Patents

Literature

151results about How to "Addressing inhomogeneity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

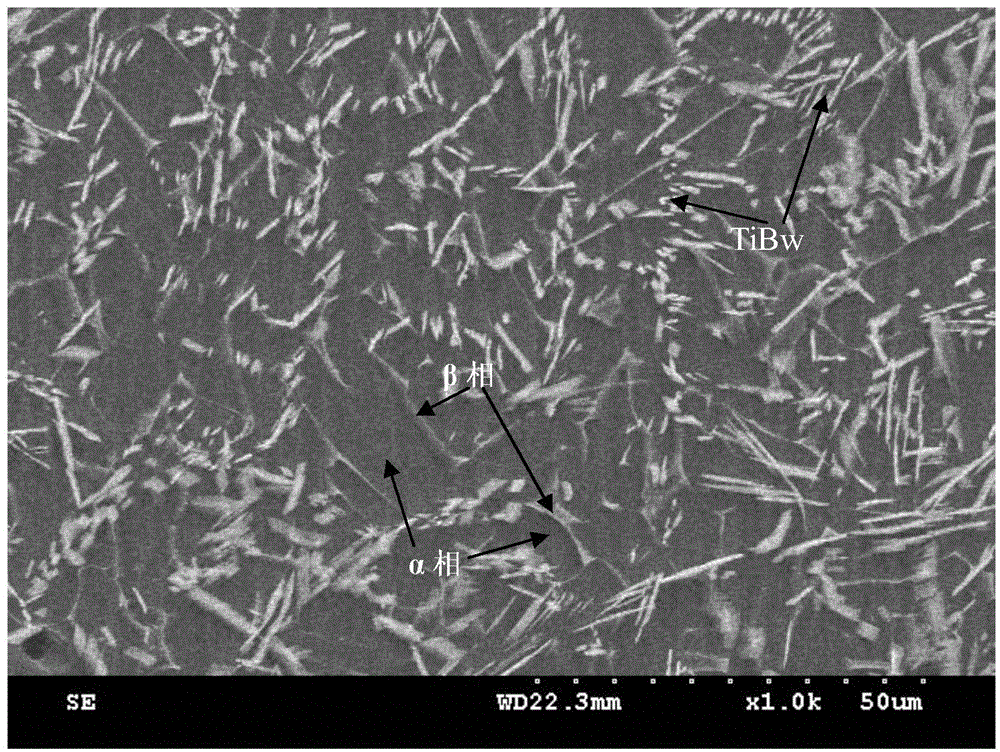

Improvement method for titanium alloy laser 3D printing

ActiveCN104928513AEasy to printImprove wettabilityAdditive manufacturing apparatusTitanium metalTitanium alloy

The invention discloses an improvement method for titanium alloy laser 3D printing and relates to an improvement method for laser 3D printing. The improvement method for titanium alloy laser 3D printing solves the problems that titanium alloy and components prepared through laser 3D printing at present are low in strength level and heat resistant temperature, the metallographic structure is thick and big and not even, the metallographic structure grows to be big in the subsequent heat treatment modification process, the technological parameter selectable range in subsequent heat treatment is narrow, the mechanical property improvement is limited, and the plasticity level of the alloy and the components is low. The improvement method includes the steps that firstly, titanium or titanium alloy powder is evenly mixed with improved raw material powder in a ball milling mode; secondly, laser 3D printing is conducted. The metallographic structure of a laser 3D titanium metal product prepared through the mode of execution is thin and small, a subsequent heat treatment window can be greatly expanded, a balanced structure formed by high-temperature annealing can be achieved, long-time solution strengthening processing or annealing processing can be conducted, the even metallographic structure is obtained, and the mechanical performance of the metallographic structure is greatly improved.

Owner:HARBIN INST OF TECH

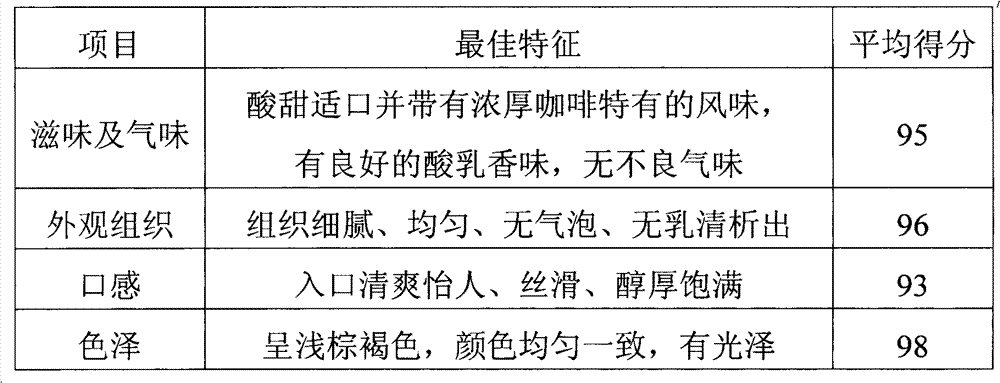

Coffee yoghurt and preparation method thereof

The invention discloses a coffee yogurt, which comprises the following raw materials by mass: 687.9-975.099 parts of cow milk, 50-100 parts of a coffee extract solution or 0.5-30 parts of coffee powder, 0.3-100 parts of a sweetening agent, 3-20 parts of a stabilizer, 1-10 parts of an emulsifier and 0.001-0.1 part of a fermentation strain. The invention also discloses a preparation method of the coffee yoghurt. The method includes the steps of: 1) mixing the coffee extract solution or coffee powder, the sweetening agent, the stabilizer, the emulsifier with the preheated cow milk until the raw materials are dispersed and dissolved; 2) conducting index detection, homogenizing and sterilizing; 3) cooling the mixed material, adding the fermentation strain, and carrying out constant temperature culture; and 4) performing cooling when reaching a fermentation terminal point. The coffee yogurt retains the nutritional value of both yoghurt and coffee, has a stable texture state and a good flavor acceptable to consumers.

Owner:BRIGHT DAIRY & FOOD

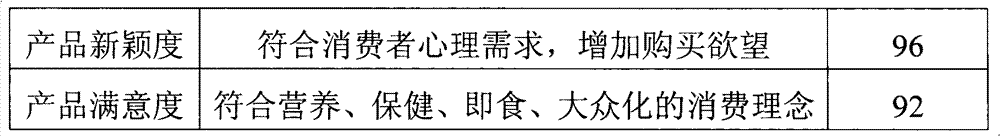

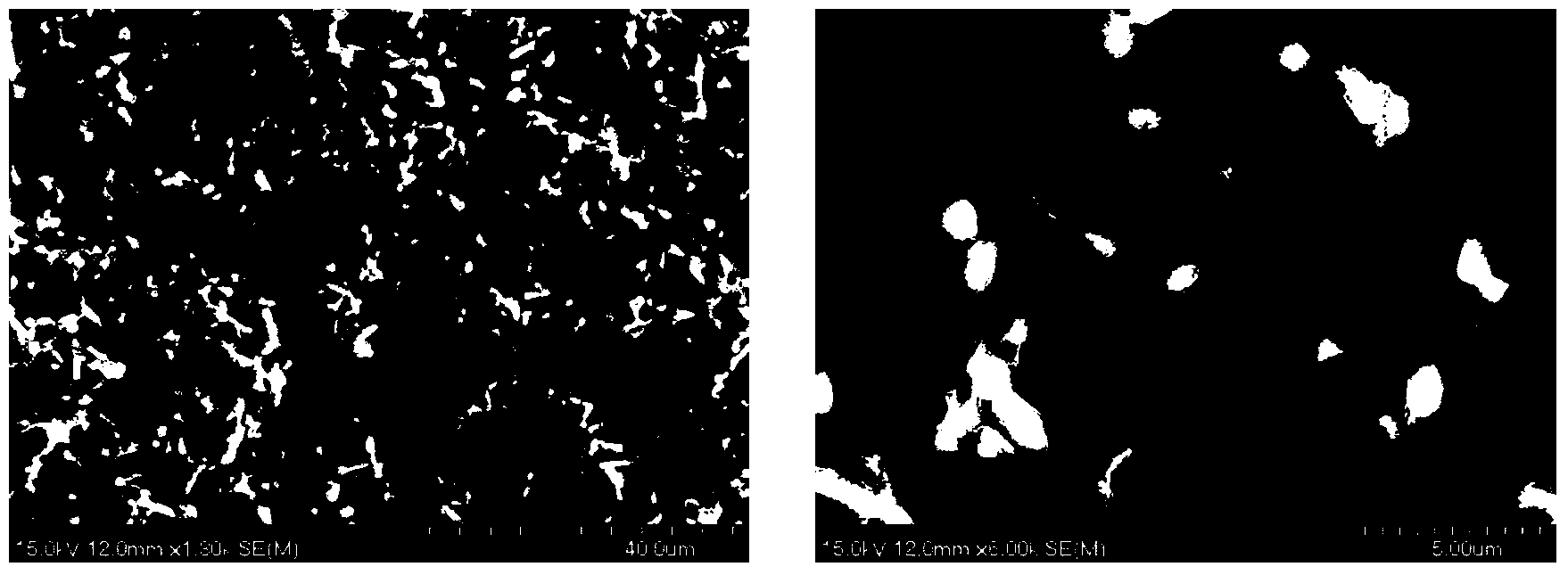

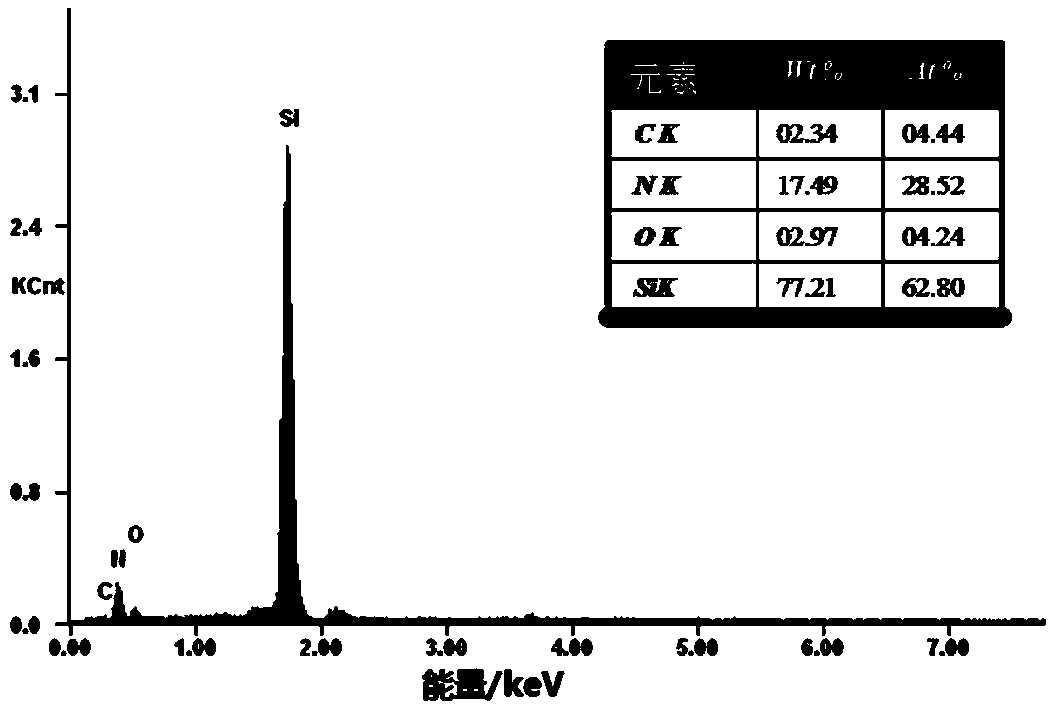

Near shape preparation method of multiphase ceramic Si3N4-SiC

ActiveCN103833370AAddressing inhomogeneityImprove absorbing performanceCeramic shaping apparatusNanowireComposite ceramic

The invention relates to a near shape preparation method of multiphase ceramic Si3N4-SiC, which completes component molding directly by bonding between particles through a three-dimensional printing method, needs no dies, and is capable of molding components with complex shapes. The Si3N4-SiC multiphase ceramic prepared by 3DP combined with PIP methods solves the problem of nonuniformity of CVI methods, and SiC nanocrystallines and SiC nanowires are uniformly distributed in a Si3N4 substrate. The Si3N4-SiC composite ceramic which is continuous, compact, free of impurities, good in uniformity and stable in wave absorbing property is obtained by using Si3N4 powder and polycarbosilane as raw materials through steps of three-dimensional printing, sintering, dipping, curing, cracking and heat treatment.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

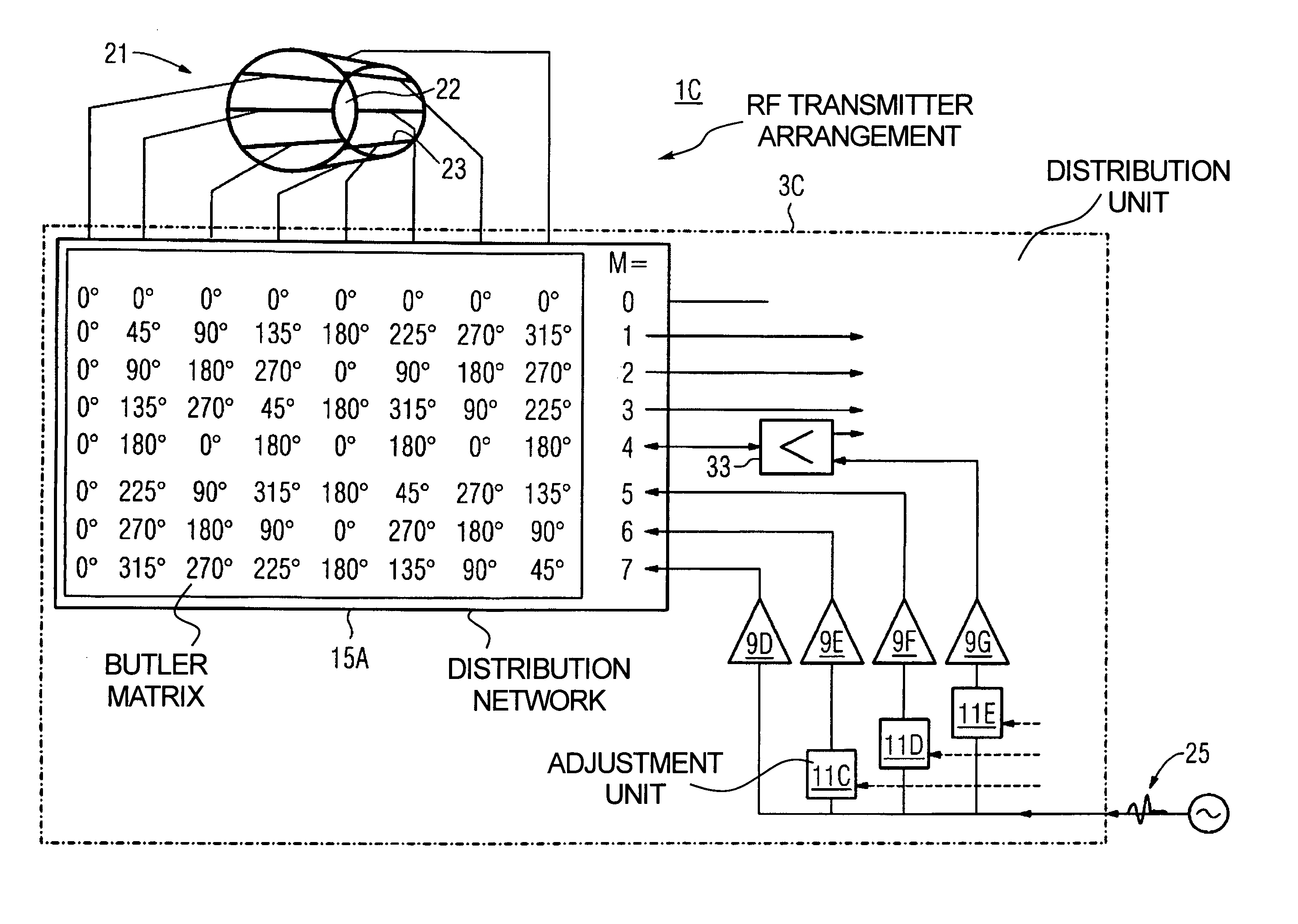

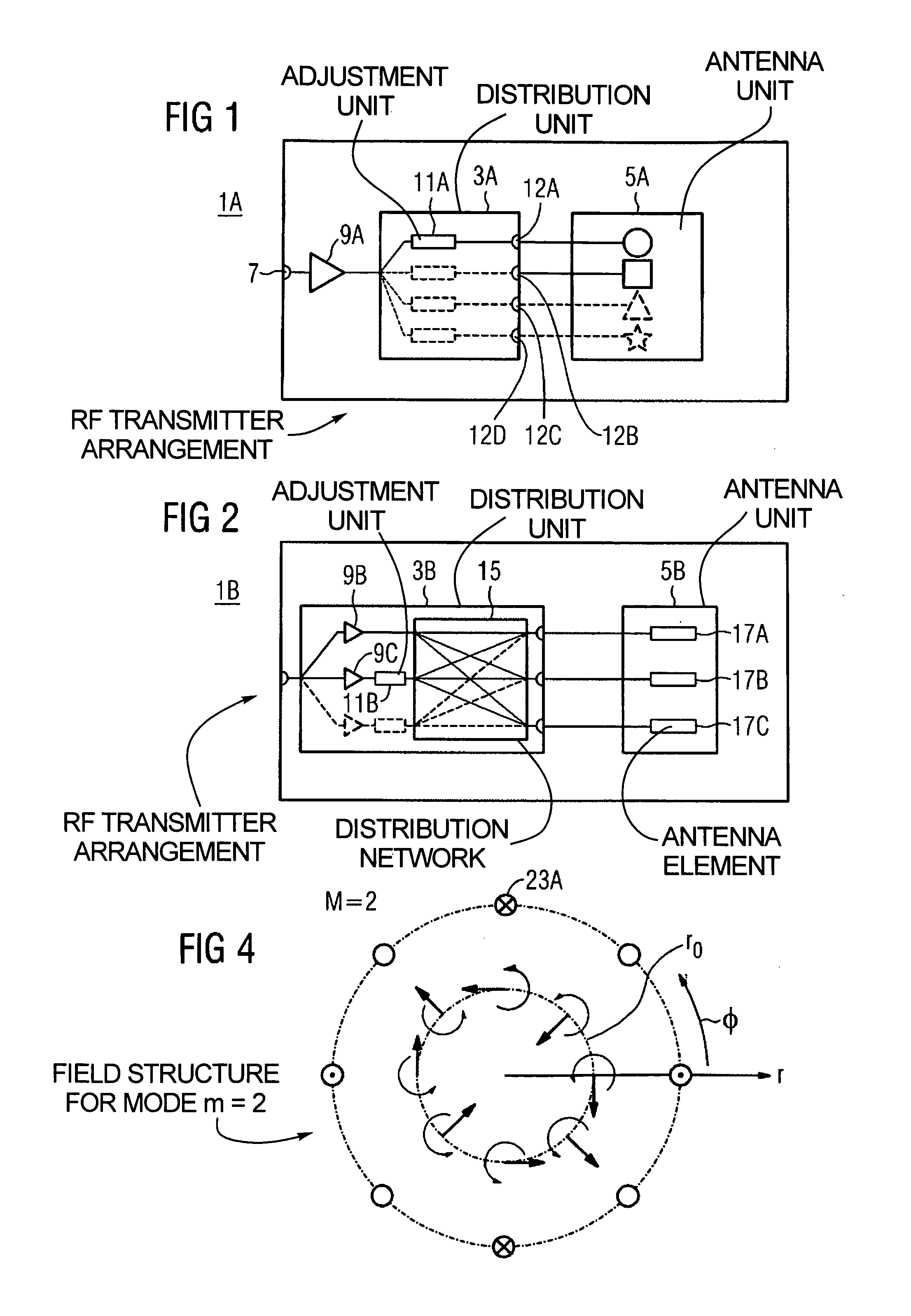

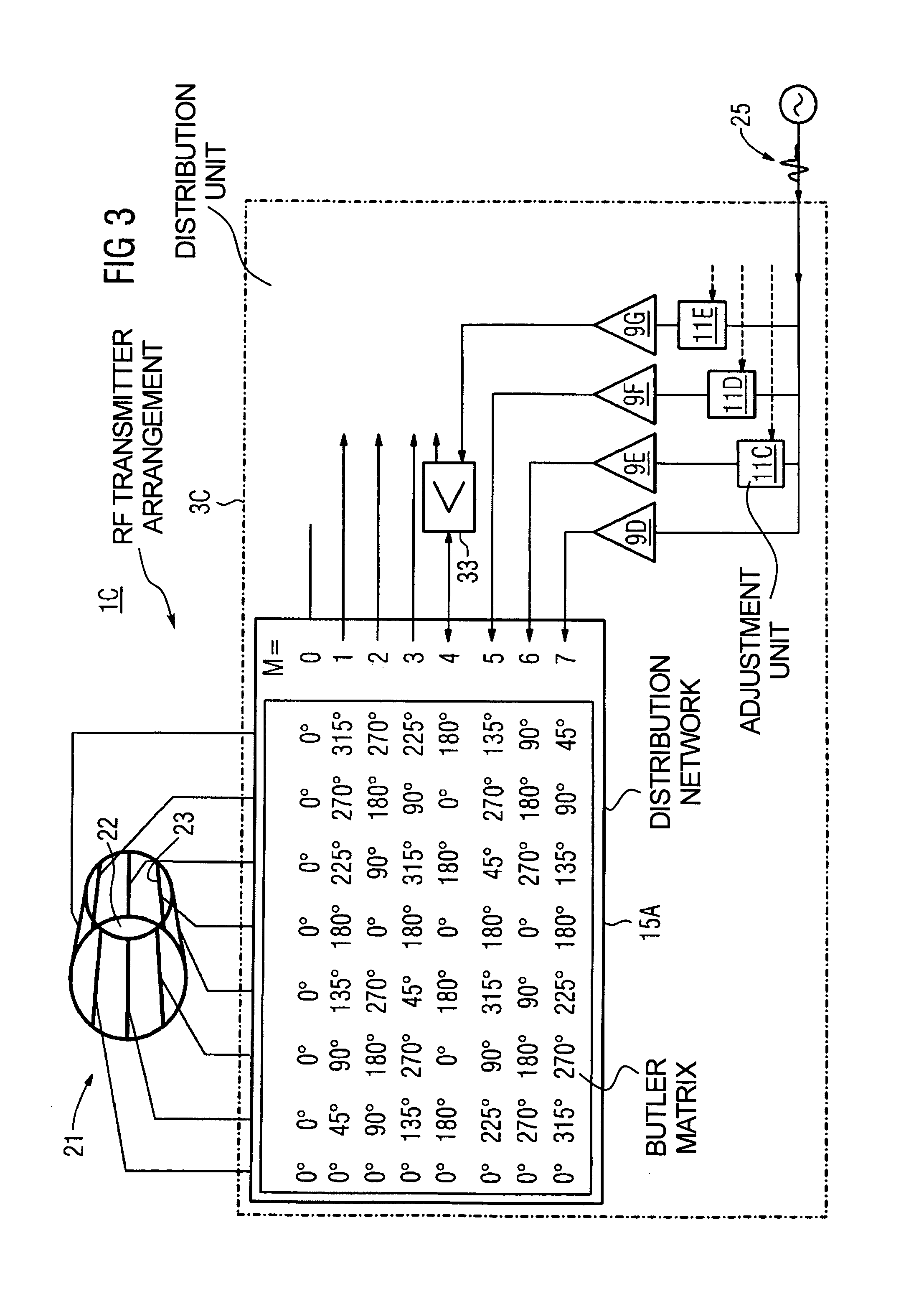

RF transmitter arrangement for an MR system, and method for determining a setting parameter therefor

ActiveUS7221162B2Reduce unevennessLeakage of RF power can be substantially preventedElectric/magnetic detectionMeasurements using magnetic resonanceResonanceEngineering

A radio frequency transmitter arrangement for a magnetic resonance apparatus has a distribution unit and an antenna unit, wherein the antenna unit, to generate radio frequency fields, is fashioned in at least two orthogonal modes, and the distribution unit is fashioned for the division of an RF transmission signal into at least two mode feed signals. At least one adjustment unit is provided to adjust the amplitude and / or phase of one of the mode feed signals and is connected with the antenna unit such that each of the mode feed signals generates a radio frequency field in one of the modes. A multiple transmitter arrangement has at least two radio frequency transmitter arrangements and at least two 180° hybrids. A method is provided to determine at least one setting parameter of the adjustment unit.

