Patents

Literature

396results about How to "Beautiful and fragrant" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Salty salicornia europaea egg tart and preparation method thereof

InactiveCN102669244ADisadvantages of changing the taste of heavy additives that are too greasy and too sweetImprove blood acidificationDough treatmentBakery productsBiotechnologyAnimal science

The invention relates to salty salicornia europaea egg tart and a preparation method thereof. In the tart wrapper, the weight ratio of salicornia europaea meal, rye meal, oat meal, wheat germ meal, natural cream, vegetable oil to clean water is 1: 18: 3: 2: 12.5: 0.25: (5-7.5); and in the aqueous tart, the weight ratio of the salicornia europaea meal, Chinese yam meal, egg white to fresh milk is 2: 1: 24: 36. The preparation method for the salty salicornia europaea egg tart comprises the following steps of: preparing the tart wrapper and the aqueous tart, shaping and baking. The preparation method for the egg tart is easy to master; and salicornia europaea containing amino acids, trace elements and vitamins which are necessary for human body is added in the raw materials, and the egg tartdoes not contain any chemical additive and is fully natural healthy food.

Owner:NANJING UNIVERSITY OF TRADITIONAL CHINESE MEDICINE

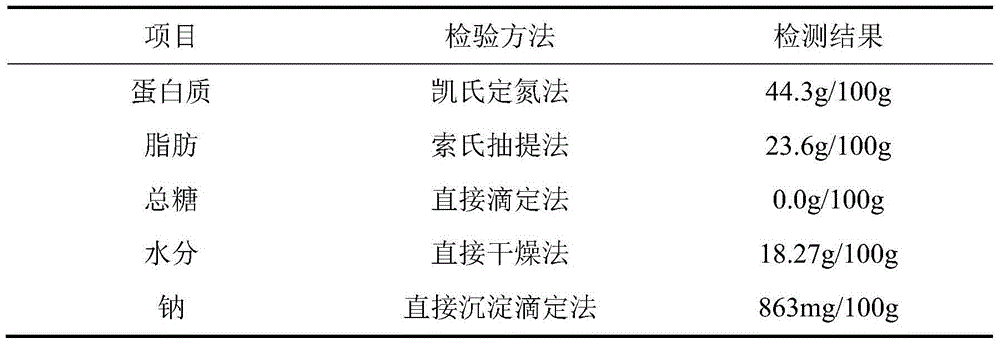

Bologna sausage and preparation method thereof

InactiveCN102038208AThe ratio of group allocation is reasonableBeautiful and fragrantFood preparationMonosodium glutamateFood additive

The invention relates to a bologna sausage. The bologna sausage comprises pork, chicken, emulsified skin, ice water, salt, sugar, monosodium glutamate, composite phosphate, modified starch, protein isolate, carrageenan, scallion powder, garlic powder, sodium erythorbate, potassium sorbate, a food additive, white wine, an edible pigment and sodium nitrite; and the raw materials are rolled, rubbed, salted, smoked, cooked and sterilized in turn after being mixed. The produced product has good color, aroma and taste, rich nutrition, low fat content and high protein content, and is convenient to eat and suitable for old people and children; and the preparation process is suitable for quick industrial production.

Owner:天津宝迪农业科技股份有限公司

A preparation method for high-fiber recombinant asparagus chips

The present invention discloses a preparation method for high-fiber recombinant asparagus chips, and belongs to the deep processing field of fruits and vegetables. The asparagus chips use discarded scraps of old stems and old roots from asparagus production enterprises as raw materials, and are prepared by the following steps: pre-treating the raw materials, blanching the materials in hot water, preserving color, conducting beating, mixing the materials with adjuvant materials, cooking the mixture for a short time, placing the mixture on plates, drying the mixture under vacuum by two section-type microwave to a moisture content of 10% -15%, drying the mixture by short- and medium-wave infrared method under vacuum to a moisture content below 5%, and packaging the mixture to obtain the end products. The dietary fiber content of the asparagus chips is 8.35% - 10.27%, and every 100g of the chips contains flavonoids 12.73-16.86 mg, polysaccharide 9.34-11.28 mg. The preservation rate of chlorophyll is 70% to 75% after processing, and the chip breaking force is 1123-1443 g. The preparation method provides a novel method for taking full advantage of asparagus scraps, and the microwave vacuum drying and the short- and medium-wave infrared vacuum drying have advantages of quick drying, low temperature and higher nutrient retention rate, etc. The asparagus chips are high in cellulose content, rich in flavonoids, polysaccharide and other active substances, crispy and delicious in taste and high in nutritional value. Therefore, the asparagus chips are leisure crisps for people of all ages.

Owner:JIANGNAN UNIV +1

Preparation method for oil cooked chili

ActiveCN101791103AFor long-term storageRefined completelyFood preparationFlavouring agentOil temperature

The invention discloses a preparation method for oil cooked chili, which comprises the following steps that: (1) primary oil refining: oil is poured into a frying pan and is heated for refining, the heating is stopped after oil temperature reaches 190-210 DEG C, and the oil is cooled to 34-36 DEG C; (2) secondary oil refining: oil obtained after the primary oil refining is heated to 165-175 DEG C; (3) chili refining: chili is poured into the oil obtained after the secondary oil refining and is continuously stirred and fried, and the heating is stopped after the chili is refined for 24-26 minutes; and (4) flavoring: 100kg of chili obtained after refining is taken out and flavoring additives are added for flavoring, wherein the flavoring additives are formed by gourmet powder, salt, beef, chicken, black salted turnip and peanuts. The prepared oil chili has the advantages of delicious taste and bright color.

