Mung bean chocolate crackling and production method thereof

A chocolate and mung bean technology, applied in dairy products, milk preparations, baking, etc., can solve the problems of single taste of chocolate crispy skin, unreasonable nutritional composition, and rare research on chocolate crispy skin, and achieve bright color and nutrition Reasonable composition and the effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

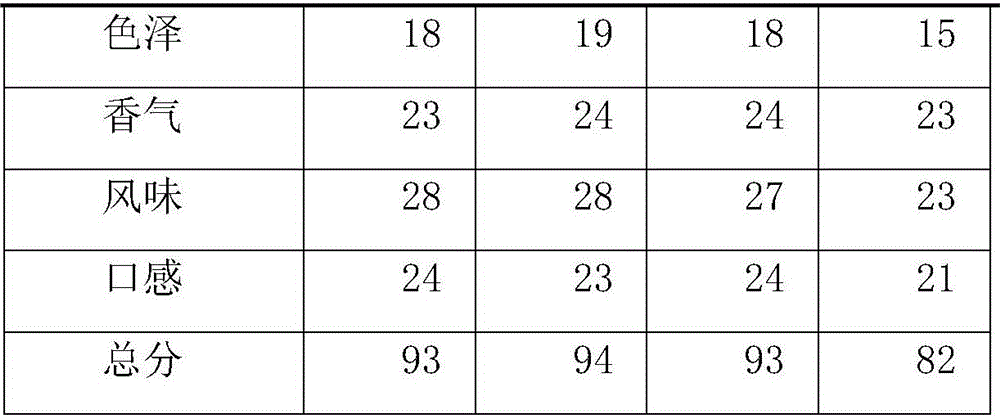

Examples

Embodiment 1

[0034] A mung bean chocolate crispy skin is prepared from raw materials comprising the following parts by weight:

[0035]60 parts of sugar, 130 parts of palm oil, 40 parts of cocoa butter, 20 parts of cocoa mass, 30 parts of coconut oil, 65 parts of mung bean powder, 0.15 parts of monoglyceride fatty acid ester, 0.1 part of polyglycerol fatty acid ester, 1.2 parts of phospholipid, 0.12 parts of salt, 0.15 parts of essence;

[0036] A preparation method for mung bean chocolate crispy skin, comprising the steps of:

[0037] Mung bean is fried, ultrafinely pulverized to 10-25μm, and mung bean powder is obtained;

[0038] White sugar is crushed to 0.1-0.14mm;

[0039] Melt palm oil, add coconut oil and mix evenly, heat to 50°C, add cocoa liquor, cocoa butter, finely grind, start stirring, rotate speed 550r / min, add crushed white sugar, mung bean powder, monoglyceride fatty acid ester, Polyglycerol fatty acid ester, table salt; after stirring well, adjust the speed to 700r / min,...

Embodiment 2

[0041] A mung bean chocolate crispy skin is prepared from raw materials comprising the following parts by weight:

[0042] 50 parts of white sugar, 100 parts of palm oil, 20 parts of cocoa butter, 30 parts of cocoa mass, 5 parts of cocoa butter substitute, 40 parts of coconut oil, 30 parts of mung bean powder, 0.3 parts of monoglyceride fatty acid ester, 0.2 part of polyglycerol fatty acid ester, phospholipid 2 parts, 0.05 parts of salt, 0.3 parts of essence;

[0043] A preparation method for mung bean chocolate crispy skin, comprising the steps of:

[0044] Mung bean is fried, ultrafinely pulverized to 10-25μm, and mung bean powder is obtained;

[0045] White sugar is crushed to 0.1-0.14mm;

[0046] Melt palm oil, add coconut oil and mix evenly, heat to 45°C, add cocoa liquor, cocoa butter, cocoa butter substitute, finely grind, turn on stirring, speed 500r / min, add crushed white sugar, mung bean powder, monoglycerin in turn Fatty acid ester, polyglycerin fatty acid ester,...

Embodiment 3

[0048] A mung bean chocolate crispy skin is prepared from raw materials comprising the following parts by weight:

[0049] 70 parts of sugar, 160 parts of palm oil, 60 parts of cocoa butter, 10 parts of cocoa mass, 10 parts of cocoa butter substitute, 10 parts of coconut oil, 100 parts of mung bean powder, 0.3 parts of monoglyceride fatty acid ester, 0.01 part of polyglycerol fatty acid ester, phospholipid 0.5 parts, 0.05 parts of salt, 0.01 parts of essence;

[0050] A preparation method for mung bean chocolate crispy skin, comprising the steps of:

[0051] Mung bean is fried, ultrafinely pulverized to 10-25μm, and mung bean powder is obtained;

[0052] White sugar is crushed to 0.1-0.14mm;

[0053] Melt palm oil, add coconut oil and mix evenly, heat to 55°C, add cocoa liquor, cocoa butter, cocoa butter substitute, finely grind, start stirring, speed 530r / min, add crushed white sugar, mung bean powder, monoglycerin in sequence Fatty acid ester, polyglycerin fatty acid este...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com