Method for modifying flywheel ring gear tooth profile error

A flywheel ring gear and tooth profile error technology, applied in fuel injection control, engine control, machine/engine, etc., can solve problems such as injection angle and injection width error, and achieve the effect of solving injection angle and injection width error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

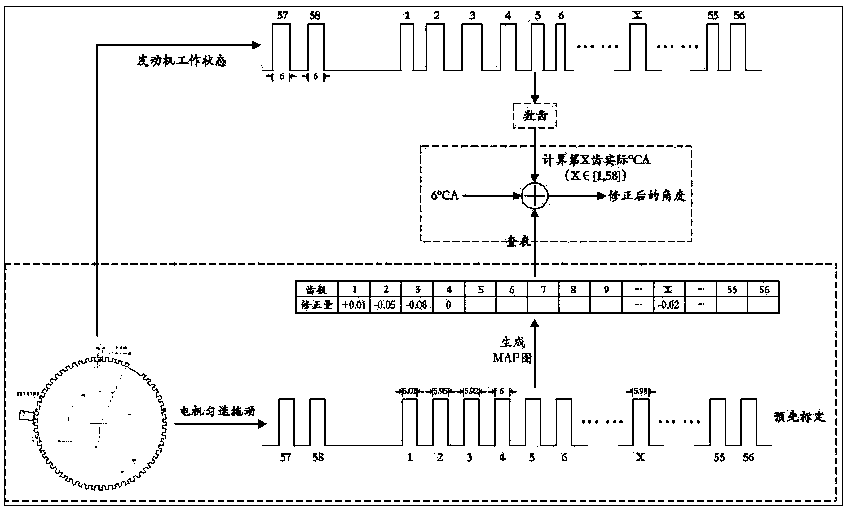

[0012] Such as figure 1 As shown, a flywheel ring gear tooth shape error correction method, the steps are as follows: ⑴Drag the flywheel ring gear with a motor at a constant speed, collect the tooth shape signal on the ring gear through a speed sensor and record it with an oscilloscope; ⑵Under constant speed rotation, 60 -For a ring gear with 2 teeth, the pulse width of each tooth shape should be 6oCA under ideal conditions. Calibrate from the first tooth after the missing tooth signal, record the error value of each tooth, and form a MAP diagram; (3) Make the engine in In the online working state, start counting the teeth after detecting the missing teeth of the ring gear, and prepare for injection; (4) The error correction method corresponding to each tooth is 6oCA under the ideal state plus the corresponding tooth number in the MAP diagram in step (2) The error value, the output after calculation is the actual angle of the tooth, which is used for injection control.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com