Automatic zipper machine

A zipper machine and zipper technology, applied in the directions of sliding fastener components, clothing, optical device exploration, etc., can solve problems such as poor reliability, inconvenient use, mechanical failure, etc., to improve reliability and stability, and improve detection efficiency. , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below in conjunction with the accompanying drawings.

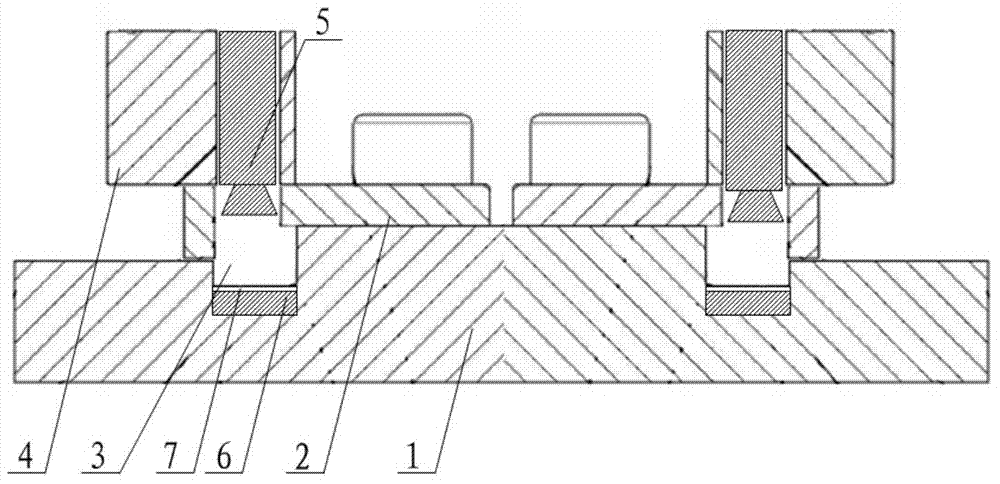

[0014] like figure 1 As shown, the zipper missing tooth automatic detection device in the automatic zipper machine of the present invention includes a base 1, a connecting plate 2 is arranged on the base 1, a zipper channel 3 is provided on the end face of the base 1 facing the connecting plate 2, and the zipper channel 3 is directly above An infrared light emitter 5 is provided, and the infrared light emitter 5 is fixed by the support 4, and the height of the infrared light emitter 5 can be adjusted up and down on the support 4, so as to adapt to the detection of missing teeth of different types of zippers; under the infrared light emitter 5 An infrared sensor 6 corresponding to the infrared light emitter 5 is arranged directly below the zipper channel; a transparent protective layer 7 is arranged above the infrared sensor 6 to provide better protection for the infr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com