Production equipment and production method of anti-counterfeit prints

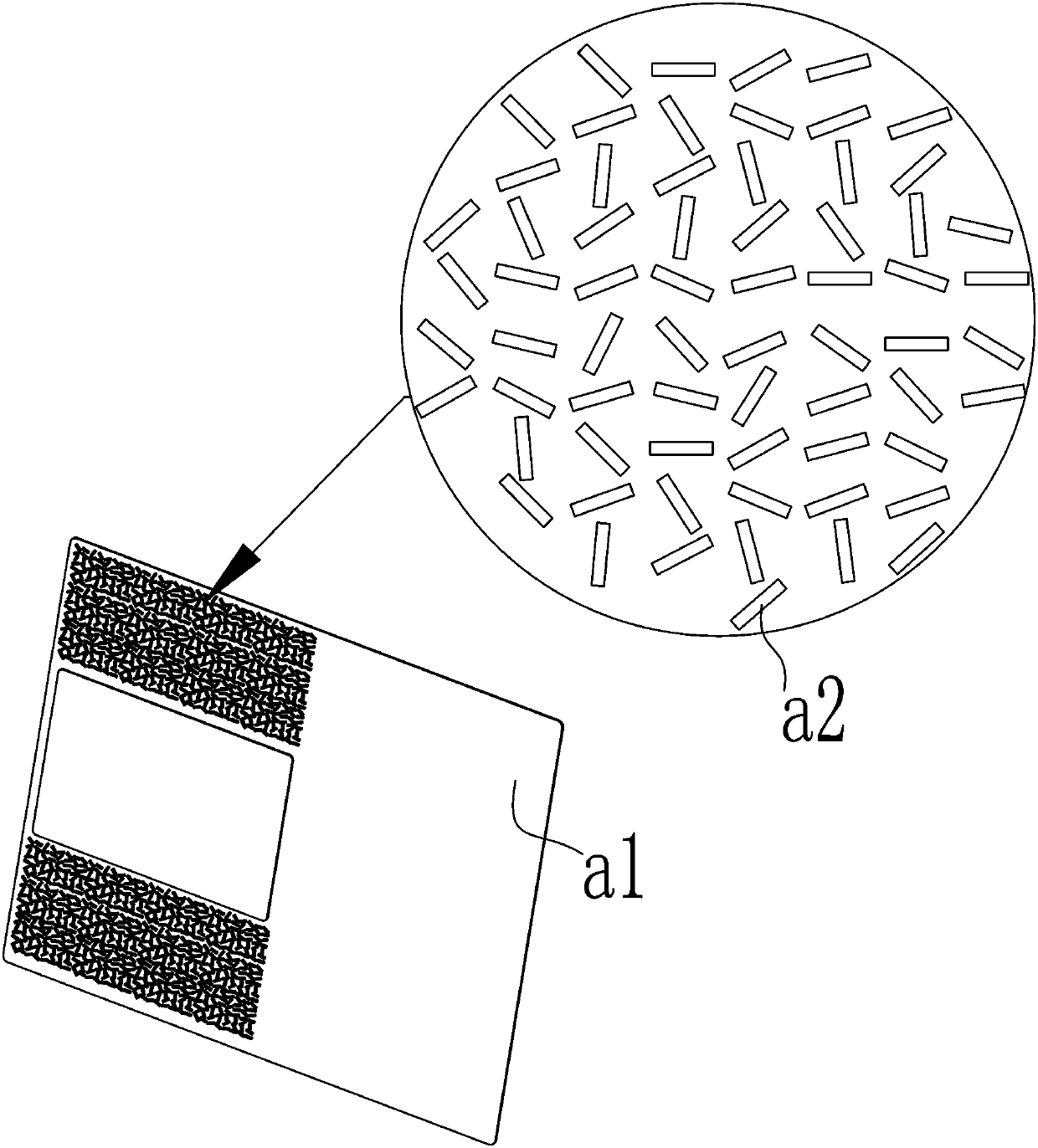

A technology of production equipment and production method, which is applied to the device and coating of the surface coating liquid, which can solve the problems of uneven powder, uneven characteristic particles, height difference, etc., and achieve the solution of irregular boundaries and characteristic Particle uneven effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