Owner:SIEMENS HEALTHCARE GMBH

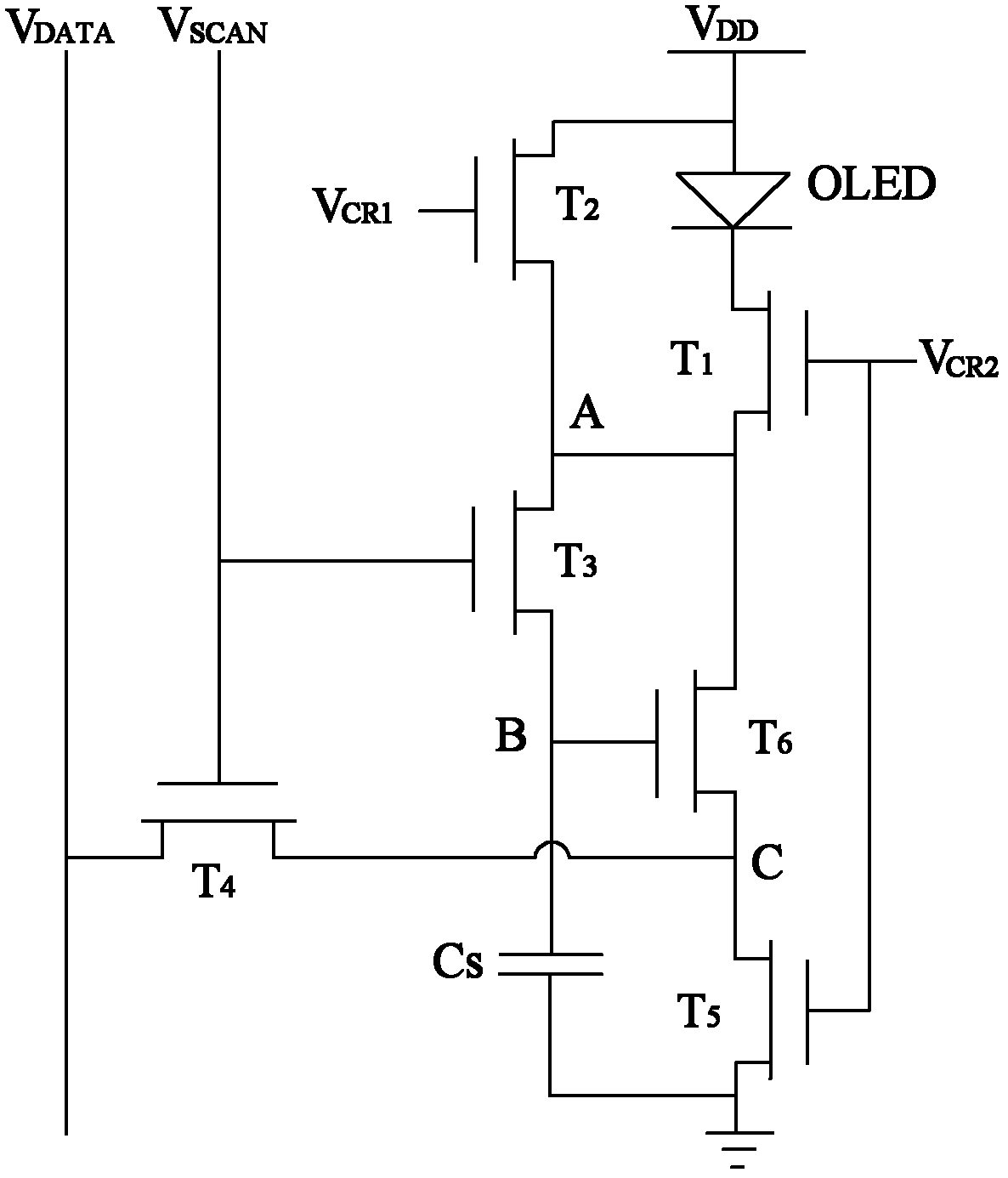

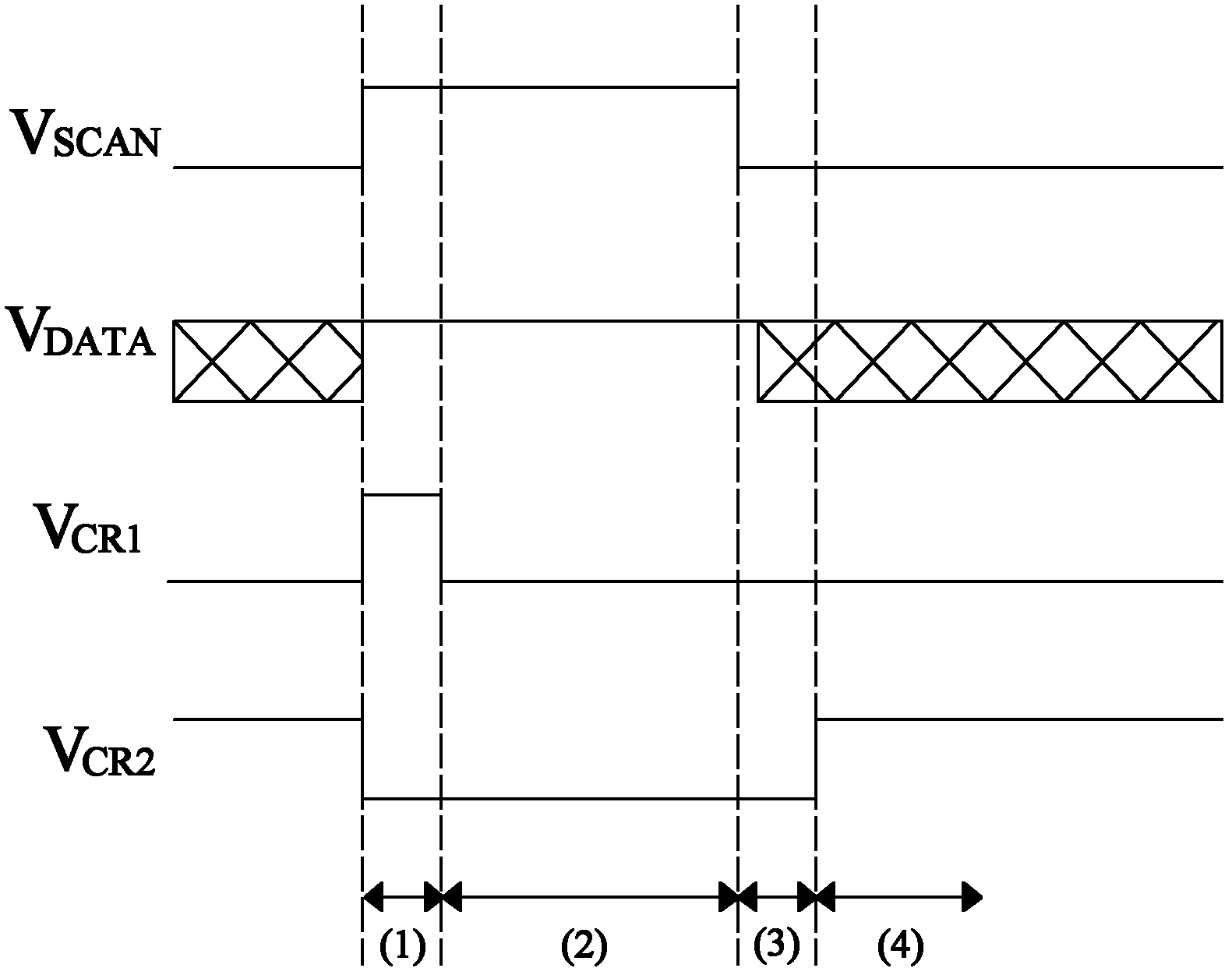

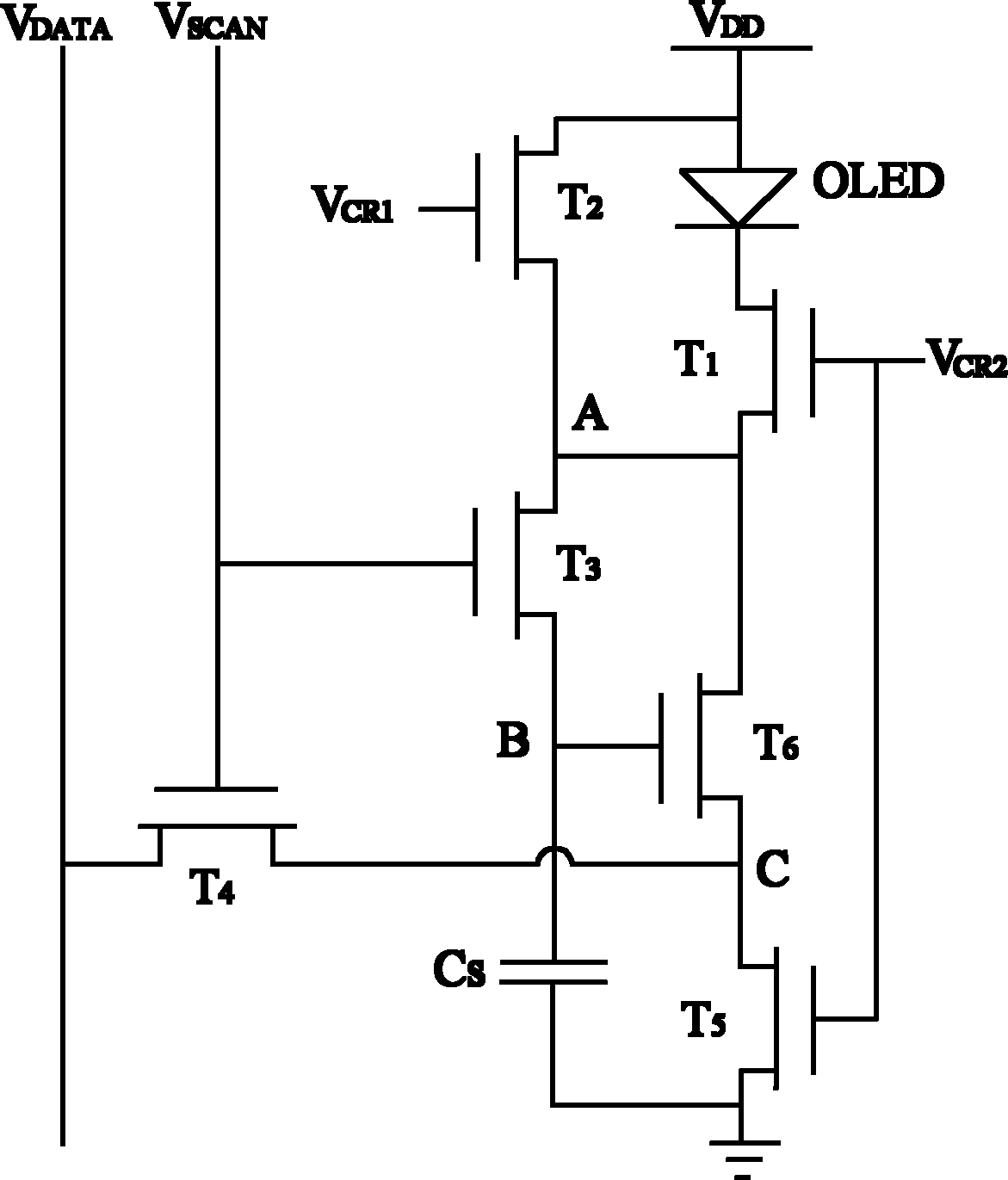

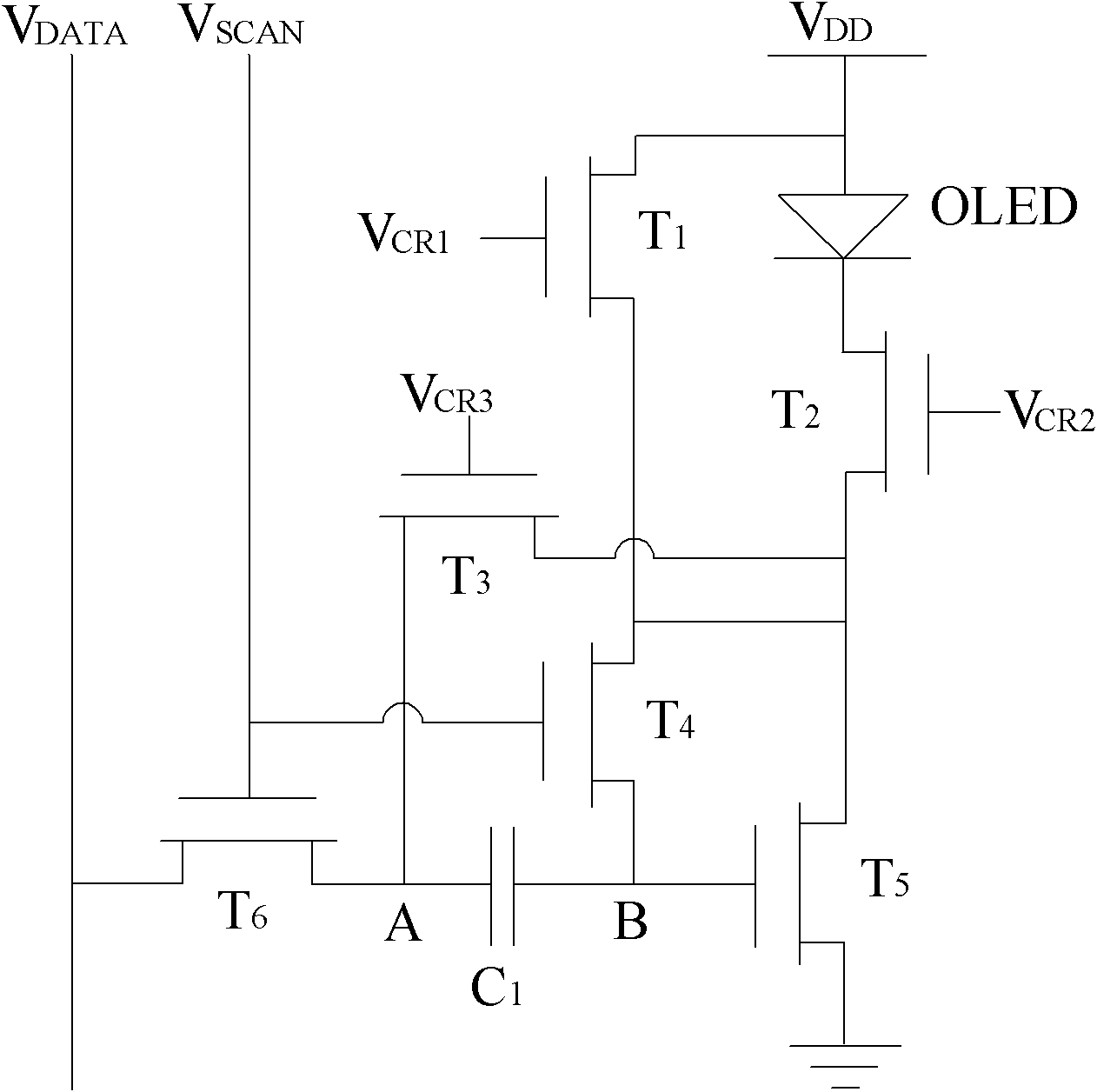

Organic light emitting diode driving circuit, display panel, display and driving method

InactiveCN102651197AEliminate work status inconsistenciesSolve attenuationStatic indicating devicesCapacitanceDisplay device

The invention discloses an organic light emitting diode driving circuit, a display panel which uses the circuit, a display and a driving method, which are designed to solve the problem that the brightness and uniformity of an organic light emitting diode are affected by the threshold voltage of a driving unit of the existing driving circuit. The organic light emitting diode driving circuit disclosed by the invention comprises a driving unit, a threshold compensation unit and an organic light emitting diode. A preferable circuit structure comprises five switching tubes, one driving tube, one capacitor and one organic light emitting diode, wherein the switching tubes and the driving tube are N type thin film transistors preferably. The working principle of the organic light emitting diode driving circuit is that the threshold voltage Vth of the 6T1C circuit compensation driving tube is utilized to eliminate the phenomenon of an inconsistent working state of the organic light emitting diode caused by different threshold voltages of the driving tube of the integrated circuit, thereby solving the problems of brightness and uniformity of the organic light emitting diode.