Owner:遵义椒源食品有限公司

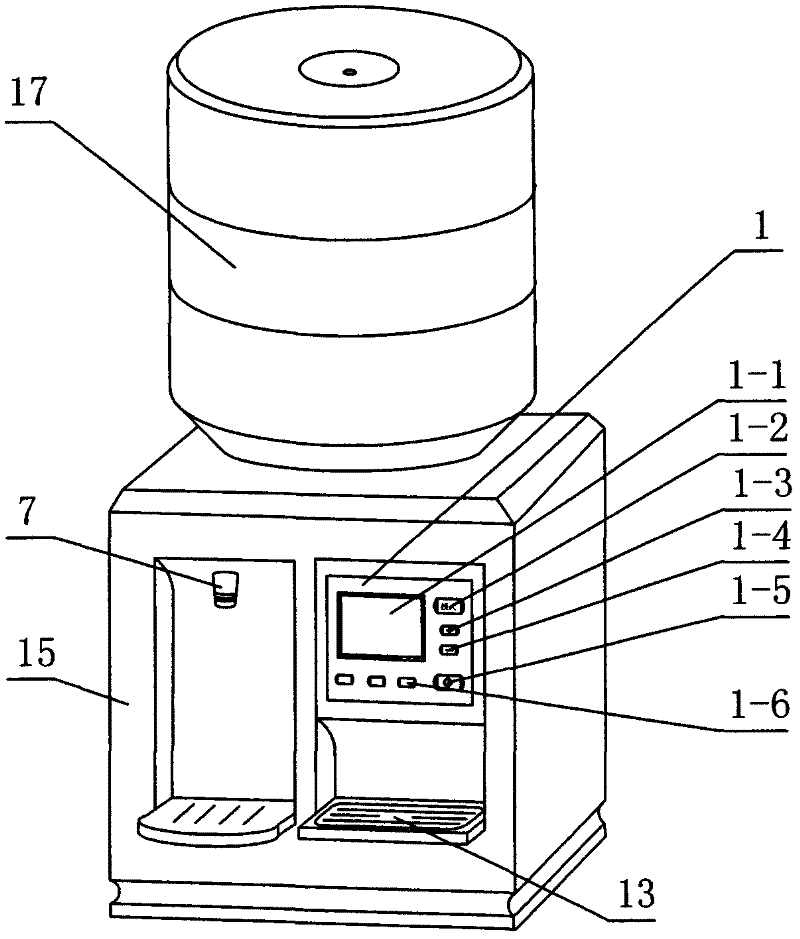

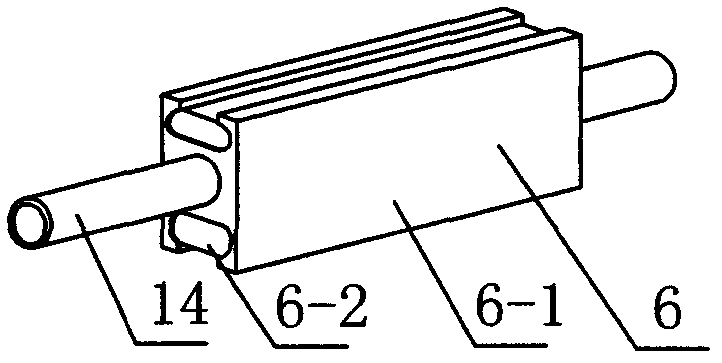

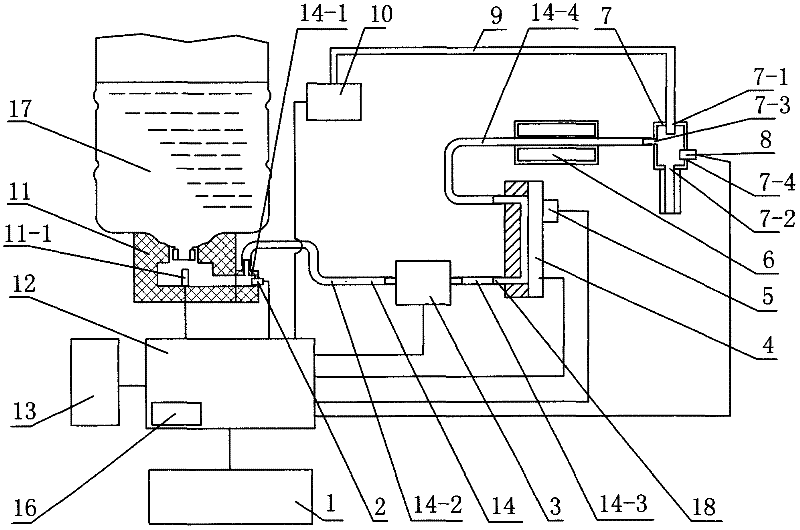

Ultra high-speed preparation method and device for tea making water

InactiveCN102357003AHigh activityIncreased oxygen levelsBeverage vesselsWater/sewage treatment by heatingUltra high speedLinear region

The invention provides an ultra high-speed preparation method and a device for tea making water. The method comprises the steps of: setting flow and each-stage electric power; dividing a water body heating curve of a pipeline heater into a quickly-heated linear region and a slowly-heated nonlinear region; leading the pipeline heater to work in the controllable nonlinear region and keep away from the linear region by a master control board; heating up the water which is fed into the pipeline heater; obtaining the water with a target water temperature from a water outlet; installing an outlet water temperature sensor at the water outlet; computing, tracking and compensating the water temperature decrease caused by the characteristic drift and the air injection since the pipeline heater works for a long time by the master control board; automatically adjusting the electric power by a heating body sensor according to the heating curve when the water is heated up; and precisely controllingthe water temperature at the water outlet at + / -2 DEG C. After the tea making water is prepared by the method and the device, and the phenomena that the temperature rise is too fast, the water is highly burnt, and the water cluster is broken caused by the hysteretic response speed of the heating body sensor are thoroughly eradicated, so that the water can be used for making the tea which is mellow, fragrant, sweet and good in aroma and taste, and therefore, the device is a substitute for upgrading and updating the existing water dispenser.

Owner:陈晓明

Aromatic sunflower oil

the invention discloses a super fine sunflower seed oil in the edible oil manufacturing technological domain, which comprises the following steps: toasting; dewatering; hulling; rolling the model; evaporating the model; cooking the model; squeezing through large-size squeezer; removing phosphine wax; reserving; packing.

Owner:SHANDONG LUHUA GROUP

Bamboo-scented pressed salted duck and preparation method thereof

ActiveCN103385481AHigh nutritional valueFull of nutritionFood preparationAdditive ingredientFood flavor

The invention discloses a bamboo-scented pressed salted duck and a preparation method thereof. The pressed salted duck is prepared from the following ingredients, by weight: 1000 to 1200 parts of duck, 2 to 3 parts of dahurian angelica roots, 3 to 4 parts of dried old orange peels, 4 to 5 parts of bamboo leaves, 1 to 2 parts of Indocalamus tessellatus leaves, 2 to 3 parts of laurel leaves, 2 to 3 parts of perilla leaves, 1 to 2 parts of Mongolian thyme, 1 to 2 parts of Japanese thistle roots, 2 to 3 parts of lemon grass, 2 to 3 parts of cassia barks, 1 to 2 parts of corn stigmas, 2 to 3 parts of infested bamboo shoots, 1 to 2 parts of calabash, 2 to 3 parts of red cabbages, 4 to 5 parts of mushrooms, 7 to 8 white sesame seeds, and proper amount of osmanthus honey. The preparation method soaks a duck in yellow serofluid, which contains health-care Chinese medicine ingredients, to increase nutritional values of the duck. Mushroom powder, the white sesame seeds and the osmanthus honey are spread inside and outside the duck before the duck is air-dried, and the bamboo leaves are used as a fuel to smoke the duck after the duck is air-dried, so that the duck is substantially improved in taste and flavor. The finished pressed salted duck is nutritious and chewy, with a good color, scent and taste. And the pressed salted duck has the effects of regulating qi and normalizing the middle energizer, nourishing kidney and moistening lung, relieving cough and reducing sputum, clearing heat and relieving restlessness, detoxifying and reducing swelling, promoting diuresis and unblocking bowels, invigorating stomach, and preventing cancer.

Owner:ANHUI WANSHAN FOODS

Preparation method of coarse cereal porridge

The invention provides a preparation method of coarse cereal porridge. By the method, bitter taste of bitter buckwheat and peculiar smell of coarse cereals are better removed, and the nutrient components of the original cereals are not destroyed. Tea leaves and orange peel are put into a steamer, the tea leaves are used for absorbing the peculiar smell in various coarse cereals, and the orange peel plays a role in keeping fresh and prolonging the quality guarantee period, so the peculiar smell in the coarse cereals is removed, original taste is kept, fresh thick taste is increased, and the mouthfeel is good; multiple coarse cereals of different colors are adopted, corn and black rice are kept granular, jujube pulp is finally added, and the jujube pulp is kept fresh and tender, so that the coarse cereal porridge has chewing feeling and achieves the effect on comprehensive nutrition; and the coarse cereal porridge is good in color, aroma and taste by a specific process.

