Patents

Literature

62results about How to "Solve rough taste" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

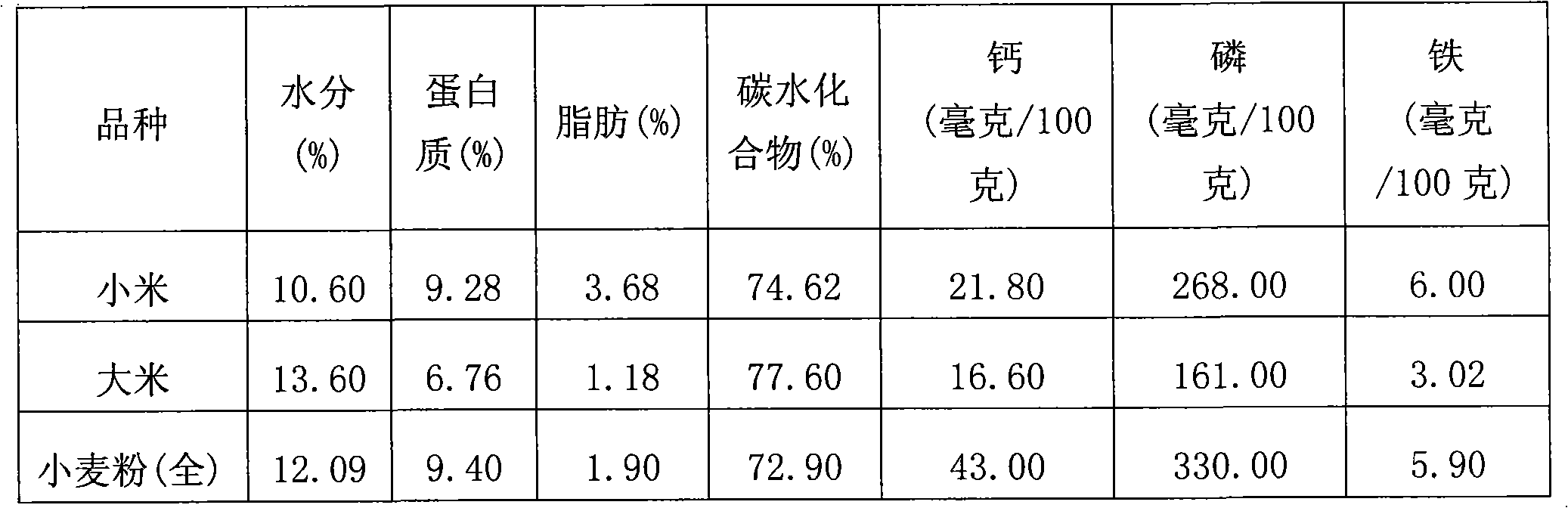

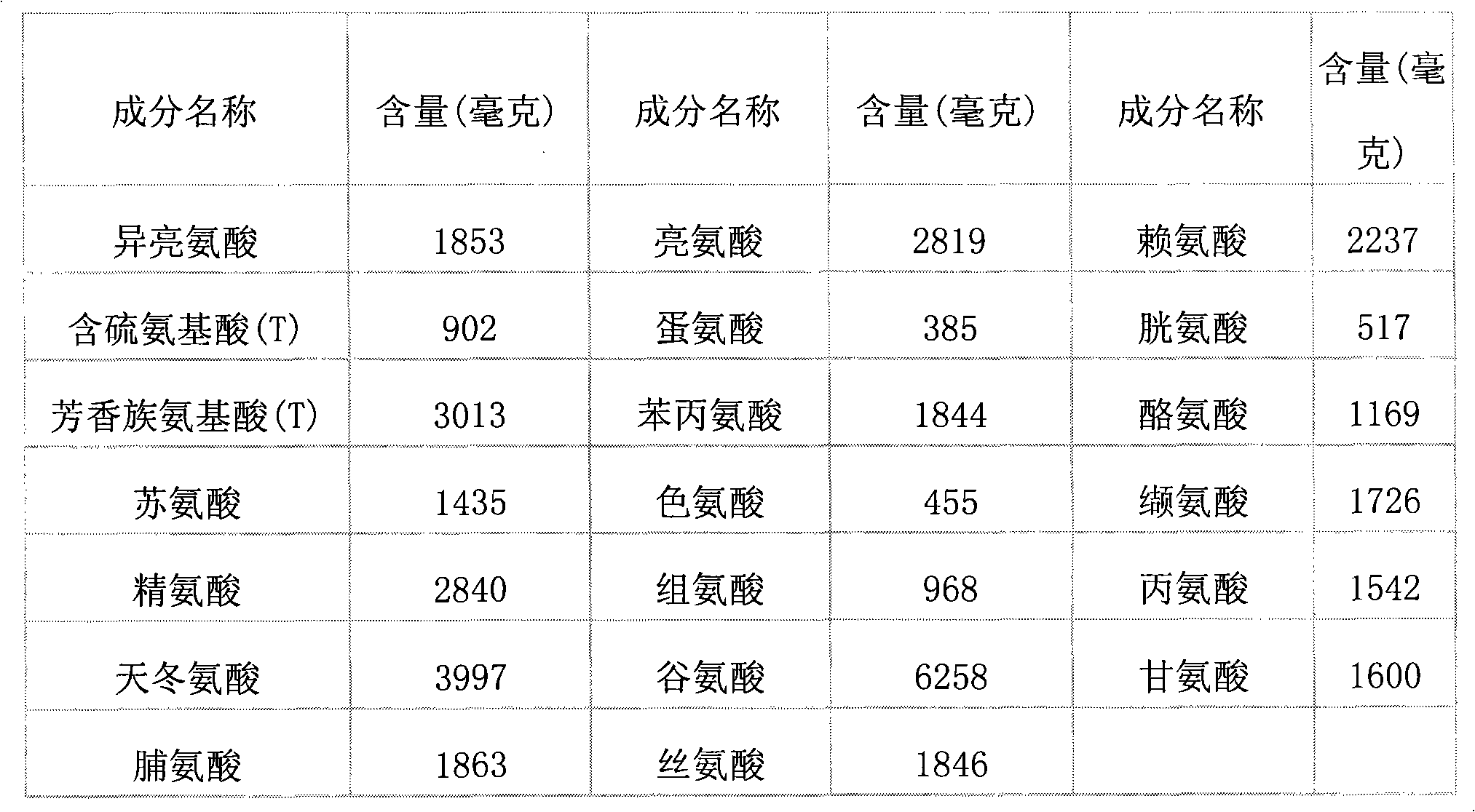

Method for preparing millet rice flour for infantile

The invention discloses a preparation method of millet rice flour for infant which belongs to the preparation technology field of infant food. The millet and other rice are mixed according to the weight portion, rinsed, cooked, ground, filtered and homogenized and dried to obtain the millet rice flour. Or filtrate is obtained after raw beating, gelatinization and filtration, and the filtrate is mixed with the ingredients of vegetable oil, soy protein isolate, sugar and skim milk powder, and homogenized and dried to obtain the millet rice flour. Comparing with the existing rice flour for infant, the invention has more balanced and rich nutrient, especially high minerals contents and is more suitable to the physical development of infant. The invention has the advantages of simple, stable and reliable process, providing a fire-new method for the deep processing of the millet and having the wide prospects of industrial applications.

Owner:CHINA AGRI UNIV +1

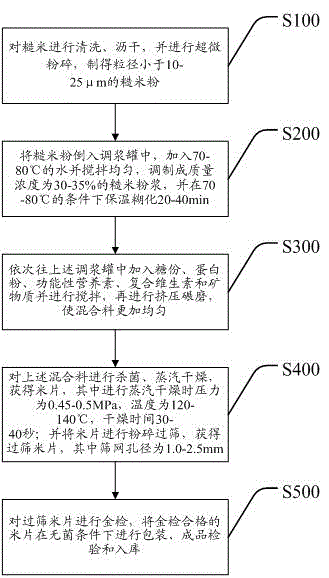

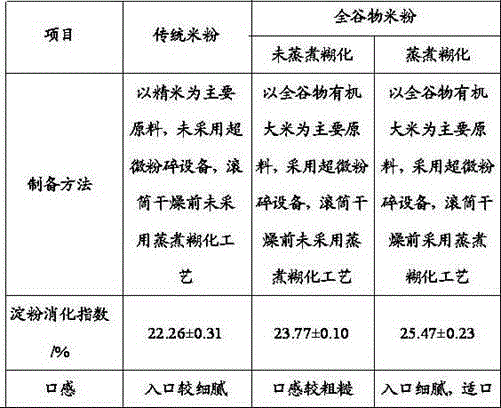

Whole-grain nutritional rice flour for infants and preparation method of rice flour

InactiveCN104872513AFull of nutritionNutritional diversityVitamin food ingredientsMulti-step food processesBiotechnologyNutrition

The invention discloses whole-grain nutritional rice flour for infants and a preparation method of the rice flour. The whole-grain nutritional rice flour for infants comprises the following components in percentage by mass: 60-65% of coarse rice powder, 20-24% of sugar, 10-12% of protein powder, 3-5% of functional nutrients, 0.2-0.4% of complex vitamin and 1-2% of mineral substance; the sum of the percentages by mass of the components is 100%. According to the whole-grain nutritional rice flour for infants, whole-grain organic rice is used as a main raw material; other nutrient substances are added into the whole-grain organic rice; the single nutrient structure of the traditional rice flour is changed; the prepared whole-grain nutritional rice flour for infants is relatively abundant and comprehensive; the quality, the flavor and the taste of the prepared whole-grain nutritional rice flour for infants are improved; the solubility is improved; the whole-grain nutritional rice flour for infants are relatively liable to assimilate; the whole-grain nutritional rice flour for the infants has a good market application prospect.