Owner:BOE TECH GRP CO LTD +1

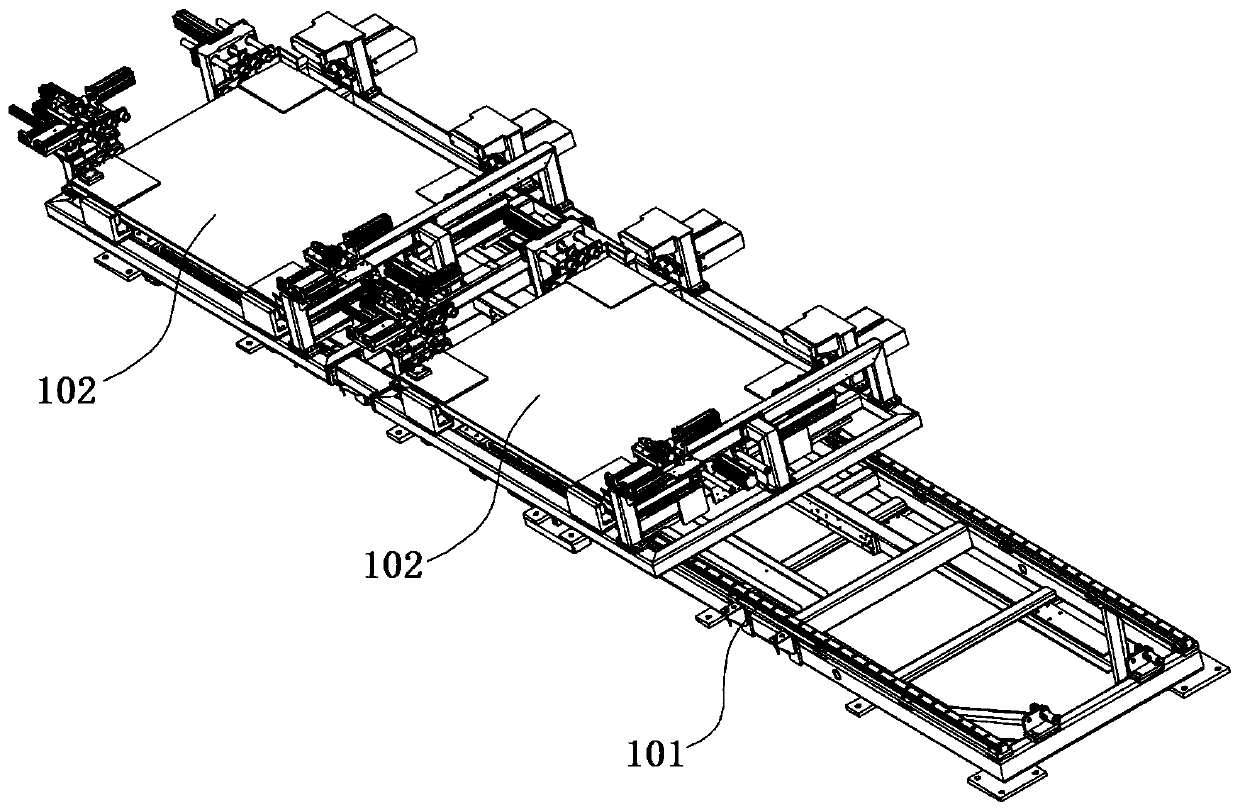

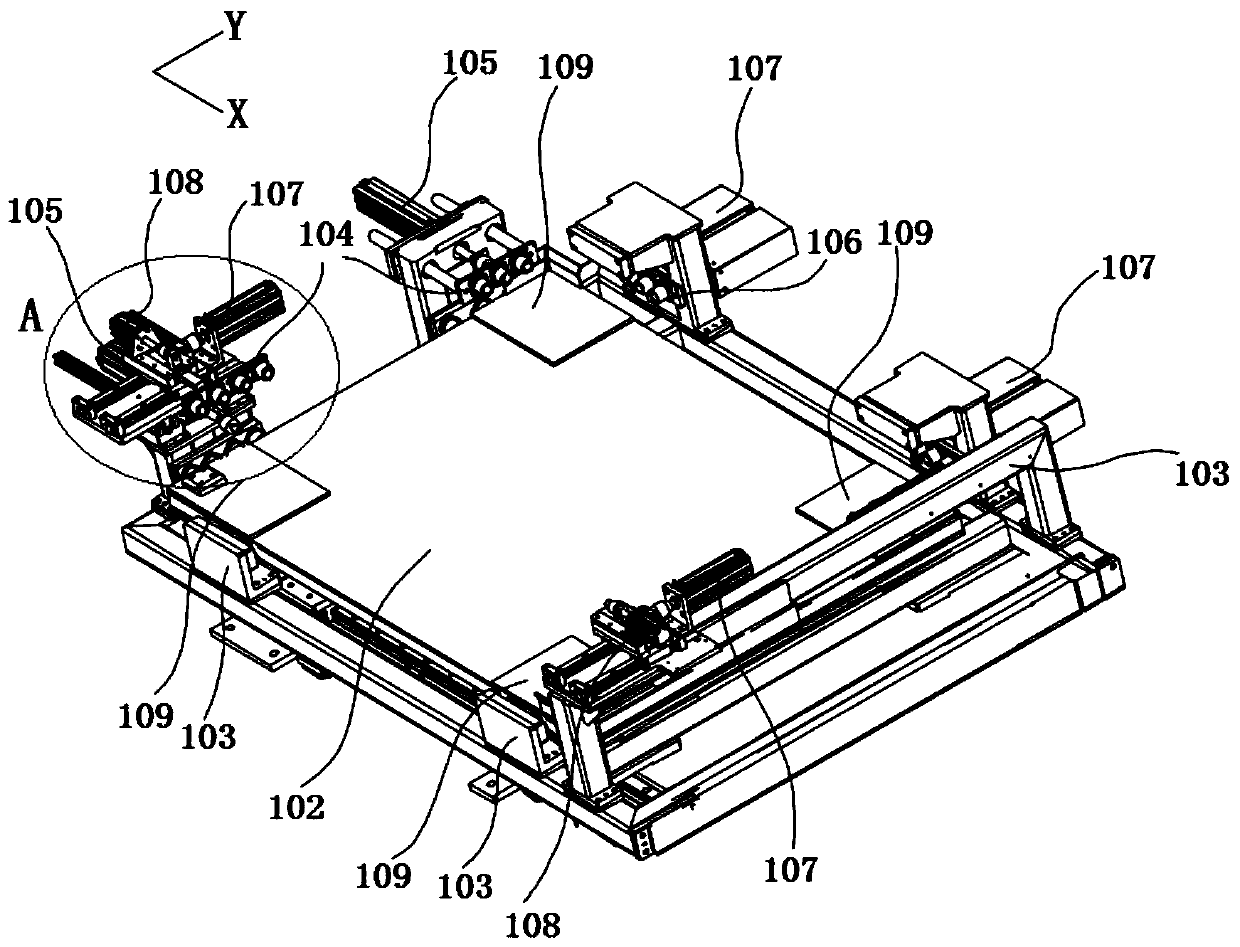

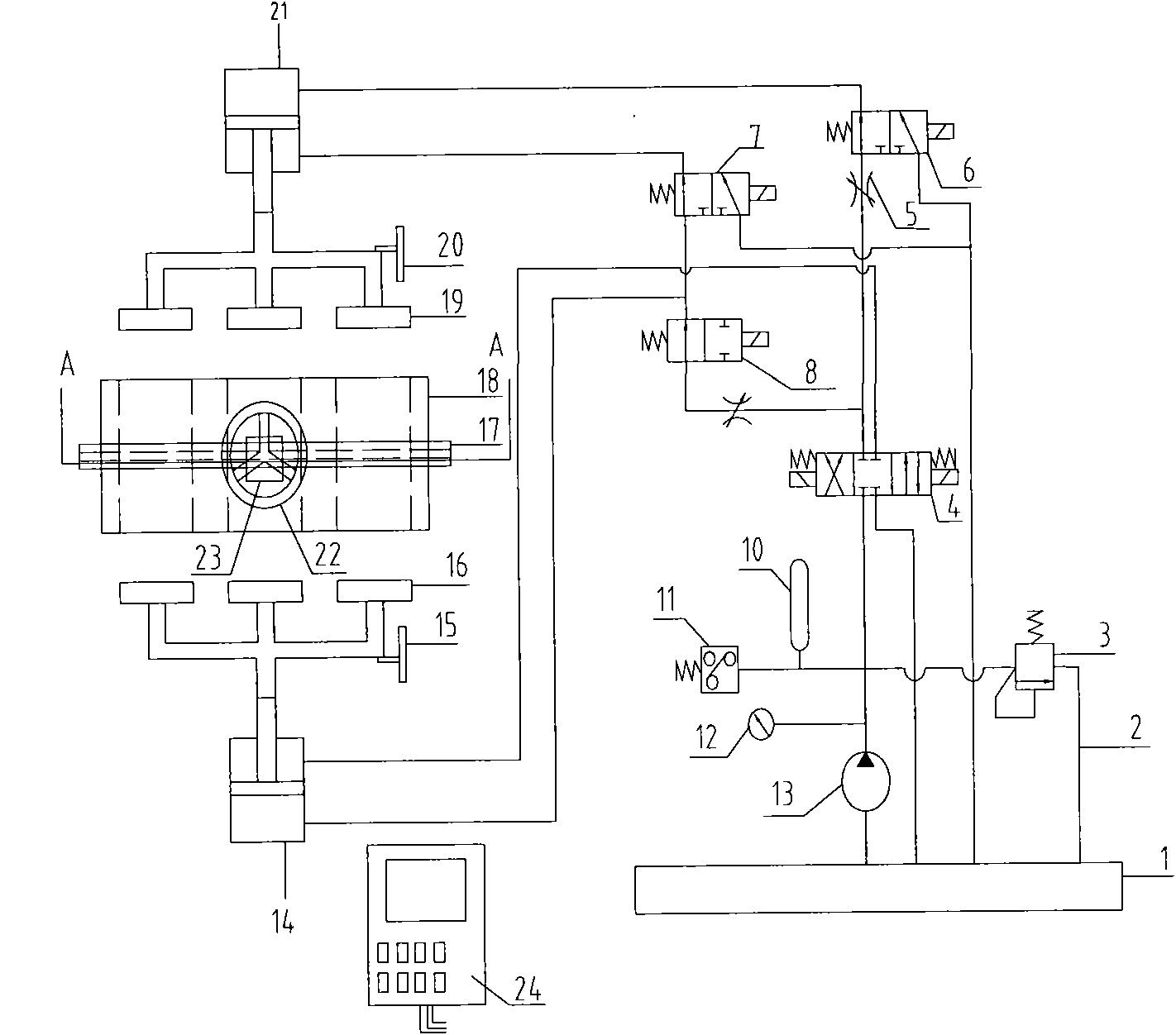

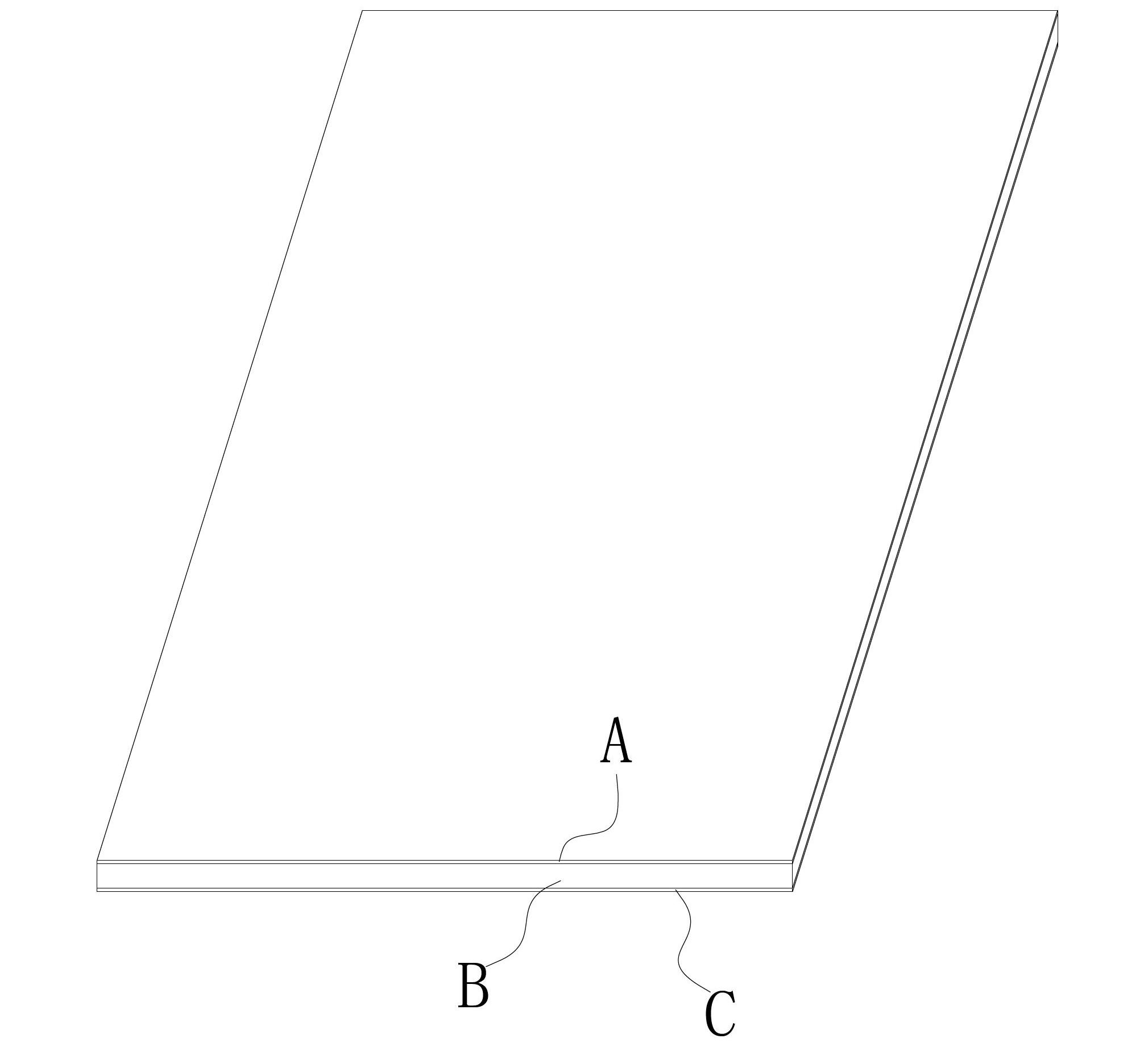

Car windshield glue coating system

ActiveCN109954627AAddressing inhomogeneitySolve efficiency problemsPretreated surfacesCoatingsCoating systemEngineering

The invention provides a car windshield glue coating system. The car windshield glue coating system comprises a pre-coating robot and a pre-coating device; the pre-coating device is used for providinga pre-coating agent during pre-coating, the pre-coating robot is used for grabbing glass at the corresponding position, them moving to the lower part of the pre-coating device and driving the glass to move according to the specified trajectory, and thus the glass is coated with the pre-coating agent. Manual operation is replaced by the pre-coating robot and the pre-coating device, the problems ofuneven coating, low efficiency and health damage caused by manual operation are solved, the car windshield glue coating system further comprises a first feeding device, a feeding robot, a centering device, a second feeding device and a glue coating robot, the manual operation is completely replaced by the robot, workers only need to place material frames onto the first feeding device, the automatic degree is high, and the glue coating quality can be ensured.

Owner:GUANGQI HONDA

A preparation method for high-fiber recombinant asparagus chips

The present invention discloses a preparation method for high-fiber recombinant asparagus chips, and belongs to the deep processing field of fruits and vegetables. The asparagus chips use discarded scraps of old stems and old roots from asparagus production enterprises as raw materials, and are prepared by the following steps: pre-treating the raw materials, blanching the materials in hot water, preserving color, conducting beating, mixing the materials with adjuvant materials, cooking the mixture for a short time, placing the mixture on plates, drying the mixture under vacuum by two section-type microwave to a moisture content of 10% -15%, drying the mixture by short- and medium-wave infrared method under vacuum to a moisture content below 5%, and packaging the mixture to obtain the end products. The dietary fiber content of the asparagus chips is 8.35% - 10.27%, and every 100g of the chips contains flavonoids 12.73-16.86 mg, polysaccharide 9.34-11.28 mg. The preservation rate of chlorophyll is 70% to 75% after processing, and the chip breaking force is 1123-1443 g. The preparation method provides a novel method for taking full advantage of asparagus scraps, and the microwave vacuum drying and the short- and medium-wave infrared vacuum drying have advantages of quick drying, low temperature and higher nutrient retention rate, etc. The asparagus chips are high in cellulose content, rich in flavonoids, polysaccharide and other active substances, crispy and delicious in taste and high in nutritional value. Therefore, the asparagus chips are leisure crisps for people of all ages.

Owner:JIANGNAN UNIV +1

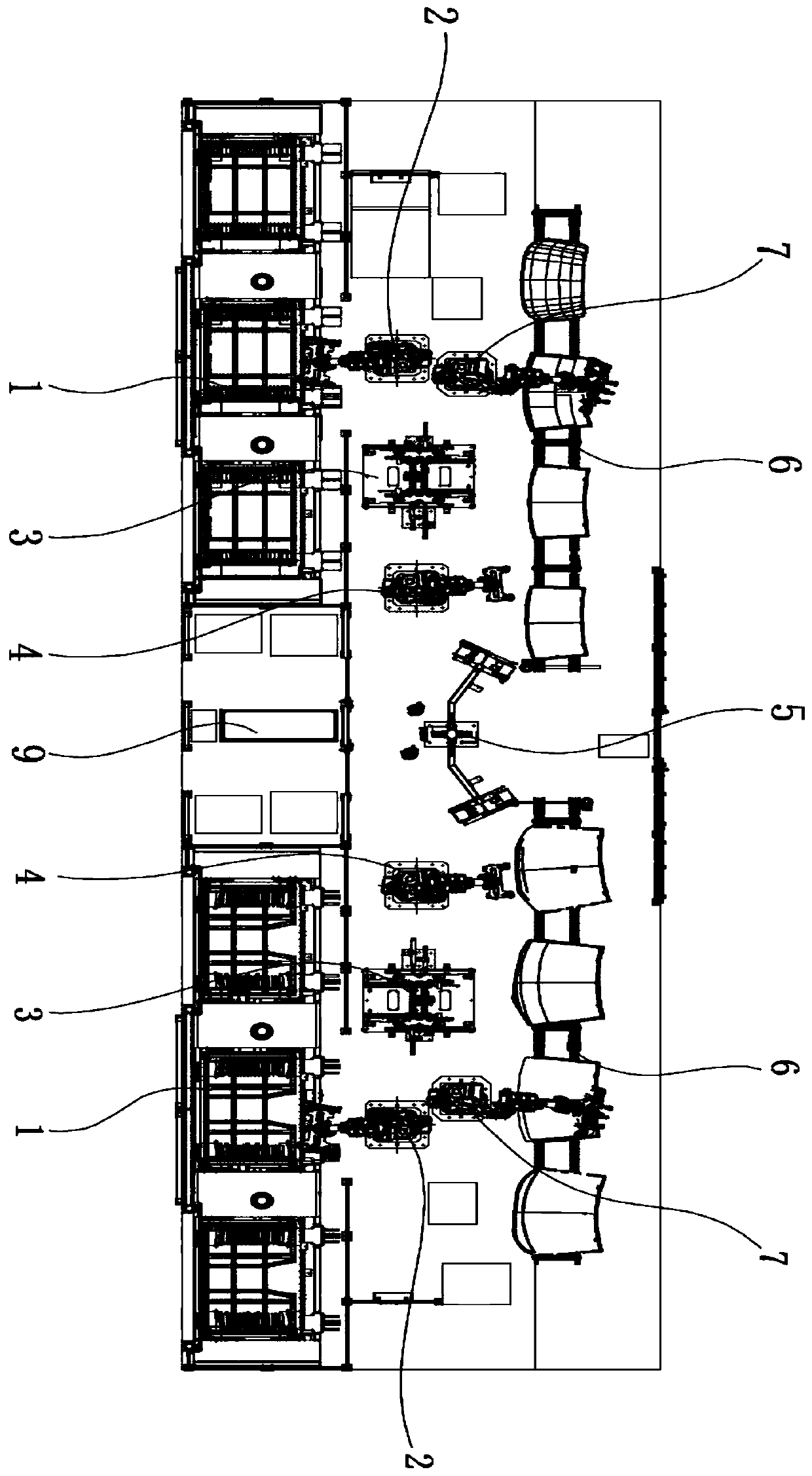

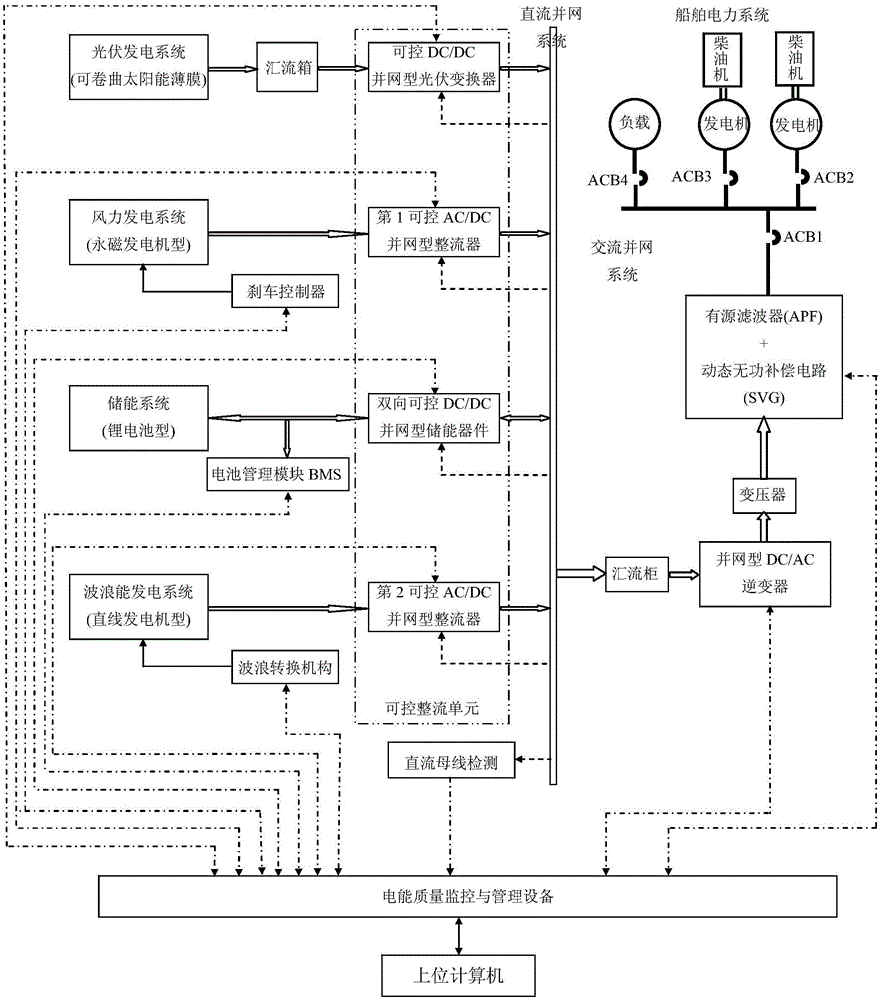

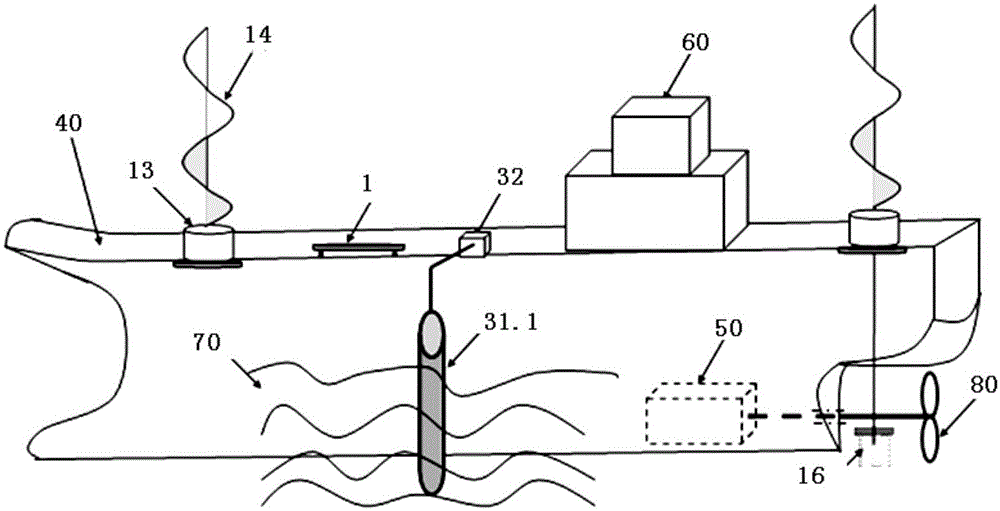

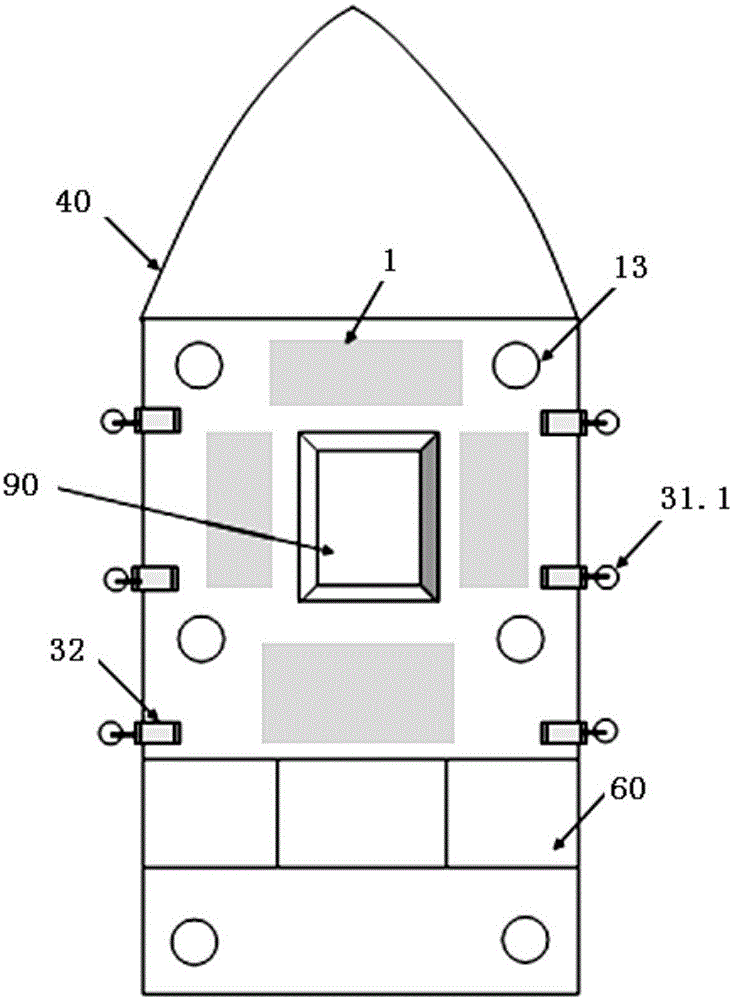

Wind power, photovoltaic power, stored energy and wave energy comprehensive utilization power generation device for ship

ActiveCN105673329AAchieve diversificationAchieve energy saving and emission reductionPhotovoltaic supportsFlexible AC transmissionShip wavesAlternating current

The invention provides a wind power, photovoltaic power, stored energy and wave energy comprehensive utilization power generation device for a ship. The comprehensive utilization power generation device comprises a ship photovoltaic power generation system, a ship wind power generation system, a ship wave energy power generation system, a ship lithium battery energy storage system, a direct current grid-connected system, an inverter system and an alternating current grid-connected system. The ship photovoltaic power generation system, the ship wind power generation system, the ship wave energy power generation system and the ship lithium battery energy storage system are all connected to the input end of the direct current grid-connected system in parallel, and the output end of the direct current grid-connected system is connected with the alternating current grid-connected system through the inverter system. The comprehensive utilization power generation device for the ship has the advantages that wind energy, solar energy, wave energy and storage battery stored energy are arranged through the systematized and integrated design, so that the power generation device has an important value on achieving ship energy diversification, energy saving and emission reduction and improving the competitiveness of the ship.