Owner:ANHUI QIUGUO FOOD

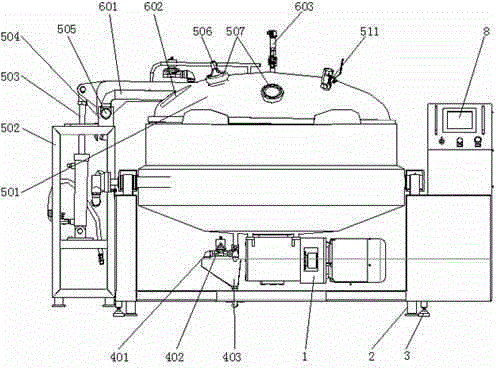

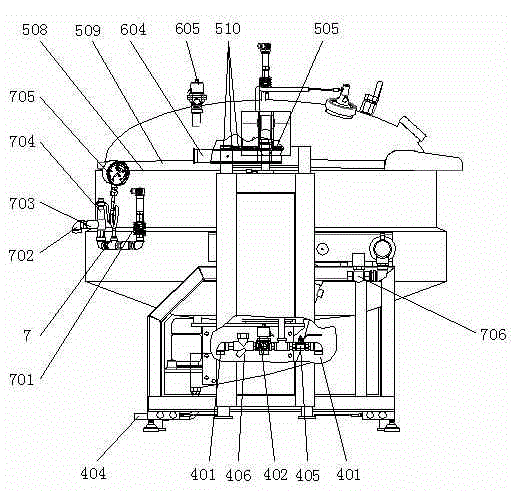

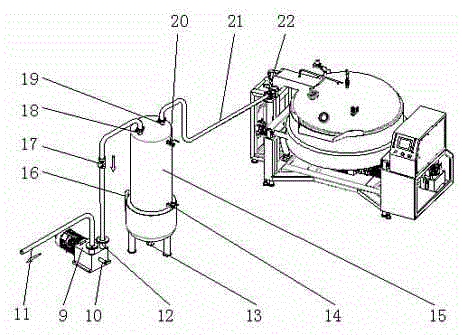

Full-automatic frying pan

The invention discloses a full-automatic frying pan. The frying pan comprises a turnover frying pan body, wherein a gear motor and fixed supporting legs are arranged at the bottom, a stirring device is mounted in the frying pan body, a heating device and an automatically turnover pan lid device are mounted on the frying pan body, a condensate water collecting device is arranged below the frying pan body, a vacuum control device and an auxiliary material feed valve are arranged on the pan lid device, a pressure control device is arranged on one side of the frying pan body and communicated with the inside of the frying pan body through a pipeline, an automatic control center is arranged beside the frying pan body, a weighing sensor for measuring material weight is arranged at the bottom of the frying pan body, and the pan lid device, the vacuum control device, the pressure control device, the stirring device and the weighing sensor are in communication connection with the automatic control center. According to the frying pan, the visual operation is simple, the vacuum frying temperature is low, the vacuum frying time is short, the weight, the temperature and the pressure of materials are accurately controlled, and fried materials are good in quality and good in color, aroma and taste.

Owner:BAODING JIALI FOOD MACHINE

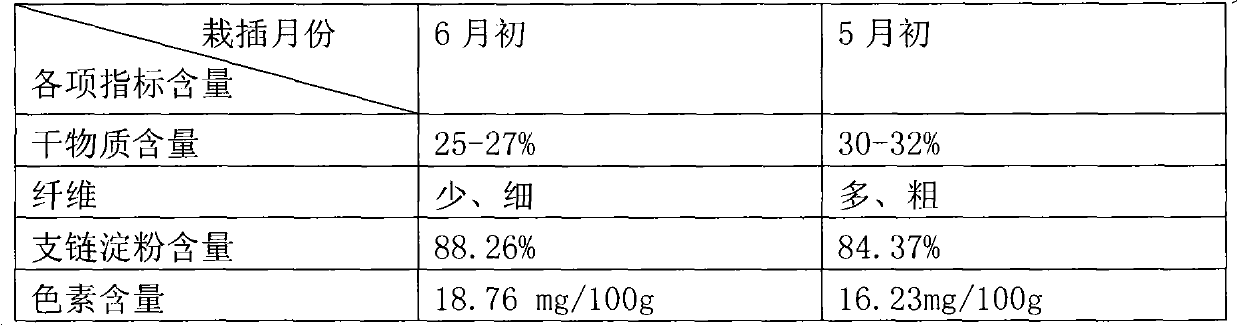

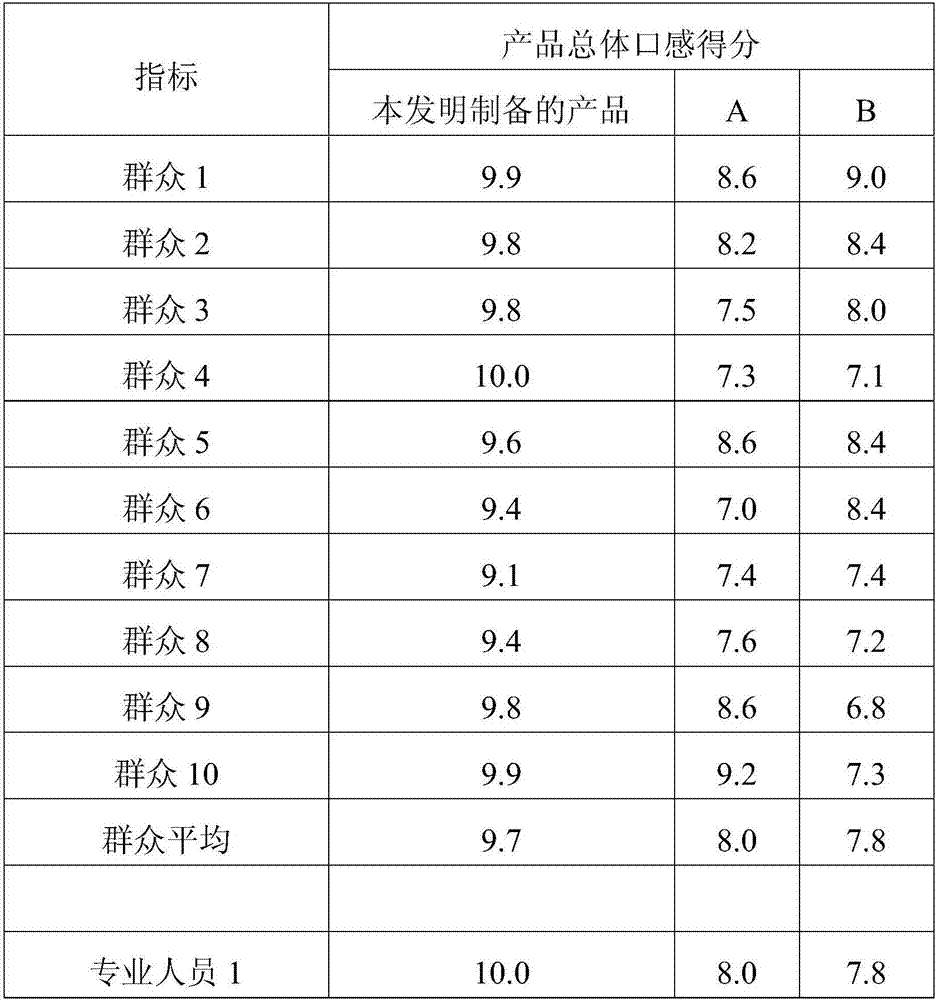

Sweet potato for processing preserved sweet potato and cultivation method and application thereof

InactiveCN101946613APromote expansionImprove baking qualityConfectionerySweetmeatsBiotechnologySugar

The invention discloses a sweet potato for processing preserved sweet potato and a cultivation method and an application thereof, belonging to the field of cultivation and processing of the sweet potatoes. The No.18 Ji sweet potatoes cultivated by adopting the cultivation method can be processed into the high-quality low-sugar purple preserved sweet potato without any additives by cleaning, shaping, steam-boiling, saccharification and baking. The preserved sweet potato has the characteristics of soft texture, low sugar content and translucent color and luster, is rich in anthocyanin and selenium element, has oxidation resistance and high free radical removing capacity which is 20 times of VE and 50 times of VC, and can prevent cardiovascular diseases, prevent tumors, prevent mutation, prevent radiation, delay aging, improve immunity and have good anti-cancer effect.

Owner:CROP RES INST SHANDONG ACAD OF AGRI SCI

Preparation method for marinating spicy and hot rabbit head

The invention aims at providing a preparation method for marinating spicy and hot rabbit head. The preparation method is as follows: firstly, unfreezing a rabbit head, washing the rabbit head to clean, adding ginger pieces, onion junctions, refined salt, cooking wine and nitrate, then stirring uniformly, pickling the rabbit head for 12 hours, then taking out, cleaning the pickled rabbit head by clear water, then putting the rabbit head into a pot with boiled water for quick boiling, then taking out the rabbit head for standby; secondly, preparing marinated seasoning secretly; thirdly, marinating: putting the rabbit head after the primary process into boiled spicy marinated juice, marinating the rabbit head for one hour by small fire, then extinguishing the fire; soaking the rabbit head in the spicy marinated juice for 30 minutes, then taking out the rabbit head for cooling, and finally chopping the rabbit head for eat. The rabbit head prepared by the method is complete in color, flavor and taste.