Owner:SHENZHEN WEICKY BIOLOGICAL TECH

High-calcium composite shrimp meat sausage and preparation method thereof

ActiveCN103610131ASolve rough tasteSatisfy Food DeliciousFood mechanical treatmentFood ingredient functionsBiotechnologyMicrobiology

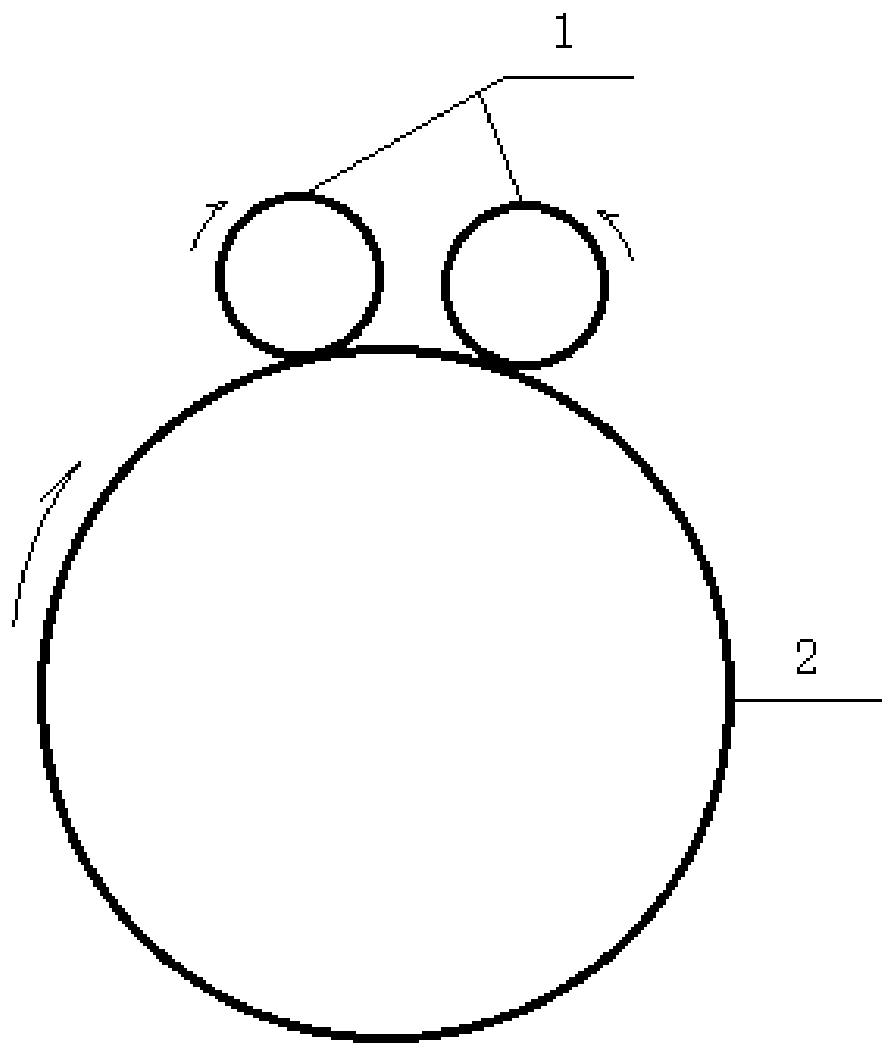

The invention relates to a high-calcium composite shrimp meat sausage and a preparation method thereof. The preparation method is characterized in that fresh acete chinensis with shells are crushed into full acete chinensis paste by a colloid mill; the prepared full acete chinensis paste is mixed with minced fillet, chicken and the like; a mixture is processed by chopping, filling, steaming and the like to obtain the shrimp meat sausage. With the adoption of a colloid mill crushing process, the problem that a traditional shrimp meat sausage only contains shrimp meat so that a lot of shrimp shell leftovers are generated is solved, and a problem that the mouth feel is rough due to that shrimp shells are added into a food is also solved. Meanwhile, the acete chinensis, a natural calcium source, is utilized, and is safer and is easier to absorb by a human body when being compared with an inorganic calcium source added into a traditional calcium-supplementing sausage, so that the requirements on healthy and safe foods of consumers are met.

Owner:BOHAI UNIV

Method for processing food stick

The invention relates to a method for processing a food bar. The method comprises the following steps of mixing syrup and grease to carry out high-pressure homogenization emulsion; evenly blending and doughing with other components and incising the components into the bar. The process of the high-pressure homogenization emulsion is added in the method, so that the mixture of the syrup and the grease is more even and the emulsion is more sufficient, thereby the product has more delicate quality and better taste.

Owner:BEIJING COMPETITOR SPORTS SCI & TECH +2

High-plumule millet nutritious rice flour and processing method thereof

InactiveCN101904464ABalanced nutritionImprove immunityDough treatmentFood preparationFiberDietary fiber

The invention discloses high-plumule millet nutritious rice flour, which comprise the components of plumule-containing millet outer flour, soybean flour, all-millet flour and wheat flour in a weight mixing ratio of 20-30:1-5:3-5:60-80. The processing method of the nutritious rice flour comprises: removing large-size impurities by using a primary cleaning screen; removing small-size impurities in a vibrating screen; removing light impurities; removing stones by a stone removing machine; dressing by magnetic separation; primarily striking grains for husking 40 to 50 percent of grains; secondarily striking grains for husking over 90 percent of grains; dressing by magnetic separation; forcefully coarsening by a roller 1 and coarsely rolling; finely rolling by a roller 4; taking the plumule-containing outer flour by a flour sucker; grading by a grader; dressing by magnetic separation; mixing by a mixer; and packing. The high-plumule millet nutritious rice flour is advantageous over rice flour in terms of vitamin content, mineral content, trace element content and the like, can be used to make various foods and has a balance nutrition structure due to the combination of coarse and fine rice flour. The high-plumule millet nutritious rice flour can improve body immunity and has a remarkable health-care effect. The high-plumule millet nutritious rice flour contains rich dietary fibers and therefore is favorable for promoting gastrointestinal motility and digestion of people. A problem of coarse mouthfeel of millet is solved. The high-plumule millet nutritious rice flour has a strong and agreeable fragrance and is suitable for people of all ages.

Owner:辽宁兴诺米业有限责任公司

Preparing method of acidophilus milk lump

The invention discloses a preparation method for yogurt lump. The method comprises the steps of fermenting, acidization, curdling, whey discharging, water washing, storing, forming, sealing, after-ripening and packaging by adopting special lactic acid bacteria to inoculate milk or goat milk which is standardized and pasteurized. The invention can not only lead the traditional yogurt lump product to be safer and more sanitary with stable quality, subtle taste and modest hardness. And since the step of the after-ripening is controlled appropriately, the prepared yogurt lump is of fuller flavor with little cream precipitated, high yielding rate and can meet popular taste and be used for producing yogurt lump with different water content, tastes and textural quality, which has more market competitiveness and can greatly enrich the processing technology and flavor of traditional yogurt lump.

Owner:SOUTH CHINA AGRI UNIV +1

Bean flour press cakes and making method thereof

InactiveCN106212590ARich in nutrientsSolve rough tasteDough treatmentBakery productsPearl barleySugar

The invention relates to bean flour press cakes and a making method thereof. The cakes are prepared from, by weight, 40-50 parts of flour, 30-40 parts of soybean flour, 8-10 parts of red date powder, 8-10 parts of rhizoma dioscoreae powder, 6-9 parts of pearl barley powder, 3-6 parts of white sugar, 110-140 parts of spring water, 8-12 pieces of eggs, 8-10 parts of edible oil and 2-5 parts of lard oil. By using purely natural spring water and adding eggs and edible oil, the obtained press cakes are more crispy and delicious. By adopting soybean flour, red date powder, rhizoma dioscoreae powder and pearl barley powder besides flour and eggs, the obtained press cakes contain rich nutrients; besides, sesame seeds are spread on the cakes, so that color, aroma and taste are all good.

Owner:山西绿德农业科技股份有限公司

Crisp and high-tenacity double-layer composite biscuits and making method thereof

ActiveCN103891849ASolve rough tasteFast coloringDough treatmentBakery productsSodium bicarbonatePyrophosphate

The invention discloses crisp and high-tenacity double-layer composite biscuits and a making method of the crisp and high-tenacity double-layer composite biscuits, and belongs to the technical field of foods and food processing methods. The crisp and high-tenacity double-layer composite biscuits and the making method of the crisp and high-tenacity double-layer composite biscuits mainly solve the technical problem that existing biscuits made of coarse cereals taste rough, look pale and are complex to make. According to the technical scheme, with wheat flour, white granulated sugar, vegetable oil, potato flakes, purple potato flakes, margarine, edible salt, sodium bicarbonate, ammonium bicarbonate, roasted chicken powder, calcium hydrogen phosphate, soyabean lecithin, disodium dihydrogen pyrophosphate, water and the like serving as raw materials, the crisp and high-tenacity double-layer composite biscuits are made through the processes of weighing, mixing, forming, baking and the like. The crisp and high-tenacity double-layer composite biscuits made through the making method taste crisp and delicious, look bright and are easy to make.