Owner:达器船用推进器(江苏)有限公司

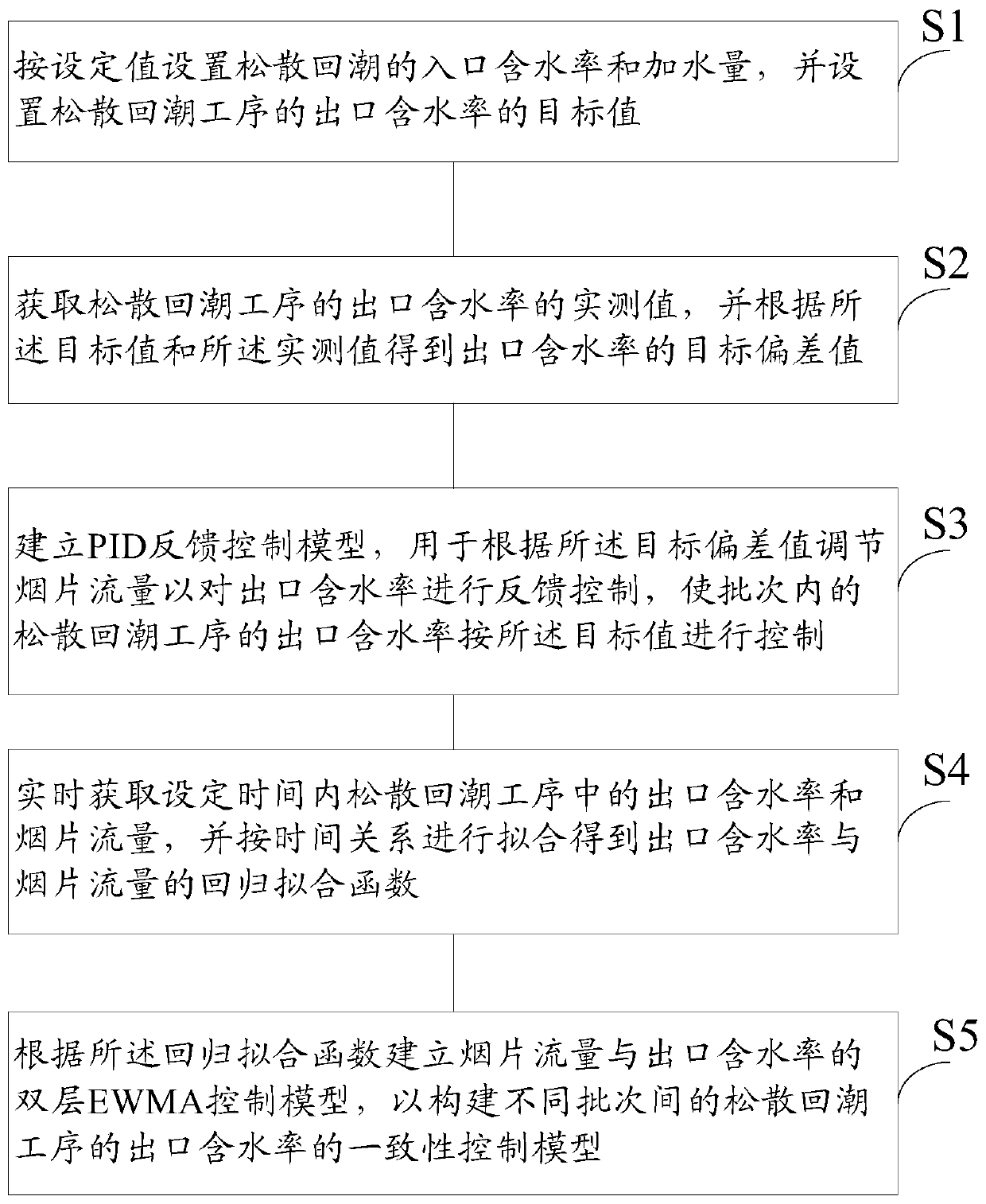

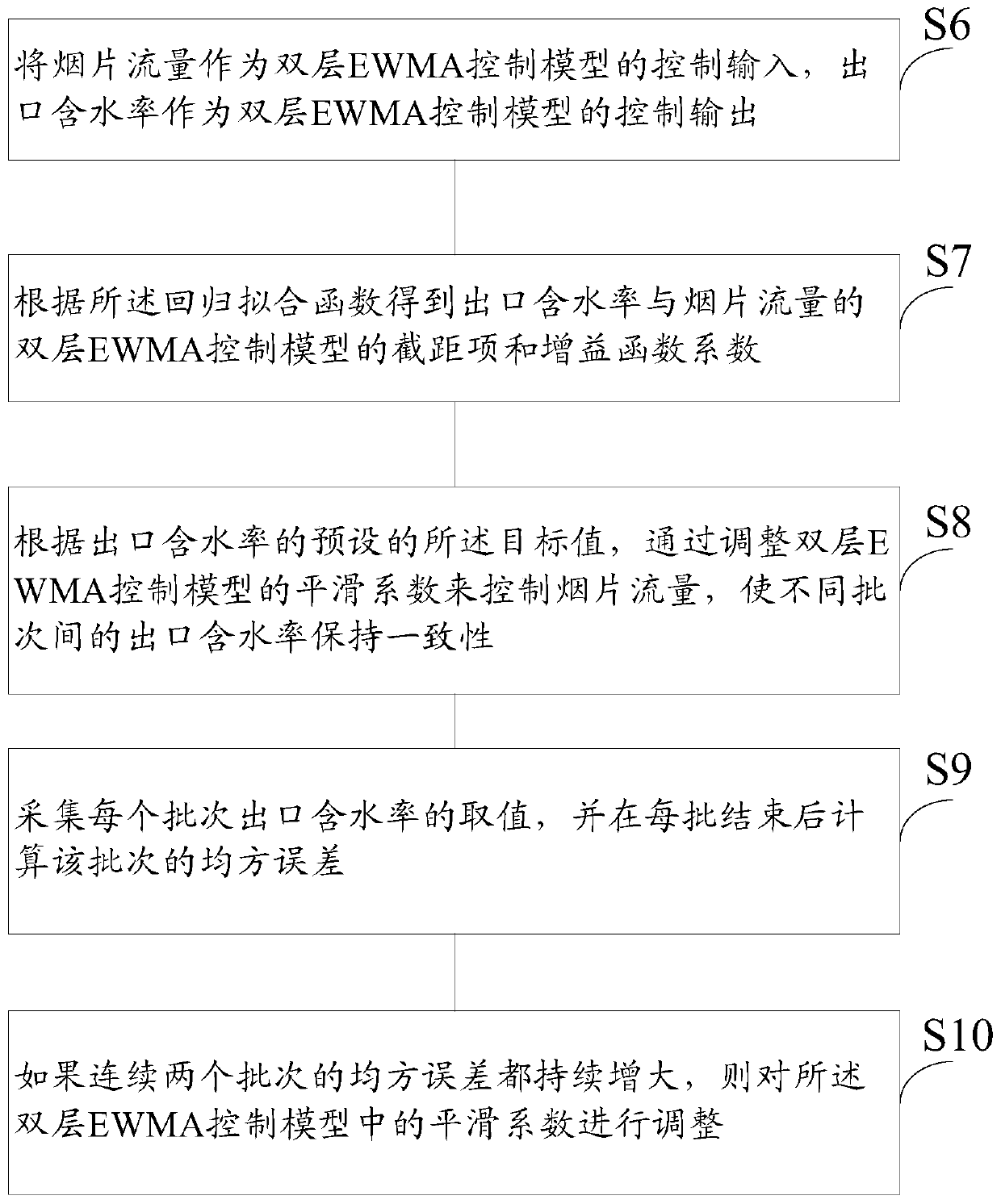

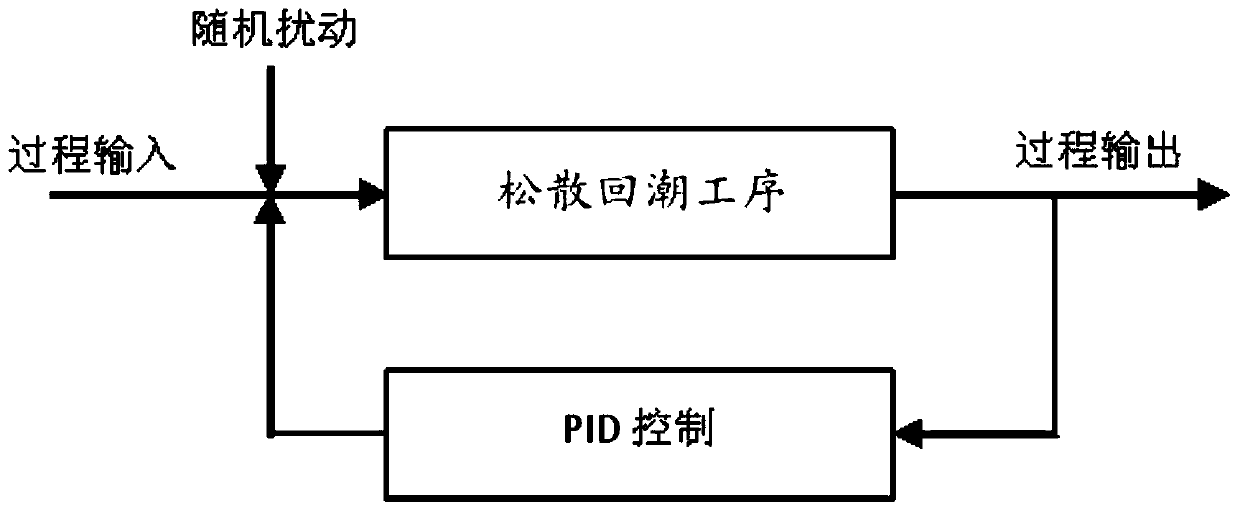

Method and system for controlling outlet moisture content of loosening and dampening process

ActiveCN110893001AResolve accuracyAddressing inhomogeneityTobacco preparationTobacco treatmentProcess engineeringFeedback control

The invention provides a method and a system for controlling the outlet moisture content of a loosening and dampening process, and the method comprises the steps: setting the inlet moisture content and water adding amount of a loosening and dampening machine according to a set value, and setting a target value of the outlet moisture content of the loosening and dampening process; obtaining an actual measurement value of the outlet moisture content of the loosening and dampening process, and obtaining a target deviation value of the outlet moisture content according to the target value and theactual measurement value; and establishing a PID feedback control model for adjusting the flow of the tobacco flakes according to the target deviation value so as to perform feedback control on the outlet moisture content, so that the outlet moisture content of the loosening and dampening process in the batch is controlled according to the target value. The consistency of the loosening and dampening uniformity of all batches can be improved, and the quality control capacity in the production process is improved.

Owner:CHINA TOBACCO HENAN IND

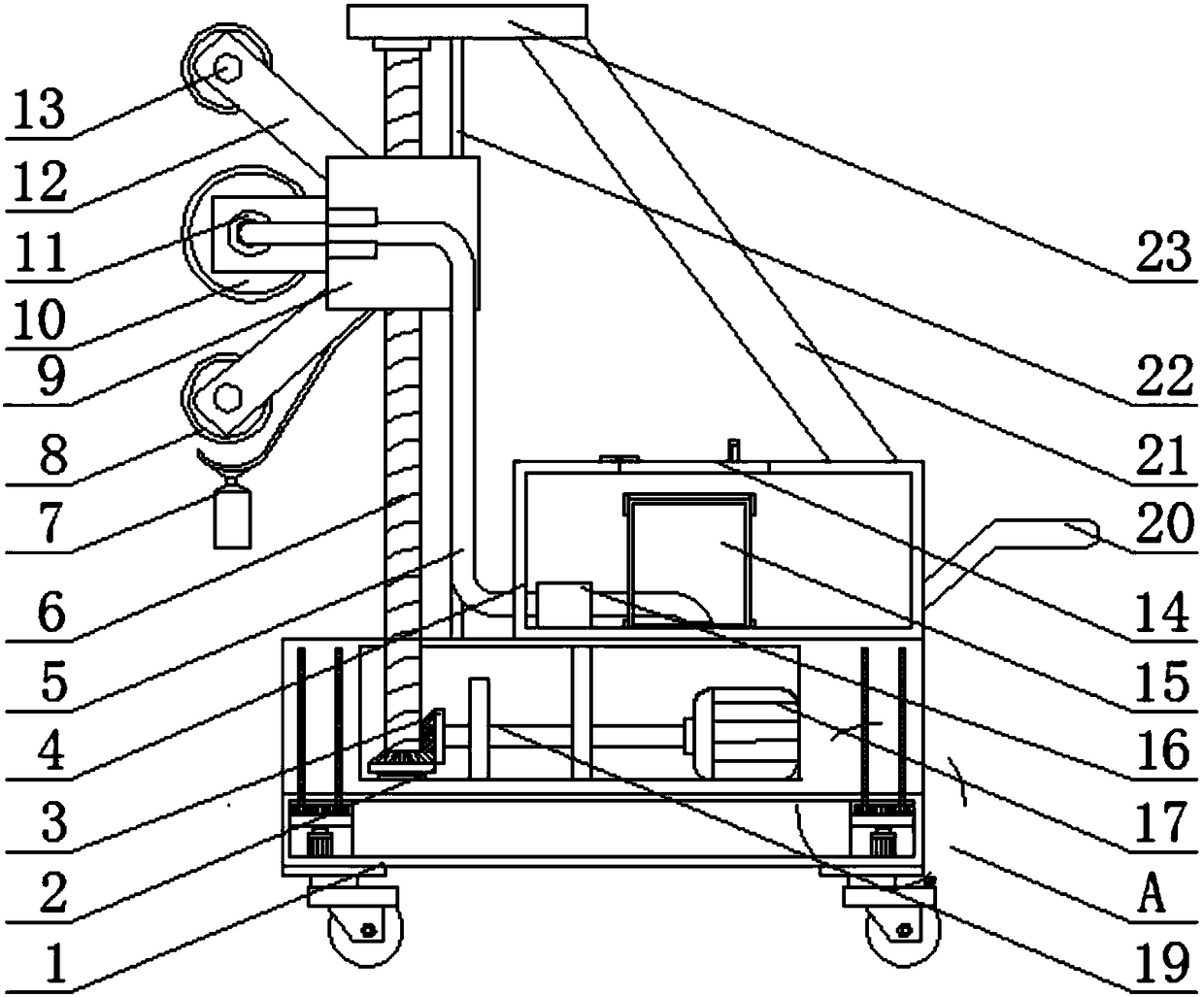

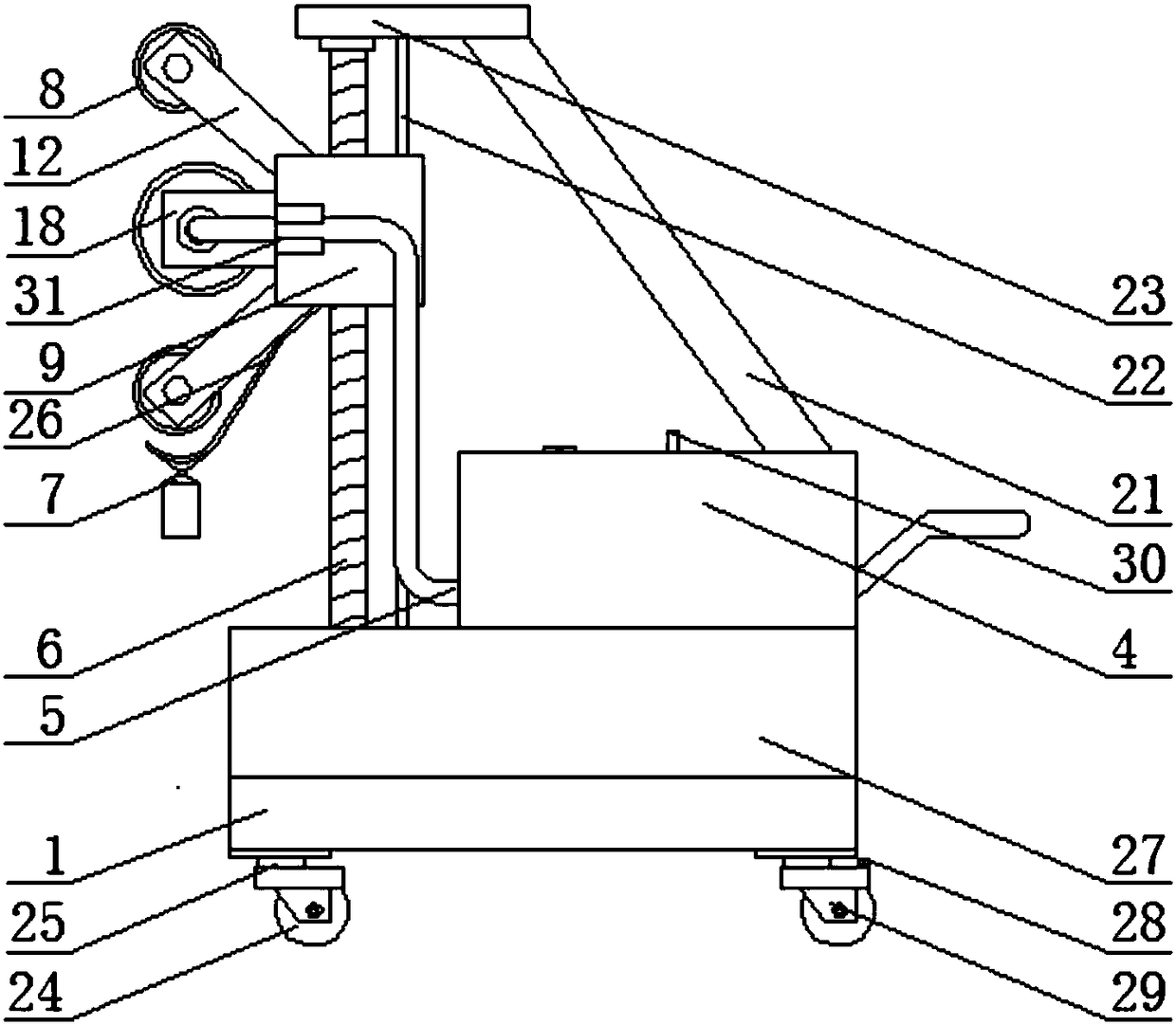

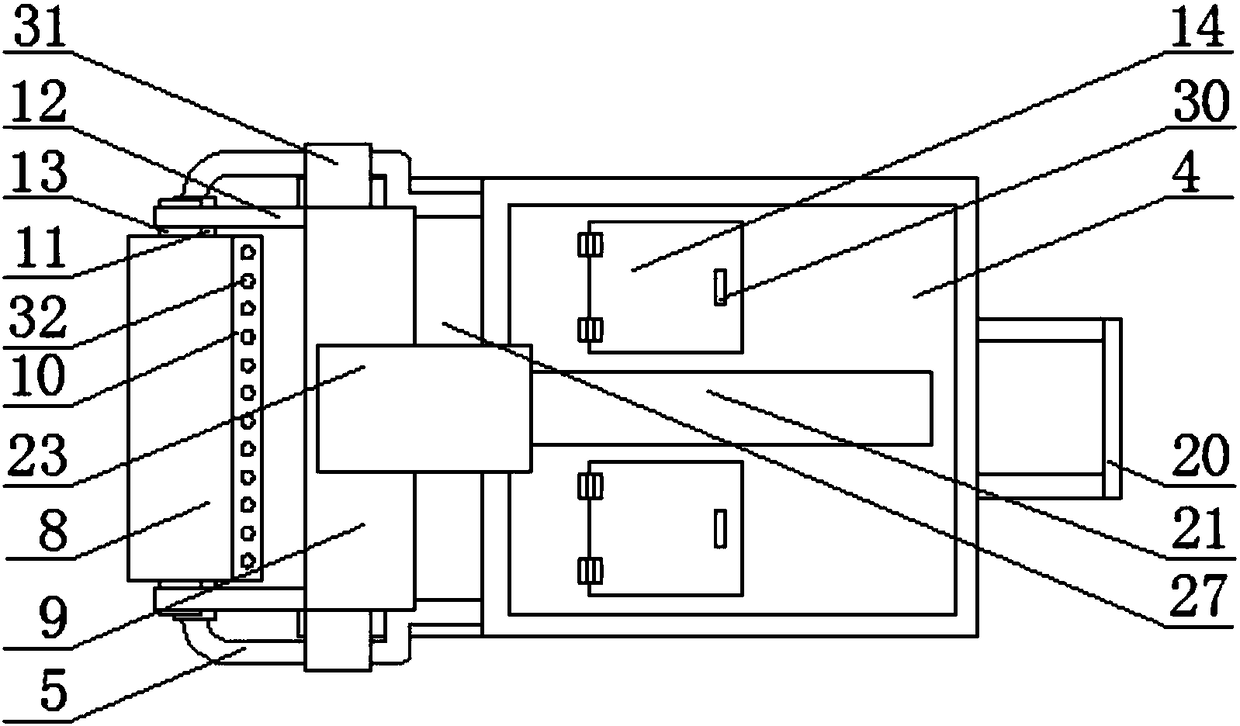

Wall painting device

InactiveCN108412164AImprove uniformityAddressing inhomogeneityBuilding constructionsEngineeringIdler-wheel

The invention discloses a wall painting device. The device comprises a bottom plate, four corners of the lower end of the bottom plate are all fixed with mounting plates, the lower ends of the mounting plates are rotationally connected with rotating blocks, the lower ends of the rotating blocks are rotationally connected with U-shaped blocks, fourth threaded rods penetrate through the U-shaped blocks, the four fourth threaded rods are all rotationally connected with walking wheels, two ends of the fourth threaded rods are all provided with nuts, the four corners of the bottom plate are all provided with first cavities, lifting mechanisms are arranged in the first cavities, the upper end of the bottom plate is provided with a bearing box, a second cavity is formed in the bearing box, and afirst servo motor is arranged at one end of the bottom in the second cavity. The wall painting device has the advantages that the problems of uneven painting and uncontinuous feeding of machines are solved through the improvement of the wall painting device, secondary painting is carried out by using two idler wheels, the uniformity of the painting is improved, the working efficiency is improved,the cost is reduced, and the use is convenient.

Owner:杨孝耀

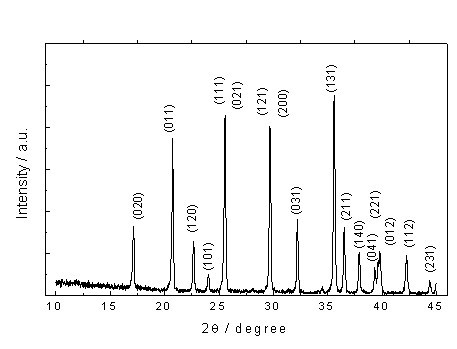

Preparation method of water-heated carbon cladding lithium iron phosphate

InactiveCN102088079AAddressing inhomogeneitySolve loose defectsCell electrodesLithium iron phosphateRoom temperature

The invention discloses a preparation method of water-heated carbon cladding lithium iron phosphate, aiming to provide a preparation method of water-heated carbon cladding lithium iron phosphate, which can overcome the deficiencies of nonuniform and loose cladding and the like of the traditional carbon cladding method. In order to solve the problem, the adopted technical scheme comprises the following steps of: Step 1. mixing lithium iron phosphate powder and organic solution according to the mass ratio of (10-30):100, adding dispersing agent, and carrying out ultrasonic stirring for certain time to obtain well dispersed suspension; Step 2. transferring the well dispersed suspension to a reaction kettle and making the well dispersed suspension react at the temperature of 120 to 300 DEG C for 3 to 10 hours; Step 3. after reaction, cooling the material to the room temperature and then filtering, and washing the material by water and ethanol in sequence; and Step 4. drying the washed material in a vacuum or inert environment at the temperature of 80 to 150 DEG C for 3 to 6 hours to obtain the water-heated carbon cladding lithium iron phosphate powder material. The water-heated carbon cladding lithium iron phosphate prepared by the preparation method has the advantages of uniform and compact cladding, long service life and the like.

