An inductor full-automatic and high-efficiency assembly device

An assembly equipment, fully automatic technology, applied in the direction of inductance/transformer/magnet manufacturing, circuits, electrical components, etc., can solve the problem of not being able to output one by one, and achieve the effect of saving external force output, increasing labor output, and ingenious structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

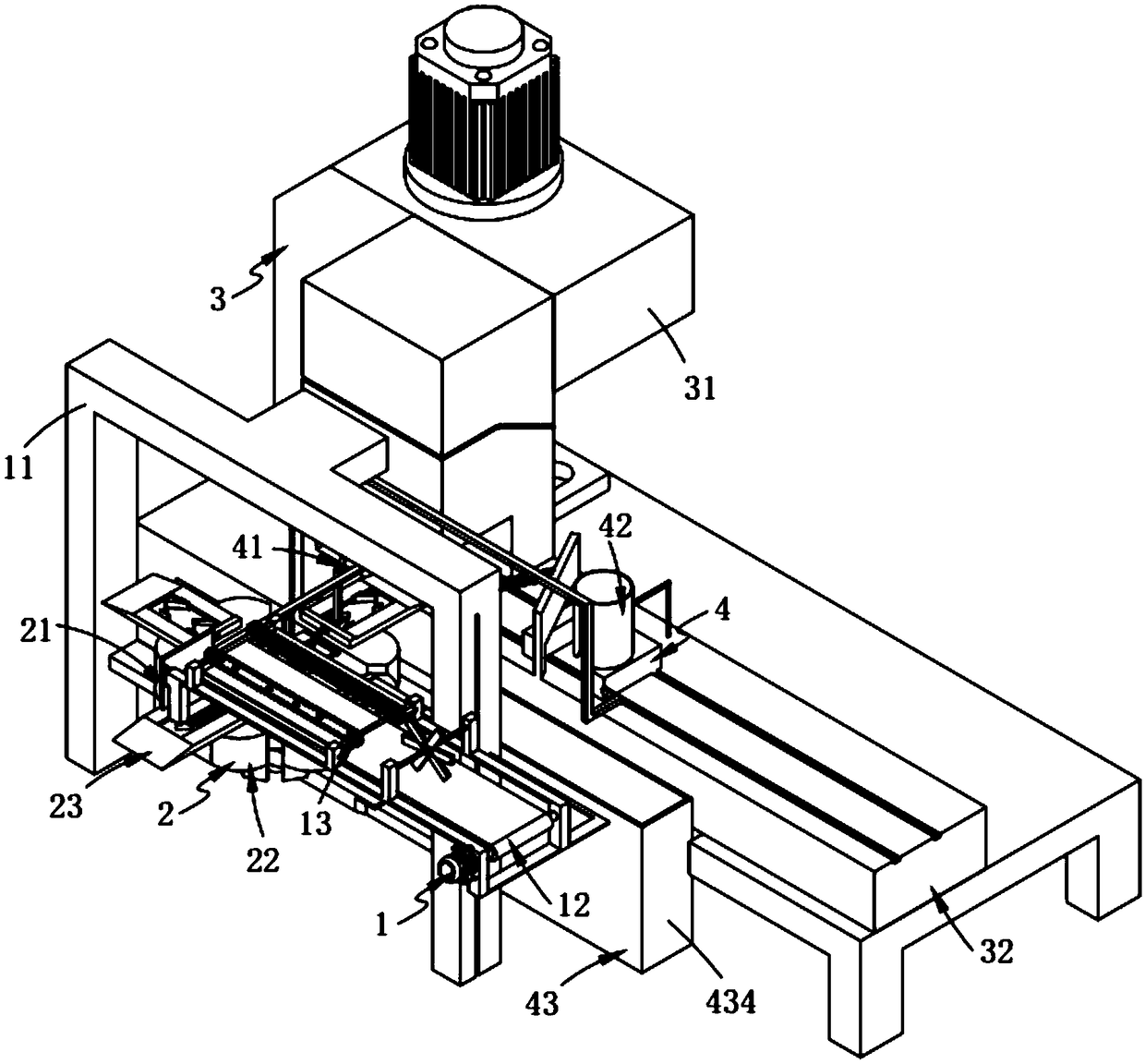

[0073] Such as figure 1 As shown, a fully automatic high-efficiency assembly equipment for inductance includes:

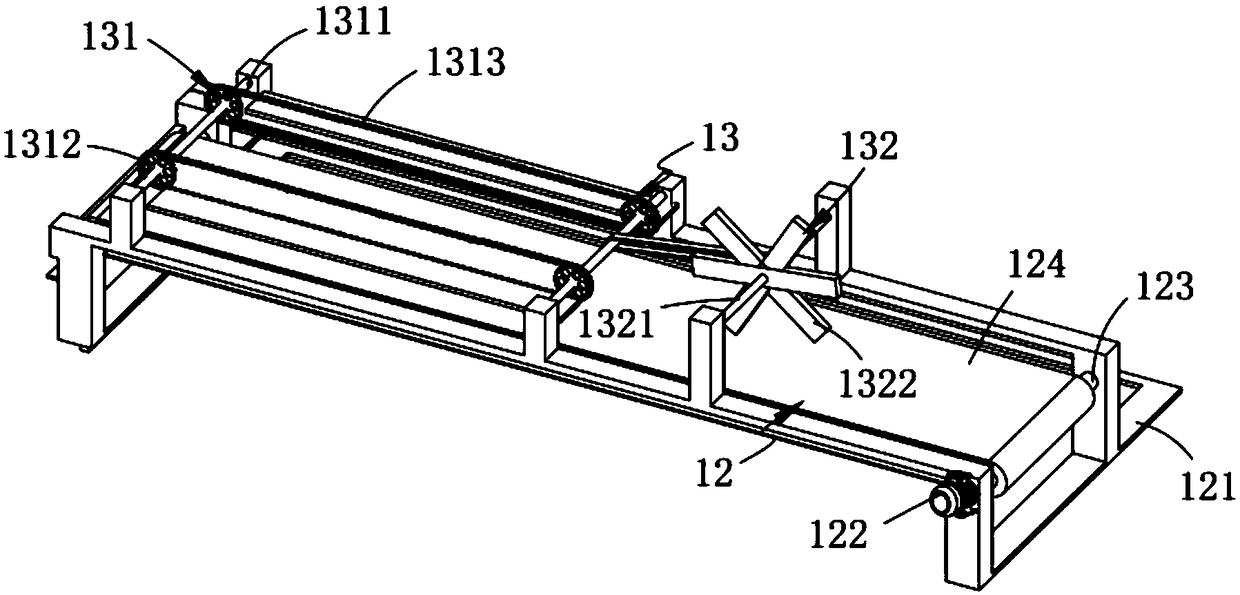

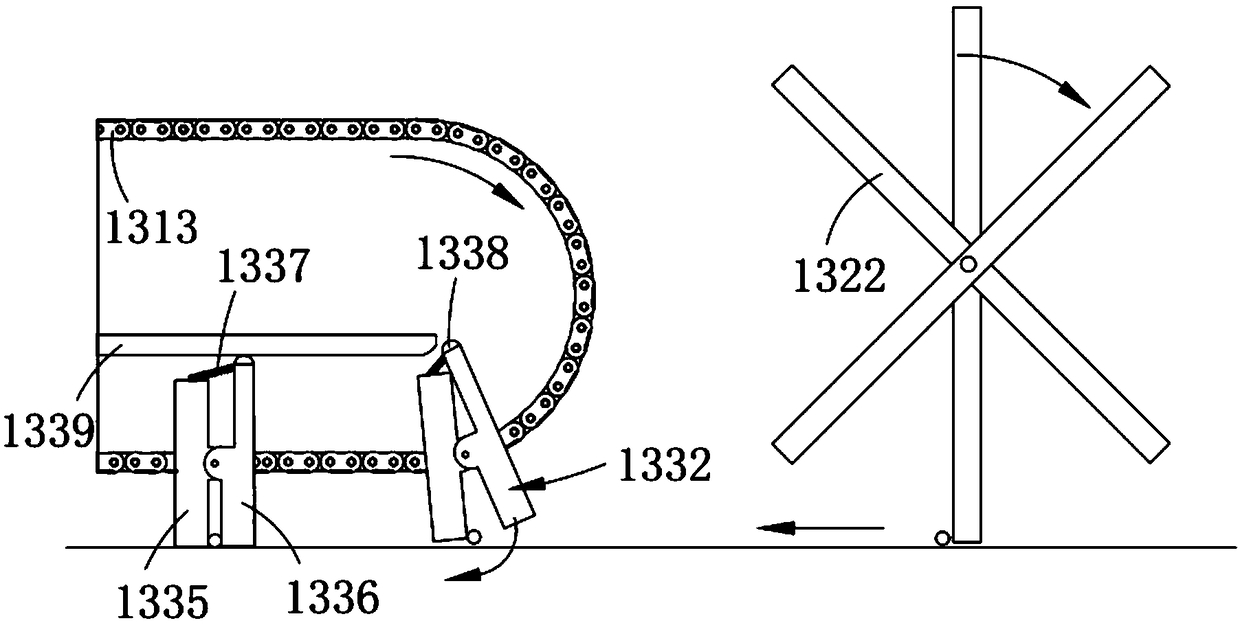

[0074] A wire flattening mechanism 1, the wire flattening mechanism 1 includes a frame 11, a conveying assembly 12 arranged on the frame 11, and a stretching assembly installed on the conveying assembly 12 and located above the conveying assembly 12 13;

[0075] The wire transmission mechanism 2, the wire transmission mechanism 2 includes a wire crimping assembly 21 arranged below the output end of the delivery assembly 12, a switching assembly 22 located below the crimping assembly 21 and rotatably arranged on the frame 11 and several clamping assemblies 23 arranged on the switching assembly 22 and arranged along the circumference of the switching assembly 22;

[0076] A wiring mechanism 3, the wiring mechanism 3 comprising a crimping machine 31 and a support assembly 32 fixedly connected to the crimping machine 31; and

[0077] The coil transmission mechanism ...

Embodiment 2

[0131] Such as Figure 8 , Figure 9 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between this embodiment two and embodiment one is:

[0132] further, such as Figure 8 , Figure 9 As shown, the drive assembly 41 includes:

[0133] Flat push piece 411, described flat push piece 411 comprises the cylinder 4111 that is fixedly installed on the frame 11 by cylinder frame, the fixed rod 4112 that one end is fixedly connected with the telescoping end of described cylinder 4111 and the fixed rod 4112 that is connected with described fixed rod 4112 The other end is fixedly connected to the positioning tube 4113; and

[0134] The orientation member 412, the orientation member 412 includes a pull rod 4121 fixedly connected to the fixed rod 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com