Owner:晋城市古陵山食品有限公司

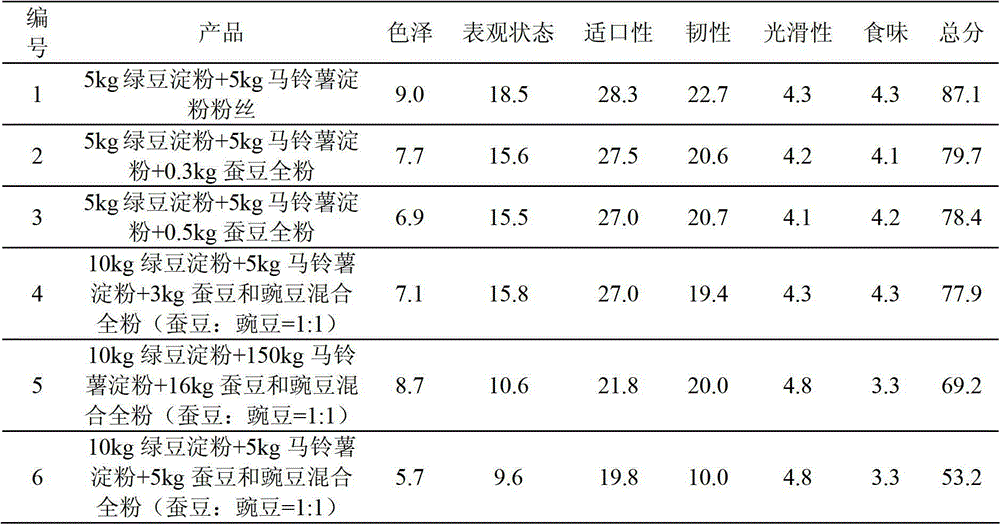

Whole broad bean flour glass noodles and sheet jelly and production method thereof

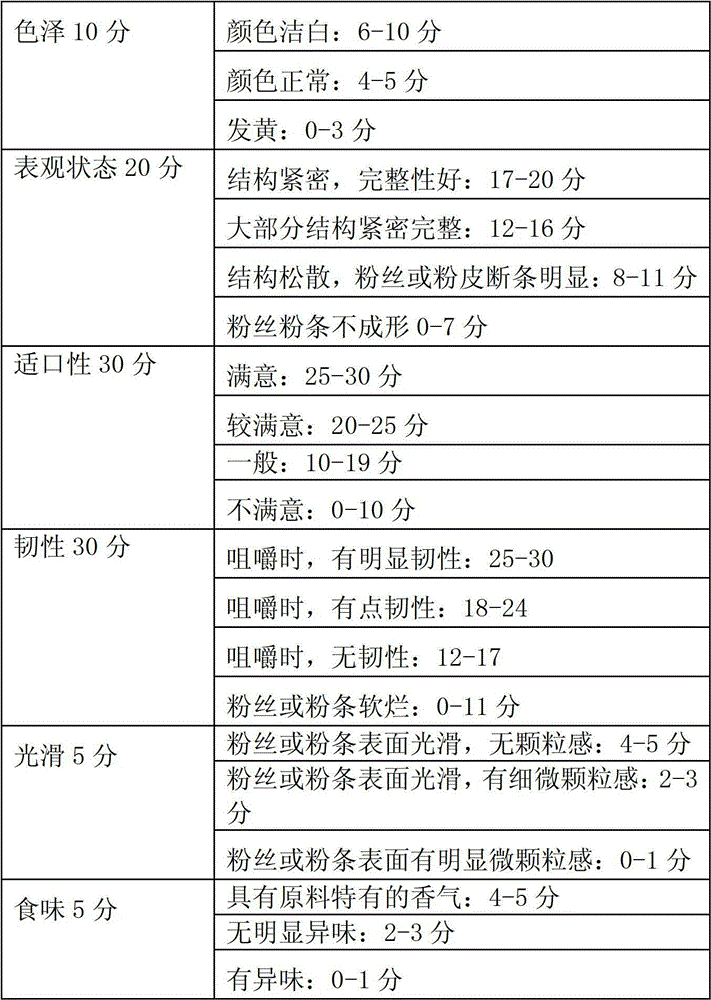

The invention discloses whole broad bean flour glass noodles and sheet jelly and a production method thereof. The whole broad bean flour glass noodles and sheet jelly is prepared by the following steps: 1), crushing broad beans or a mixture of broad beans and peas to obtain whole flour with the grain size of less than 50 microns; and 2), mixing mung bean starch and potato starch according to the mass ratio of 10:(5-150), adding 0.1 to 30 mass percent of crushed whole flour obtain in the step 1), adding water with the temperature of 50 to 100 DEG C, stirring uniformly, shaping, cooking the shaped glass noodles or sheet jelly in water at the temperature of 70 to 100 DEG C for 1 to 16 seconds, cooling and drying the glass noodles or sheet jelly to obtain the whole broad bean flour glass noodles or sheet jelly. The whole broad bean flour glass noodles or sheet jelly can be directly eaten after being mixed with water with the temperature of 80 DEG C for 3 to 10 minutes. The prepared glass noodles or sheet jelly has abundant nutrients and has fine, smooth and tenacious mouthfeel.

Owner:诸城市桃林食品有限责任公司

Multifunctional fermented corn flour and production process thereof

ActiveCN103876037AImprove featuresImprove palatabilityFood ingredientsFood preparationAmylaseAdditive ingredient

The invention provides multifunctional fermented corn flour and a production process thereof, relates to the field of processing of corn flour and solves the problems that corn flour prepared by adopting an existing rough processing method is low in viscoelasticity, the mouth feel of a finished product prepared from the corn flour by adopting an existing rough processing method is rough, the palatability is poor, the taste is spicy and the corn flour is not easy to digest. The multifunctional fermented corn flour comprises following components in percentage by weight: 99.92%-99.95% of corn dreg, 0.03%-0.05% of amylase, 0.02%-0.03% of yeast and the balance being water. The surface of the corn flour can pass through a 90-mesh sieve and the flour can pass through a 150-200-meshseive after water is added for kneading; the surface color of the flour keeps faint yellow of corns; the strengthen physicochemical indexes can reach the standard of wheat flour, and preservatives and chemical adhesive substances are not contained; after the flour is mixed, dough has the certain ductility and viscoelasticity; nutritional components are not changed and the mouth feel is fine, smooth, tough, chewy and smooth; after the multifunctional fermented corn flour is eaten, gastric acid is not generated, and bitter and astringent and spicy tastes are not generated; the flavor of the corns is kept and soup is not muddy after a product is boiled.

Owner:浙江森蓝食品有限公司

Soluble dietary fiber biscuits rich in wheat bran and making method of soluble dietary fiber biscuits

InactiveCN109430334AHigh nutritional valueImprove product gradeDough treatmentFood ingredientsFood additiveVegetable oil

The invention discloses soluble dietary fiber biscuits rich in wheat bran and a making method of the soluble dietary fiber biscuits. The soluble dietary fiber biscuits comprise the following components in percentage by mass of 10-20% of wheat bran soluble dietary fibers, 10-15% of refined vegetable oil, 5-10% of a sweetening agent, 0.2-1.0% of a fermenting agent, 0.1-0.5% of a loosening agent, 0.1-1.0% of seasoning, 0.1-0.5% of an emulsifying agent, 0.1-1.0% of a food additive, and the balance of flour or other powder for the biscuits. The making method of the biscuits comprises the making processes of making a base material of soluble dietary fibers by a coupling method of ultrasonic wave pretreatment and enzymolysis with complex enzymes on the wheat bran, and then processing biscuits products rich in soluble dietary fibers. According to the soluble dietary fiber biscuits, the mouth feel of products is improved, the texture of the products is improved, absorption of functional dietaryfibers can be promoted, and the nutrient value of the soluble dietary fiber biscuits is increased. The method is simple in technology, convenient to operate and low in equipment investment, and the used raw materials are low in cost and easy to obtain. The soluble dietary fiber biscuits disclosed by the invention are suitable for industrialized production and have favorable economic benefits andapplication prospects.

Owner:SUQIAN HUIWEI FOOD

Sugar-free full-tartary buckwheat tea yoghourt and preparation method thereof

InactiveCN107156294AImprove probioticsGood health effectMilk preparationPolygonum fagopyrumSaccharum

The invention discloses sugar-free full-tartary buckwheat tea yoghourt and a preparation method thereof. The sugar-free full-buckwheat tea yoghourt is prepared from raw milk, tartary buckwheat tea ultra-fine powder, a non-sugar sweetening agent and a stabilizer through burdening preparation, blending, filtration, homogenization, sterilization, cooling, fermentation, after-maturation and the like. By replacing saccharose with the non-sugar sweetening agent, the calorific value of a product can be decreased, and the healthcare functions of decreasing three highs can be reinforced; by replacing traditional tartary buckwheat tea soup with the tartary buckwheat tea ultra-fine powder and combining with a proper stabilizer, the problem that traditional tartary buckwheat tea yoghourt is only prepared from tea soup but not tea residues is solved, the maximum utilization rate of the tartary buckwheat tea is realized, and the nutritional value of the product is enriched. The sugar-free full-tartary buckwheat tea yoghourt has the nutritional and healthcare functions of yoghourt, tartary buckwheat, probiotics and xylitol, does not contain saccharose and is suitable for being drunk by patients of diabetes mellitus, hyperlipidemia, obesity and the like besides normal people.

Owner:XUCHANG UNIV

Preparation methods for functional enzymolyzed soybean protein isolate and dual-protein pure milk

InactiveCN102742718AImprove stabilitySolve solubilityMilk preparationVegetable proteins working-upSubtilisinNeutral protease

The invention discloses preparation methods for functional enzymolyzed soybean protein isolate and dual-protein pure milk. Protease used in the invention is selected from the group consisting of papain, bromelain, pepsin, trypsin, Aspergillus niger acidic protease, flavourzyme, subtilisin, peptidoglutaminase, 2709 alkali protease, the neutral protease Neutrase, AS1.398 neutral protease and transglutaminase, and the addition amount of the protease is 0.2 to 1.0%. The dual-protein pure milk is prepared by mixing the above mentioned soybean protein isolate with fresh milk and carrying out hydration, homogenization, sterilization and filling, and the dual-protein pure milk has high protein content and is free of a stabilizing agent, thus more beneficial for health of human bodies.

Owner:谷神生物科技集团有限公司

Preparation method of green tea yoghourt

InactiveCN105994627ASolve rough tasteSolve the problem of easy precipitation and stratification of tea powderMilk preparationFlavorSugar

The invention relates to green tea yoghourt and a preparation method thereof. The green tea yoghourt adopts the formula comprising the following raw materials in parts by weight: 1000 parts of raw milk, 60-80 parts of white granulated sugar, 2.5-3.5 parts of ultramicro green tea powder, 15-25 parts of a stabilizing agent, and 1 part of a yoghourt fermenting agent. The green tea yoghourt is distinct in green tea flavor, good in color, fine and smooth in mouth feel and good in tissue state, and tea powder is not precipitated and not layered, so that the green tea yoghourt has a very high nutrient value and certain health-care functions.