Owner:ZHEJIANG RICHPOWER TECH

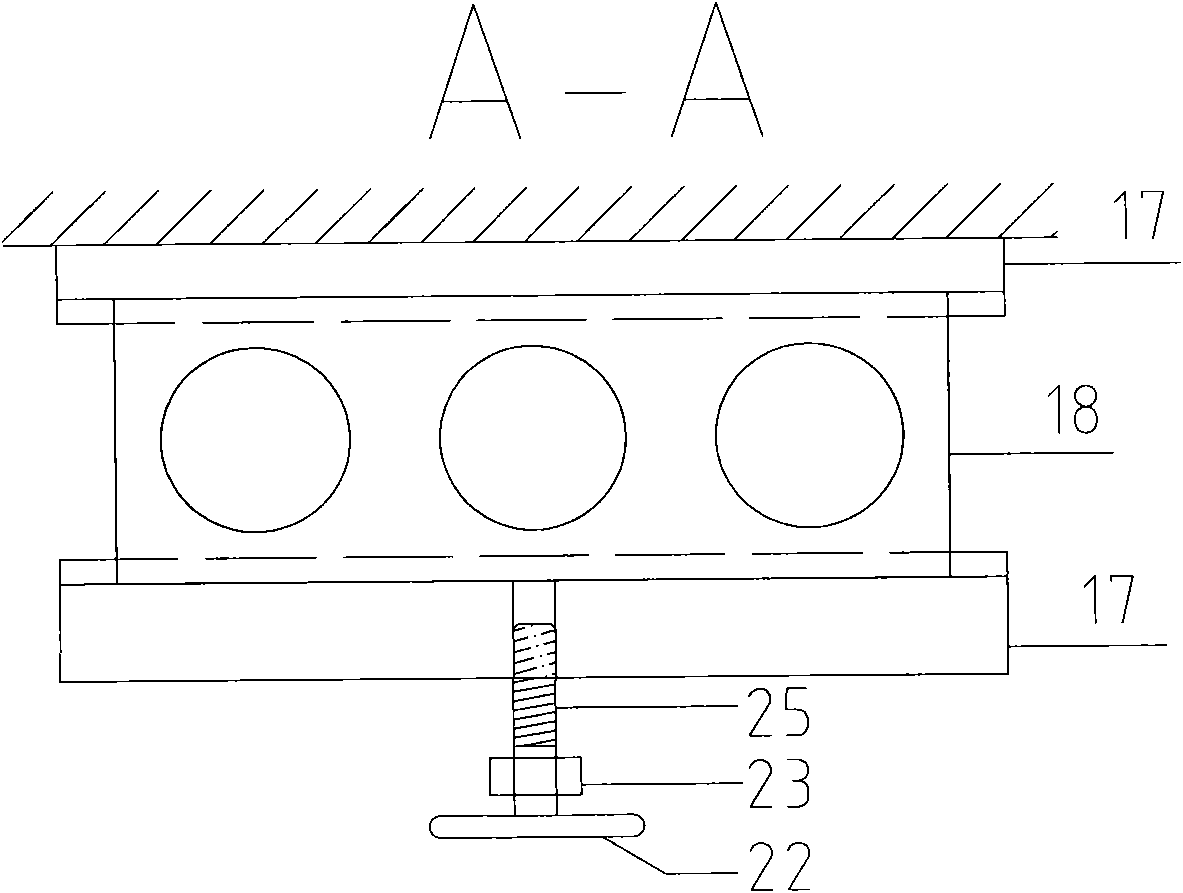

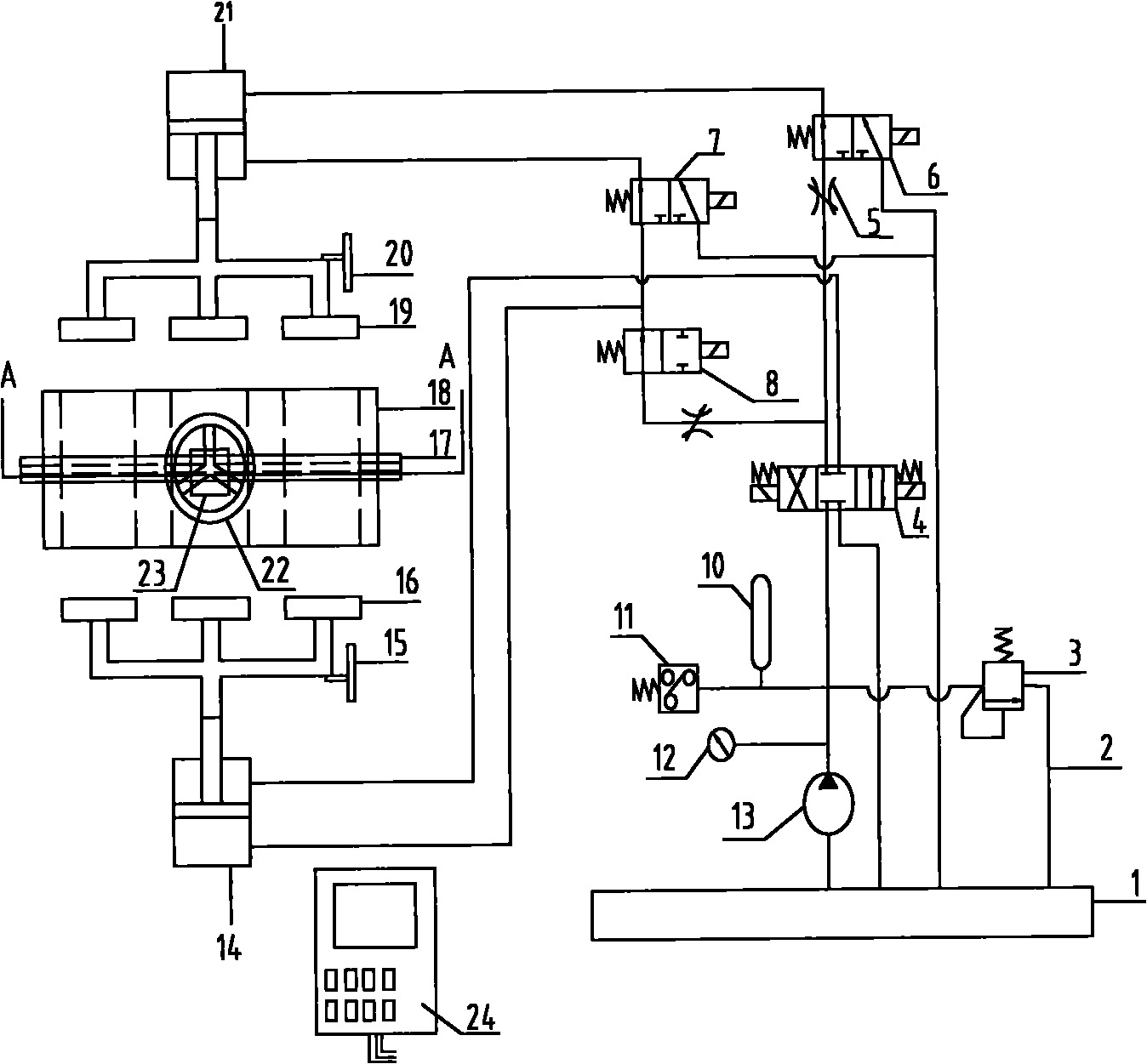

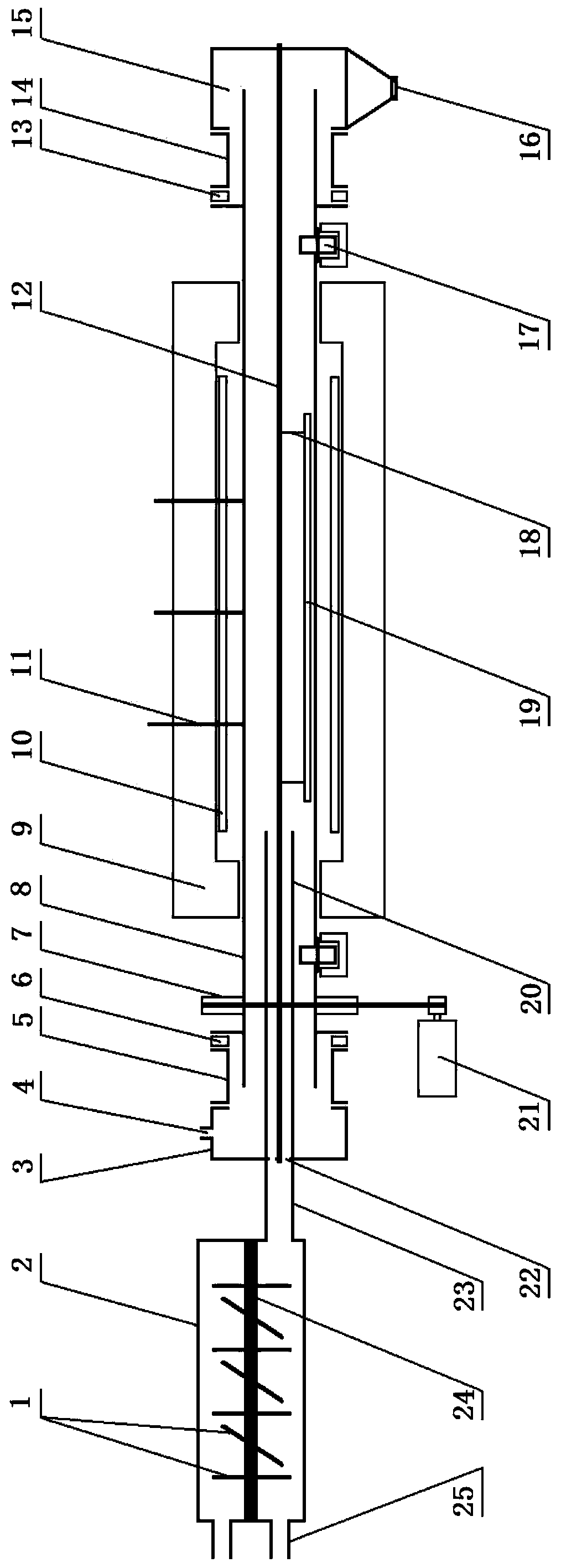

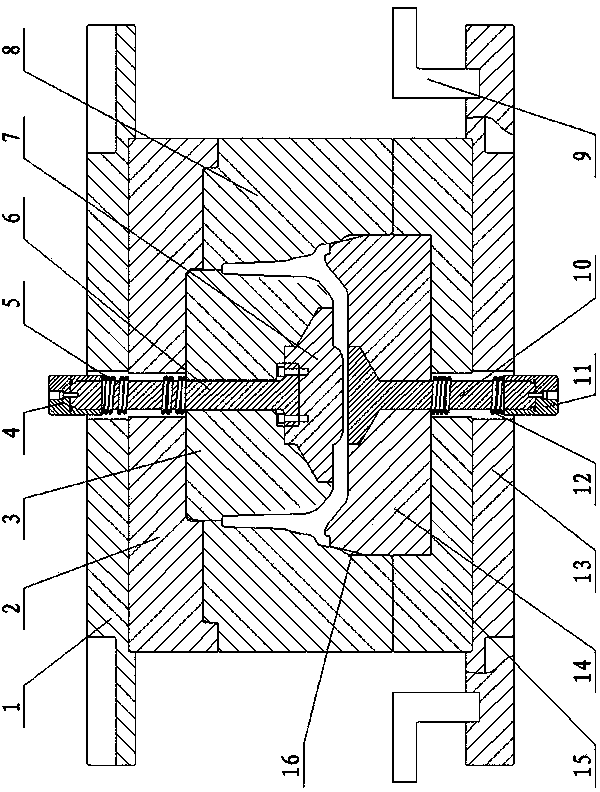

Sample preparing and demoulding integrated instrument

InactiveCN101863075AControl automatic demouldingAddressing inhomogeneityDischarging arrangementHigh densityEngineering

The invention discloses a sample preparing and demoulding integrated instrument. The integrated instrument at least comprises a driving mechanism, a transmission mechanism, a base and a material loading die which is arranged on the base, wherein an upper pressure plate is arranged above the material loading die; a lower pressure plate is arranged below the material loading die; and both the upper pressure plate and the lower pressure plate are connected with the transmission mechanism. The integrated instrument has the advantages of capability of preparing a plurality of test pieces at the same time, and realizing a mode of bidirectional vertical pressurization, simple operation and using, certain automation degree, convenient maintaining, capability of preparing geotechnical samples with higher density and uniform water content, and high efficiency of sample preparation.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

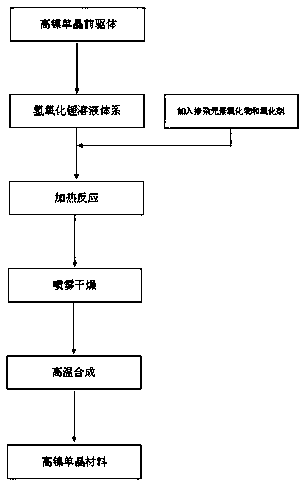

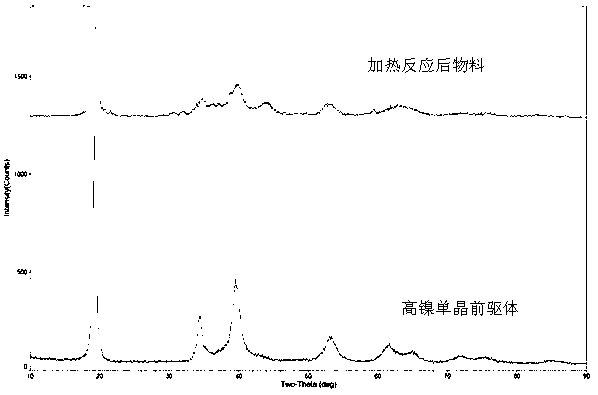

Wet-process preparation method of high-nickel single crystal anode material

InactiveCN109680333ALow costIncrease productivityPolycrystalline material growthFrom solid stateSolution systemNickel

The invention discloses a wet-process preparation method of a high-nickel single crystal anode material. A high-nickel single crystal precursor is directly used as a raw material, a doped element oxide and an oxidant are added into a lithium hydroxide solution system, and a high-nickel single crystal ternary anode material with uniform particle size is obtained through heating reaction, spray drying and high-temperature sintering treatment. The chemical general formula of the ternary anode material is Li1+a(NixCoyMnz)1-bMbO2. Compared with a traditional industrial solid phase synthesis method,the wet-process preparation method of the high-nickel single crystal anode material not only can solve the problem of non-uniformity of mechanical mixing of a precursor and a lithium source, but alsocan effectively reduce the residual alkali content of the high-nickel material, and also can reduce the use amount of the lithium source, thereby reducing the cost and improving the production efficiency. The high-nickel single crystal ternary anode material prepared by the method has the characteristics of uniform composition, complete crystal form, stable structure, excellent electrochemical performance and the like.

Owner:NANTONG RESHINE NEW MATERIAL

Preparation method of TC17 titanium alloy flat square section bar

ActiveCN103143660ARefining as-cast structureAddressing inhomogeneityMetal-working apparatusIngotWork in process

The invention provides a preparation method of a TC17 titanium alloy flat square section bar. The preparation method comprises the following steps that (1) a riser and an ingot bottom of a TC17 titanium alloy cast ingot are cut off, and surface defects are removed; (2) billet forging is performed on the TC17 titanium alloy cast ingot, and primary forging stocks are obtained; (3) first middle forging is performed on the primary forging stocks, and first middle forging stocks are obtained; (4) second middle forging is performed on the first middle forging stocks, and second middle forging stocks are obtained; (5) sawing is performed on the second middle forging stocks, then forming forging is performed, and a semi-finished flat square section bar is obtained; and (6) heat treatment is performed on the semi-finished flat square section bar, and the TC17 titanium alloy flat square section bar with the length of 850 mm to 1600 mm, the width of 132 mm and the thickness of 65 mm to 100 mm is obtained. The preparation method has the advantages of integral technical scheme, strong process controllability, uniformity in product texture and shape, excellent overall performance, high batch stability and high yield and is suitable for large-scale industrial production.

Owner:WESTERN TITANIUM TECH

Water-based wood paint for padding and preparation method thereof

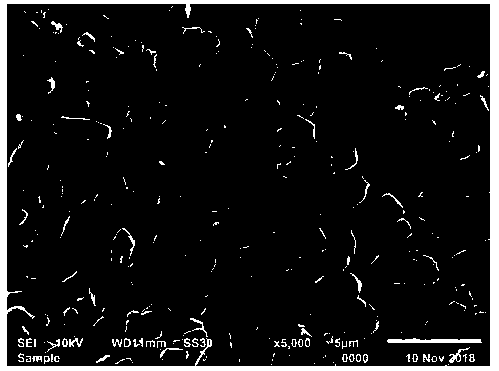

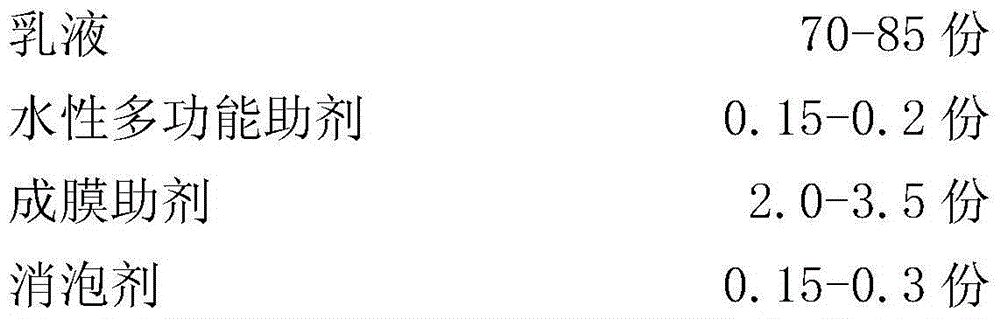

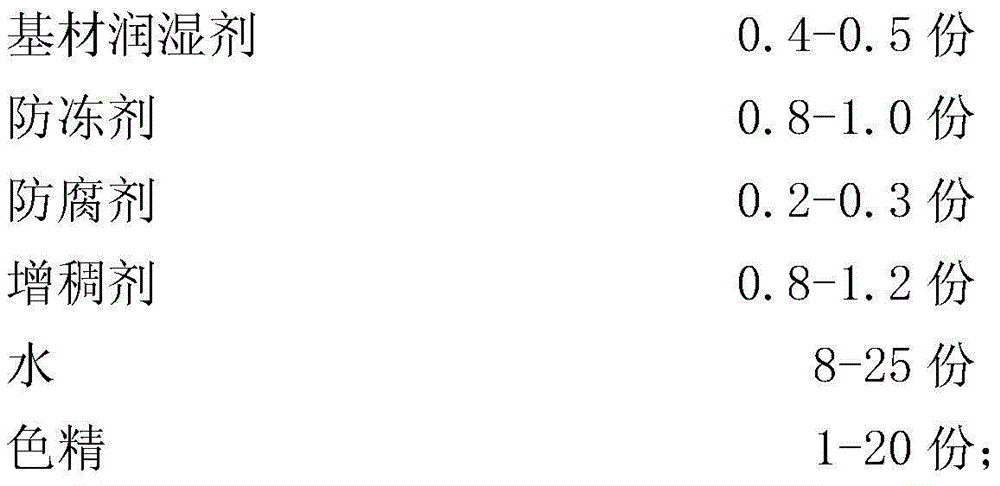

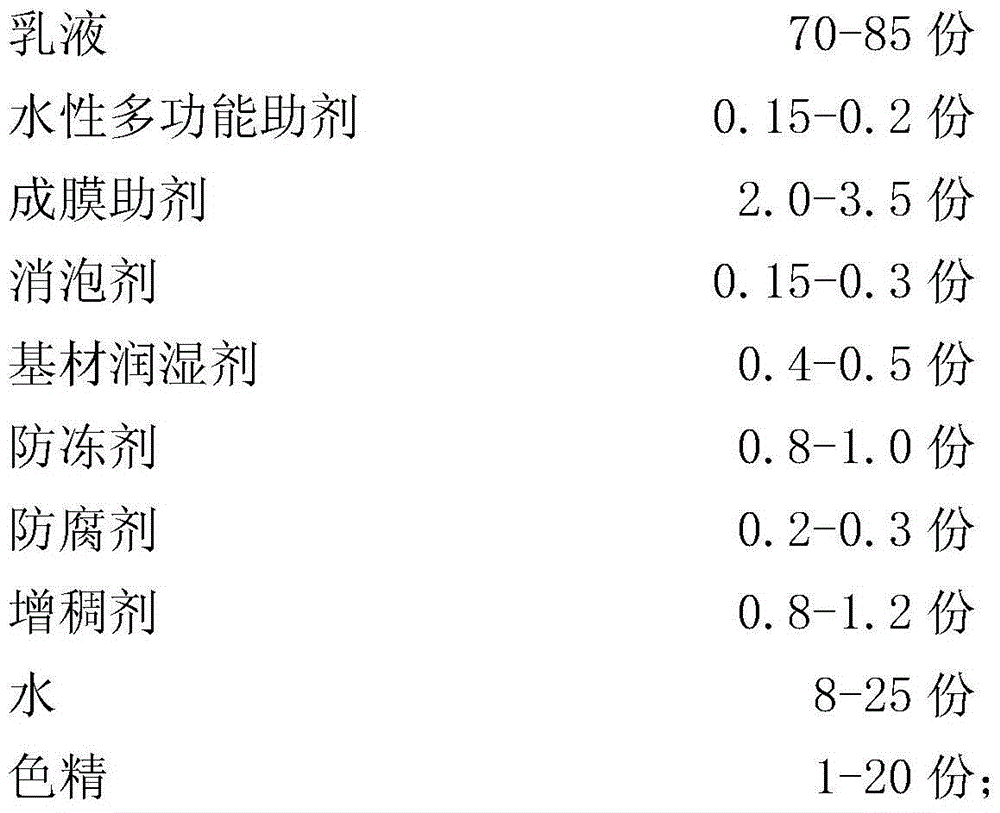

InactiveCN104592828AUniform colorImprove interlayer adhesionAnti-corrosive paintsWater basedEmulsion

The invention relates to a water-based wood paint for padding and a preparation method thereof. The water-based wood paint for padding is prepared from the following components in parts by weight: emulsion, water-based multifunctional assistant, film forming assistant, defoaming agent, substrate wetting agent, antifreezing agent, preservative, thickener, water and pigment. The emulsion is an alkali-soluble acrylic emulsion. The paint film of the water-based wood paint for padding has the advantages of uniform color, no floating and favorable ply adhesion with the finish paint.

