Instant octopus and production method thereof

An octopus and sugar syrup technology is applied in the field of ready-to-eat octopus, which can solve the problems of low octopus content and low nutritional value, and achieve the effects of high octopus content, high nutritional value and convenient eating.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

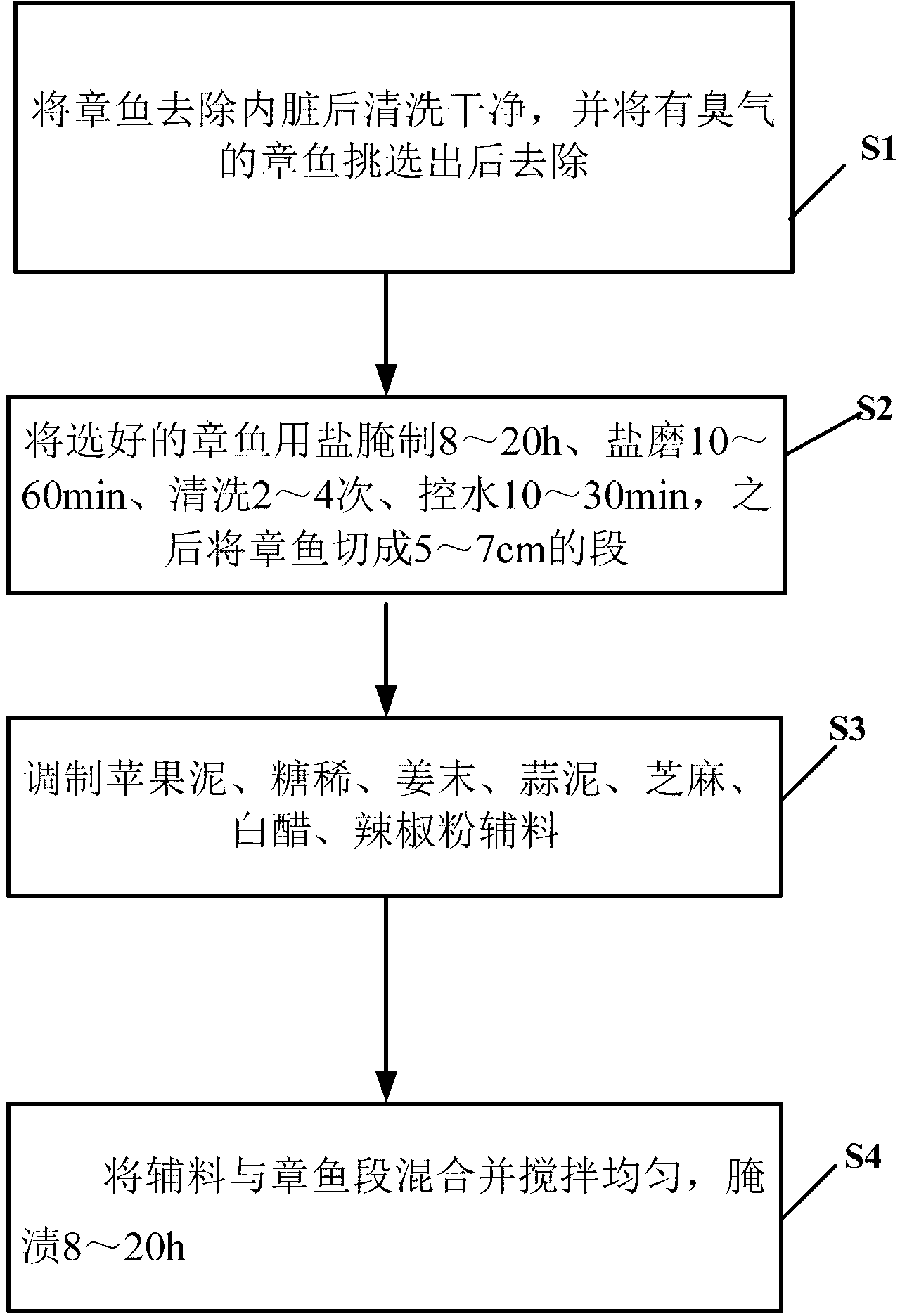

[0038] Taking 60 parts by weight of octopus as the main ingredient, and selecting 3 parts by weight of apple puree, 6 parts by weight of syrup, 2 parts by weight of minced ginger, 5 parts by weight of mashed garlic, 2 parts by weight of sesame seeds, 2 parts by weight of white vinegar, 5 parts by weight of The chili powder of weight part is auxiliary material, comprises following processing steps:

[0039] Step 1: material selection: remove the internal organs of the octopus and clean them, and select and remove the octopus with odor;

[0040] Step 2: Pretreatment: marinate the selected octopus with salt for 8 hours, grind the salt for 10 minutes, wash twice, control the water for 10 minutes, and then cut the octopus into 5cm sections;

[0041] Step 3: Prepare apple puree, syrup, minced ginger, garlic, sesame, white vinegar, and chili powder as accessories;

[0042] Step 4: Marinate: Mix the auxiliary materials with the octopus segments and stir evenly, marinate for 8 hours. ...

Embodiment 2

[0047] Taking 65 parts by weight of octopus as the main ingredient, and selecting 6 parts by weight of apple puree, 10 parts by weight of syrup, 4 parts by weight of minced ginger, 8 parts by weight of mashed garlic, 4 parts by weight of sesame seeds, 4 parts by weight of white vinegar, 7 parts by weight of The chili powder of weight part is auxiliary material, comprises following processing steps:

[0048] Step 1: material selection: remove the internal organs of the octopus and clean them, and select and remove the octopus with odor;

[0049] Step 2: Pretreatment: marinate the selected octopus with salt for 12 hours, grind the salt for 30 minutes, wash 3 times, control the water for 20 minutes, and then cut the octopus into 6cm sections;

[0050] Step 3: Prepare apple puree, syrup, minced ginger, garlic, sesame, white vinegar, and chili powder as accessories;

[0051]Step 4: Marinate: Mix the auxiliary materials with the octopus segments and stir evenly, and marinate for 12...

Embodiment 3

[0056] Taking the octopus of 75 parts by weight as the main ingredient, and selecting 8 parts by weight of apple puree, 15 parts by weight of syrup, 5 parts by weight of minced ginger, 10 parts by weight of mashed garlic, 5 parts by weight of sesame seeds, 5 parts by weight of white vinegar, 8 parts by weight of The chili powder of weight part is auxiliary material, comprises following processing steps:

[0057] Step 1: material selection: remove the internal organs of the octopus and clean them, and select and remove the octopus with odor;

[0058] Step 2: Pretreatment: marinate the selected octopus with salt for 20 hours, grind the salt for 60 minutes, wash 4 times, control the water for 30 minutes, and then cut the octopus into 7cm sections;

[0059] Step 3: Prepare apple puree, syrup, minced ginger, garlic, sesame, white vinegar, and chili powder as accessories;

[0060] Step 4: Marinate: Mix the auxiliary materials with the octopus segments and stir evenly, marinate for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com