Owner:XUCHANG UNIV

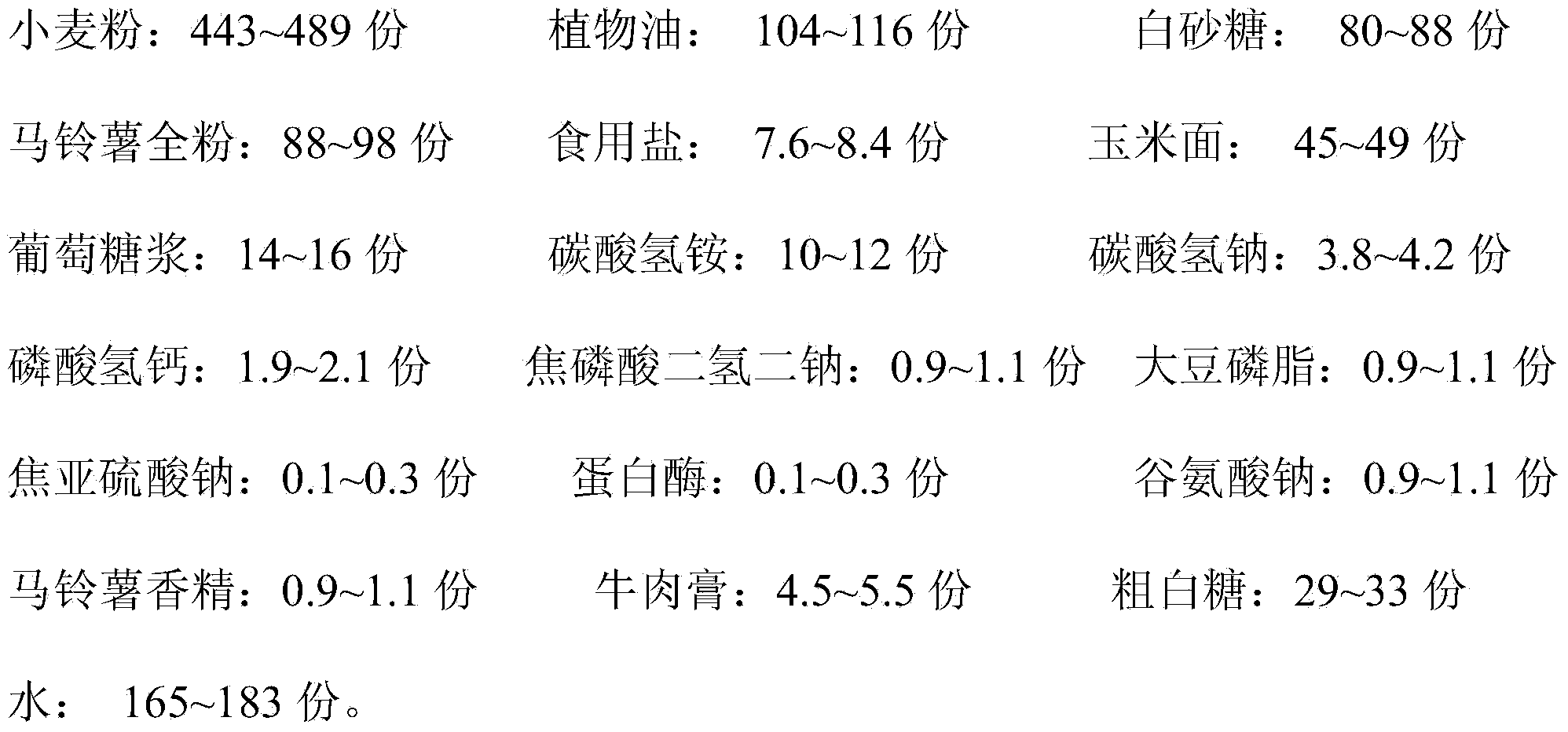

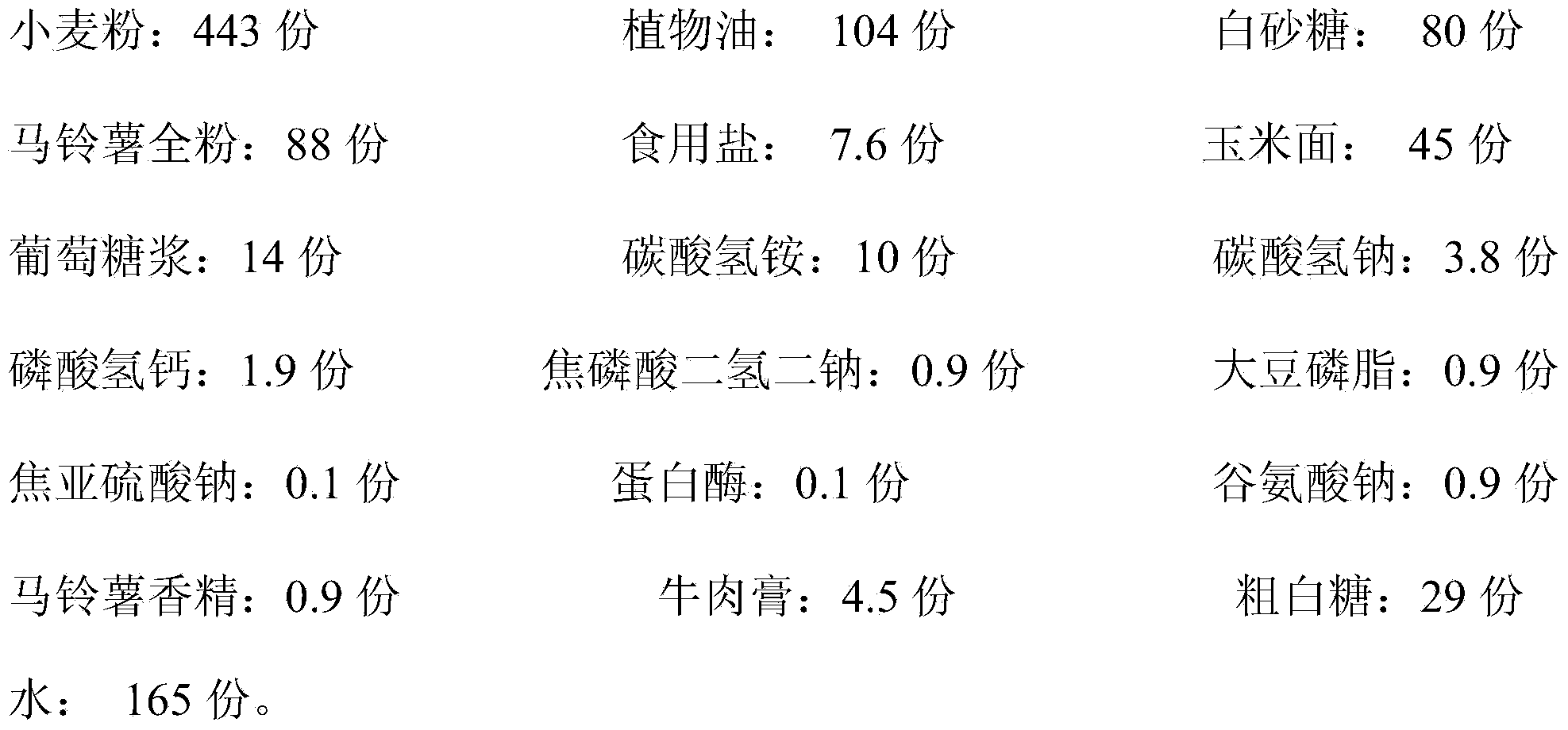

Crispy cereal biscuit and making technology thereof

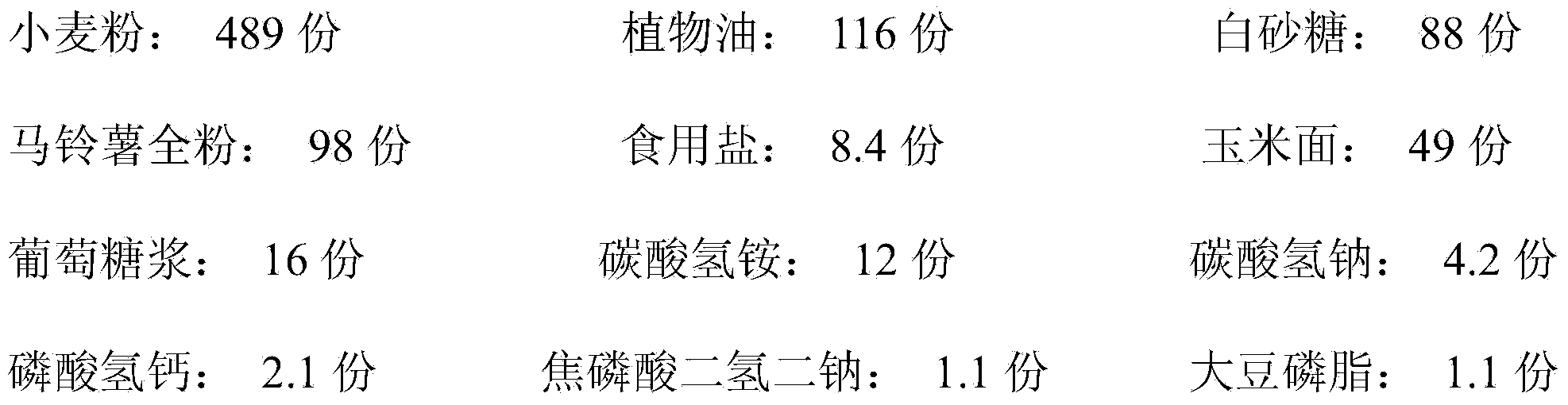

ActiveCN103891848ASolve rough tasteFast coloringDough treatmentBakery productsPyrophosphatePotato starch

The invention belongs to the technical field of foods and processing technology of the foods, and particularly relates to a crispy cereal biscuit and a making technology of the crispy cereal biscuit. The crispy cereal biscuit and the making technology mainly solve the technical problems that an existing biscuit is rough in taste, dim in color and luster and complex in making method. By the adoption of the technical scheme, the crispy cereal biscuit comprises following raw materials, by weight, 443-489 parts of wheat flour, 104-116 parts of vegetable oil, 80-88 parts of white granulated sugar, 88-98 parts of potato starch, 7.6-8.4 parts of edible salt, 45-49 parts of corn flour, 14-16 parts of glucose syrup, 10-12 parts of ammonium bicarbonate, 3.8-4.2 parts of sodium bicarbonate, 1.9-2.1 parts of calcium hydrophosphate, 0.9-1.1 parts of disodium dihydrogen pyrophosphate, 0.9-1.1 parts of granulesten, 0.1-0.3 part of sodium pyrosulfite, 0.1-0.3 part of protease, 0.9-1.1 parts of sodium glutamate, 0.9-1.1 parts of potato essence, 4.5-5.5 parts of beef extracts, 29-33 parts of coarse sugar and 165-183 parts of water. The crispy cereal biscuit is made through weighing, mixing, shaping, baking and the like. The crispy cereal biscuit is crispy in taste, delicious and bright in color and luster, and the making method is simple.