Owner:杜赏

Preparation method of five-spice multi-layer dried bean curd mock meat

InactiveCN103859056AGreat tasteUniform colorCheese manufactureFood scienceDry beanProcess conditions

The invention discloses a preparation method of five-spice multi-layer dried bean curd mock meat and relates to the technical field of bean product production. The preparation method comprises the following steps: screening raw materials, soaking, grinding and separation, boiling, coagulating, watering, pressing, stripping cloth, soaking, pressing for the second time, and airing for storage. The process is different from a conventional marinating method; dried bean curd is relatively tasty through the process of two-time pressing, watering and soaking; the process conditions are strictly controlled, so that the finished dried bean curd is uniform in color and taste; the multi-layer dried bean curd mock meat prepared by adopting the method is good in color, aroma and taste, and is popular in masses of consumers.

Owner:DEZHOU DOULAISHUN FOOD

Five-spice dried bean curd flavoring processing process

InactiveCN103404605AIncrease flexibilityGreat tasteCheese manufactureFood scienceTemperature controlRoom temperature

The invention discloses a five-spice dried bean curd flavoring processing process. The process comprises the steps that: alkali quick-boiling is carried out, wherein sliced and shaped dried bean curds are added into an alkali solution and steaming is carried out for 4min, wherein the alkali solution is an edible alkali solution, and the dried bean curds are added when the alkali solution is heated to 90 DEG C; marinating is carried out, wherein the dried bean curds processed with the alkali quick-boiling step is marinated in a marinating soup for 52-56min under a temperature controlled at 84-88 DEG C; drying is carried out, wherein the marinated and flavored dried bean curds are dried by using a drier; water content in the dried bean curds is 55%, and the dried bean curds is cooled to room temperature; and blending is carried out, wherein the dried bean curds are added into a blending machine; blending materials are added, and mechanical blending is carried out. According to the invention, through the alkali quick-boiling step, dried bean curd properties are changed. Toughness is enhanced, and bean odor is removed, such that the dried bean curds are easier to flavor during the subsequent marinating step. Conditions of various processes are strictly controlled, such that finished dried bean curd products has uniform color and consistent taste. With a unique formula, the finished dried bean curd product has good color, good fragrance, and good taste. The dried bean curds are popular among consumers.

Owner:CHENGDU XIANGXIANGZUI FOOD

Normal juice freshwater mussel can and production method thereof

The invention relates to a normal juice freshwater mussel can and a production method thereof. The normal juice freshwater mussel can comprises the following components in parts by weight: fresh freshwater mussel 280-320 and soup bases 90-110, wherein the soup bases comprise the following components in parts by weight: water 90-105, common salt 1-3, ginger juice 1-3, and yellow rice (or millet) wine 1-3. The production method thereof comprises the following steps of (1) non-feeding fostering, (2) poaching, (3) gutting, (4) washing, (5) rubbing salt and alkali, (6) filling and (7) sterile cooling. The normal juice freshwater mussel can produced by the method is good in color, scent and taste, has strong fresh flavor of normal juice freshwater mussel, and is a good product for going with dishes and for ordinary eating.

Owner:朱长满

Spiced duck neck food and preparation method thereof

InactiveCN106942634AUnique tasteBeautiful and fragrantFood ingredient as taste affecting agentOrganic compound food ingredientsMonosodium glutamateCost savings

The invention discloses a spiced duck neck food and a preparation method thereof. The spiced duck neck food is prepared from 40 to 60 portions by weight of duck necks, 30 to 40 portions by weight of water, 0.5 to 1.3 portions by weight of pericarpium zanthoxyli, 1 to 6 portions by weight of dried chilli, 0.5 to 2 portions by weight of Chinese prickly ash, 5 to 10 portions by weight of soybean oil, 1 to 3 portions by weight of edible salt, 0.5 to 1.0 portion by weight of monosodium glutamate, 0.02 to 0.04 portions by weight of seasoning disodium ribonucleotide, 0.03 to 0.5 portions by weight of a mixed auxiliary material No. 1, and 4 to 12 portions by weight of a mixed auxiliary material No. 2 through a decoction method. In preparation, the duck necks are cut into duck neck blank sections having length of 15 to 50mm, the duck neck blank sections are punctured along the end surfaces through a perforator so that seasoning holes are obtained, the number of the seasoning holes is greater than or equal to 3 and the seasoning holes are uniformly distributed on the end surfaces of the duck neck blank sections so that the spicing soup uniformly passes through the duck neck blank sections. The spiced duck neck food has a unique formula, and pickling and soup-stock boiling are avoided. The product has good color, fragrance and taste, is rich in nutrients and has a unique taste. The preparation method has the advantages of standardized and processized operation, cost saving and high work efficiency.

Owner:江苏五香居食品有限公司

Method for processing mustard vegetables

The invention relates to a processing method for spicy leaf mustard, comprising the following steps: (1) heading mustard which is mature in autumn is put in clear water for washing and unedible mustard peel is pared; (2) the washed heading mustard is cut into mustard strips or mustard slivers with the width of 3-4mm and the thickness of 1-1.5mm for standby; (3) the mustard strips or the mustard slivers are added with cooked bean oil according to the ratio of 33:1 by parts by weight, pepper water and aniseed water with the concentration of 8-10% and ginger juice with the concentration of 4-5% and the ratio of parts by weight of the pepper water, aniseed water and the ginger juice is 33:0.5:0.5; the mixture is put in a vessel to be stirred evenly; (4) the evenly stirred mustard strips or mustard slivers are added with cool water which is heated up and boils and then is cooled by 20 DEG C and the weight of the cool water is 4 / 10 of the overall weight; the strips or the slivers are fried in a round-bottomed frying pan to be 90% well done with the temperature of the fire of 150-180 DEG C for 20-40 minutes; refined salt is added and then the strips or the slivers and the salt are evenly stirred; (5) the fried mustard strips or mustard slivers are stirred and placed in a pottery jar which is then sealed for pickling; the pottery jar is placed at a room without light at the temperature of 5-6 DEG C for 6-8 days; the mustard strips or mustard slivers can be eaten after being taken out. The method has the advantages of convenient eating and combination of color, smell and taste.

Owner:王北安

Calcium-supplementing sliced dried beef containing shrimp meat and making method of sliced dried beef

InactiveCN105935127AFull of flavorBeautiful and fragrantFood ingredient functionsShrimpTangerine Peel

The invention discloses calcium-supplementing sliced dried beef containing shrimp meat. The calcium-supplementing sliced dried beef is made from, by weight, 250-300 parts of beef, 4-5 parts of blueberries, 6-7 parts of strawberries, 5-6 parts of shrimp meat powder, 0.2-0.3 part of endothelium corneum gigeriae galli, 0.4-0.5 part of plantain herb, 0.3-0.4 part of emblic leafflower fruit, 5-6 parts of salt, 4-5 parts of white sugar, 2-3 parts of ginger juice, 2-3 parts of chili powder, 3-4 parts of pepper powder, 11-12 parts of green tea powder, an appropriate amount of dried tangerine peel and an appropriate amount of water. The adopted auxiliary materials of the shrimp meat and the like have the functions of tonifying the kidney, supplementing calcium, regulating qi and promoting appetite, and the adopted Chinese herbal medicine of endothelium corneum gigeriae galli and the like have the effects of eliminating stagnation and strengthening the spleen and stomach.

