Mechanical automatic feeding mechanism

An automatic feeding and frame technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of high use cost, inconvenient production matching, complex structure, etc., achieve convenient use, overcome the poor interchangeability between manual and mechanical, good interchangeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

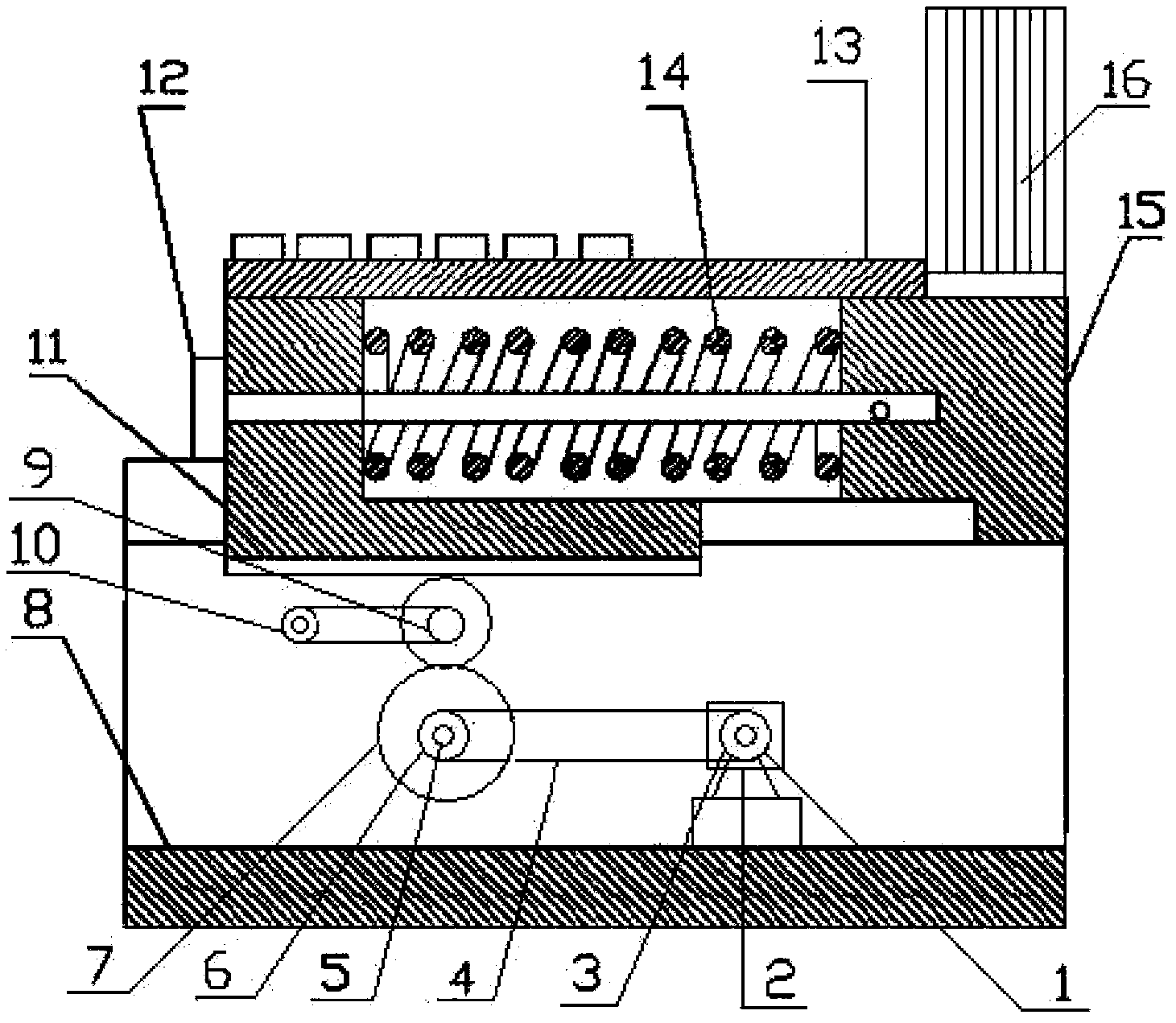

[0009] The automatic feeding mechanism has a transmission guide post (12). The transmission guide post (12) is inserted into the hole of the rack (11), and the rack (11) is loaded into the guide rail of the frame (8). (12) There is a return spring (14) on the upper sleeve, a hopper seat (15) is connected to the right end of the transmission guide column (12), and a feeding plate (13) and a feed hopper (16) are installed on the hopper seat (15). ); on the frame (8) a variable frequency speed regulating motor (1) is installed, and a speed changer (2), a driving chain (3) and a chain (4) are connected on the frequency variable speed regulating motor (1), and the chain ( One end of 4) is connected with a transmission shaft (5), on which is connected a passive chain (6) and a tooth-missing gear (7), and a roller shaft (9) is connected to the tooth-missing gear (7). A roller (10) is connected to the axle (9), and a transmission guide post (12) is connected to the roller (10).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com