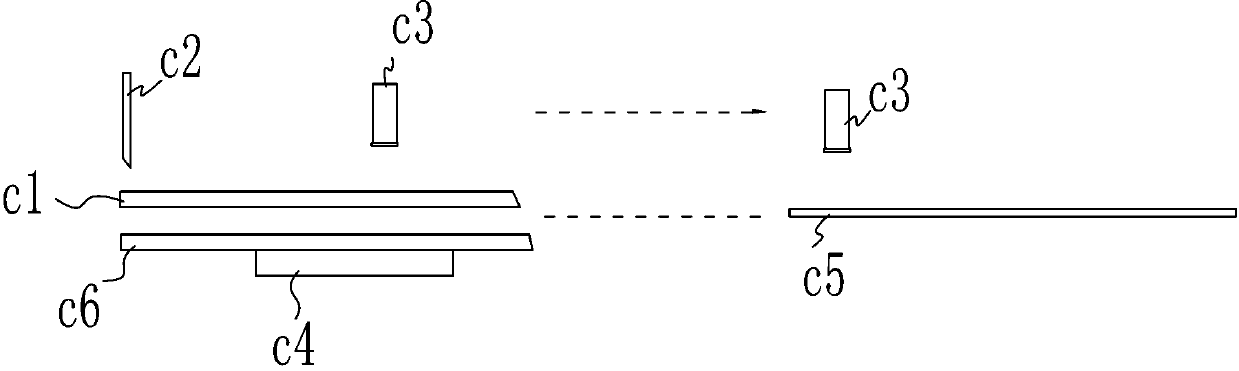

[0037] Example 1, such as figure 2 and 3 as shown,

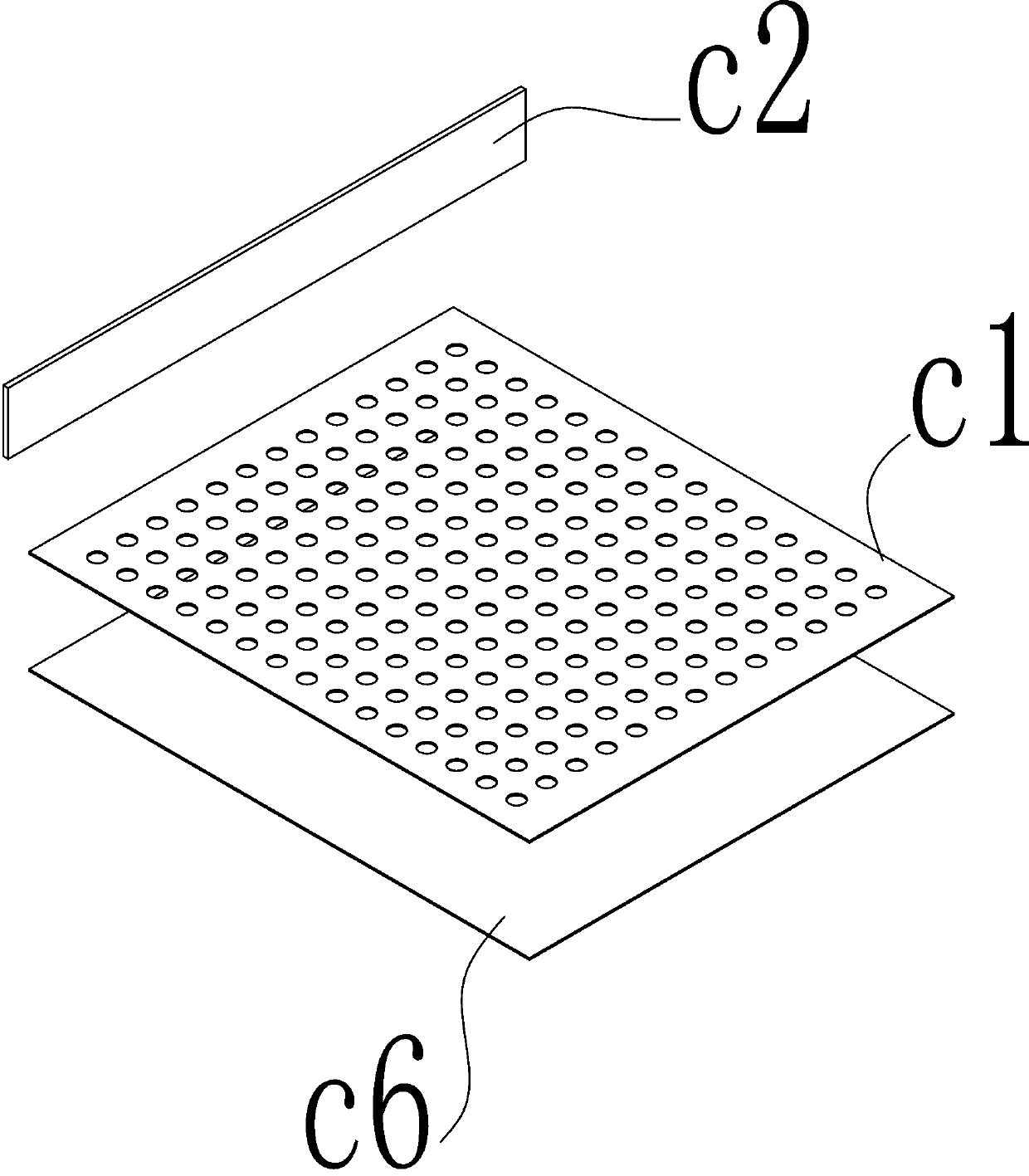

[0038] The production equipment of a kind of anti-counterfeiting printed matter described in this embodiment includes a bottom plate c6, an orifice c1 located above the bottom plate c6, the orifice c1 is provided with at least one hole; The powder spreading unit d1 for dusting and the cleaning device c2 for cleaning the excess powder remaining on the surface of the orifice c1; it also includes a movable suction head c3 and a transfer table c5, and the transfer table c5 is equipped with Gluing material d4; also includes a vibration generator c4 for evenly vibrating the powder on the bottom plate c6; a kind of production equipment for anti-counterfeiting printed matter described in this embodiment, how many holes are there on the orifice plate c1? a plurality of holes arranged in a matrix. In the production equipment for anti-counterfeit printed matter described in this embodiment, the cleaning device c2 is a scraper; when...

Embodiment 2

[0041] Example 2, such as Figure 9 As shown, this embodiment is an example of a specific implementation. The bottom plate c6 is attached to the orifice c1; the scraper and the powder spreading unit d1 move above the orifice c1 through the first track d2 respectively, and the suction head c3 moves along the second track d2. The track d3 can move in the area above the orifice c1 and the area above the transfer table c5, and the suction head c3 can be lowered to a specified distance, and the suction head c3 can be driven down by a cylinder. A glue-coating material d4 is provided on the transfer table c5, specifically, glued paper.

[0042] In the production equipment for anti-counterfeit printed matter described in this embodiment, the suction head c3 is a special suction head c3. It can be seen from the figure that the characteristic particle a2 is generally a particle with a thickness, such as a rectangle, etc., so when grabbing It can be adsorbed on the bottom of the suction...

Embodiment 3

[0045] Example 3 of suction head c3: a suction head for characteristic particulate matter a2 powder, including a suction head body b1, a button cover b3 is movably connected to the bottom of the suction head body b1, and a shape opening b4 is opened on the button cover b3. A gauze or mesh panel is pasted on the bottom of b3.

[0046] Tip c3 Example 4: as Figure 8 As shown, a characteristic particle a2 powder suction head includes a suction head body b1, and a mesh component b2 is movably connected to the bottom of the suction head body b1, and the mesh component b2 is a gauze or a mesh with small holes plate, the mesh component b2 is divided into an air-permeable area and a non-air-permeable area, and the non-air-permeable area is coated with a coating to prevent air-breathing. The characteristic particle a2 is blocked by the net component b2 or the net plate when it is sucked, that is, the characteristic particle a2 is attached to the net component b2 or the net plate, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com