Owner:HEFEI FULAIDUO FOOD

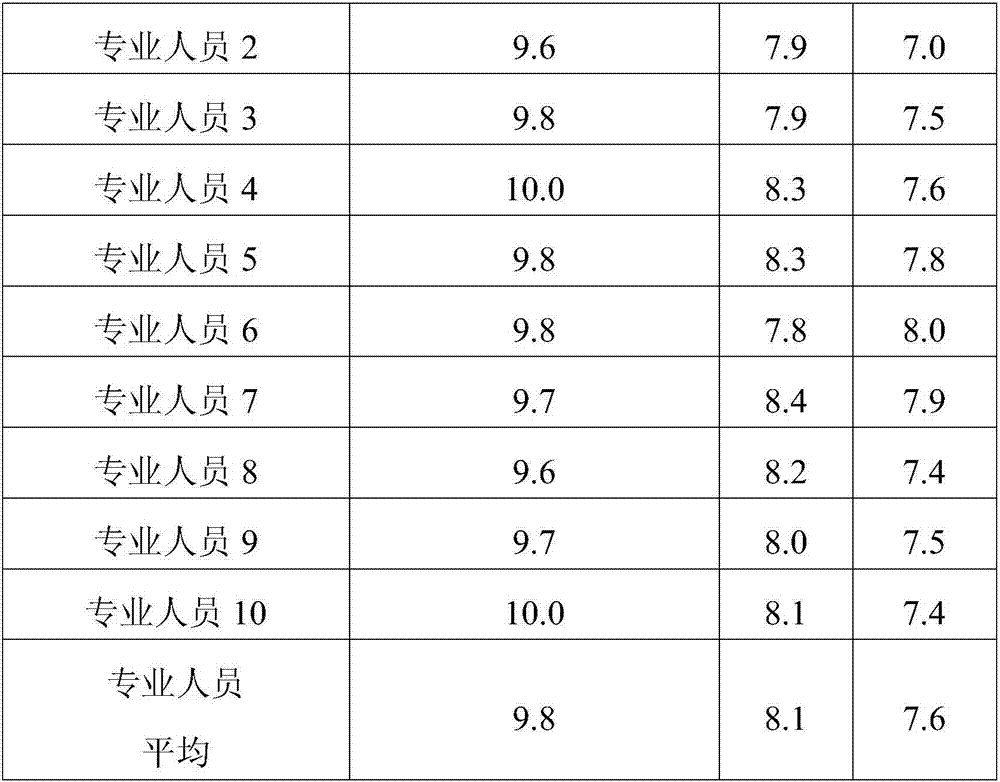

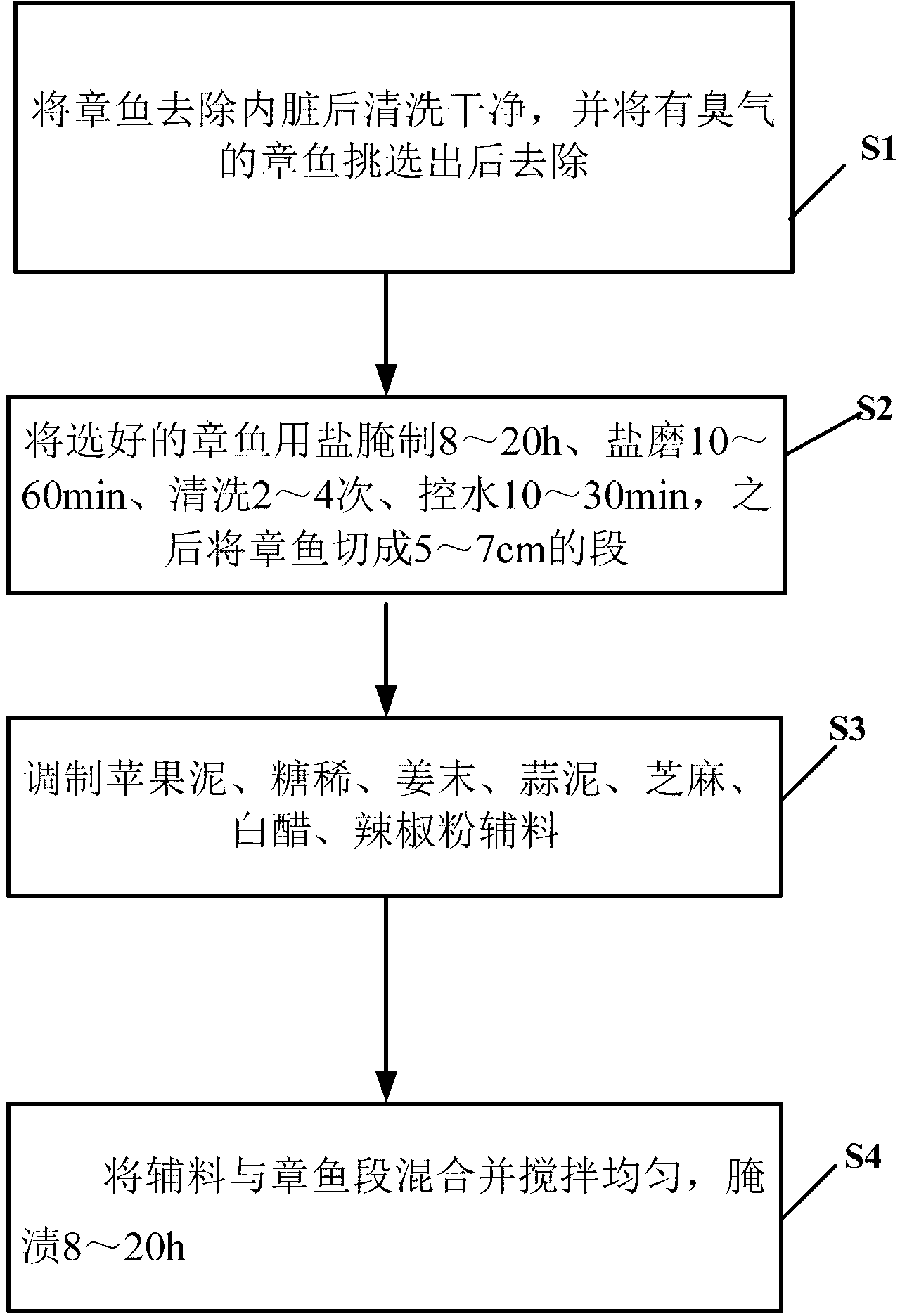

Instant octopus and production method thereof

InactiveCN103070428ASolve the low content of octopusHigh nutritional valueFood preparationNutritive valuesAdditive ingredient

The invention provides an instant octopus and a production method thereof. According to the production method, 60-75 weight parts of octopuses are taken as main ingredients and 3-8 weight parts of apple butter, 6-15 weight parts of syrup, 2-5 weight parts of bruised ginger, 5-10 weight parts of mashed garlic, 2-5 weight parts of sesame, 2-5 weight parts of white vinegar and 5-8 weight parts of paprika are selected as auxiliary materials. The production method comprises the following steps: after removing entrails from the octopuses, cleaning the octopuses, selecting the odor octopuses and removing; curing the selected octopuses for 8-20h with salt, milling for 10-60min with salt, cleaning for 2-4 times and controlling water for 10-30min, and then cutting the octopuses into 5-7cm sections; modulating the auxiliary materials, namely, the apple butter, syrup, bruised ginger, mashed garlic, sesame, white vinegar and paprika; mixing and uniformly stirring the auxiliary materials with the octopus sections; and curing for 8-20h. The problems that the present octopus processed products contain few octopuses and are low in nutritive value are solved.

Owner:QINGDAO JISHENG AQUATIC FOODSTUFFS CO LTD

Bean flour press cakes and making method thereof

InactiveCN106212590ARich in nutrientsSolve rough tasteDough treatmentBakery productsPearl barleySugar

The invention relates to bean flour press cakes and a making method thereof. The cakes are prepared from, by weight, 40-50 parts of flour, 30-40 parts of soybean flour, 8-10 parts of red date powder, 8-10 parts of rhizoma dioscoreae powder, 6-9 parts of pearl barley powder, 3-6 parts of white sugar, 110-140 parts of spring water, 8-12 pieces of eggs, 8-10 parts of edible oil and 2-5 parts of lard oil. By using purely natural spring water and adding eggs and edible oil, the obtained press cakes are more crispy and delicious. By adopting soybean flour, red date powder, rhizoma dioscoreae powder and pearl barley powder besides flour and eggs, the obtained press cakes contain rich nutrients; besides, sesame seeds are spread on the cakes, so that color, aroma and taste are all good.

