Method for designing and manufacturing repair-orientated planting bone augmentation guide plate

A production method and incremental technology, applied in the direction of dental implants, dental prosthetics, computer-aided planning/modeling, etc., can solve the problems of increasing the patient's economic burden, increasing the risk of surgery, spending time and energy, and improving the success rate. , the effect of reducing risk and accurate control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

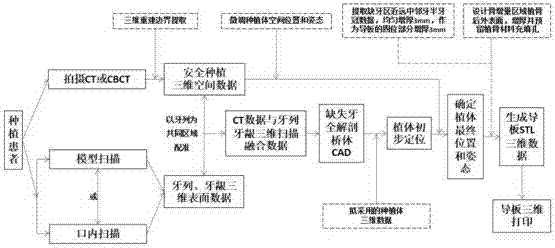

[0028] see figure 1 , a kind of repair-oriented bone implant augmentation guide plate design and manufacture method of the present invention has the following steps:

[0029] A repair-oriented method for designing and manufacturing a bone augmentation guide plate, characterized in that it has the following steps:

[0030] (1) Take a CT or CBCT of the patient's edentulous area, obtain the data in DICOM format, and use the CT data 3D editing software to 3D reconstruct it into STL data. From this data, extract the 3D boundary between the jawbone and soft tissue in the implant area, and extract the mesial and distal adjacent teeth The three-dimensional boundaries of important anatomical structures such as the root of the tooth, the floor of the maxillary sinus, and the canal of the mandibular nerve;

[0031] (2) Direct scanning with an i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com