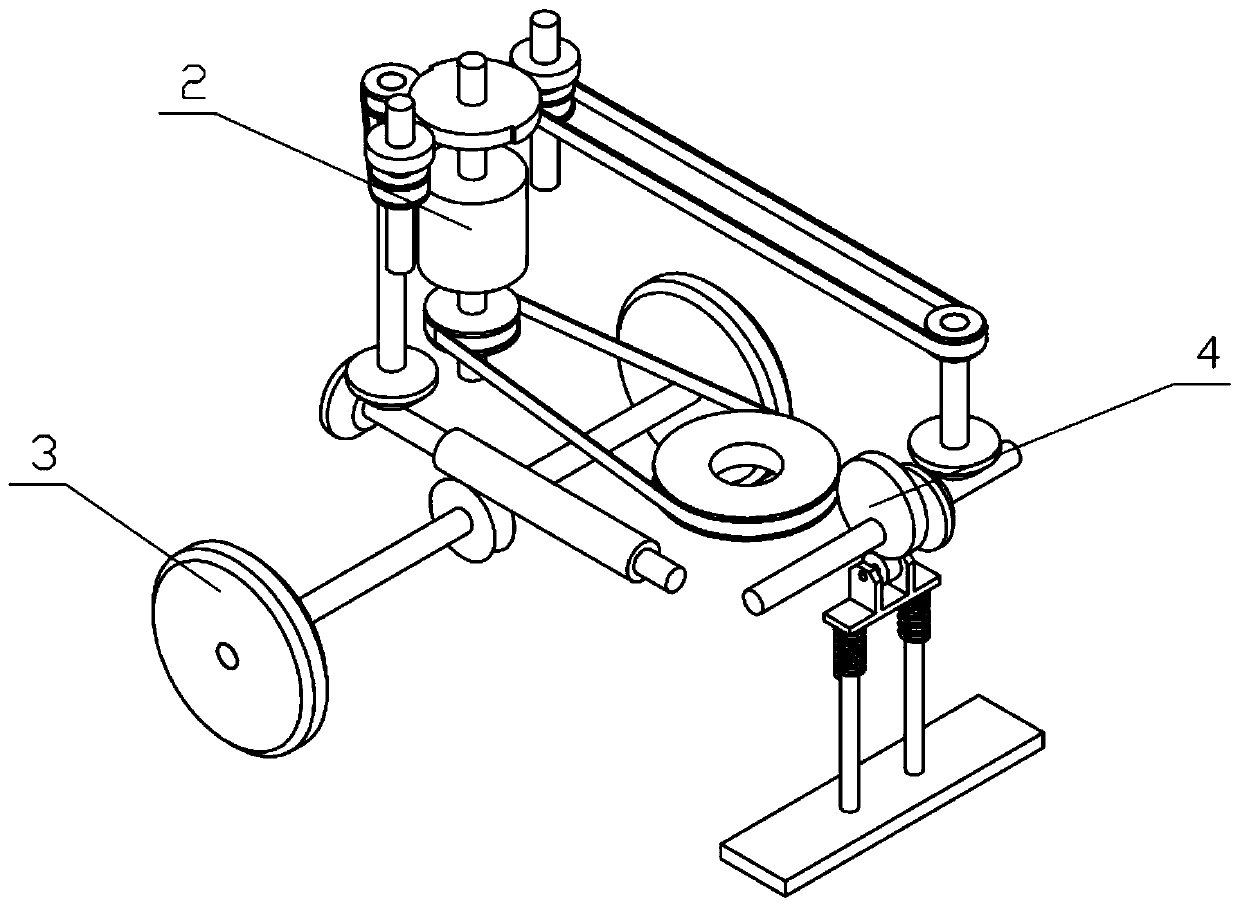

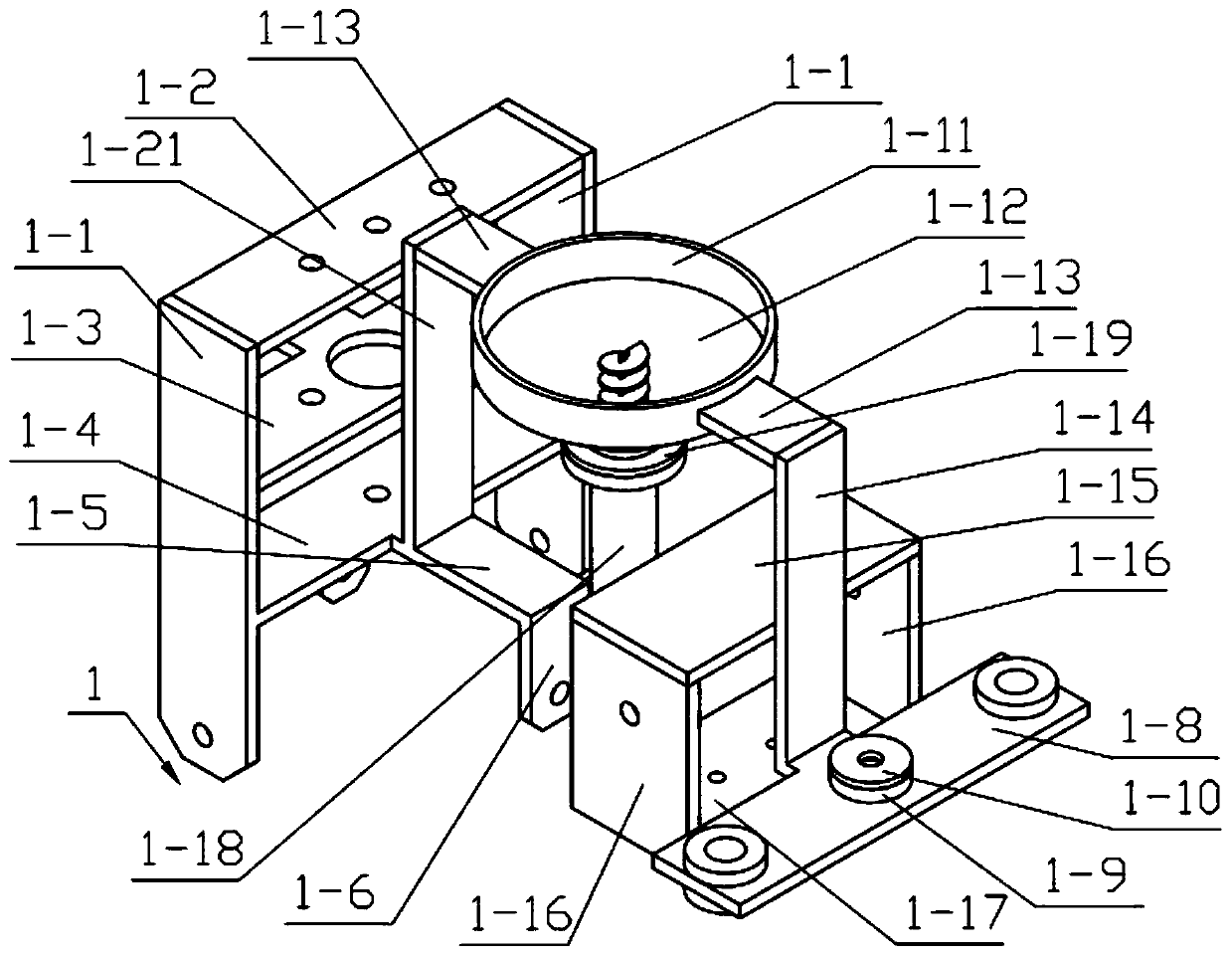

[0027] Combine below Figure 1-8Illustrating this embodiment, a feeding device for a power ultrasonic-promoting soil remediation device includes a whole machine support 1, a power mechanism 2, a motion mechanism 3 and an extrusion mechanism 4. The toothless gears 2- 2. The power gear I2-4 and the power gear II2-10 make the motor 2-1 produce intermittent motion. When the missing tooth gear 2-2 and the power gear I2-4 mesh for transmission, the missing tooth gear 2-2 and the power gear II2- 10 Exit the meshing transmission. When the power gear I2-2 rotates, it drives the motion mechanism 3 to move, and the motion mechanism 3 drives the device to move. When the power gear II2-10 rotates, it drives the extrusion mechanism 4 to move, and the extrusion mechanism 4 is squeezed by ultrasonic waves. The plate 4-7 squeezes the soil, the ultrasonic squeezing plate 4-7 emits ultrasonic waves to oscillate the soil, and the feeding pulley 2-13 drives the feeding screw body 1-20 in the feedi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com