Owner:晋城市古陵山食品有限公司

Whole Taraxacum goloskokovii green tea

The invention relates to whole Taraxacum goloskokovii green tea. The whole Taraxacum goloskokovii green tea is prepared from whole Taraxacum goloskokovii with the length ranging from 5 cm to 7 cm through blanching, cooling, dewatering, deblocking, rolling, high-temperature dewatering, shaping and drying; roots of the Taraxacum goloskokovii have diameters smaller than or equal to 0.5 cm and the length smaller than or equal to 0.5 cm and are cut into cross shapes; leaves of the Taraxacum goloskokovii are complete, and 9-11 leaves exist. The whole Taraxacum goloskokovii is used as a raw material, the problem that the roots rich in phytosterol and flavone are wasted due to the fact that the roots of the Taraxacum goloskokovii cannot be used as a part of tea making raw materials at present is solved, and the whole Taraxacum goloskokovii green tea has the flavone content up to 53 mg / g and the polyphenol content up to 42 mg / g.

Owner:HEILONGJIANG BAYI AGRICULTURAL UNIVERSITY

Tartary buckwheat thick broad-bean sauce and preparation method thereof

InactiveCN106942610ARich in nutrientsSolve rough tasteFood ingredient functionsMonosodium glutamateBiotechnology

The invention discloses a tartary buckwheat thick broad-bean sauce, which comprises the following components in parts by weight: 40 to 60 parts of broad bean seed, 20 to 30 parts of tartary buckwheat rice, 10 to 18 parts of salt, 5 to 8 parts of wheat flour, 1 to 3 parts of spice, 0.1 to 0.5 part of sauce koji, 10 to 20 parts of edible plant oil, 8 to 10 parts of pepper, 5 to 9 parts of monosodium glutamate, and a proper amount of water. The invention also discloses a preparation method of the tartary buckwheat thick broad-bean sauce. The tartary buckwheat thick broad-bean sauce and preparation method have the advantages that the rough taste of tartary buckwheat food is improved; the nutrients of thick broad-bean sauce are enriched; the thick broad-bean sauce can prevent and control hyperlipidemia, hyperglycemia, and hypertension, protect heart and blood vessels, promote appetite, invigorate the spleen, and keep beauty; the operation is simple, and the cost is low.