Owner:山西绿德农业科技股份有限公司

Fried spicy chicken wing roots and processing method thereof

The invention discloses a preparation method of spicy chicken wing roots. The spicy chicken wing roots are prepared by marinating chicken wing roots, coating the chicken wing roots with paste, coating the chicken wing roots with powder, and frying. The preparation method of the spicy chicken wing roots is characterized by comprising the following steps: selecting raw materials, preparing a marinade from the raw materials, preparing paste, coating the chicken wing roots with the paste, coating the chicken wing roots with powder, frying, cooling, and packaging, wherein the ratio of hawthorn fruit slices to barbary wolfberry fruit to red dates for preparing the marinade is 1 to 1 to 1. The chicken wing root marinated with the marinade has a high content of protein and is rich in a variety of trace elements from the hawthorn fruits, the barbary wolfberry fruit and the red dates, which are necessary for the human body. The connection part of flesh and blood of the chicken wing root can be marinated deeply, and the fried spicy chicken wing root is good in color, aroma and taste, retains a variety of nutritional values and is beneficial to health.

Owner:WEIFANG RUNTIAN FOOD

Roast suckling pig processing method

InactiveCN101366532AFor long-term storageEasy to transportFood preparationAnimal scienceSpray coating

The invention discloses a processing method for roasting pigs, which can be used for the batch production of the roasted pigs. The processing method comprises the following: 1) a step of trimming, during which, trimming an anthony pig body to remove parts of the anthony pig which can not be edible and roasted, and cutting openings on the anthony pig body; 2) a step of preparing curing material; 3) a step of curing, during which, curing the anthony pig for 3 to 5 days; 4) a step of heating up the skin for coloring, during which, putting the cured anthony pig into boiled water to cook for 4 to 6 minutes after cleaning the cured anthony pig, and evenly spraying the sugar color onto the skin of the anthony pig; 5) a step of roasting, during which, roasting the anthony pig for 18 to 24 hours at the temperature between 60 and 70 DEG C; and 6) a step of re-roasting, during which, roasting the anthony pig for 20 to 30 minutes at the temperature between 125 and 140 DEG C. The method can be used for the batch production of roasted pigs with reduced cost. The roasted pigs which have golden yellow and crisp skin, and fragrant and soft pork integrate good color, fragrance and taste. In the further technical proposal, secondary trimming, preserving oil spray coating and vacuum packaging are carried out to bring about the long-term storage of the roasted pigs, thereby facilitating transportation and storage.

Owner:CHONGQING HUAIXIANG FOOD

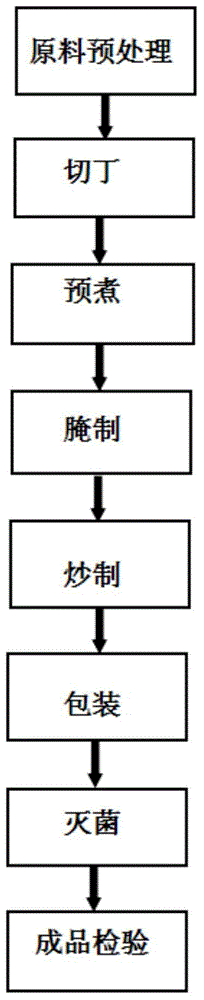

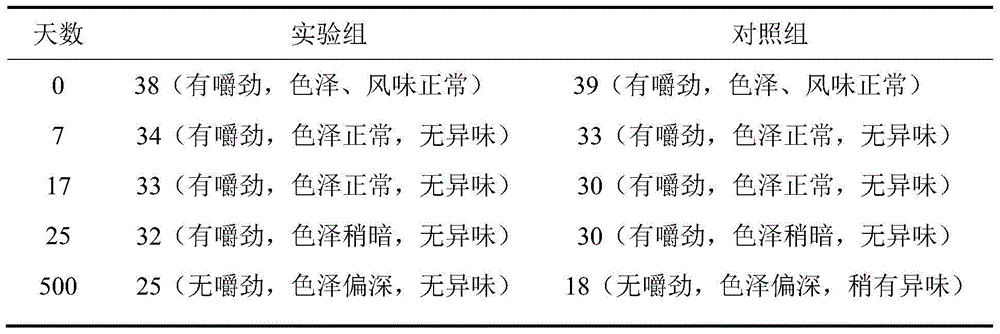

Spicy lengchi (Chinese character) rabbit and preparation method thereof

InactiveCN104872693AUnique spicy flavorImprove featuresFood preparationChinese charactersPre treatment

The invention relates to the field of food processing, and in particular relates to a spicy lengchi (Chinese character) rabbit. The spicy lengchi rabbit comprises the following components in parts by weight: 100 parts of rabbit meat, 1-3 parts of salt, 1-3 parts of yellow rice, 30-40 parts of colleseed oil, 15-25 parts of dried chilli, 1-3 parts of Chinese prickly ash, 1-3 parts of old ginger, 0.5-1.5 parts of anise, 0.8-1.2 parts of sesames and 1-3 parts of dark soy sauce; and the preparation method of the spicy lengchi rabbit comprises the following steps: (1) pretreating the raw materials; (2) dicing; (3) precooking; (4) pickling; (5) frying; (6) packaging; (7) sterilizing; and (8) inspecting a finished product. The spicy lengchi rabbit product provided by the invention is outstanding in spiciness, good in sensory properties, nutrient, delicious, good in color, aroma and taste, long in storage time and suitable for industrialized large-scale production.

Owner:SICHUAN AGRI UNIV

Method for processing chicken soup containing Ficus simplicissima Lour.

The invention provides processing method for radix fici simplicissimae chicken soup, which pertains to the technical field of cooked food processing. The radix fici simplicissimae is fragrant, pungent, sweet, hot in nature, capable of spleen tonifying, qi benefiting, superficial consolidating, qi adjusting, pain killing, cough relieving, and phlegm eliminating. The invention is processed into various kinds of delicious soup for dietary treatment and supplement matched with domestic chicken, pig bone, pig lung, Chinese yam, medlar, white fungus, carrot, white cow gram, red jujube, fructus momordicae. The soup has scientific formula, functions of nutrition supplement, warm nourishing, light nourishing, lung moistening, cough relieving, diuresis promoting, dewetting, which is suitable for daily eating by men and women, old and young. The food is beneficial to dietary treatment and prevention for commonly encountered diseases of human, and body nourishing.

Owner:HELANG FOOD NANTONG CO LTD

Green bean curd processing technology

The invention discloses a green bean curd processing technology. The green bean curd is processed by using green beans and soybeans as raw materials, wherein the green beans and the soybeans account for 50 percent respectively. The technology comprises the following steps of: soaking the green beans and the soybeans into clean water in an amount which is 5 times weight of the green beans and the soybeans at normal temperature, wherein the green beans are soaked for 12 to 15 hours and the soybeans are soaked for 8 to 10 hours so that the green beans and the soybeans fully absorb water and are swollen, and the green beans and the soybeans are soaked till the green beans and the soybeans can be broken off by hand and foam is not produced; grinding the green beans and the soybeans together with the soaking water, wherein the pulping granularity is 120 to 150 meshes; timely filtering the ground milk with residue, separating the soybean milk and the soybean residue, and repeatedly flushing with warm water for over three times to filter out soybean milk; quickly heating and boiling for 5 to 6 minutes; when the soybean milk is cooled to the temperature of between 75 and 85 DEG C, solidifying the soybean milk by using gluconate-sigma-lactone; and quickly filling the solidified soybean milk into a box and squeezing after 5 to 8 minutes, performing block division, and thus obtaining the green bean curd. The technology has the advantages that: by adding the green beans, the bean curd has the mouthfeel of the green beans, also has the color and the aroma of the green beans and is a new-style bean curd with compressive color, aroma and taste.

Owner:石爱军

Preparation method of peanut soy

The invention relates to a preparation method of peanut soy, belonging to the technical field of preparation methods of soy. The peanut soy provided by the invention adopts groundnut kernels as a raw material, bacillus licheniformis, brevibacterium flavum, clostridium acetobutylicum and rhamnose lactobacilli are taken as composite fermentative bacteria of a peanut fungi solution; the special proportional aspergillus oryzae, aspergillus niger and monascus are utilized as fermenting aspergillus of a peanut yeast, and a preparation process of natto soy is adopted. The preparation method provided by the invention has the advantages that the fermentation period is shortened, natto kinase is generated after fermenting of groundnut kernels, the kinase can restrain the browning of the soy in preservation, a maillard reaction is reduced, the nutritive values of the groundnut kernels are high, the flavor is unique, and the color, the aroma and the taste of the prepared soy are good; the content amino acid nitrogen is improved by 43.9%, the full nitrogen content is improved by 17.5%, a soluble salt-free solid is improved by 18.8%, and the preparation method is especially used for preparing ideal soy of pickles.

