Design and manufacture method of a restoration-oriented tooth-supported implant surgery guide

A production method and supportive technology, which can be used in prosthodontics, dental implants, dentistry, etc., can solve the problems of time and energy, increase the risk of surgery, increase the economic burden of patients, etc., so as to improve the success rate, reduce risks and costs. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

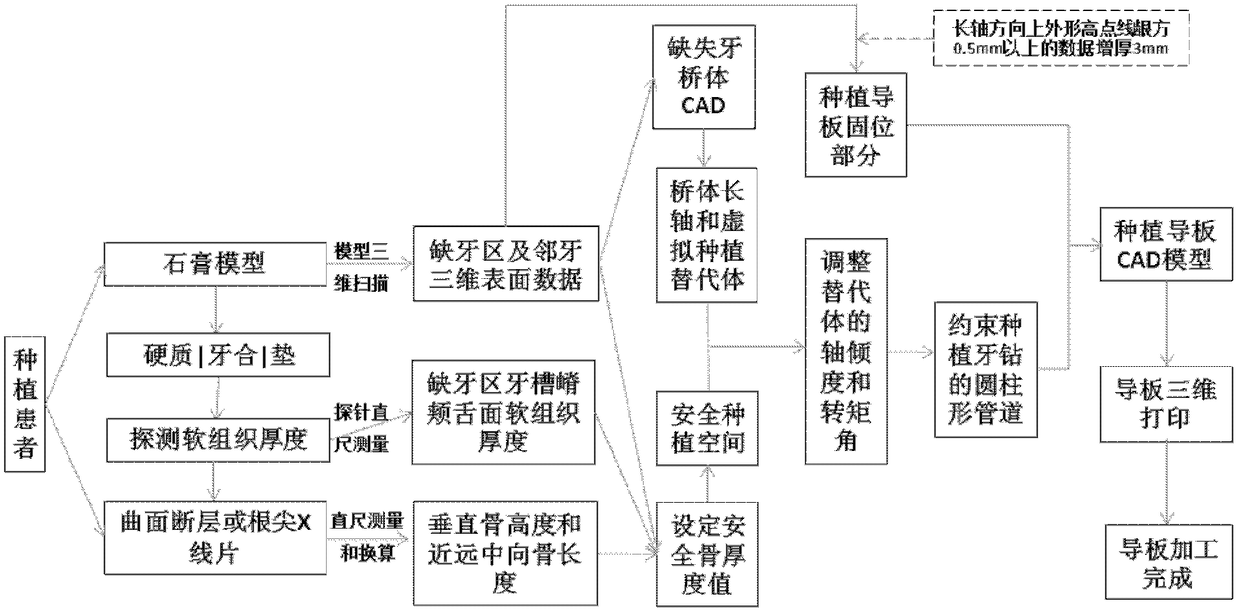

[0024] Referring to Fig. 1, a method for designing and manufacturing a restoration-oriented tooth-supported implant surgery guide plate of the present invention has the following steps:

[0025] (1) Make a plaster model of the dentition where the tooth to be implanted is located; make a hard|occlusal|pad with a 5mm steel ball on the alveolar ridge top of the edentulous area and a uniform sampling detection hole of the buccal-lingual soft tissue thickness;

[0026] (2) Topically anesthetize the alveolar ridge mucosa of the patient's edentulous area, place the |occlusal| pad on the patient's dentition completely, and use a pointed probe with a depth indicator sheet and a steel ruler to measure the position of each probe hole soft tissue thickness;

[0027] (3) Take the X-ray film or root tip film of the patient's oral surface with|occlu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com