Water-based wood paint for padding and preparation method thereof

A technology for water-based wood lacquer and color repair, which is applied to coatings, anti-corrosion coatings, etc., can solve the problems of difficult factoryization of water-based wood lacquer, difficulty in construction of water-based wood ware, and difficulty in achieving decorative effects, etc., and achieves good interlayer adhesion. Reduce the number of times, the effect of uniform wood grain coloring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

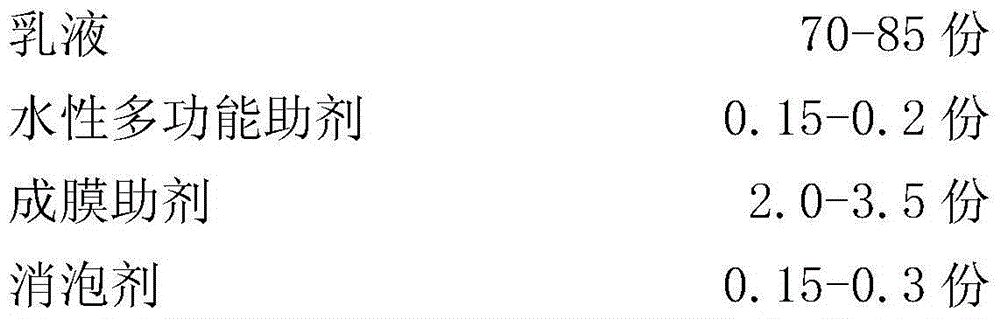

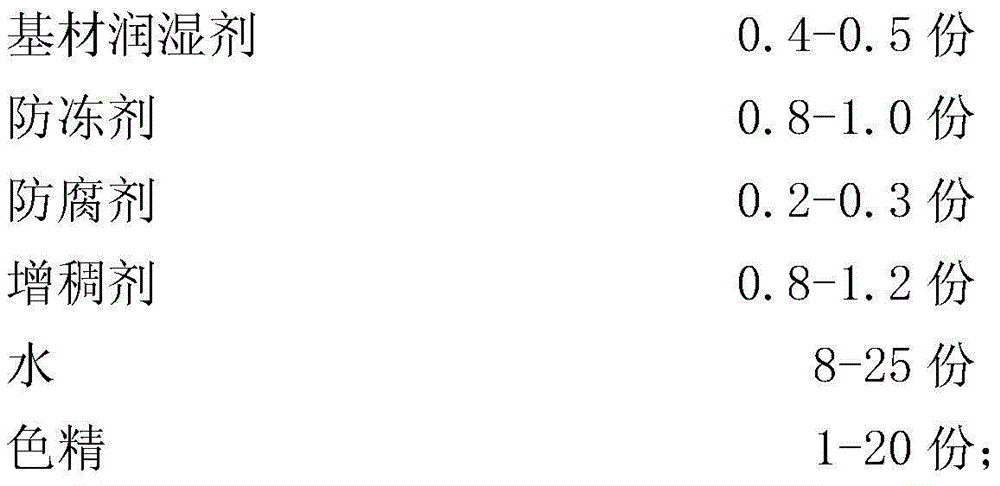

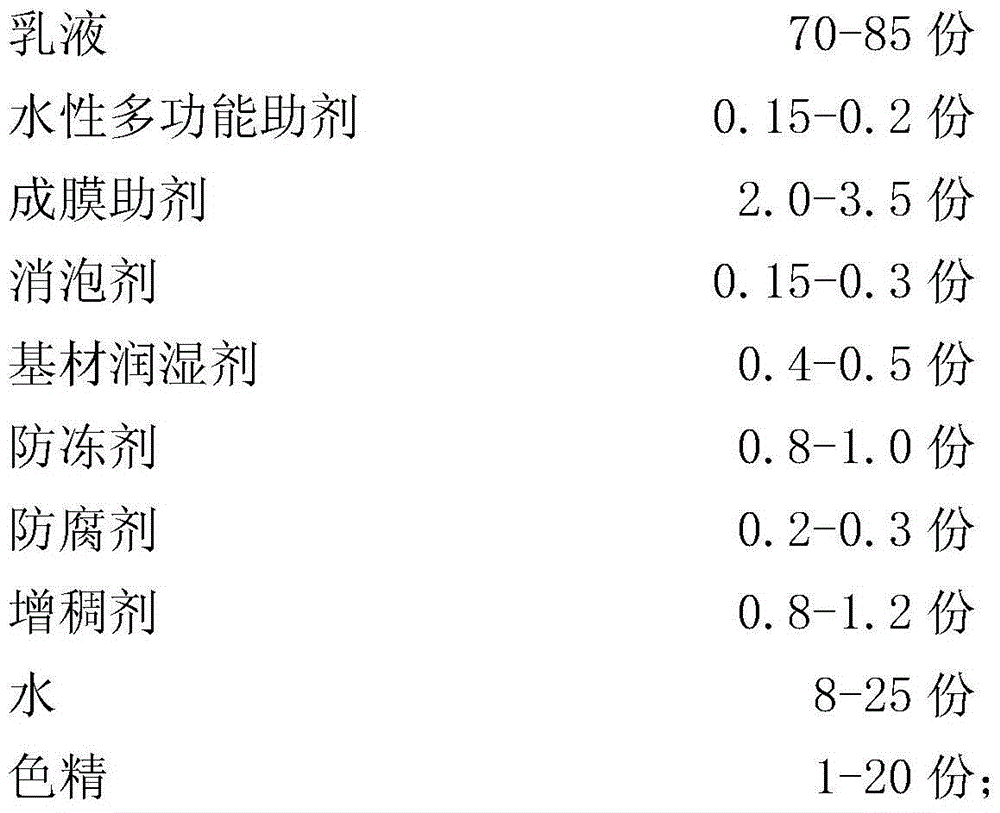

[0023] A color-repairing water-based wood lacquer formulated from the following components and weight / number ratios:

[0024]

[0025] The emulsion is an alkali-soluble acrylic emulsion.

[0026] A kind of preparation method of the water-based wood lacquer of repairing color, it comprises the steps:

[0027] Add 70-85 parts of emulsion into the dispersion tank, and add 0.15-0.2 parts of water-based multifunctional additives, 2.0-3.5 parts of film-forming additives, 0.15-0.3 parts of defoamers, 0.4- 0.5 parts of substrate wetting agent, 0.8-1.0 parts of antifreeze, 0.2-0.3 parts of preservative, 0.8-1.2 parts of thickener, 8-25 parts of water and 1-20 parts of color essence, after dispersing for 20-30 minutes Get a color-retouching water-based wood finish.

[0028] The emulsion described in the above components adopts the BT-24 emulsion of Dishman. The water-based multifunctional additive adopts Dow's AMP-95 multifunctional additive. The film-forming aid adopts DPNB or D...

Embodiment 1

[0030] Embodiment 1: a kind of water-based wood lacquer of repairing color, is formulated by following component and weight and number ratio:

[0031]