Owner:松原北大荒食品科技有限公司

Manufacturing method of sauced duck

The invention relates to the technical field of foodstuffs, and specifically relates to a manufacturing method of sauced ducks. The method comprises technological processes of butchering, thawing, washing and finishing, curing, cooking and saucing, quantitative cutting, weighing, packaging, microwave disinfecting, vacuum packaging and sealing, high-temperature sterilizing, cooling, outer-packaging, and examining. After the processes, finished products can be obtained. With the technical scheme provided by the invention, the produced sauced ducks are advantaged in good mouthfeel, appropriate salinity, delicate meat quality, good color, good flavor, and good taste. According to the invention, microwave disinfecting and high-temperature sterilizing are adopted, such that the shelf lives of the products can be effectively prolonged to above one and a half years. According to the invention, a drying process is not adopted, such that the water content in the meat tissues is high, and the meat quality is soft. Also, the method is advantages in high production efficiency, stable color, and suitability for industrialized productions.

Owner:CHANGZHOU ZUNLONG FOOD

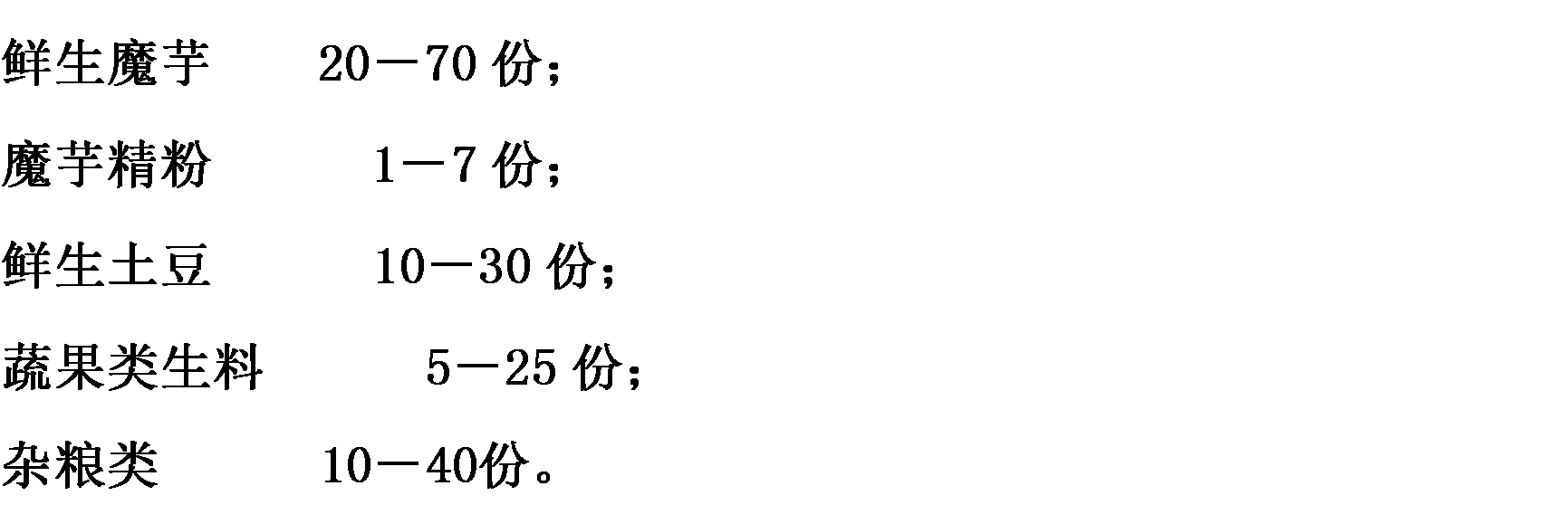

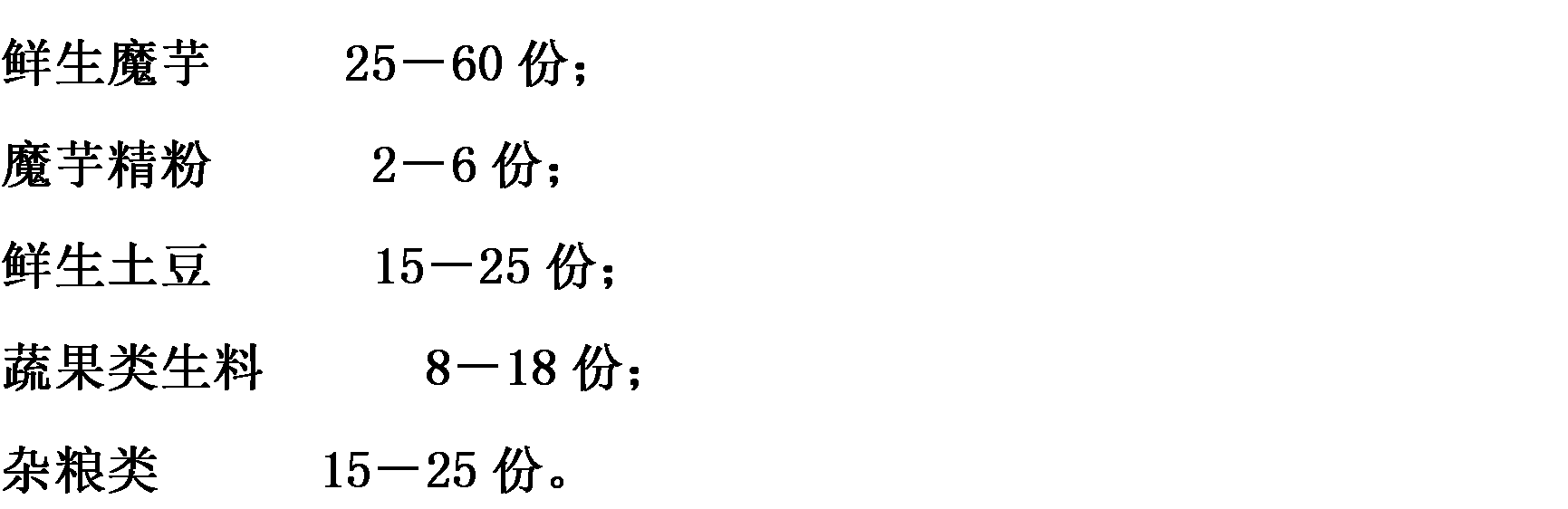

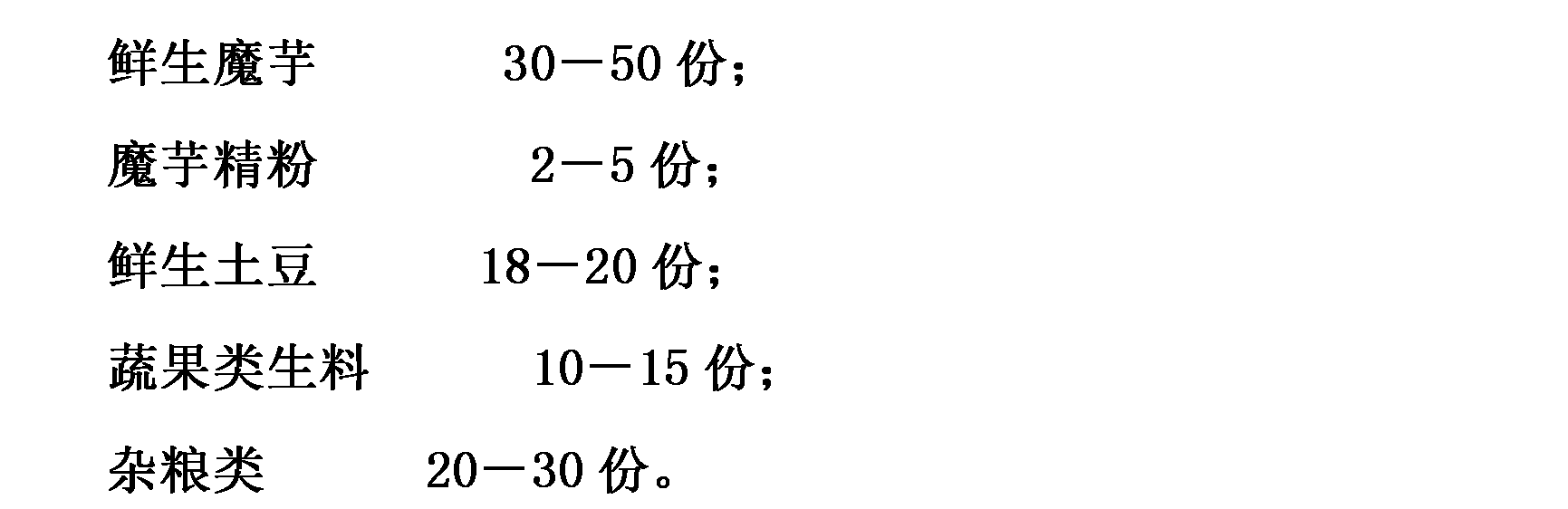

Multi-fiber safe nutrient convenient konjac porridge prepared by using fresh raw konjac

The invention discloses a multi-fiber safe nutrient convenient konjac porridge prepared by using fresh raw konjac. The multi-fiber safe nutrient convenient konjac porridge is prepared from the following raw materials in parts by weight: 20-70 parts of fresh raw konjac, 1-7 parts of konjac fine flour, 10-30 parts of fresh raw potatos, 5-25 parts of raw vegetables and fruits and 10-40 parts of minor cereals. In the invention, a convenient and fast health-care principal food is provided for people with hypertension, diabetes, hyperlipidemia, adiposis, and the like and people who need to be replenished with celluloses, and outstanding health-care function and food therapy effect are achieved.

Owner:贵州中山魔芋农业发展有限公司

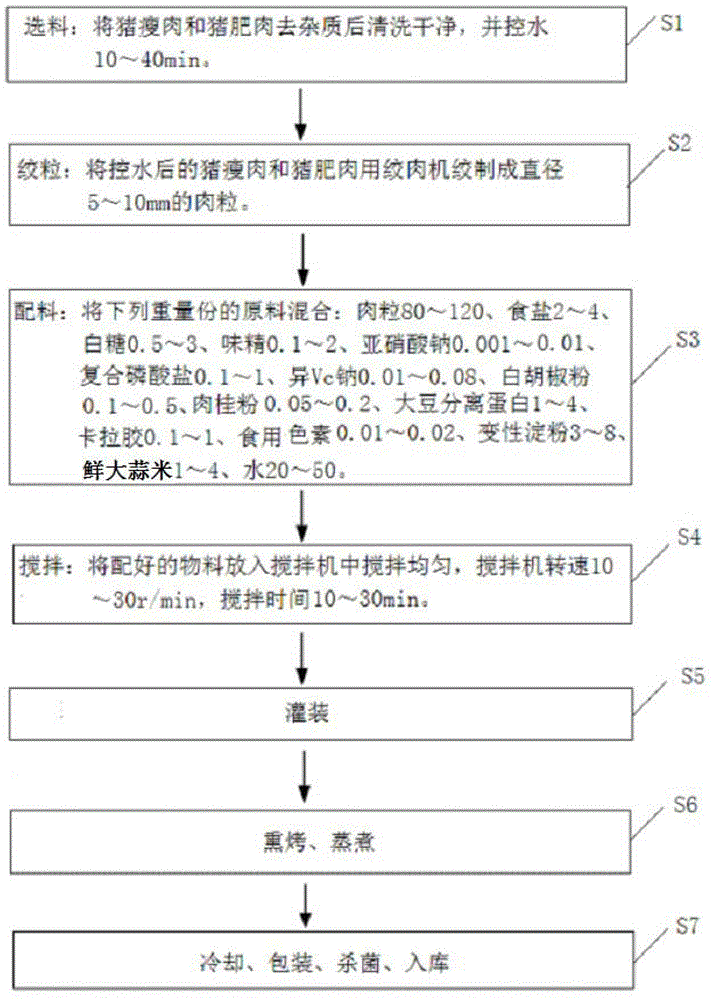

Bologna sausage and making method thereof

The invention provides a bologna sausage and a making method thereof, and solves the food safety problem caused by the addition of too much food additives of bologna sausages in the prior art. Raw materials for making the bologna sausage comprise, by weight, 80-120 parts of pork, 2-4 parts of salt, 0.5-3 parts of white sugar, 0.1-2 parts of monosodium glutamate, 0.001-0.01 parts of sodium nitrite, 0.1-1 part of composite phosphate, 0.01-0.08 parts of sodium isoascorbate, 0.1-0.5 parts of white pepper powder, 0.05-0.2 parts of cinnamon powder, 1-4 parts of soybean protein isolate, 0.1-1 part of carragheenan, 0.01-0.02 parts of an edible pigment, 3-8 parts of modified corn starch, 1-4 parts of fresh garlic and 20-50 parts of water. The method comprises the following steps: choosing the raw materials, granulating, burdening, stirring, loading, fire-curing, boiling, cooling, packaging, sterilizing, and warehousing. The bologna sausage has the advantages of perfect combination of color, smell and taste, abundant nutrition, safety, health, and eating convenience; and the making method of the bologna sausage is simple, and is suitable for industrial rapid production.

