Damper apparatus

A damper device and sector gear technology, which is applied to valve devices, transmission devices, gear transmission devices, etc., can solve problems such as abnormal noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

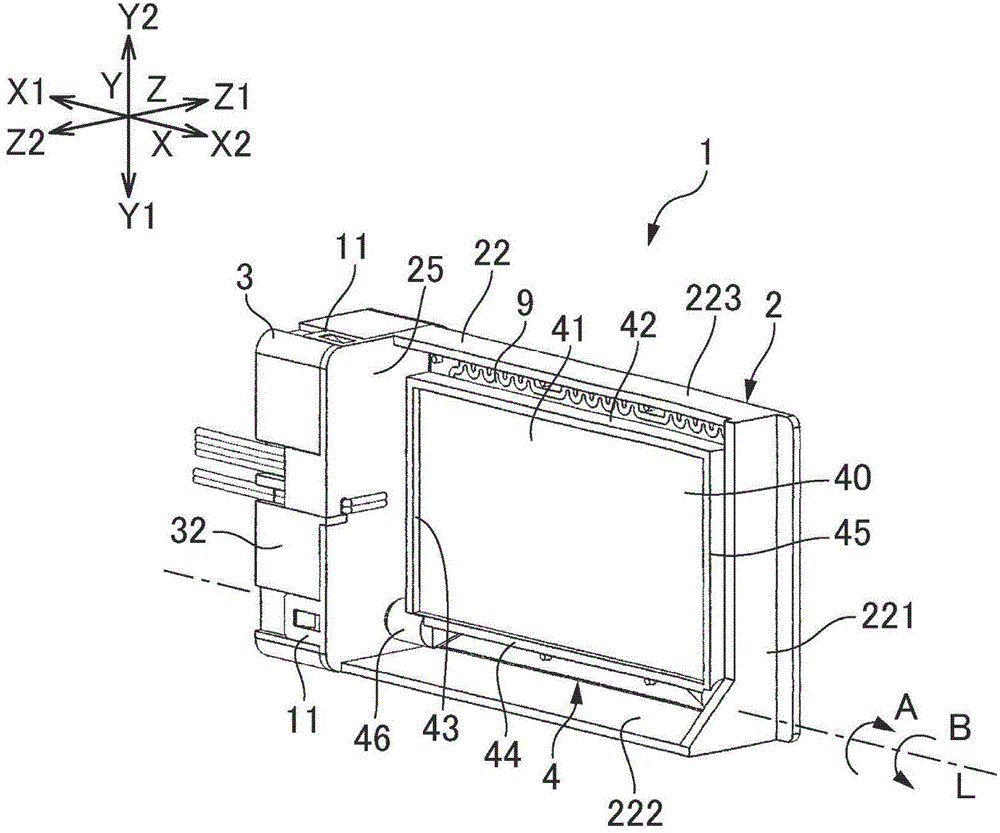

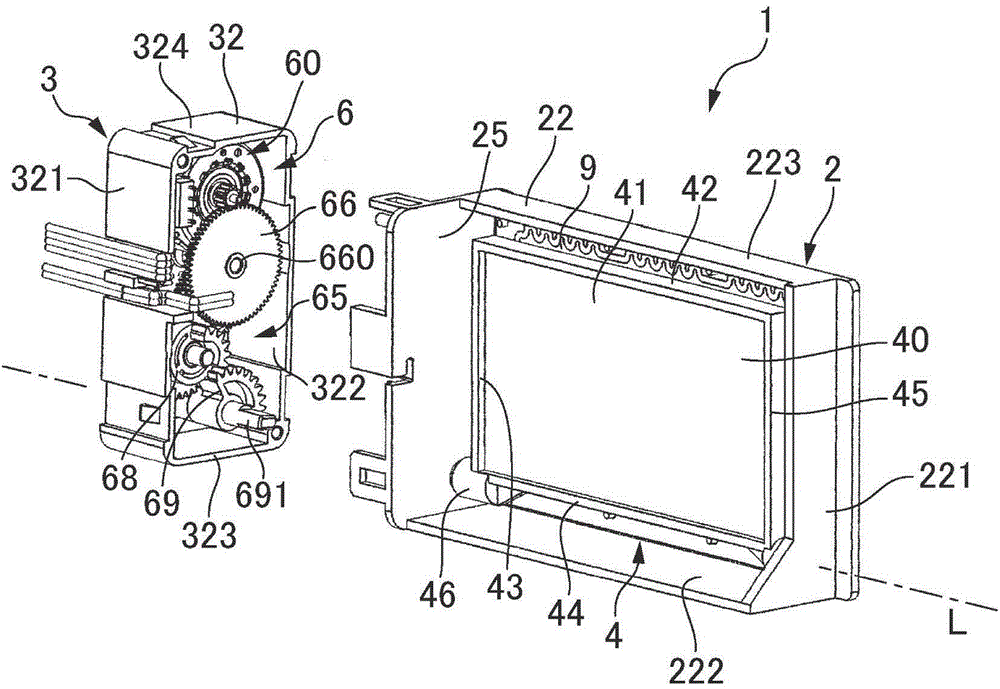

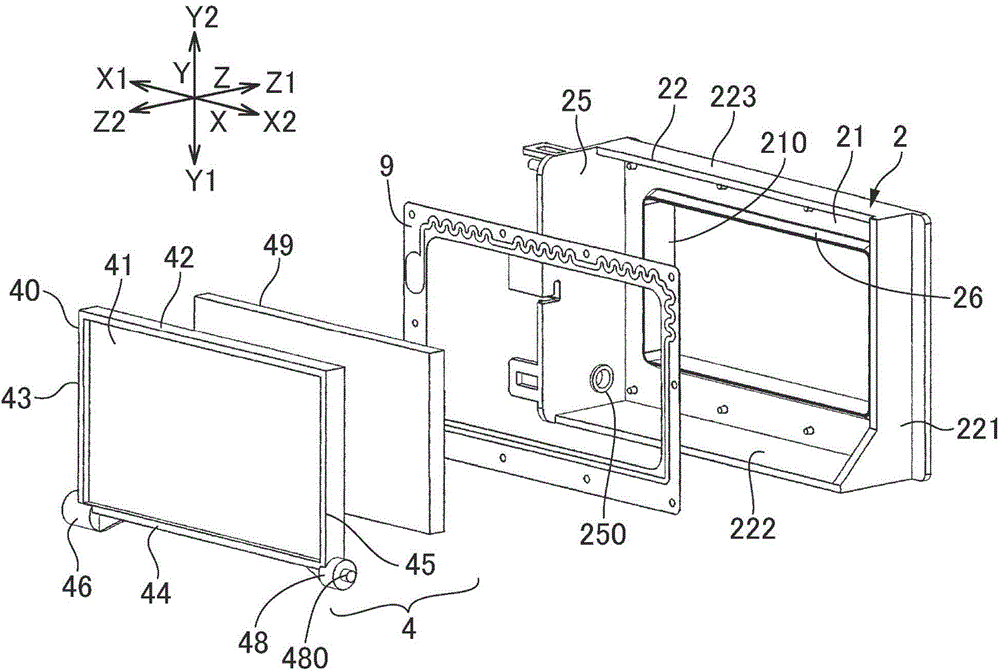

[0063] Hereinafter, a damper device for a refrigerator to which the present invention is applied will be described with reference to the drawings. In the following description, let the rotation center axis of the baffle 4 be L, the direction along the rotation center axis L be the X direction, and the direction facing the opening be the Z direction, and be perpendicular to the X direction and the Z direction. The direction is the Y direction for description. And, let one side of the X direction be X1, the other side of the X direction be X2, one side of the Y direction be Y1, the other side of the Y direction be Y2, one side of the Z direction be Z1, and The other side in the Z direction is described as Z2. In addition, the rotation central axis L is defined as a horizontal direction, the one side Y1 in the Y direction is the lower side in the direction of gravity, and the other side Y2 in the Y direction is described as the upper side in the direction of gravity.

[0064] (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com