Owner:湖南双晟科技信息咨询有限公司

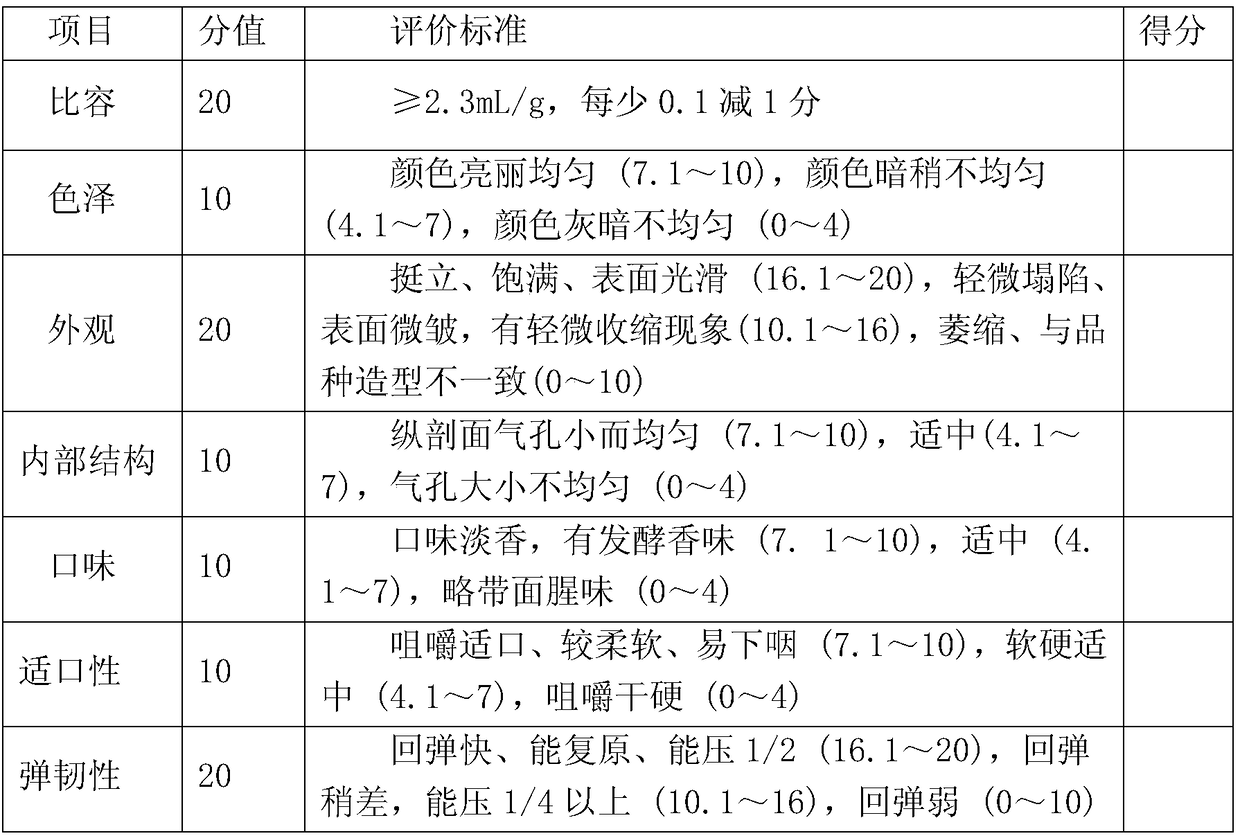

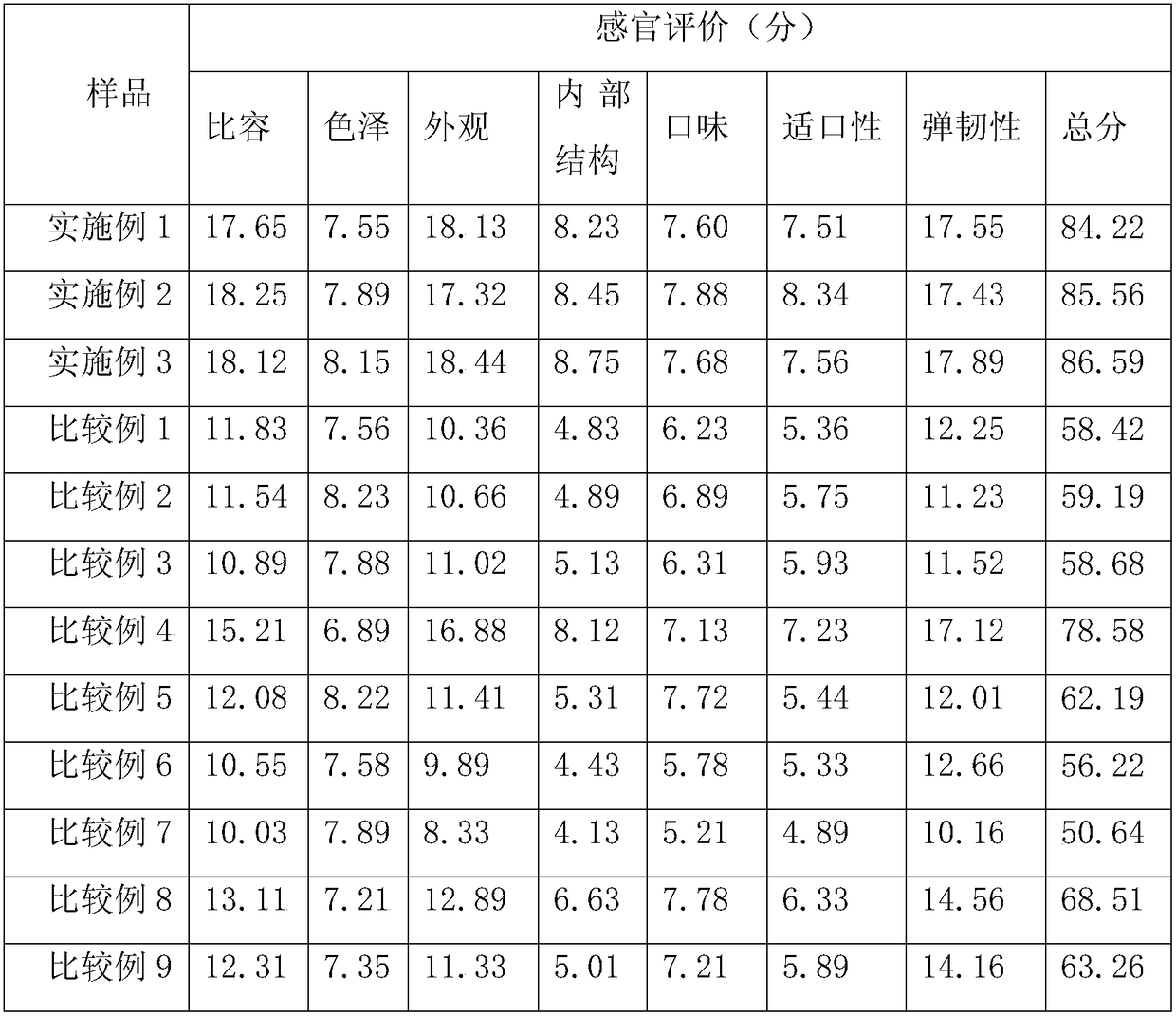

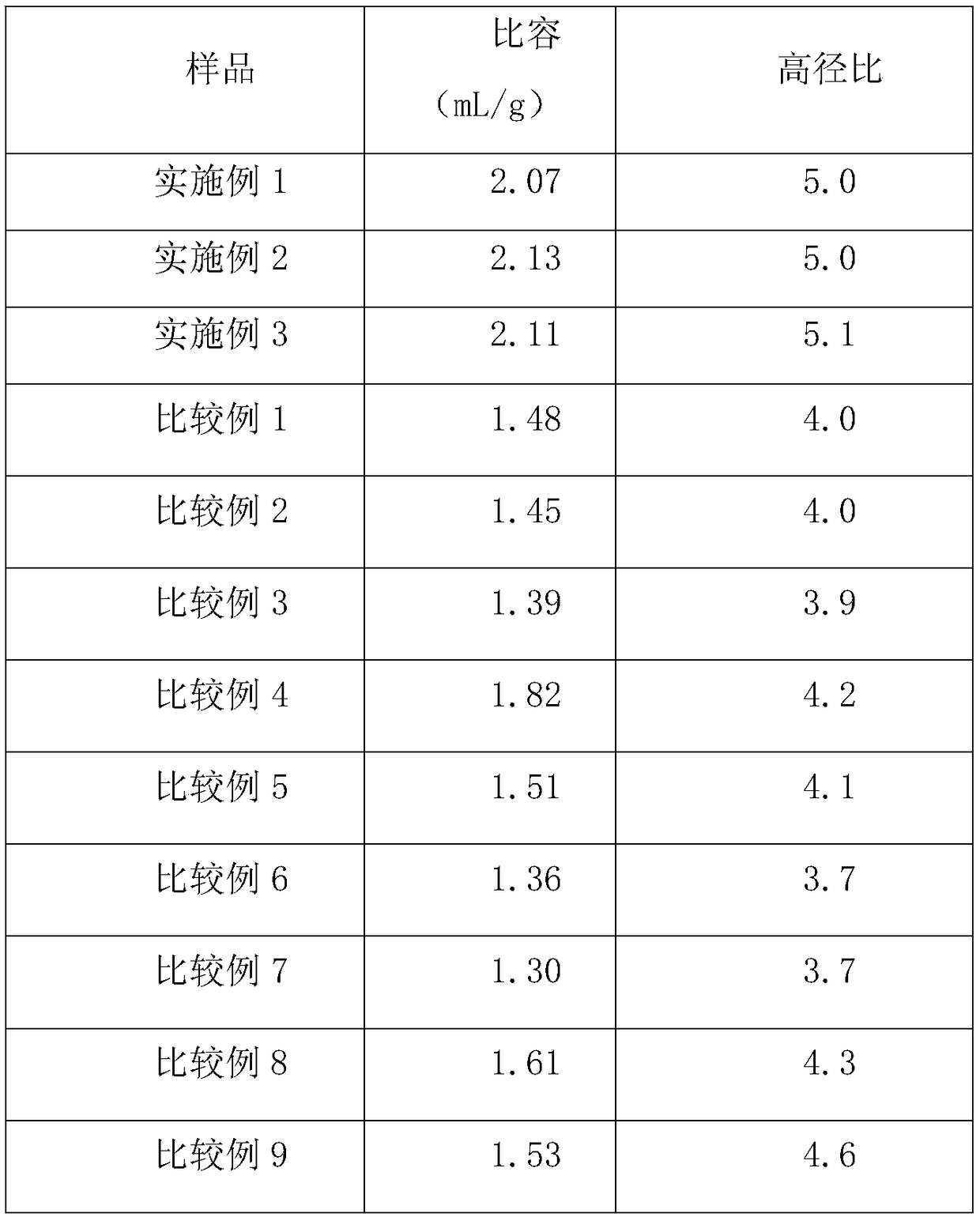

Composite quality improver for coarse cereal-sourced steamed bread and using method thereof

InactiveCN108617945AWith aromaDelicate tasteYeast food ingredientsFood ingredient as mouthfeel improving agentSpecific volumeCellulase

The invention relates to a composite quality improver for coarse cereal-sourced steamed bread and a using method thereof. In order to solve the problems that the coarse cereal-sourced steamed bread issmall in volume, small in specific volume, rough in mouth feel and nonuniform in surface, nutrients thereof are not easily absorbed by a human body and the like, the invention develops the compositequality improver which effectively improves the quality of whole-coarse cereal steamed bread through organic and reasonable cooridaintion of a composite cellulase, glutamine transaminase, azodicarbonamide (ADA), an emulsifier, wheat protein and the like, the using method thereof and the coarse cereal-sourced steamed bread produced by using the composite quality improver for the coarse cereal-sourced steamed bread. The invention further finds that joint addition of the glutamine transaminase and the azodicarbonamide into the steamed bread better improves the specific volume, the aspect ratio, the outer shape and the mouth feel of the steamed bread than separate addition of any one into the steamed bread, and a very good effect of improving the outer shape and the mouth feel can be achievedthrough lower addition amount of the glutamine transaminase and the azodicarbonamide than the dosage of any separately added component.

Owner:四川东方主食产业技术研究院

Waxy corn zongzi and method of removing bitter taste thereof

InactiveCN102132823ASolve rough tasteSolving Bitter Technical DifficultiesFood preparationBiotechnologyWaxy corn

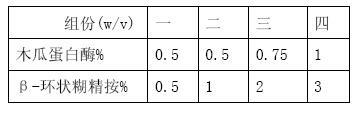

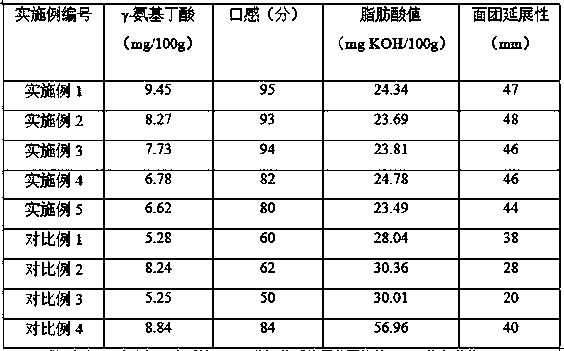

The invention relates to a waxy corn zongzi and a method of removing bitter taste thereof. The waxy corn zongzi is prepared by the following steps: taking dry waxy corn grits as raw materials, adding protease and / or beta-cyclodextrine in the waxy corn grits for soaking, dissolving papain into water at 55-60 DEG C according to 0.5-1 percent (w / v) of proportion, soaking the waxy corn grits for 12 hours, and / or dissolving the beta-cyclodextrine in the water of 55-60 DEG C according to 1-3 percent of percent (w / v) of proportion, soaking the waxy corn grits for 12 hours again; and pouring the soaked liquid, and washing the waxy corn grits for three times by drinking water. The advantages are that: the waxy corn zongzi does not contain preservative or chemical gel substances; the preparation by dry waxy corn relieves the freshness and maintains light corn scant, remove the limit of bitter, spicy and seasons in original protein and embryo to the food processing; the nutrition property of the processed waxy corn is unchanged; the light corn scent is retained, the bitter and spicy tastes in the original protein and embryo are removed; and the product is fine and smooth, and does not mix the soup after being cooked, thus thoroughly removing the problem of coarse mouthfeeling of the original corn food.

Owner:上海众喻食品有限公司

Nutrition balanced fruit and coarse grain snack

The fast fruit-coarse grains meal has hominy and potato, rather than rice and wheat flour, as the main carbohydrate source; soybean as main protein source; and fresh apple and pumpkin for increasing vitamins, cellulose and mineral content. It has balanced nutrient components and good taste.

Owner:姜泓

Preparing method for coarse rice powder special for baking

PendingCN109619400AHigh nutritional valueEnhance sensory effectDough treatmentModified nutritive productsNutritive valuesExtensibility

The invention discloses a preparing method for coarse rice powder special for baking. The preparing method includes the following steps that (1) seasonablecoarse rice is selected, sterilized and cleaned, then is introduced into a cellulose solution under the humidification condition, and is subjected to micro germination treatment; (2) the obtained coarse rice is subjected to superheated steam treatment, and is cooled to the temperature of 40 DEG C to 45 DEG C after superheated steam treatment is completed, heat preservation is carried out, then the obtained coarse rice is added into a glutamine transaminase solution and soaked, and moisture is drained off; (3) the coarse rice after being drained off is subjected to microwave dryingtreatment; (4) the coarse rice after being subjected to microwave dryingtreatment is subjected to superfine grinding, and the coarse rice powder special for baking is obtained. According to the preparing method, the processing performance of the coarse ricepowder can be remarkably improved, the nutritive value of the coarse rice powder is improved, the problem that the taste of the coarse rice powder is coarse is solved, the baking processing adaptability of the coarse rice powder is improved, thedigestibility of the coarse rice powder is improved, the plasticity and the extensibility of the coarse rice powder are improved, the storage stability ofraw-material coarse rice powder is kept, and the coarse rice powder is suitable for production of bakery products such as biscuits, walnut cakes, cookies and cakes.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

Golden corn cake and making method thereof

ActiveCN104938564AImprove utilizationReduce utilizationBakery productsFood preparationArabinoseBiotechnology

The invention discloses a golden corn cake which is prepared from, by weight, 80%-90% of premixed flour of corn, brown rice, Tilapia mossambica bones and dough, 1%-3% of L-arabinose, 1%-3% of vegetable oil, 2%-4% of egg liquid, 0.05%-0.1% of salt and 5%-10% of water. The invention further discloses a making method of the golden corn cake. Firstly, Tilapia mossambica bone flour and germinated brown rice are prepared, then the premixed flour of corn, brown rice, Tilapia mossambica bones and dough is prepared, and finally the golden corn cake is prepared. The golden corn cake is loosened, porous and soft in appearance, the cake is crispy and rich in taste, no residue falls when the cake is eaten, and the cake is coarse but not rough, and is a low-grease low-calorie high-calcium and high-fiber product.

