Ultra high-speed preparation method and device for tea making water

A tea and extremely fast technology, which is applied in beverage preparation devices, heating water/sewage treatment, household appliances, etc., can solve the problems of overburning water, easy scalding, and no compensation instructions, so as to avoid response lag effect and ensure flushing Bubble quality, the effect of not wasting water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

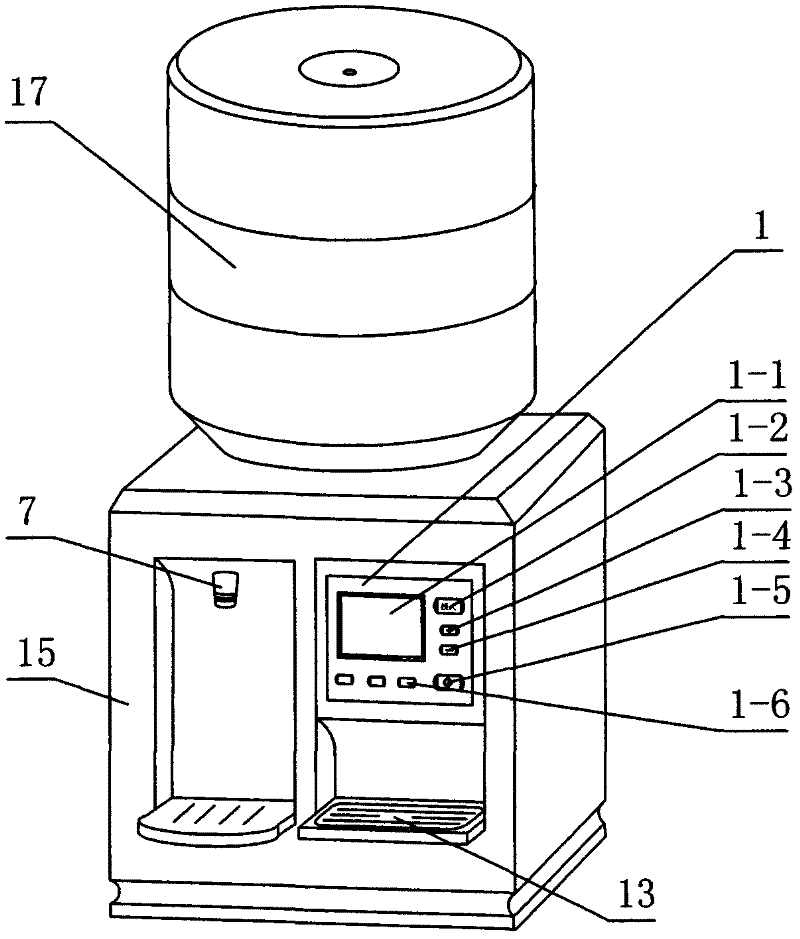

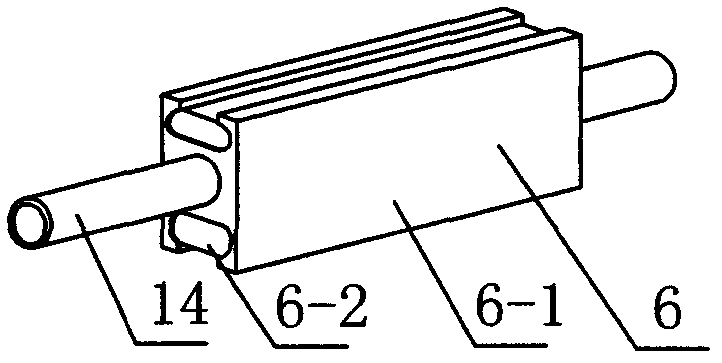

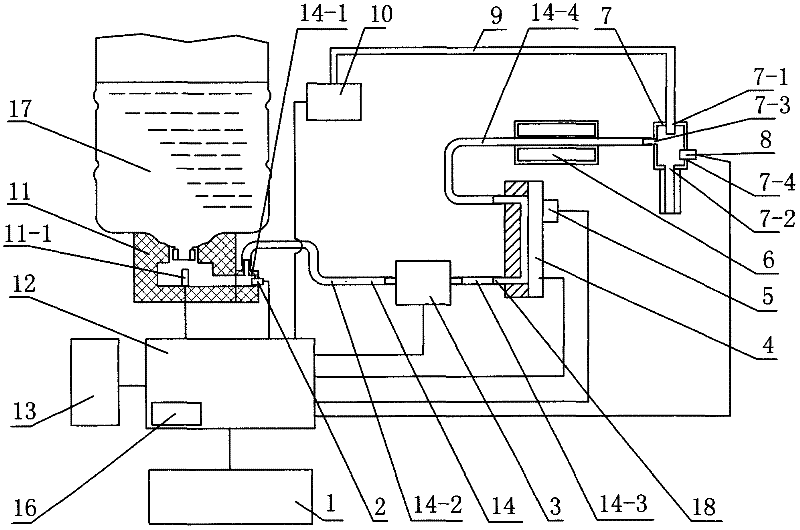

[0021] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0022] The temperature rise curve based on the extremely fast preparation method of brewing tea water is the heating temperature rise curve of the pipe heater 4 used, the flow rate setting value of the electromagnetic pump 3 is L1=5.5ml / s, and the inlet water temperature T J = 10 degrees, the ordinate temperature T is the target water temperature Tm and the inlet water temperature T J The difference between them, the abscissa is the heating time t, draw the temperature rise curve at different electric powers P1, P2, P3, P4..., forming the linear heating zone S zone with rapid temperature rise and the nonlinear heating zone K with slow temperature rise Zone, K zone extends to t 2 , The upper and lower two adjacent temperature rise curves are also called the heating area of the target water temperature for the electric power pair in the area surrounde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com