Waxy corn zongzi and method of removing bitter taste thereof

A technique for removing bitterness and astringency from waxy corn, which is applied in the field of waxy corn dumplings and its debitterness and astringency. It can solve problems such as rough taste, no marketability, and product failure, and achieve the removal of bitterness and astringency, maintaining chewiness and maintaining nutritional properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Example 1: Method for removing bitterness from waxy corn grits:

[0038] A method for removing bitterness and astringency from waxy corn, using dried waxy corn grits as raw material, adding protease and / or β-cyclodextrin to the waxy corn grits for soaking, comprising the following steps:

[0039] Step 1: Dissolve papain (w / v) in 0.5%, 0.75% or 1% water at 55-60°C in a stainless steel container, soak waxy corn grits for 12 hours, and / or make β-ring paste Dissolve the essence in 1-3% (w / v) water at 55-60°C, then soak the waxy corn grits for 12 hours;

[0040] Step 2, remove the soaking liquid, and wash the corn grits with drinking water for 3 times.

[0041] Among them, dissolving papain at 1% (w / v) in water at 55-60°C has the best taste effect on waxy corn grits soaked for 12 hours.

Embodiment 2

[0042] Example 2: Method for removing bitterness from waxy corn grits:

[0043] A method for removing bitterness and astringency from waxy corn, using dry waxy corn grits as raw material, adding β-cyclodextrin to the waxy corn grits for soaking, comprising the following steps:

[0044]Step 1: Dissolve β-cyclodextrin (w / v) in 0.5%, 1%, 2%, and 3% water at 55-60°C in a stainless steel container, and then soak waxy corn grits for 12 hours;

[0045] Step 2, remove the soaking liquid, and wash the corn grits with drinking water for 3 times.

[0046] Among them, 3% β-cyclodextrin (w / v) was dissolved in water at 55-60°C, and it had the best taste effect on waxy corn grits soaked for 12 hours.

Embodiment 3

[0047] Example 3: Method for removing bitterness from waxy corn grits:

[0048] A method for removing bitterness and astringency from waxy corn, using dry waxy corn grits as raw material, adding protease and β-cyclodextrin to the waxy corn grits for soaking, comprising the following steps: soaking β-cyclodextrin, including Follow the steps below:

[0049] Step 1, dissolving papain and β-cyclodextrin in water at 55-60°C in a stainless steel container, and then soaking waxy corn grits for 12 hours, wherein:

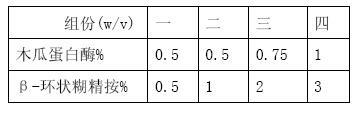

[0050]

[0051] Step 2, remove the soaking liquid, and wash the corn grits with drinking water for 3 times.

[0052] One to four have the effect of removing bitterness. Among them, 0.5% (w / v) of papain and 1% (w / v) of β-cyclodextrin are dissolved in water at 55-60°C, and the glutinous corn grits are soaked for 12 hours Taste works best.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com