Owner:DONGGUAN HAOLONG FOOD

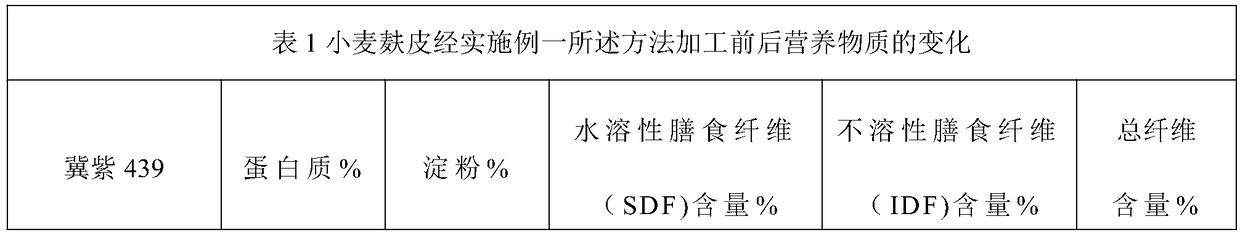

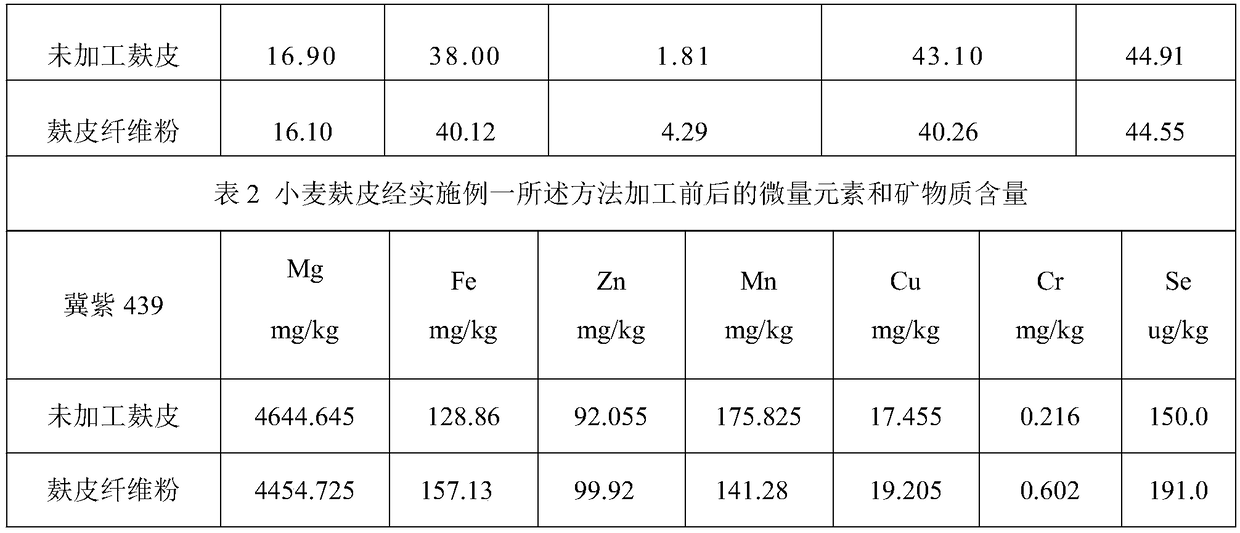

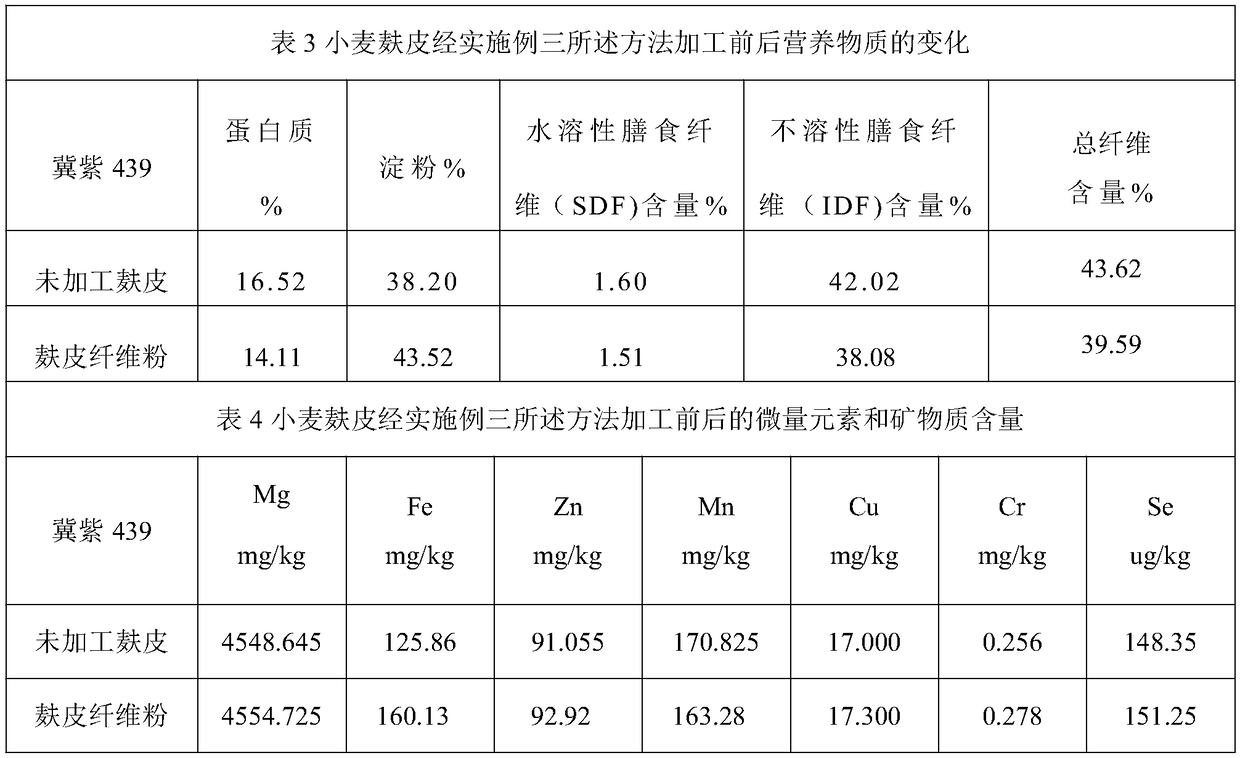

Triticale bran dietary fiber powder and manufacturing method thereof

InactiveCN108720031ASolve rough tasteRetain high nutritional valueFood ingredient as mouthfeel improving agentFiberFibers tissue

The invention discloses a manufacturing method of triticale bran dietary fiber powder. The manufacturing method organically combines the sequential steps of crushing, puffing and grinding for triticale bran to produce the triticale bran dietary fiber powder not in bran speck form, but in powder form. The manufacturing method herein changes internal fiber tissue structure in bran such that the branhas fine taste, greatly reserves high nutritional value of triticale bran in nutrition term, especially in protein, trace element and mineral contents, and enables soluble dietary fiber and insolublefiber are matched to be better absorbable and usable by human; therefore, high-nutrition triticale bran dietary fiber powder widely applicable as food processing materials is manufactured. Such fiberpowder is applicable to making of bread, cookies, various dough foods and the like and is also directly eatable or directly consumable as drinks after brewing, daily consumption is facilitated for people, and dietary and health effect of triticale bran can be better exerted.

