Magnetic control arc ion plating composite depositing process and magnetic control arc ion plating composite depositing device

An arc ion plating and deposition process technology, applied in ion implantation plating, metal material coating process, sputtering plating and other directions, can solve problems such as stability reduction, reduce emission, expand adjustment range, and improve deposition rate and deposition uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

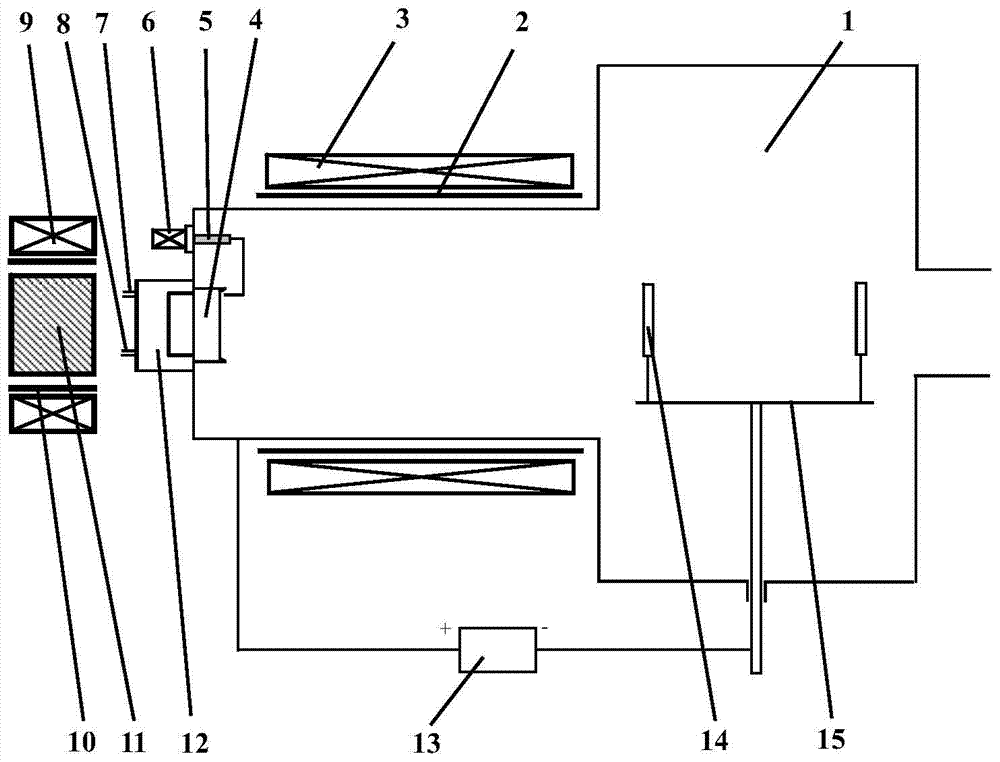

[0028] In this embodiment, the arc ion coating device such as figure 1 As shown, the arc ion plating device mainly includes: a vacuum chamber 1, a plasma confinement electromagnetic coil support cylinder 2, a plasma confinement electromagnetic coil 3, a target material 4, an arc strike needle 5, an arc strike coil 6, a water outlet pipe 7, Water inlet pipe 8, arc spot restraining electromagnetic coil 9, arc spot restraining electromagnetic coil support cylinder 10, nickel-plated pure iron 11, water cooling jacket 12, pulse bias power supply 13, workpiece 14, workpiece table 15, etc. The specific structure is as follows:

[0029]One end of the target material 4 extends into the vacuum chamber 1, and the other end of the target material 4 is provided with a water cooling jacket 12, which is connected with a water outlet pipe 7 and a water inlet pipe 8 to form a circulating water cooling structure for the target material 4. One end of the arc starting needle 5 in the vacuum chamb...