Owner:SKSHU PAINT

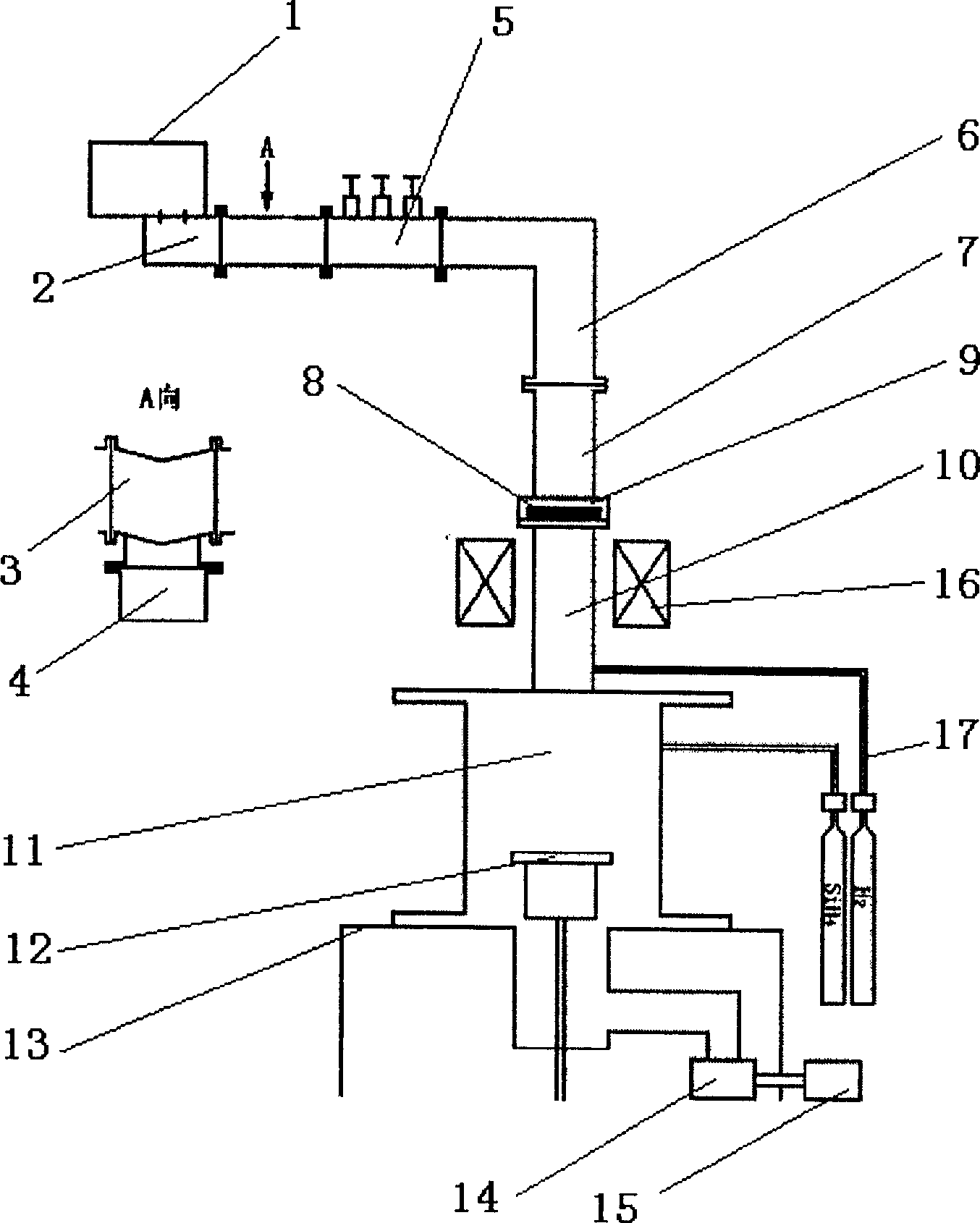

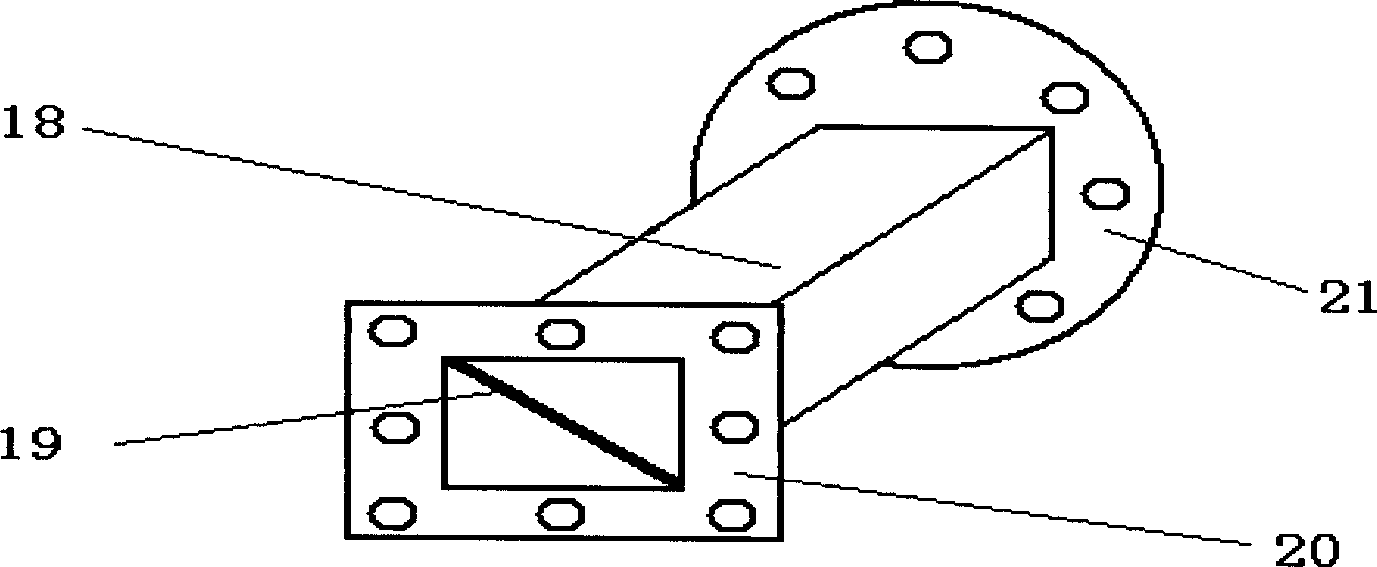

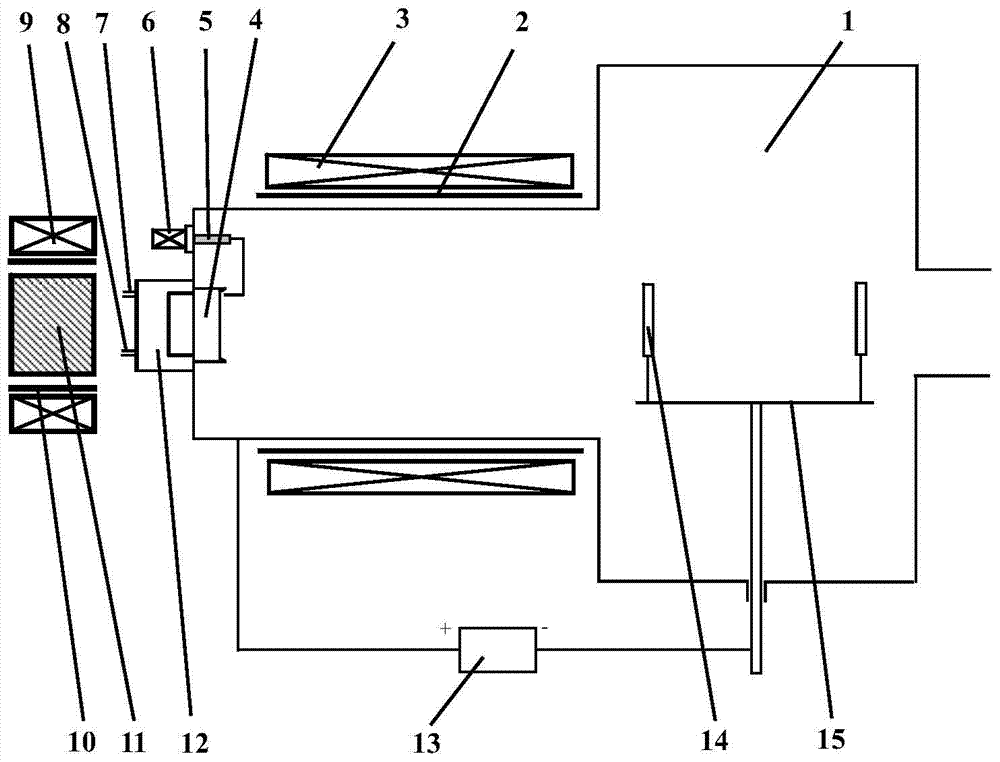

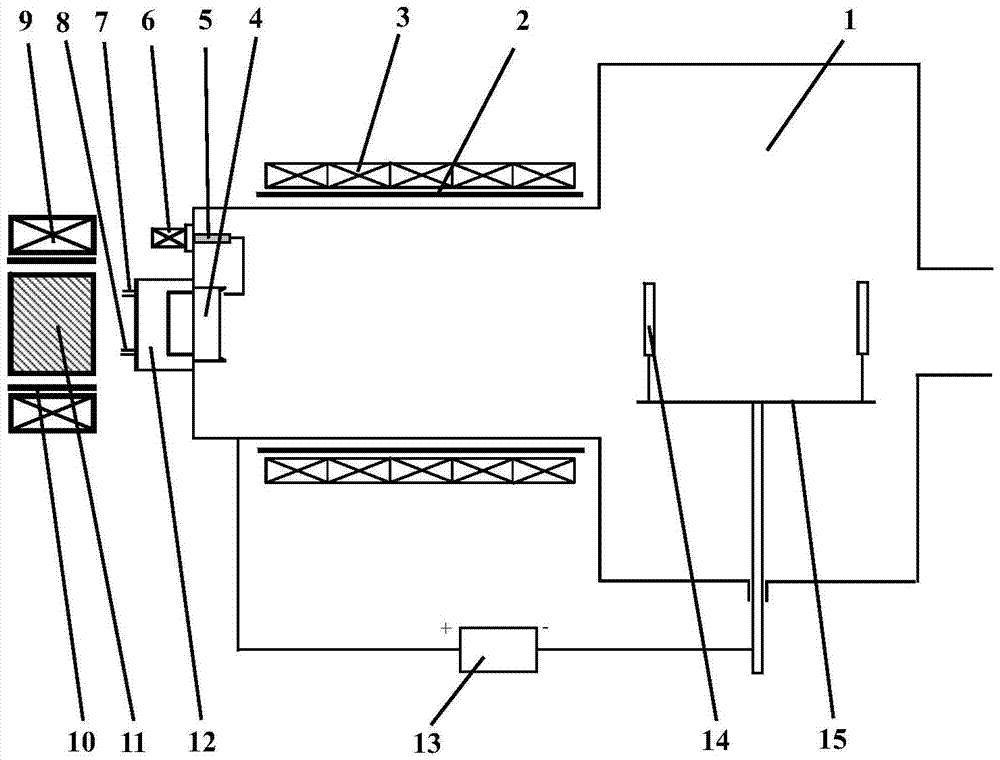

Method for averaging plasma by using microwave electron cyclotron resonance

InactiveCN1416307AImprove uniformityNo pollution in the processPlasma techniqueResonant cavityMicrowave

The invention belongs to the microwave low-temperature plasma. Microwave through dual triangle typed wave-guide tube with their relation of rotated 180 degrees generates the two beam of microwave, then passing through the coupling of the microwave window entering to the resonant cavity. The two beam of microwave are superposed in the resonant cavity, forming the new two-beam microwave field. The wave-guide tube is designed as follows: The equipartition plate is inserted to the section of the rectangular wave-guide, which is positioned between the ceramics microwave window 8 and the flange 9 of the window so as to form the dual triangle typed wave-guide tube. The invention solves the problem of the uneven plasma, and features installation and no pollution for the plasma.

Owner:BEIJING UNIV OF TECH

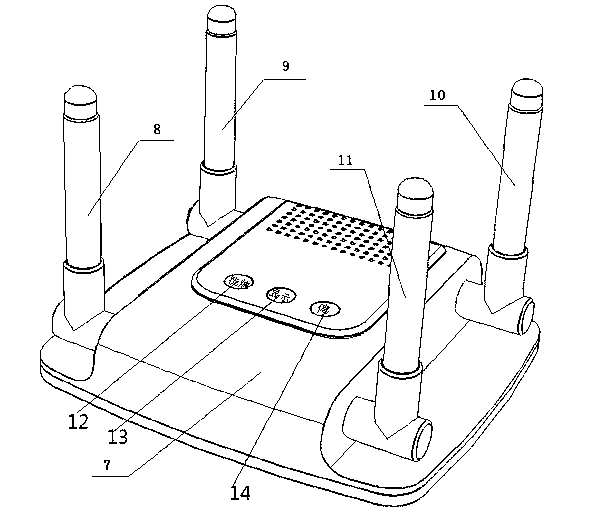

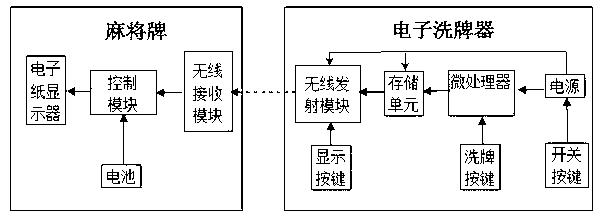

Shuffle-free electronic mahjong assembly

InactiveCN102989172ASolve the inconvenience of carryingImprove experienceVideo gamesComputer moduleControl circuit

The invention discloses a shuffle-free electronic mahjong assembly which comprises mahjong tiles and an electronic shuffling machine. A control circuit is arranged in the mahjong tiles and comprises a control module, a wireless receiving module, a battery and a display module. The wireless receiving module, the battery and the display module are connected with the control circuit. The electronic shuffling machine comprises a wireless transmitting module, a memory unit, a microprocessor and a power source, wherein the power source, the microprocessor, the memory unit and the wireless transmitting module are connected in sequence. The wireless transmitting module and the memory unit are connected with the power source, the power source is connected with an on-off key, the microprocessor is connected with a shuffling key, and the wireless transmitting module is connected with a display key and is in communication with the wireless receiving module. The shuffle-free electronic mahjong assembly can save shuffling time, guarantees competitive fairness, and is convenient to carry and green and environment-friendly.

Owner:HUNAN ELECTRONICS INFORMATION IND GRP

Rotary calcining furnace

The invention provides a rotary calcining furnace. The rotary calcining furnace comprises a furnace tube, a heating part and a liquid feeding liquid mixing device, wherein the liquid feeding liquid mixing device comprises a liquid mixing container, a turbulence plateand a fixing piece; and the liquid mixing container is provided with a feeding portand a material supplying port,the turbulence plateis fixed inside the liquid mixing container through the fixing part. The rotary calcining furnace is perfect in design, good in performance and convenient to operate, and can well solve the problemsthat materials are not uniform, the inner wall of the furnace tube is bonded, blocked and the like in a radioactive waste liquid rotary calcining process, industrial production is easy to realize, andtechnical support is provided for development and improvement of the two-step cold crucible glass curing technology in China.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

Metal powder and metal sintering mesh composite filter element and production method thereof

InactiveCN104857775AAddressing inhomogeneitySolve bridgingFiltration separationMetal layered productsMetallurgyWork in process

The invention discloses a metal powder and metal sintering mesh composite filter element which adopts a round pipe structure, and comprises a metal mesh layer and a metal powder layer which are formed through sintering in sequence from outside to inside; the metal mesh layer comprises an outer dutch wire mesh, an inner dutch wire mesh and a plurality of plain meshes; the outer dutch wire mesh and the inner dutch wire mesh are consistent in structure, and vertically crossed and stacked according to lines; the plain meshes are arranged between the inner surface of the inner dutch wire mesh and the metal powder layer. The production method comprises the following steps: 1) arranging the metal layers, 2) sintering the metal layers, 3) preparing suspension slurry, 4) preparing the metal powder layer, 5) sintering a semi-finished product, and 6) pressing the finished product. The metal powder and metal sintering mesh composite filter element has the advantages of being small in filter resistance, high in fluid flux, strong in regeneration capacity, long in service cycle, and especially suitable for being used continuously during the process of production technology, needing continuous operation, of petrochemical engineering and the like.

Owner:徐小平

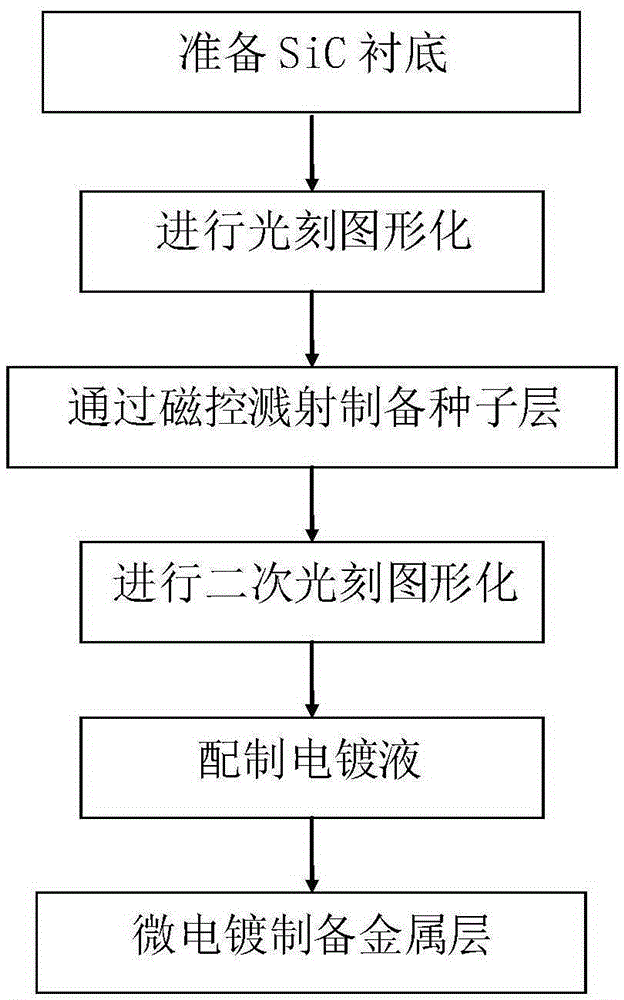

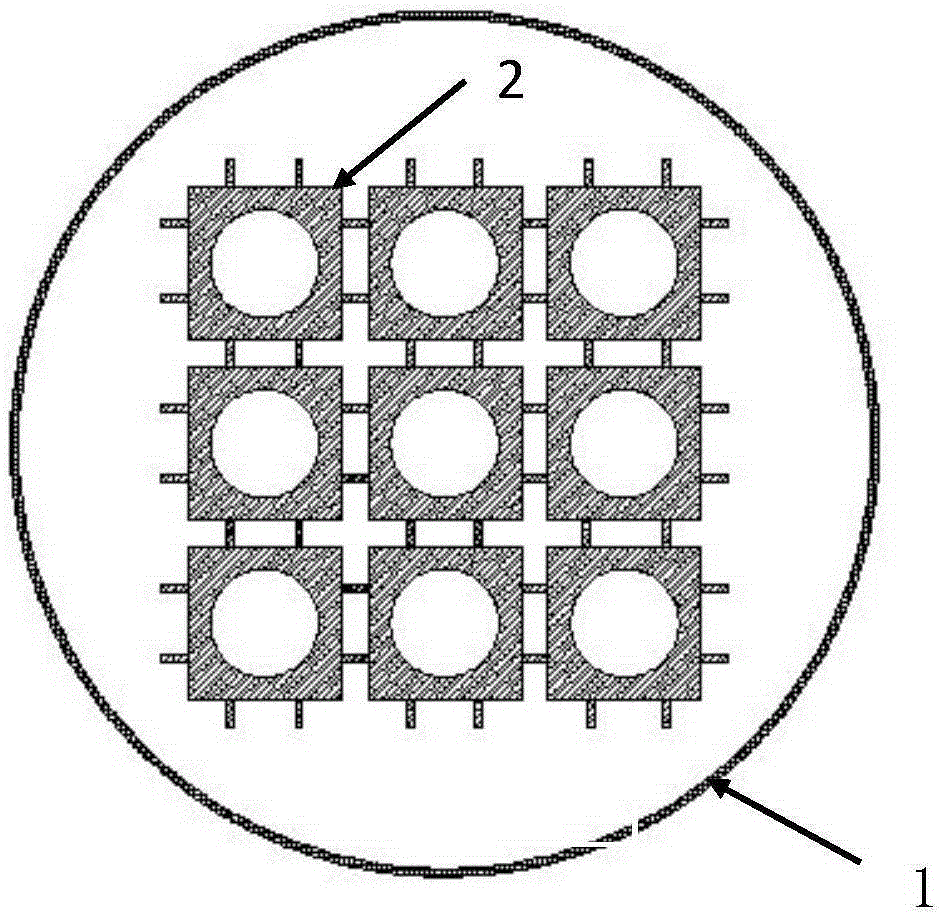

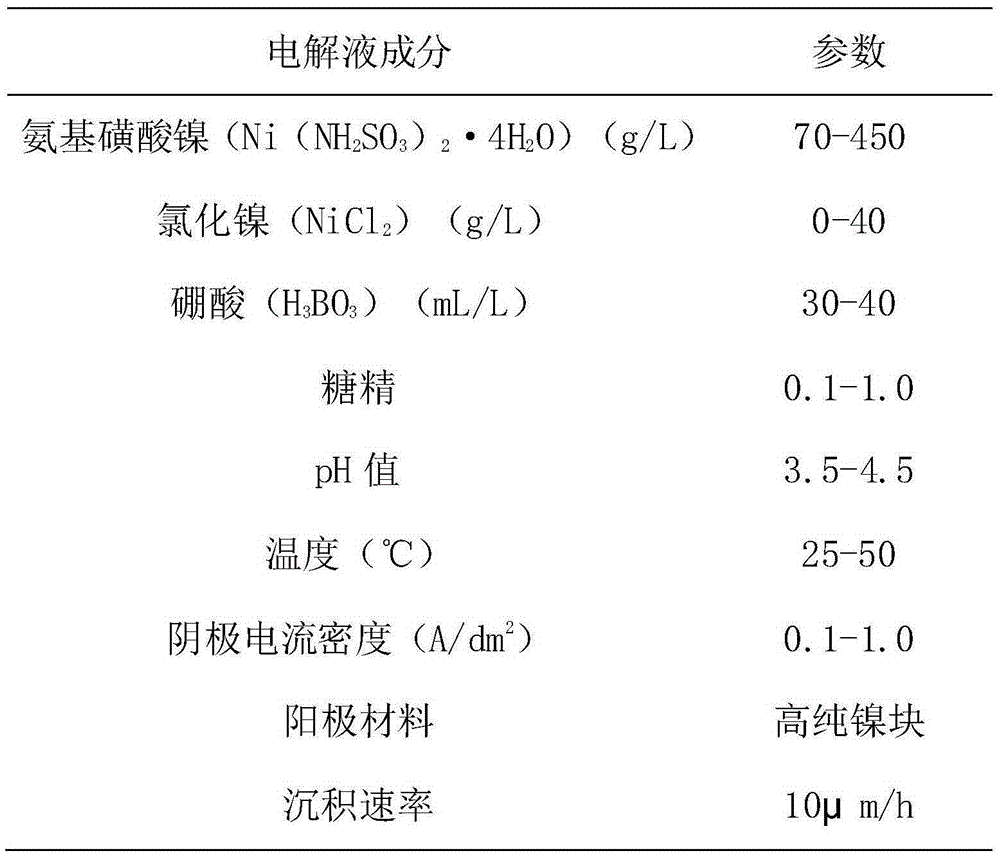

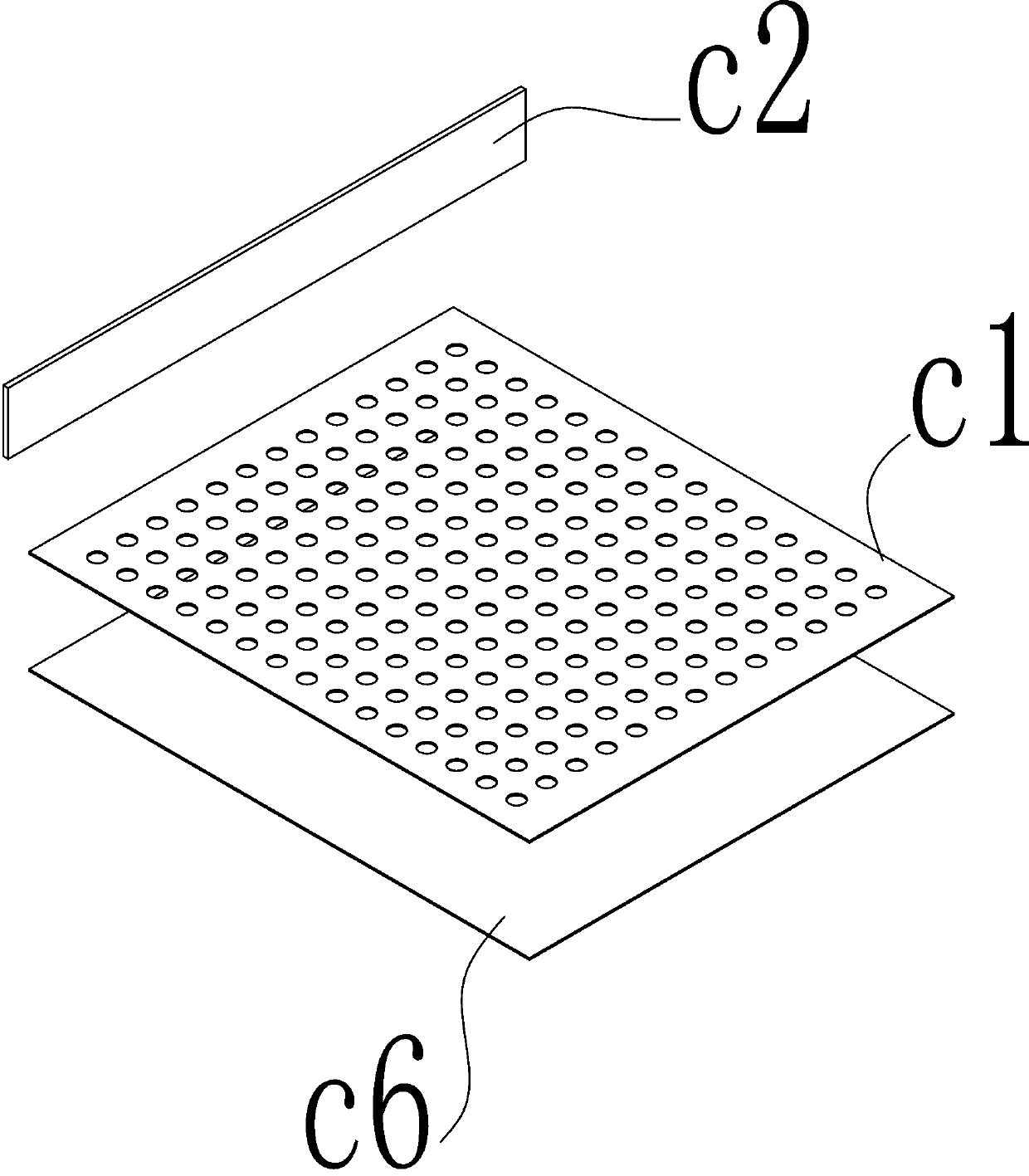

MEMS micro array structure processing method based on micro-electroplating

InactiveCN105329849AImprove adhesionAddressing inhomogeneityDecorative surface effectsVacuum evaporation coatingSemiconductor materialsHigh pressure

The invention discloses a MEMS micro array structure processing method based on micro-electroplating, and more specifically relates to a mask preparation method via semiconducting material deep etching processing, and belongs to the technical field of semiconducting material processing. A SiC material is taken as an example. The MEMS micro array structure processing method comprises following steps: SiC substrate preparation; photoetching pattern forming; seed layer preparation via magnetron sputtering; secondary photoetching pattern forming; preparation of an electroplate liquid; and preparation of metal layers via electroplating. A electroplate liquid component is optimized, micro electroplating conditions are modified, adhesive force of a coated metal with a substrate is increased, uniformity and thickness of the coated metal are increased, and a prepared metal coating is capable of satisfying requirements of SiC deep etching processing of a mask layer, and expanding applications of silicon carbide in related device preparation via a novel mask structure. The MEMS micro array structure processing method is capable of providing technical supports for applications of SiC pressure sensors at severe environments (high temperature, high pressure, strong corrosion, and strong radiation).