Owner:QINGDAO JIDECHENG FOOD

Pecan-milk compound protein beverage and processing method thereof

InactiveCN104605025APure flavorNutritional balanceMilk preparationSodium bicarbonateAdditive ingredient

The invention discloses a pecan-milk compound protein beverage and a processing method thereof. The pecan-milk compound protein beverage is characterized by comprising the following raw materials: pecan kernels, whole milk powder, a compound stabilizer, white granulated sugar, concentrated jujube juice, edible salt, starch, sodium caseinate, sodium tripolyphosphate, sodium citrate, trichlorosucrose, sodium hydrogen carbonate, edible essence and water. The processing method comprises the following steps: screening, rinsing, finely grinding, dissolving milk powder, dissolving white granulated sugar, dissolving ingredients, blending with the jujube juice, homogenizing, sterilizing, filling and sterilizing. The pecan-milk compound protein beverage has a peculiar fragrance of pecans and rich nutrition of the whole milk powder, has a unique milk red color of a pecan beverage, and has good color, fragrance and taste; the pecans and the milk powder are mixed in one beverage product, so that the pecan-milk compound protein beverage is more balanced in nutrition and has a gentle mouth feel at the same time.

Owner:ANHUI ZHANSHI FOOD

Hotpot oil extracted based on supercritical technique

InactiveCN106666621AGreat tasteTaste fastNatural extract food ingredientsFood processesYeast cell extractBeef Tallow

The invention discloses hotpot oil extracted based on a supercritical technique. The hotpot oil comprises beef tallow, plant oil, chili, bean sauce, ginger, garlic, a yeast extract, aginomoto, chicken essence, Chinese prickly ash, rice wine, fermented glutinous rice, fermented soya beans, rock candy and salt. The hotpot oil is made by frying the materials so as to obtain a dreg-containing base material, cooling the dreg-containing base material, filtering by using a horizontal spiral centrifuge till the oil content of separated material dregs is about 5%, and pouring out separated fried oil for later use; performing supercritical CO2 extraction for 1-2 hours on the separated material dregs so as to obtain supercritical extracted base material essence oil; adding the extracted base material essence oil into the fried oil, adding Chinese prickly ash oil produced by using a cold pressing process, and sufficiently mixing, thereby obtaining the hotpot oil. The hotpot oil has the advantages of being added into other hotpot base materials to improve the taste, and also added into Sichuan tasty oily stewed meal, food cooked with spicy and hot soup, braised food, fried food and the like to enrich the taste.

Owner:重庆梅香园实业集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com