Mung bean peeling machine

A technology for peeling machine and mung bean, which is applied in the fields of application, food processing, food science, etc., can solve the problems of long grinding time, clogging of holes, low rice yield, whole rice rate and productivity, etc. The effect of rice yield and avoiding clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

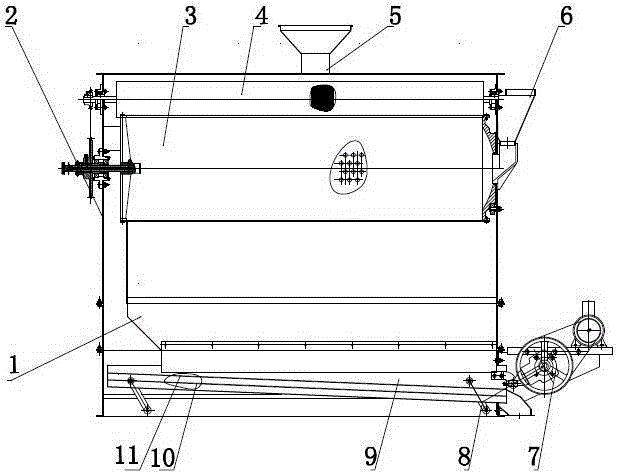

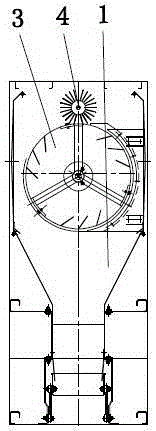

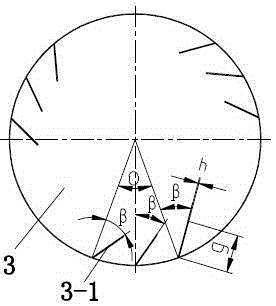

[0018] The mung bean peeling machine of this embodiment is such as figure 1 , figure 2 As shown, it includes a hopper 5 installed on the top of the frame 2. Below the hopper 5 is a horizontal peeling drum 3 supported on the frame 2. The peeling drum 3 has circular holes 3-2 distributed at intervals. Such as Figure 4 As shown, two adjacent circles of circular holes are arranged in staggered circumferential direction, the staggered spacing a is 4mm, the axial spacing b is 6-8mm, and the diameter of the circular holes is -0.1~-0.3mm of the aperture of the grading mung bean screen. The diameter d of the circular hole in the embodiment is controlled to be -0.2 mm, which is 3.3 mm, which is 3.5 mm in the sieve aperture of the classified mung bean. Therefore, in theory, 3.5mm mung beans can fall from the round hole after removing 0.1mm of skin through the rotating friction of the drum.

[0019] Such as image 3 As shown, the stripping drum 3 is provided with alternately distributed co...

Embodiment 2

[0023] The basic structure of the mung bean peeling machine of this embodiment is the same as that of the first embodiment. The difference is that the copy plate 3-1 arranged in the peeling drum 3 is spiral, which not only can make the material relative to the peeling drum circumferentially shift, but also Relative axial displacement. Therefore, the flipping is more uniform and effective, and the peeling and screening effect is better.

[0024] Compared with the prior art, the mung bean peeling machine of the above embodiment has the following significant advantages:

[0025] 1) Not only can peeled reliably, but also copied evenly, and can screen peeled mung beans in real time;

[0026] 2) It can effectively avoid the blockage of the peeling drum and ensure the smooth flow of peeling and screening;

[0027] 3) Optimize the design parameters to ensure the desired peeling and screening effect;

[0028] 4) The combination of the front rolling peeling and screening and the final vibrating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com