Owner:SHANGHAI NORMAL UNIVERSITY

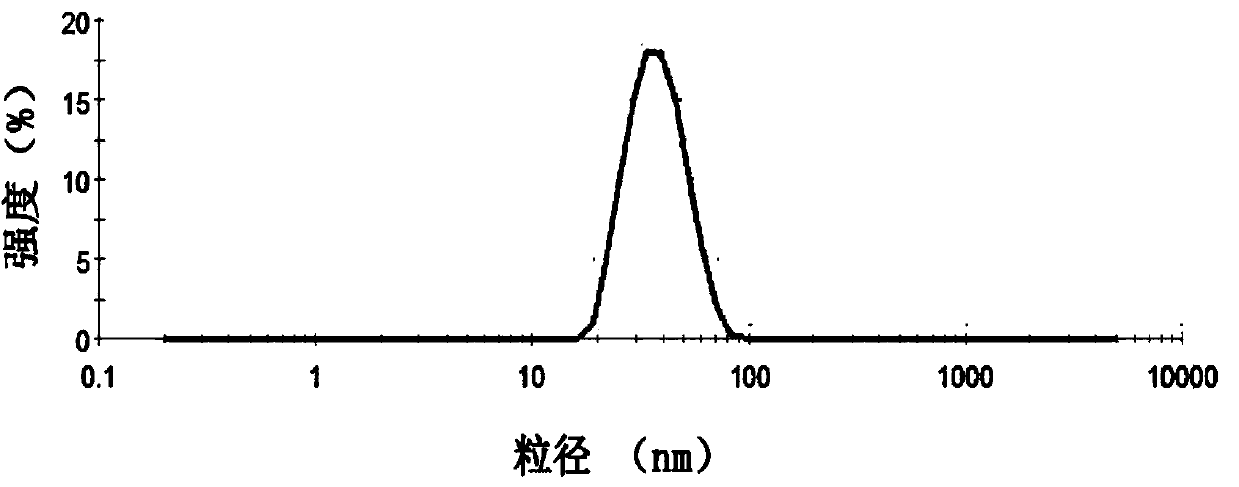

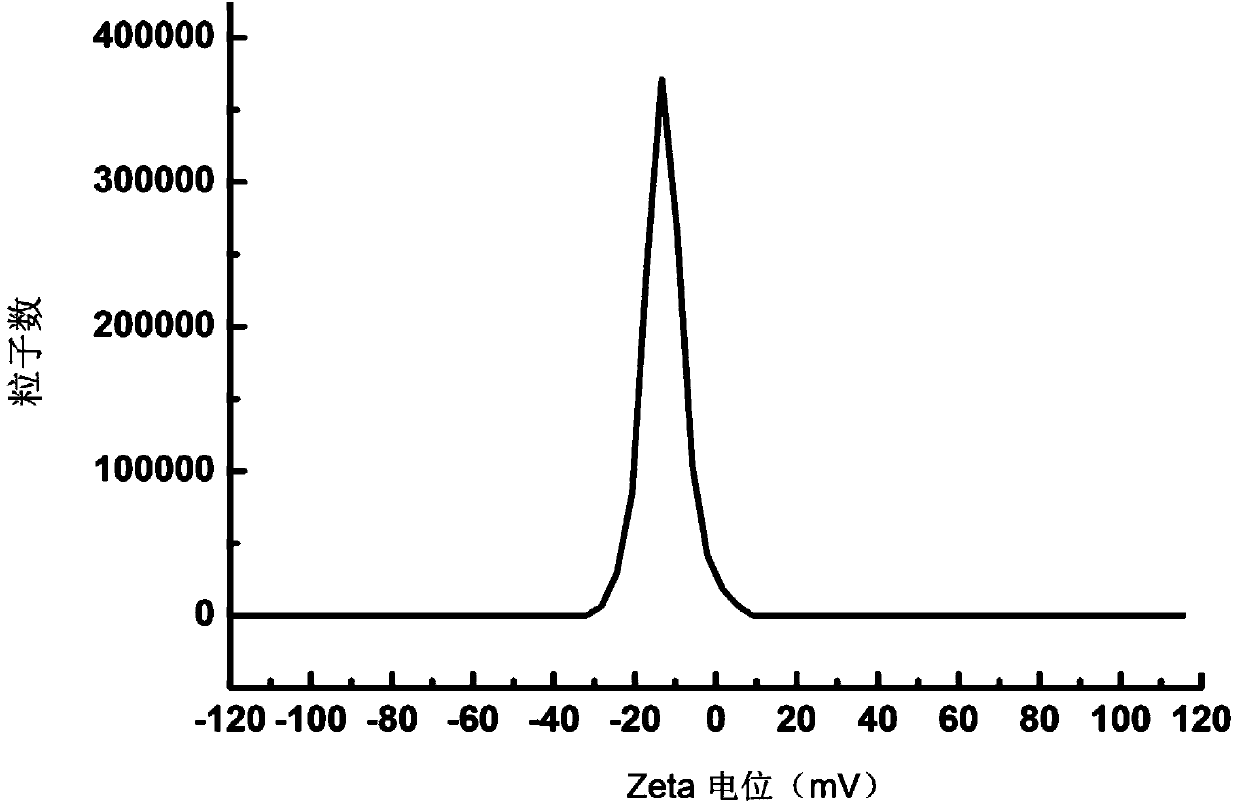

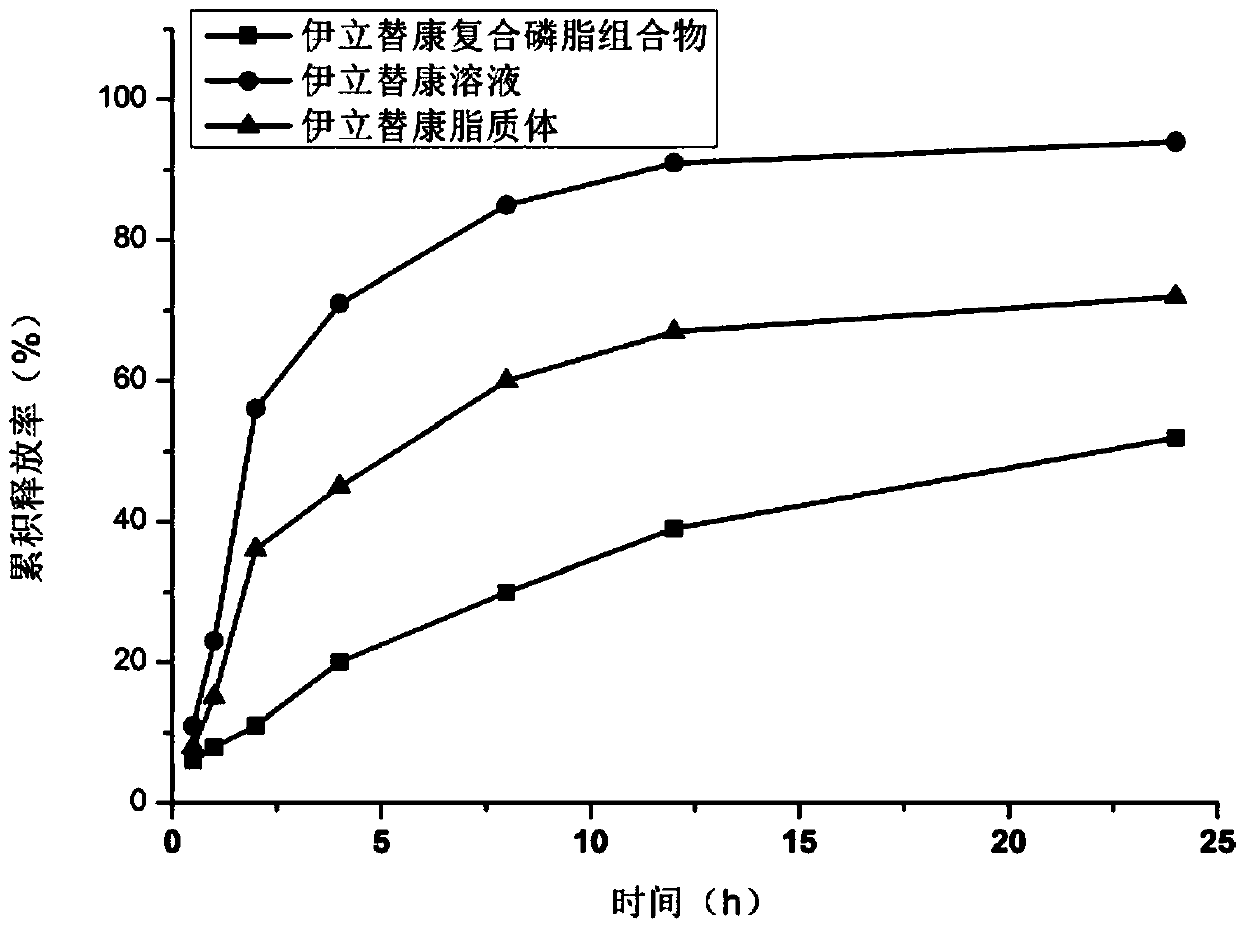

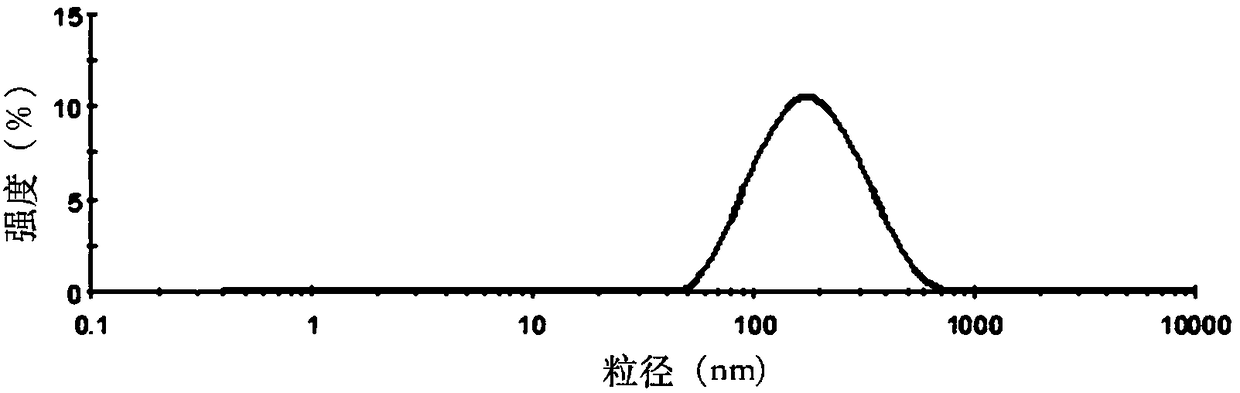

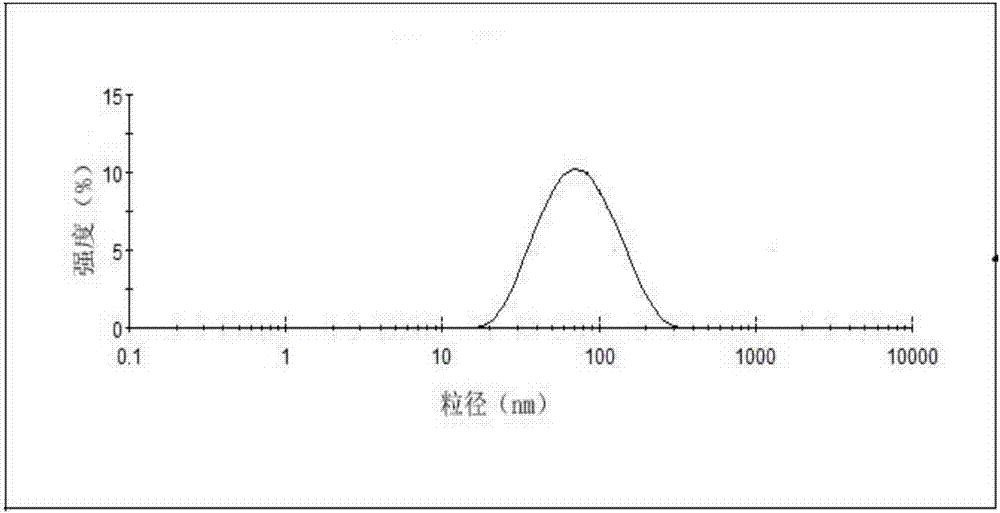

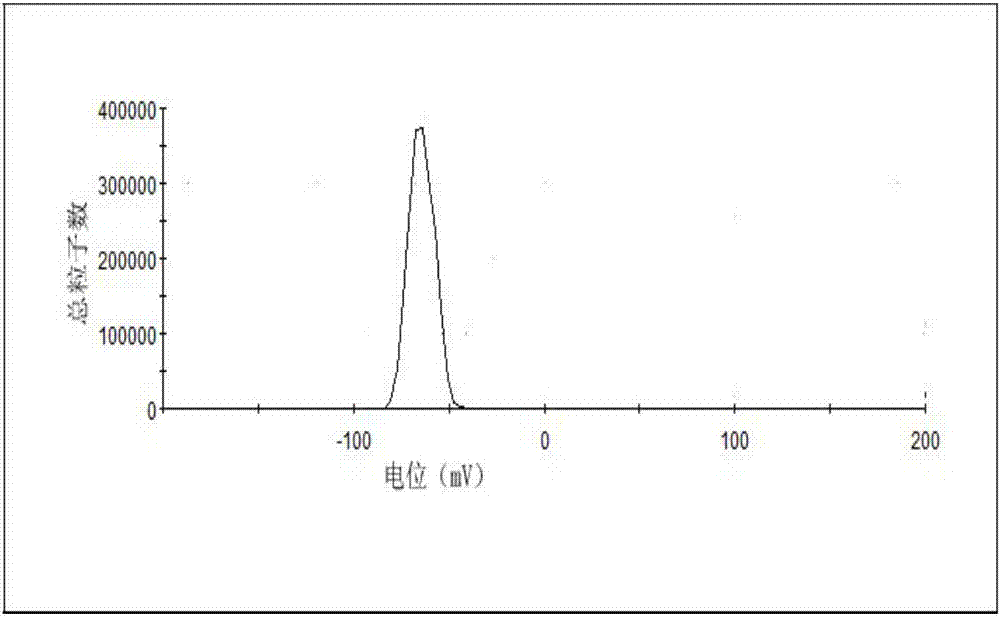

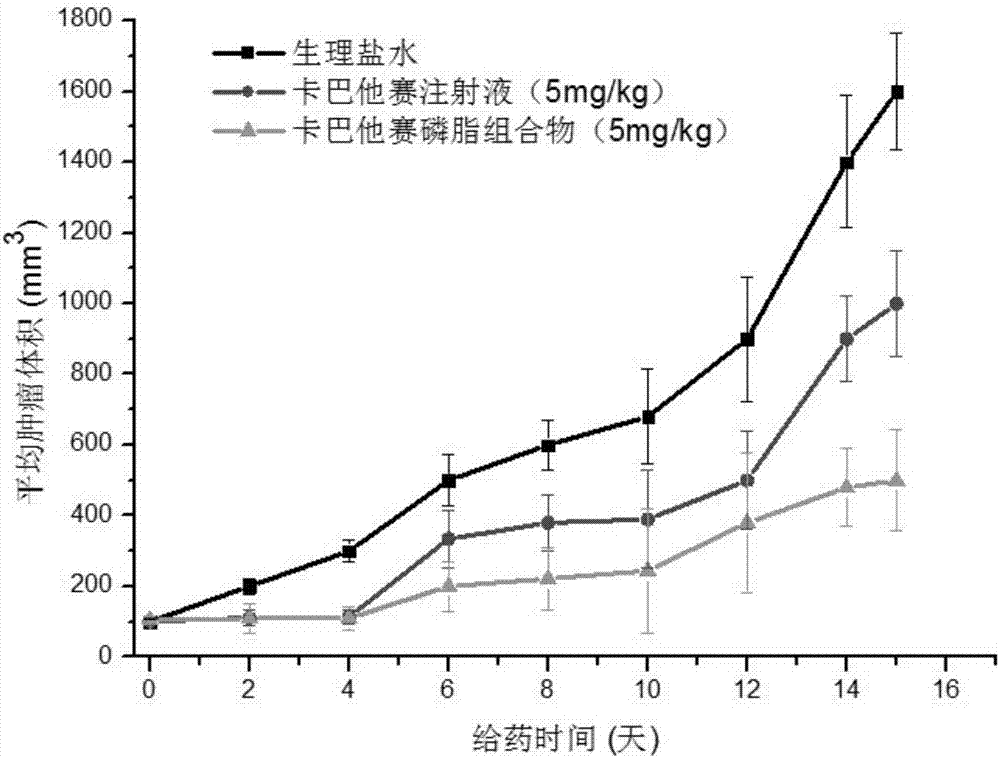

Irinotecan hydrochloride composite phospholipid composition, preparation method and applications thereof

InactiveCN104906586AImprove rigidityClosely arrangedOrganic active ingredientsInorganic non-active ingredientsCholesterolActive agent

An irinotecan hydrochloride composite phospholipid composition, preparation method and uses thereof in the preparation of drugs for treating tumors or drug resistant tumors. The composite phospholipid composition comprises irinotecan hydrochloride, composite phospholipid, cholesterol, long-circulating membrane material, surfactant and a buffer medium. The composition improves stability of lipid formulation and the anti-tumor effect of irinotecan hydrochloride, and can overcome multidrug resistance of a tumor.

Owner:SHANGHAI INST OF MATERIA MEDICA CHINESE ACAD OF SCI

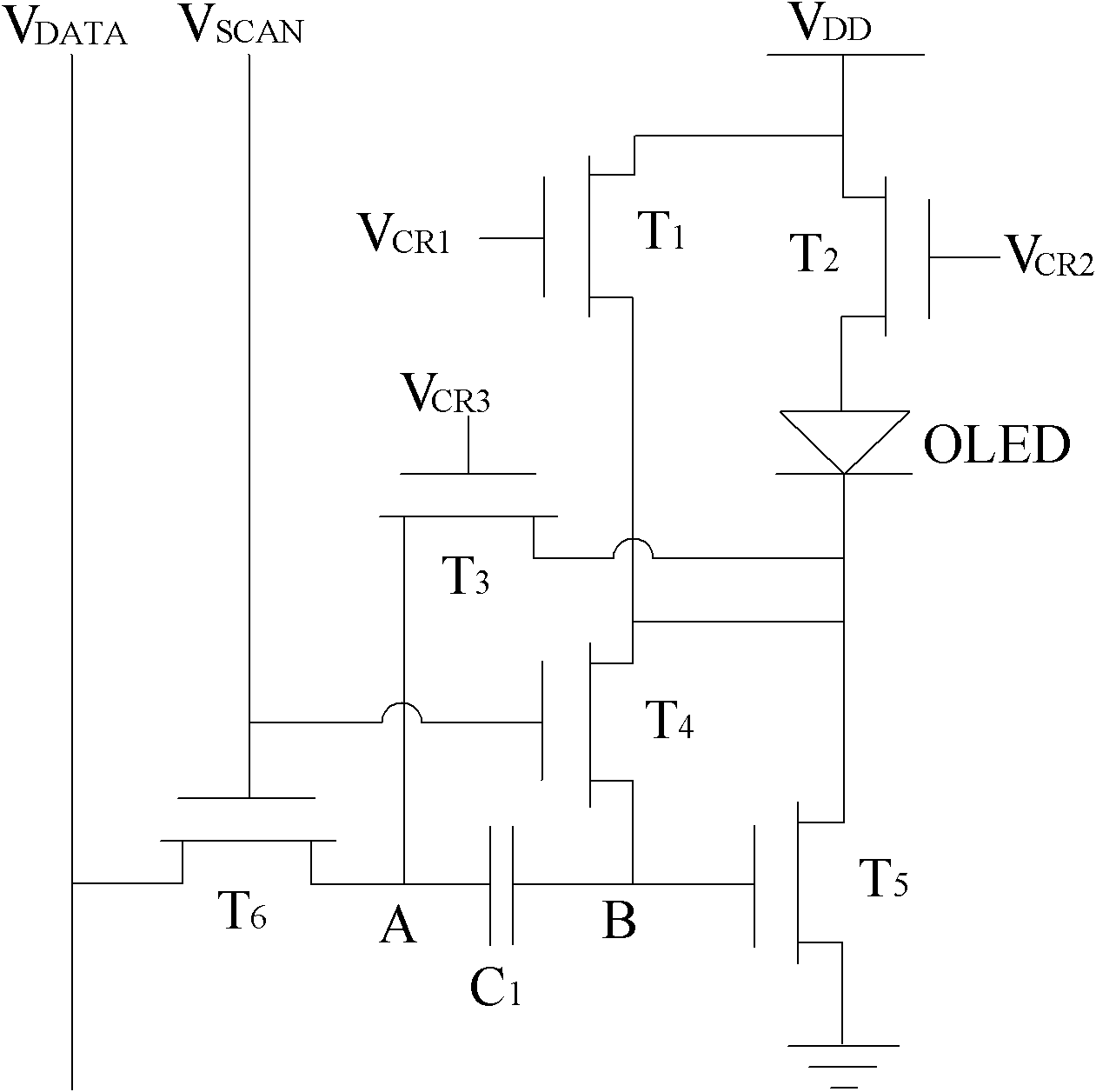

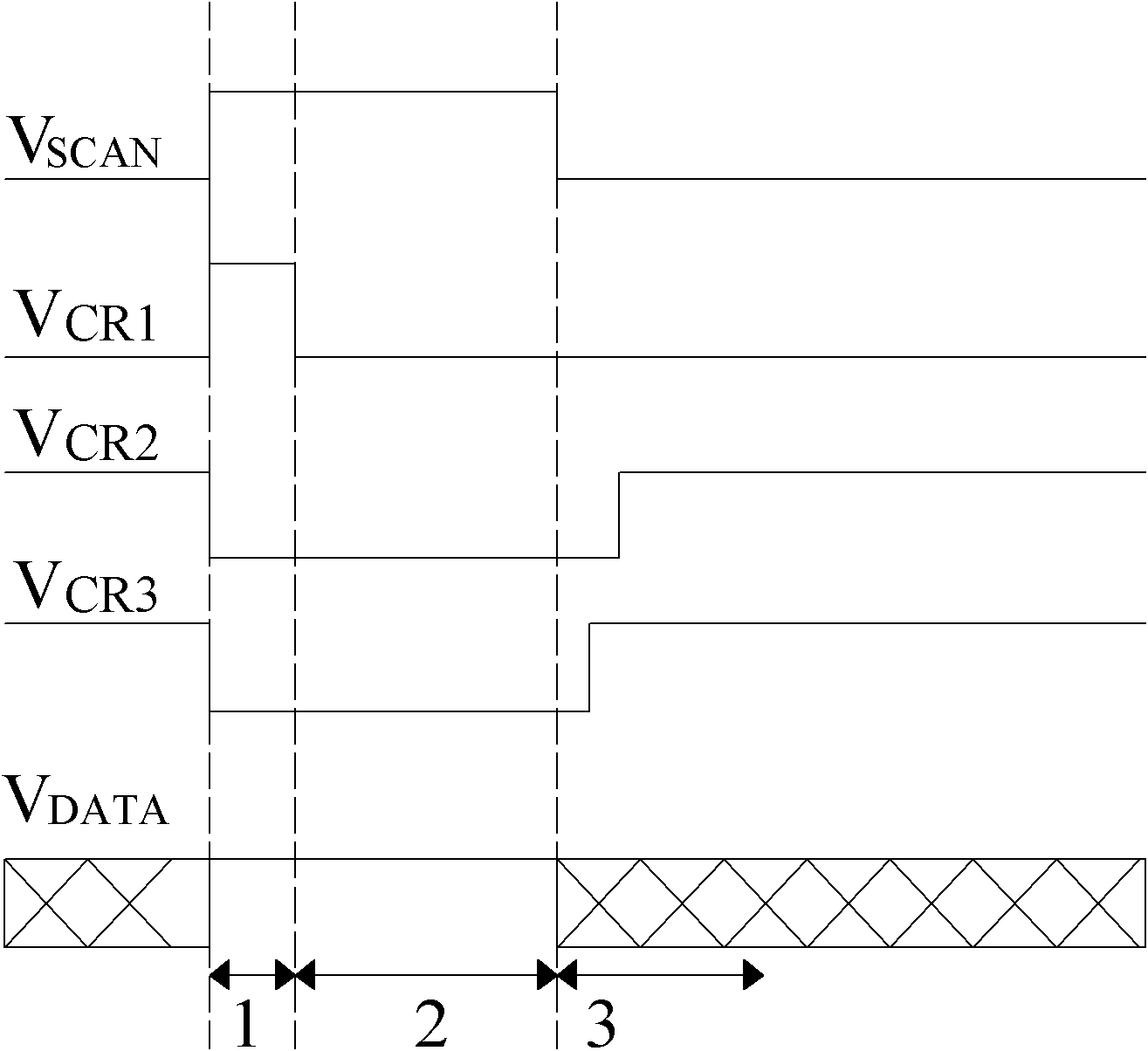

Organic light-emitting diode driving circuit, display panel and displayer

ActiveCN102651189AEliminate work status inconsistenciesSolve the problem of brightness attenuation and unevennessStatic indicating devicesCapacitanceEngineering

The invention discloses an organic light-emitting diode driving circuit, a display panel and a displayer which are designed to solve the problem of an existing driving circuit that the brightness and the uniformity of an organic light-emitting diode are affected by the threshold voltage of a driving unit. The organic light-emitting diode driving circuit comprises the driving unit, a threshold compensation unit and the organic light-emitting diode. A preferable circuit structure comprises five switch tubes, one driving tube, one capacitor and one organic light-emitting diode, wherein N-type thin film transistors are preferably selected as the switch tubes and the driving tube. According to the invention, the working principle of the organic light-emitting diode driving circuit is as follows: the phenomenon that the working states of the organic light-emitting diode are inconsistent due to different threshold voltages of the driving tube in the whole circuit is eliminated through the threshold voltage Vth of the 6T1C circuit compensation driving tube, so that the brightness and uniformity problems of the organic light-emitting diode are solved.

Owner:BOE TECH GRP CO LTD +1

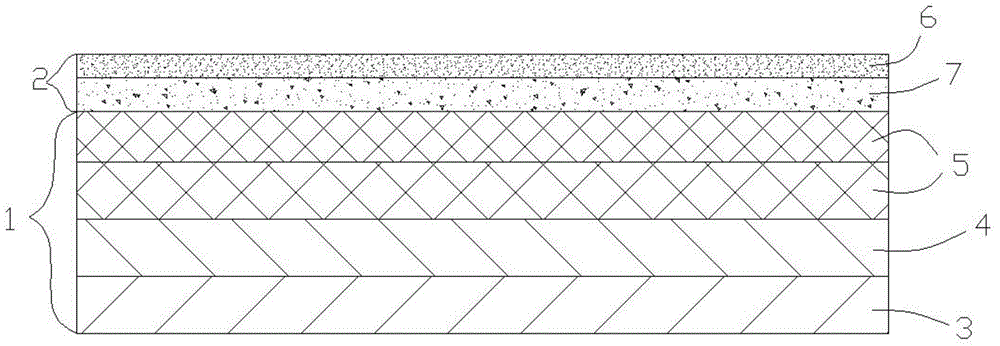

Inner container of refrigeration equipment and preparation method thereof

InactiveCN102661646AHigh strengthAvoid crackingDomestic cooling apparatusLighting and heating apparatusFoaming agentSurface layer

The invention discloses an inner container of refrigeration equipment and a preparation method thereof. The inner container of the refrigeration equipment is formed by an HIPS (high impact polystyrene) three-layer composite board, the HIPS three-layer composite board comprises a surface layer, a basic layer and a bottom layer, wherein the surface layer is composed of a surface layer HIPS, and the surface layer HIPS is selected from one or more types of natural color HIPS, tinction HIPS and modification extrusion grade HIPS; and the basic layer comprises the natural color extrusion grade HIPS and a feeding material, and the bottom layer is composed of a resistance foaming agent erosion HIPS. According to the inner container of the refrigeration equipment provided by the embodiment of the invention, the HIPS three-layer composite board is adopted to shape, and the surface layer, the basic layer and the bottom layer of the HIPS three-layer composite board are all made of HIPS materials; the different HIPS materials after screening have good consistency, and can be mutually mixed; and the appearance and processing behaviour of the board can not be obviously influenced, the intensity of the board is improved, and the cracking risk is reduced.

