Bologna sausage and making method thereof

A technology of isolated red sausage and soybean protein, which is applied in the field of red sausage and its production, can solve the problems of cumbersome production process, low nutritional value of red sausage, and worrying food safety, etc., and achieve good social benefits, high added value of products, and color Fragrance excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

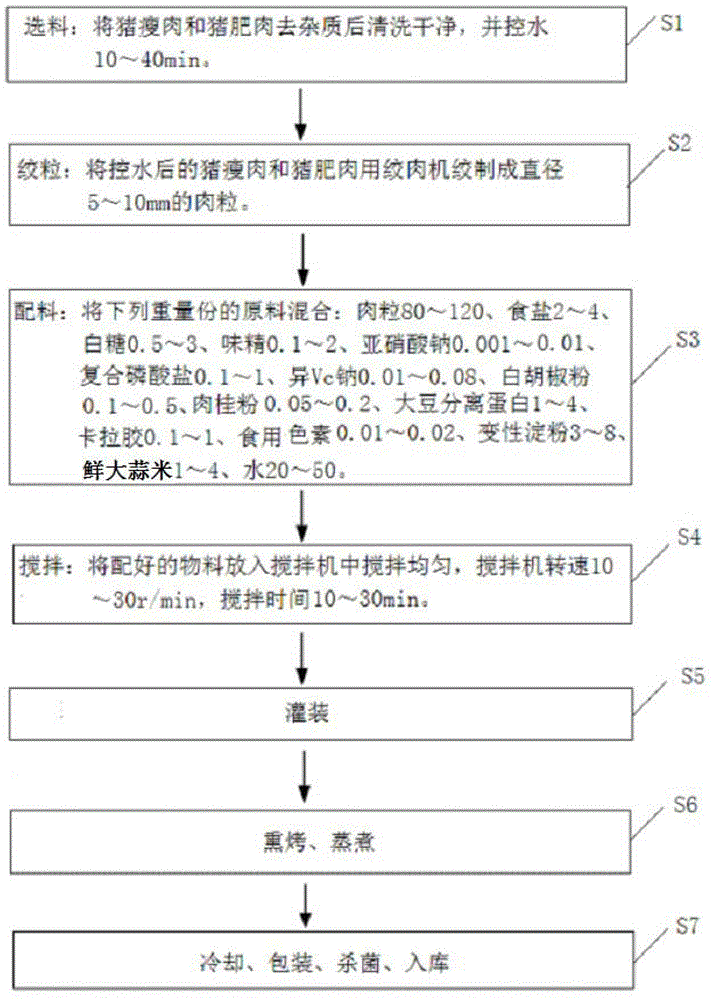

Method used

Image

Examples

Embodiment 1

[0047]With 80 parts by weight of pork grains as the main ingredient, and select 2 parts by weight of salt, 0.5 parts by weight of white sugar, 0.1 parts by weight of monosodium glutamate, 0.001 parts by weight of sodium nitrite, 0.1 parts by weight of compound sodium phosphate (sodium pyrophosphate) 0.02, sodium tripolyphosphate 0.05, sodium hexametaphosphate 0.03), 0.01 parts by weight of sodium Vc, 0.1 parts by weight of white pepper, 0.05 parts by weight of cinnamon powder, 1 part by weight of soybean protein isolate, 0.1 parts by weight of Carrageenan, the sorghum red of 0.01 weight part, the corn modified starch of 3 weight parts, the fresh garlic rice of 1 weight part, the water of 20 weight parts are auxiliary material, comprise following processing step:

[0048] Step 1: Material selection: Clean the lean pork and pork fat after removing impurities, and control the water for 10 minutes;

[0049] Step 2: Grinding: Use a meat grinder to grind the water-controlled pork in...

Embodiment 2

[0058] With the pork grain of 120 parts by weight as the main ingredient, and select the salt of 4 parts by weight, the white sugar of 3 parts by weight, the monosodium glutamate of 2 parts by weight, the sodium nitrite of 0.01 parts by weight, the compound sodium phosphate (sodium pyrophosphate) of 1 part by weight 0.4, sodium tripolyphosphate 0.2, sodium hexametaphosphate 0.4), 0.08 parts by weight of sodium Vc, 0.5 parts by weight of white pepper, 0.2 parts by weight of cinnamon powder, 4 parts by weight of soybean protein isolate, 1 part by weight of Carrageenan, the Monascus Red of 0.02 weight portion, the modified corn starch of 8 weight portion, the fresh garlic rice of 4 weight portion, the water of 50 weight portion is auxiliary material, comprises following processing step:

[0059] Step 1: Material selection: Clean the lean pork and pork fat after removing impurities, and control the water for 40 minutes;

[0060] Step 2: Grinding: Use a meat grinder to grind the wa...

Embodiment 3

[0069] With the pork grain of 100 parts by weight as main ingredient, and select the salt of 2.6 parts by weight, the white sugar of 1 part by weight, the monosodium glutamate of 0.6 parts by weight, the sodium nitrite of 0.006 parts by weight, the compound sodium phosphate (sodium pyrophosphate) of 0.6 parts by weight 0.2, sodium tripolyphosphate 0.3, sodium hexametaphosphate 0.1), 0.05 parts by weight of sodium Vc, 0.3 parts by weight of white pepper, 0.1 parts by weight of cinnamon powder, 2 parts by weight of soybean protein isolate, 0.5 parts by weight of Carrageenan, the sorghum red of 0.012 weight part, the corn modified starch of 6 weight part, the fresh garlic rice of 2 weight part, the water of 40 weight part is auxiliary material, comprises following processing steps:

[0070] Step 1: Material selection: Clean the lean pork and pork fat after removing impurities, and control the water for 20 minutes;

[0071] Step 2: Grinding: Use a meat grinder to grind the water-c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com