Embodiment 2

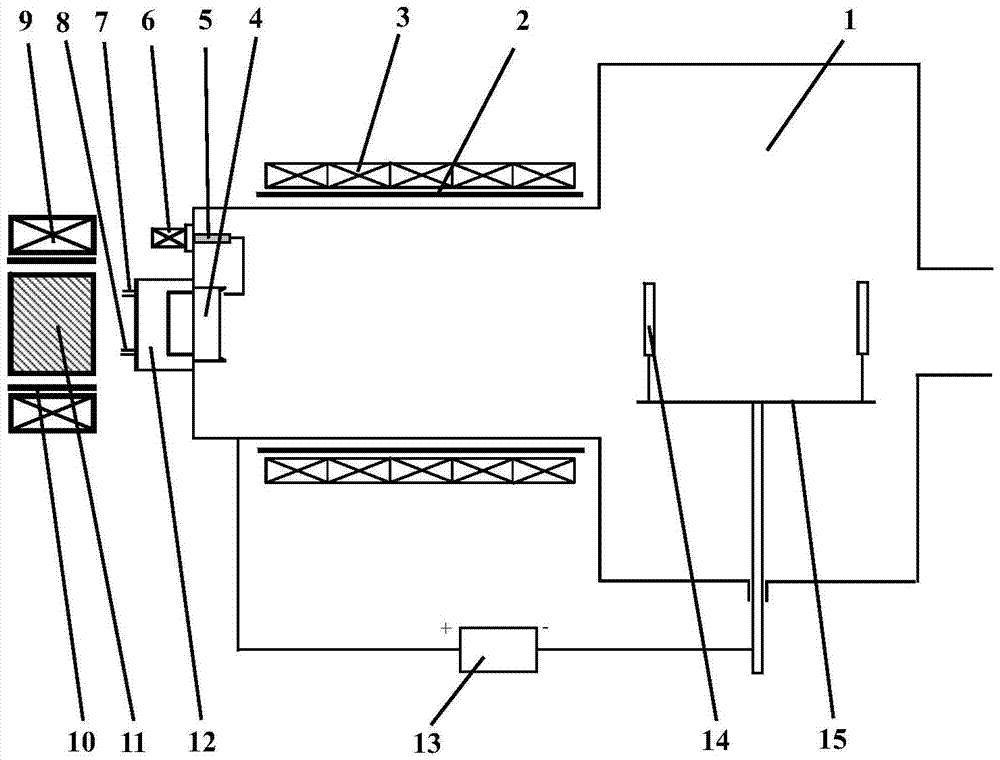

[0034] The difference from Embodiment 1 is that the plasma confinement electromagnetic coil 3 is composed of several electromagnetic coils, the magnetic inductions of these electromagnetic coils are adjusted respectively, and their sizes gradually decrease along the direction of the plasma beam. Its specific deposition device is as figure 2 shown, with figure 1 The difference is that the magnetic field of the workpiece plasma confinement electromagnetic coil 3 in this embodiment adopts a gradient magnetic field. The gradient magnetic field means that the magnetic field generating device placed outside the vacuum chamber on the plasma transmission channel is 4 electromagnetic coils. The wire diameter of the electromagnetic coil, The winding density and other parameters are the same, and the magnetic induction intensity of these electromagnetic coils is realized by adjusting the magnitude of the electromagnetic coil current respectively, and the magnetic induction intensity gra...

Embodiment 3

[0038] This embodiment adopts as figure 1 In the arc ion plating device shown, the substrate is made of cemented carbide (brand YT5), the size of the sample is 20mm×10mm×10mm, and the size of the coating surface is 20mm×10mm. Before coating, the surface of the base material is ground, polished, ultrasonically cleaned and dried, and then placed on the workpiece table in the vacuum chamber. In this embodiment, the target material is a titanium-aluminum (50at.%:50at.%) alloy target. Vacuum until the vacuum degree in the vacuum chamber reaches 5×10 -3 At Pa, argon gas is supplied, the air pressure is controlled at 1.0Pa, the arc spot confinement electromagnetic coil current is adjusted to 3.0A, the plasma confinement electromagnetic coil current is 5.0A, the magnetic induction intensity is 500 Gauss and 800 Gauss respectively, and the workpiece is pulsed with negative bias. -600V, perform glow cleaning on the workpiece for 10 minutes; then, adjust the Ar gas flow rate, adjust th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Microhardness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com