Owner:HEFEI MIDEA REFRIGERATOR CO LTD

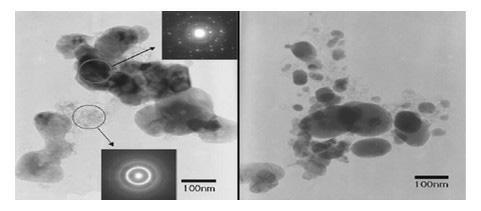

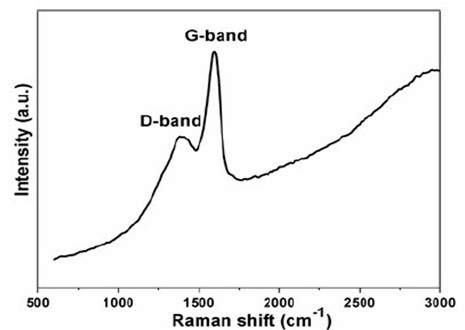

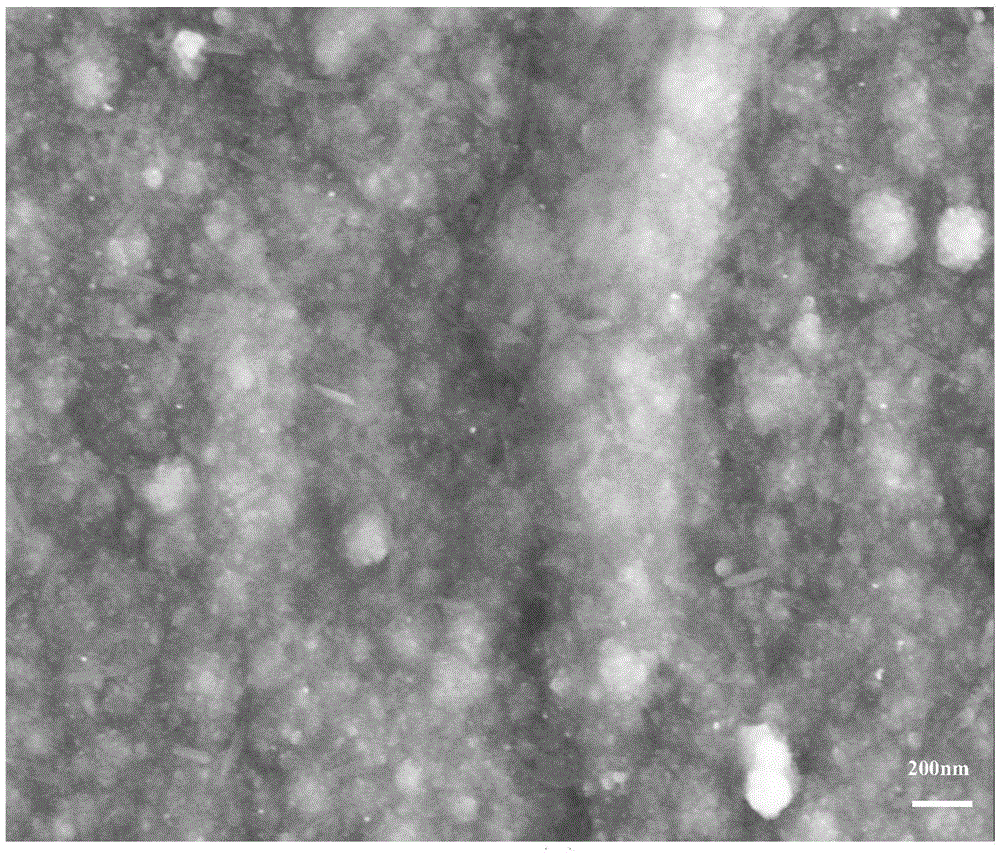

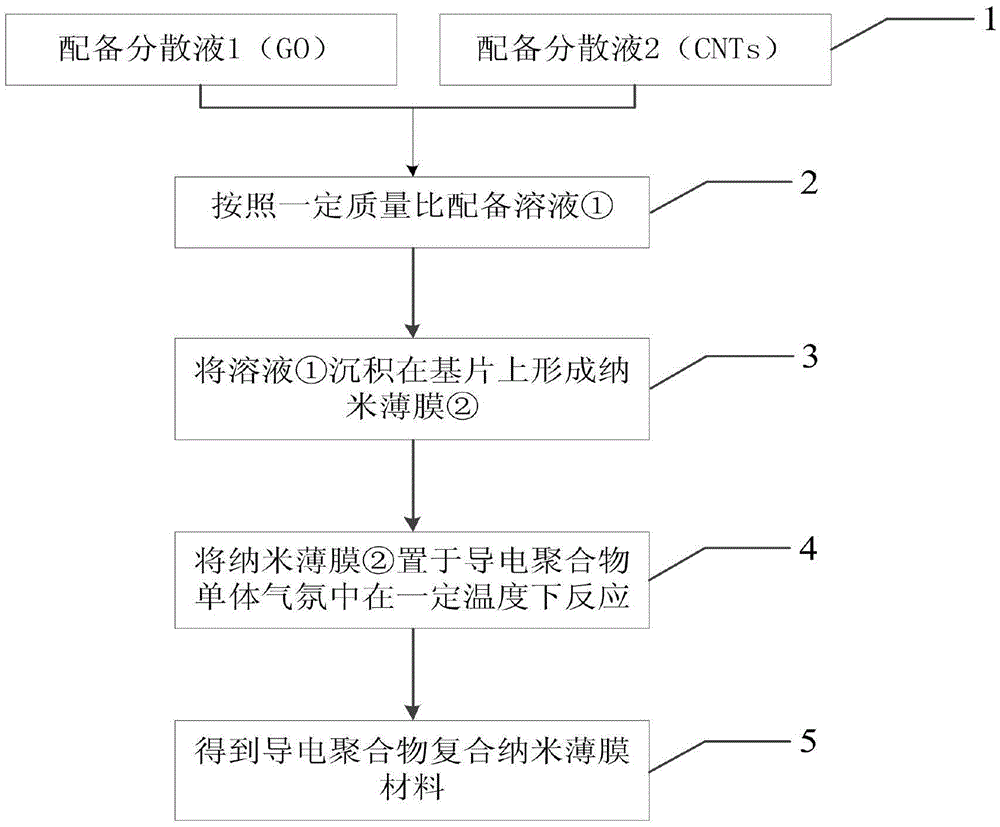

Preparation method of conducting polymer composite nano-film material

The invention discloses a preparation method of a conducting polymer composite nano-film material and relates to the technical field of conducting polymer composite materials. The preparation method comprises the following steps: a graphene oxide and carbon nano-tube composited nano-film is formed on a substrate firstly, then the nano-film is polymerized in a gaseous environment containing conducting polymer monomers, graphene oxide is reduced, and the conducting polymer film attached to the surface of a nanostructure is formed. The conducting polymer composite nano-film material prepared with the method has the advantages of excellent conducting performance, high specific surface area and environment-friendly process, the phenomenon that graphene oxide after reduction in a liquid phase reaction is not dissolved in water but forms a flocculent precipitate and hinders follow-up film forming in the prior art is avoided, and the problems of non-uniform film forming and difficulty in thickness control due to the phenomenon are solved; the preparation process is simple, the flow is controllable, and the application range of the conducting polymer composite nano-film material is expanded greatly.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Finish forging die for forging aluminum alloy wheel

InactiveCN103752752ASolve uneven iron materialEasy loading and unloadingForging/hammering/pressing machinesAluminium alloyMaterials science

A finish forging die for forging an aluminum alloy wheel comprises an upper die plate and a lower die plate. A lower die is fixed above the lower die plate. An upper die is fixed below the upper die plate. The upper die comprises an upper die core, and the upper die core is sleeved with an upper die sleeve. A circle of notch is formed in the outer wall of the upper portion of the lower die. A flash reserving cavity is formed between the inner wall of the upper die sleeve and the notch of the lower die. A lower ejector rod is arranged at the center of the lower die. An upper ejector rod is arranged at the center of the upper die core. The problems that iron materials are not even and a die is not in place when the quantity of materials is large are solved through the flash reserving cavity formed between the inner wall of the upper die sleeve and the notch of the lower die; a workpiece can be pressed on a lower die core through the upper ejector rod arranged right at the center of the upper die core so that the die can be released, and damage caused when the workpiece collides with the die is avoided; the workpiece is ejected out of the lower die core through the lower ejector rod arranged right at the center of the lower die core, and therefore the forging process is achieved; compared with a traditional die, the finish forging die has the advantages of being free of die holding, easy to release and not prone to strain.

Owner:连云港宝石精密重工科技有限公司

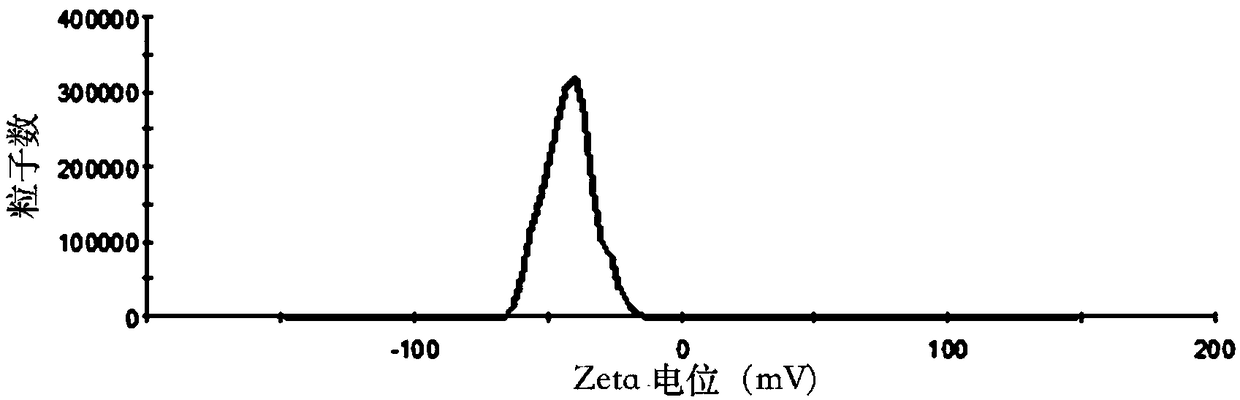

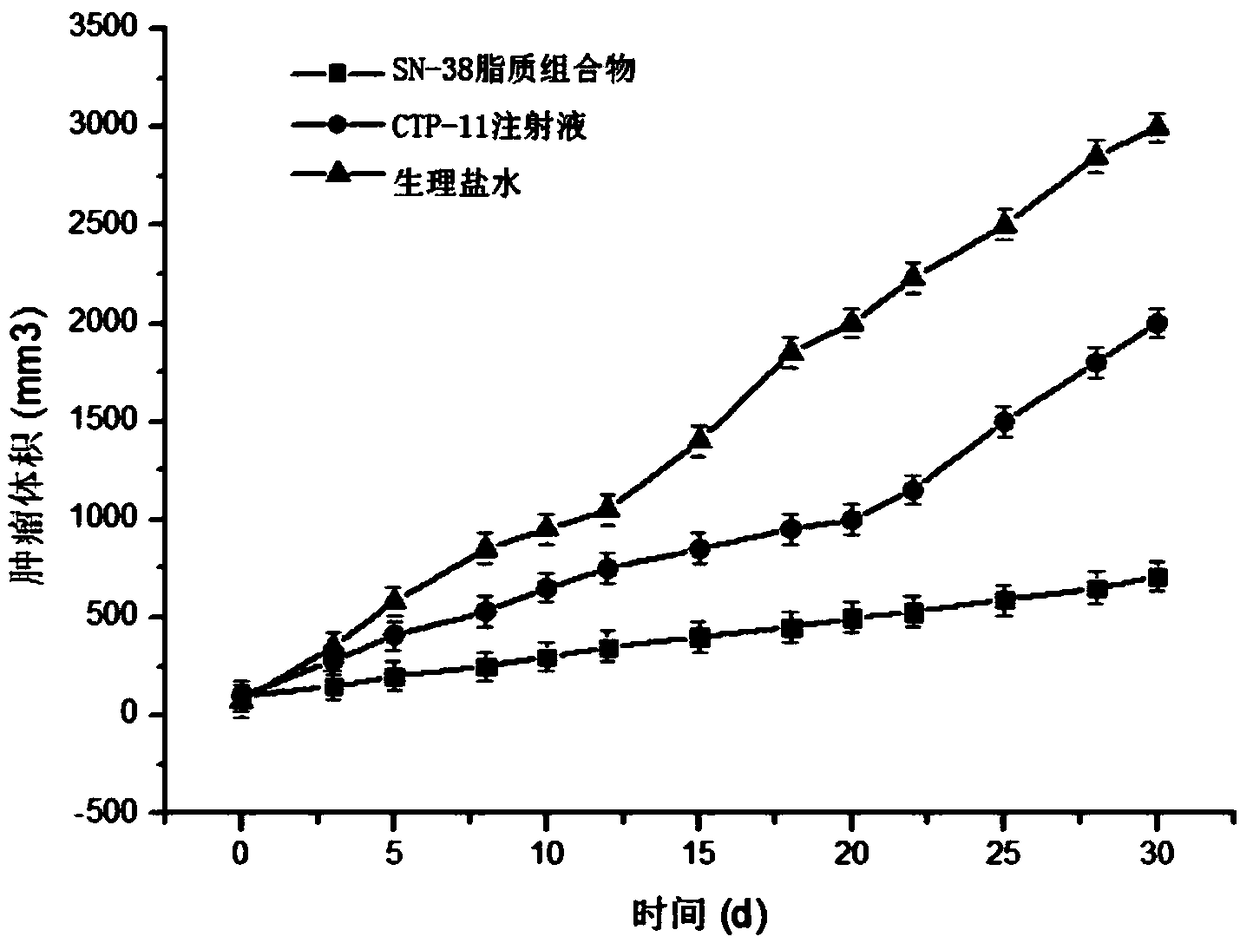

SN38 lipid composition, and preparation method and application thereof

ActiveCN108567742ASmall toxicityOvercoming multidrug resistancePowder deliveryOrganic active ingredientsSolubilityAdjuvant

The invention relates to a SN38 lipid composition, and a preparation method and application thereof. The SN38 lipid composition comprises SN38, phosphatide, oil for injection, cholesterol, a long-circulating film material, a functional material capable of forming a protection layer on the surface of lipid, and a functional adjuvant capable of reversing drug resistance. The SN38 lipid composition overcomes the problems that drugs are poor in solubility and hard to prepare preparations, that conventional lipid preparations are low in entrapment rate and poor in in-vitro stability, that drugs areprone to rapid leakage and the like in the prior art; and the SN38 lipid composition improves the in-vivo circulation time of drugs, has a certain targeting function, allows drugs to be enriched at tumor sites, reduces toxic and side effect, substantially enhances drug effect, and can overcome the multidrug resistance of tumors to a certain degree.

Owner:SHANGHAI INST OF MATERIA MEDICA CHINESE ACAD OF SCI

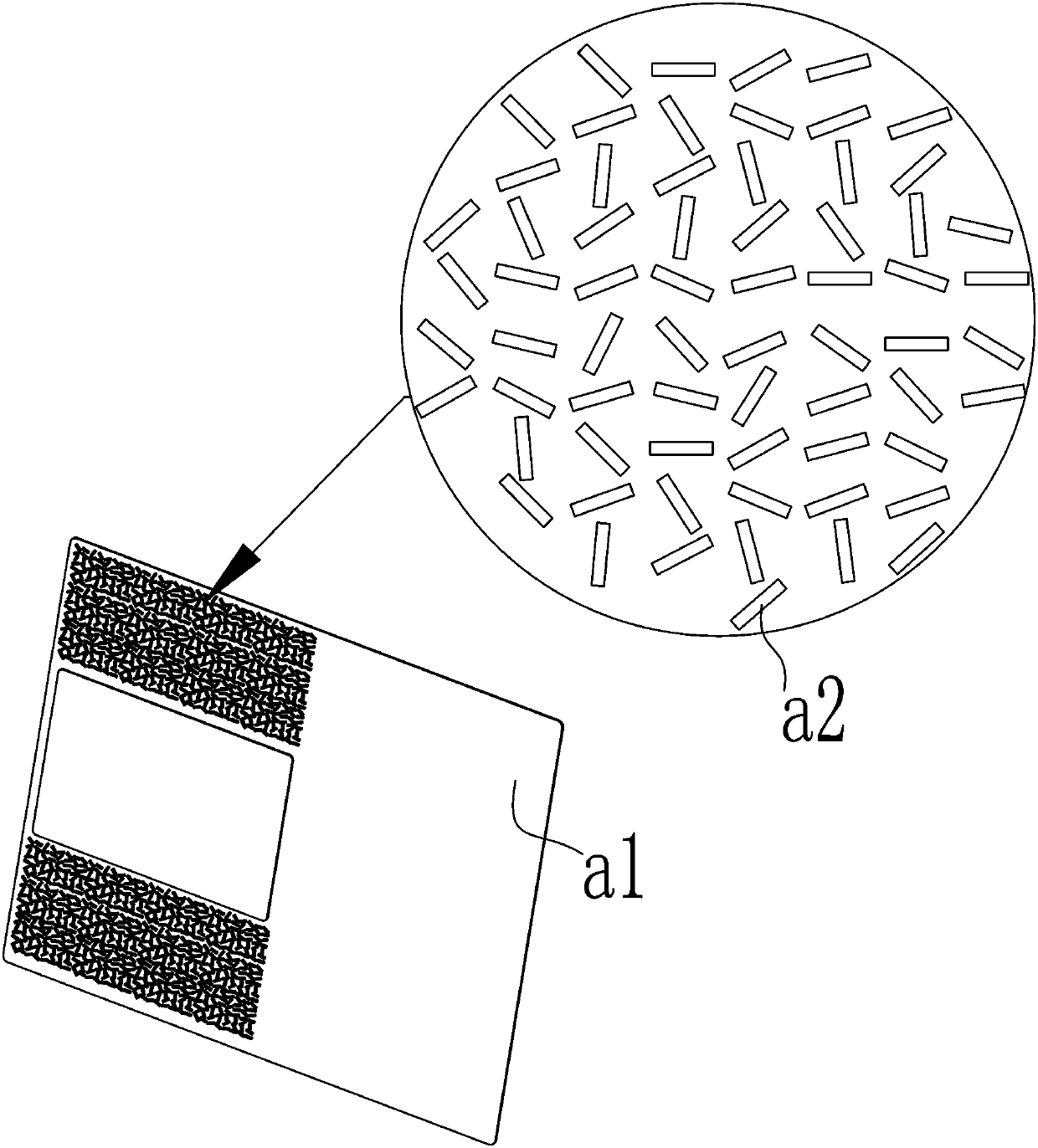

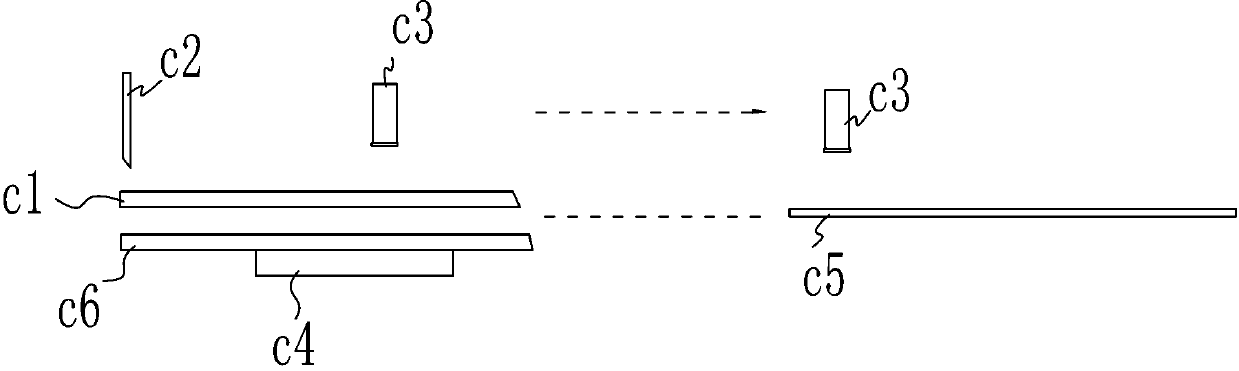

Production equipment and production method of anti-counterfeit prints

ActiveCN110076056AResolve overlapping casesAddressing inhomogeneityLiquid surface applicatorsCoatingsEngineeringMethods of production

The invention discloses production equipment of anti-counterfeit prints. The production equipment comprises a bottom plate and a hole plate located above the bottom plate, and the hole plate is provided with at least one hole. The production equipment further comprises a powder dusting unit located above the hole plate for powder dusting and a cleaning device for cleaning excess powder remaining on the surface of the hole plate. The production equipment further comprises a movable suction head and a transfer printing table, and the transfer printing table is provided with gluing materials. Theproduction equipment further comprises a vibration generator used for uniformly vibrating the powder apart on the bottom plate. Because characteristic particles are first evenly shaken apart by meansof vibration, the production equipment and the production method can eliminate the overlapping of the characteristic particles, and the characteristic particles can be evenly spread. By means of transfer printing, the equipment can transfer paper onto the gluing materials according to characteristic gravel required by different region shapes, thus solving the problems of uneven characteristic particles and irregular boundaries.

Owner:东莞市将为防伪科技有限公司

Method for prolonging service life of polycrystalline silicon chip minority carrier and reducing dislocation of polycrystalline silicon chip

InactiveCN105671634AAddressing inhomogeneityImprove conversion efficiencyPolycrystalline material growthSingle crystal growth detailsIngotPolycrystalline silicon

The invention relates to a method for prolonging service life of a polycrystalline silicon chip minority carrier and reducing dislocation of a polycrystalline silicon chip. The method comprises the following steps: preparing a raw material, loading the raw material into a crucible, and sending into an ingot furnace; carrying out the heating process; carrying out the melting process; carrying out the crystal growth process; carrying out the annealing process; and carrying out the cooling process, and after the cooling, opening the ingot furnace to obtain ingot polycrystals. The method solves the problems that the polycrystalline chip crystal particle is increased, the dislocation is increased, and the minority carrier is non-uniform and low and has the characteristics of high whole ingot conversion efficiency and low production cost.

Owner:JIANGXI SORNID HI TECH

Magnetic control arc ion plating composite depositing process and magnetic control arc ion plating composite depositing device

ActiveCN103540900AImprove film qualityAddressing inhomogeneityVacuum evaporation coatingSputtering coatingPhysicsIon

The invention belongs to the field of surface modification of materials, and particularly relates to a magnetic control arc ion plating composite depositing process and a magnetic control arc ion plating composite depositing device for controlling the movement velocity of a cathode spot, restraining the transmission of plasma, enhancing the deposition rate and deposition uniformity of a thin film, reducing the spraying of large granules positioned on the surface of a target material and enhancing the etching uniformity of the target material. The arc ion plating device is provided with two magnetic field generation devices, one is arranged behind the target material, and the other one is arranged at the outer side of a plasma transmission channel; thin film deposition is accessorily carried out on the surface of a base body through a coupling magnetic field generated by the two magnetic field generation devices. The magnetic control arc ion plating composite depositing process disclosed by the invention can reduce the spraying of the large granules positioned on the surface of the target material and the quantity of the large granules contained in the thin film through the coupling magnetic field generated by the two coupled magnetic field generation devices, thereby solving the problem of nonuniformity of the plasma on a transmission space in the traditional process, enhancing the utilization ratio of the plasma, enhancing the deposition rate of the thin film and the thickness uniformity of the thin film and providing the effective guarantee for preparing various high-property thin films.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Cabazitaxel phospholipid composition, preparation method thereof and application

ActiveCN107158395AIncrease in vivo and in vitro stabilityReduce leakageOrganic active ingredientsPharmaceutical non-active ingredientsLipid formationSide effect

The invention discloses a cabazitaxel phospholipid composition, a preparation method thereof and an application. The cabazitaxel phospholipid composition comprises a cabazitaxel lipid complex, phospholipid and cholesterol and solves the problems that drugs are unstable, preparation steps before clinical use are complicated, an existing lipid preparation has poor in vitro and vivo stability and the like, in vivo circulation time of the drugs is prolonged, the composition has a certain targeting function, the drugs are enriched on a tumor site, toxic and side effects are reduced, and bioavailability is greatly improved.

Owner:SHANGHAI INST OF MATERIA MEDICA CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com