Owner:INST OF CEREAL & OIL CROPS HEBEI ACAD OF AGRI & FORESTRY SCI +1

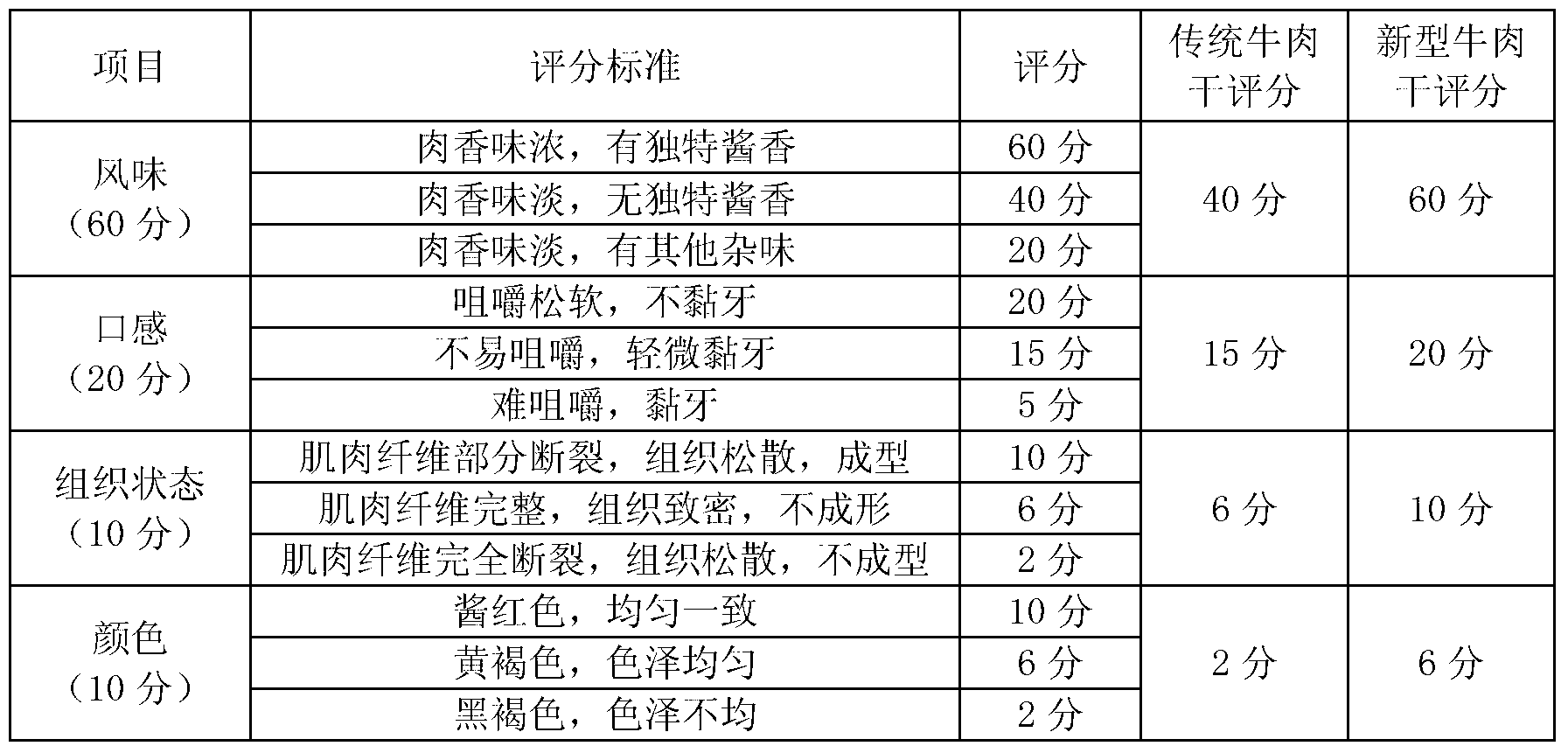

Preparation method of low-sugar type middle-water sliced dried beef

The invention belongs to the field of research and machining of foods and particularly relates to low-sugar type middle-water sliced dried beef and a preparation method thereof. The method comprises the following steps of: discharging acid of fresh beef and cooking; then adding pickling agents to cure, wherein the adding amounts of the pickling agents are as follows based on the weight of the beef: 2-8% of xylitol, 3-9% of sorbitol, 1.5% of table salt, 0.5% of curry powder and 1.0% of soybean sauce; and then carrying out tumbling, pre-boiling, dicing and boiling and marinating and carrying out two-section type drying to obtain the low-sugar type middle-water sliced dried beef. According to the low-sugar type middle-water sliced dried beef and the preparation method thereof, the problems of the traditional sliced dried beef that the mouth feel is rough, the texture is hard and fat can be oxidized and become brown in the storing process are effectively solved.

Owner:YANGZHOU UNIV

Organic grain infant nutrition rice powder and preparation method thereof

InactiveCN107432409AFull of nutritionGood processing performanceLactobacillusSugar food ingredientsProbioticInfant nutrition

The invention discloses organic grain infant nutrition rice powder and a preparation method thereof, wherein the organic grain infant nutrition rice powder comprises, by mass, 60-65% of organic grain coarse cereal powder, 20-24% of sugar powder, 10-15% of protein powder, 1-2% of a functional polypeptide, composite probiotics, and composite prebiotics. According to the present invention, by using the organic grain coarse cereal as the main raw material and adding other nutrition substances, the single nutrition structure of the traditional rice powder is changed, and the prepared organic grain infant nutrition rice powder has the rich and complete nutrition; and based on the physiological needs of different types of children, the functional polypeptide is added, such that the nutrition rice powder can achieve the new health functions on the basis of the original nutrition and function.

Owner:SHENZHEN WEICKY BIOLOGICAL TECH

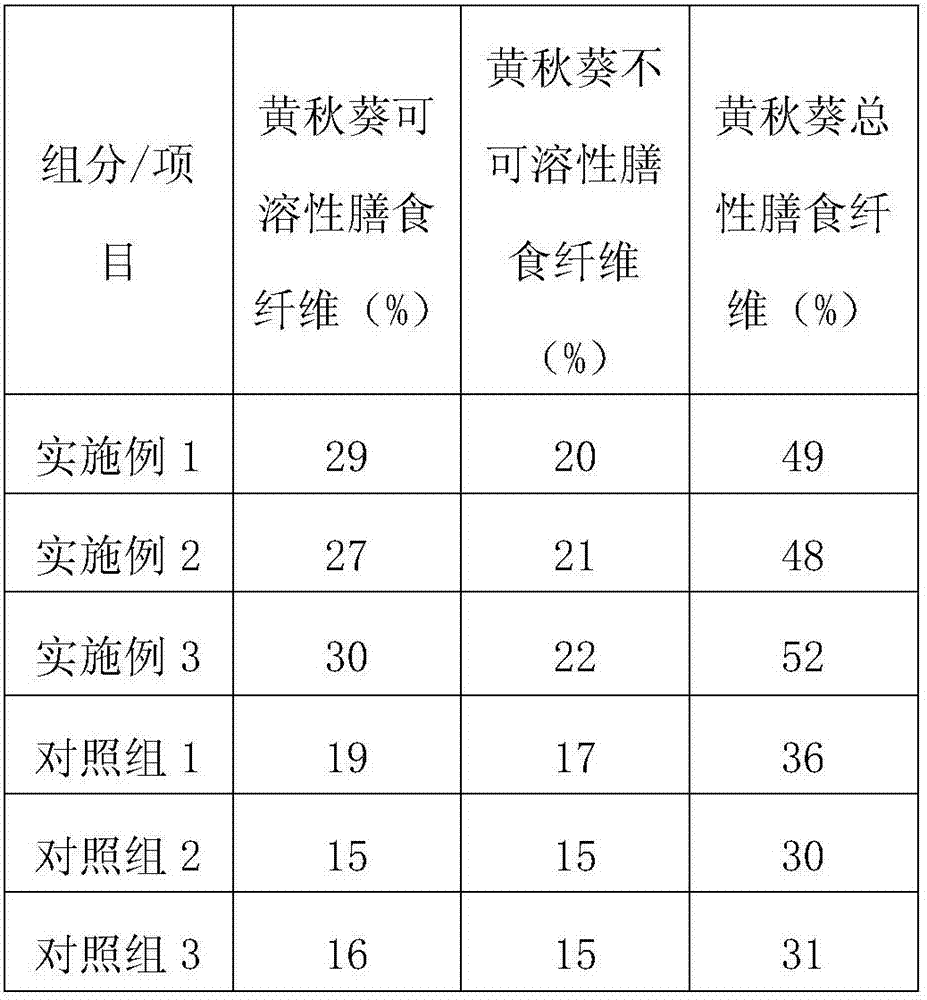

Extraction method and application of okra dietary fiber

The invention discloses an extraction method and an application of okra dietary fiber and relates to the technical field of food production and processing. The extraction method comprises steps as follows: pretreatment, ultrasonic treatment, enzymolysis, alkaline hydrolysis, washing, concentration and drying. The extraction is assisted through addition of an enzyme activator, dosage of enzyme is reduced, extraction cost is reduced, and besides, yield of finished products and purity are high; the puffed insoluble dietary fiber is used for making steamed buns, and the prepared steamed buns are rich in the dietary fiber, soft and elastic, taste smooth and reserve original flavor.

Owner:BAISE UNIV

Method for processing food stick

The invention relates to a method for processing a food bar. The method comprises the following steps of mixing syrup and grease to carry out high-pressure homogenization emulsion; evenly blending and doughing with other components and incising the components into the bar. The process of the high-pressure homogenization emulsion is added in the method, so that the mixture of the syrup and the grease is more even and the emulsion is more sufficient, thereby the product has more delicate quality and better taste.

Owner:BEIJING COMPETITOR SPORTS SCI & TECH +2

Infant nutrition rice powder and preparation method thereof

The invention discloses a nutritional rice flour for infants and a preparation method thereof, which comprises the following components in terms of mass percentage: 60-70% of brown rice flour; 10-15% of sugar; 10-20% of protein powder; functional polypeptide 5‑8%; natural substance extract 1‑2%. The invention uses organic rice as the main raw material and adds other nutrients, which changes the single nutritional structure of traditional rice noodles, makes the nutrition of the prepared rice noodles for infants and young children richer and more comprehensive, and is aimed at the physiological needs of different types of children. Vegetables, fruits or plant extracts with the same medicine and food can improve the physique of infants and young children, and add functional peptides to improve immunity, so that nutritional rice noodles can obtain new health care functions on the basis of the original nutrition and functions.

Owner:SHENZHEN WEICKY BIOLOGICAL TECH

Wet preparation method of instant whole-corn nutrition snowflake tablets

ActiveCN109892549APure flavorHigh nutritional valueFood preservationNeutral proteaseMicrowave sterilization

The invention provides a wet preparation method of instant whole-corn nutrition snowflake tablets. The method takes dry corn kernels (whole corn) containing seed coats and germs as a raw material, andcomprises the following steps that (1) the raw material is pretreated; (2) the dry corn kernels are soaked in a lactic acid solution; (3) the dry corn kernels are grinded into pulp; (4) the corn pulpis subjected to enzymolysis with neutral protease; (5) the corn pulp is homogenized; (6) the homogeneous pulp is subjected to roller pregelatinization and pre-drying to obtain corn paste; (7) the corn paste is subjected to roller drying to obtain the corn tablets of which the water content is not higher than 8%; (8) the corn tablets are crushed and sieved; (9) the corn snowflake tablets are subjected to microwave sterilization; (10) inner packaging, metal detection and outer packaging are carried out. The wet preparation method of the instant whole-corn nutrition snowflake tablets can improvethe nutritional value of the corn snowflake tablets, improve the brewing performance and taste of the corn snowflake tablets, and reduce the energy consumption.

Owner:SICHUAN UNIV +1

High-calcium composite shrimp meat sausage and preparation method thereof

ActiveCN103610131BSolve rough tasteGreat tasteFood mechanical treatmentFood ingredient functionsBiotechnologyMicrobiology

The invention relates to a high-calcium composite shrimp sausage and a preparation method thereof, which is characterized in that fresh hairy shrimps are pulverized together with meat and shells by a colloid mill to make whole-haired shrimp paste, and the prepared whole-hair shrimp paste Mix with surimi, chicken, etc., chop, mix, enema, steam and other processes to obtain shrimp sausage. The use of the colloid mill crushing process not only avoids the problem of a large amount of shrimp shell leftovers such as traditional shrimp sausages that only use shrimp meat, but also solves the problem of rough taste caused by adding shrimp shells to food. At the same time, the present invention utilizes the natural calcium source of hairy shrimp, which is safer and more suitable for human body to absorb compared with the inorganic calcium source added in the traditional calcium-supplementing sausage, thereby satisfying consumers' demands for food health and safety.

Owner:BOHAI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com