[0032] A kind of preparation method of the water-based wood lacquer of repairing color, it comprises the steps:

[0033] Put 80 parts of emulsion into the dispersion tank, add 0.15 parts of water-based multifunctional additives, 3.0 parts of film-forming additives, 0.25 parts of defoamers, 0.45 parts of substrate wetting agents, and 1.0 parts of antifreeze at a speed of 900 r / min , 0.2 parts of preservatives, 1.0 parts of thickener, 13.95 parts of water and 10 parts of color essence, after dispersing for 25 minutes, the water-based wood paint for color correction can be obtained.

[0034] The emulsion described in the above components adopts the BT-24 emulsion of Dishman. The water-based multifunctional additive adopts Dow's AMP-95 multifunctional additive. The film-forming aid adopts DPNB or DPM film-forming aid of Eastm...

Embodiment 2

[0035] Embodiment 2: a kind of water-based wood paint of repairing color, is formulated by following component and weight and number ratio:

[0036]

[0037] A kind of preparation method of the water-based wood lacquer of repairing color, it comprises the steps:

[0038] Add 70 parts of the emulsion into the dispersion tank, add 0.2 parts of water-based multifunctional additives, 2.0 parts of film-forming additives, 0.15 parts of defoamers, 0.5 parts of substrate wetting agents, and 0.8 parts of antifreeze at a speed of 800 r / min , 0.3 parts of preservative, 1.2 parts of thickener, 25 parts of water and 1 part of color essence, after dispersing for 30 minutes, the water-based wood paint for color correction can be obtained.

[0039] The emulsion described in the above components adopts the BT-24 emulsion of Dishman. The water-based multifunctional additive adopts Dow's AMP-95 multifunctional additive. The film-forming aid adopts DPNB or DPM film-forming aid of Eastman Che...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com