Patents

Literature

33results about How to "Solve bridging" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

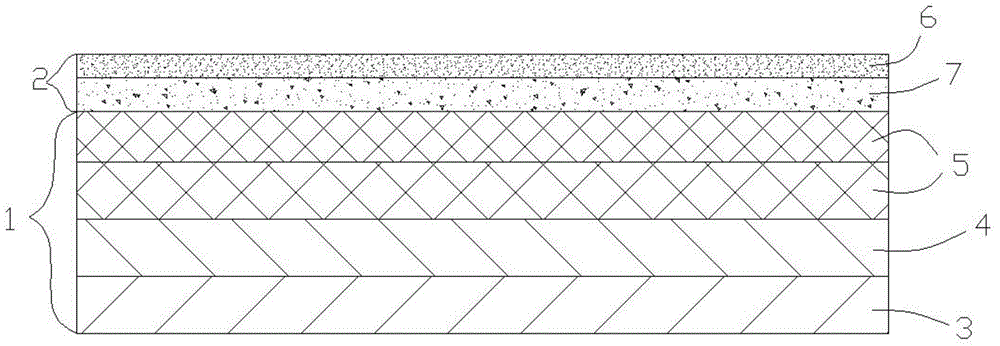

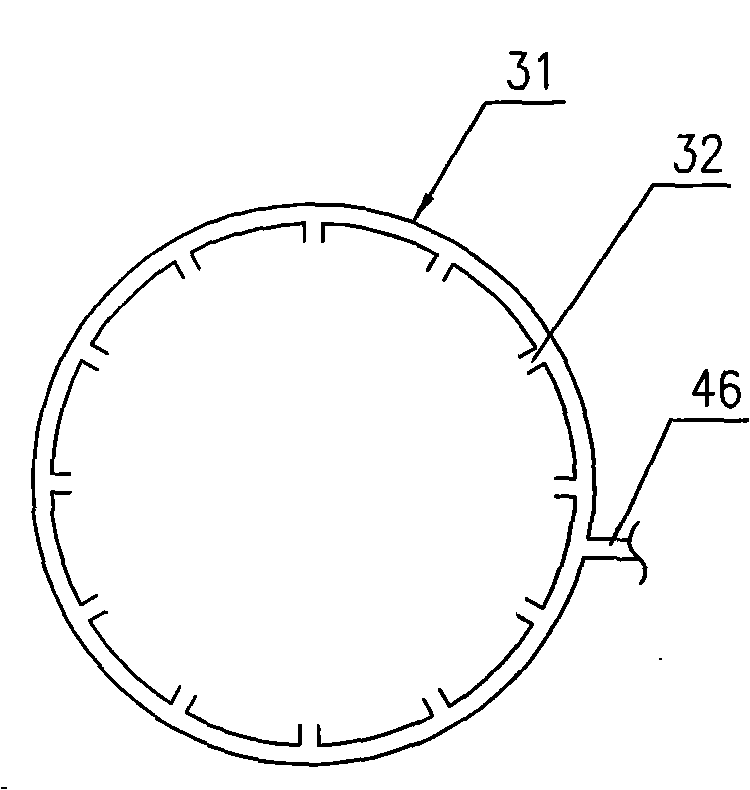

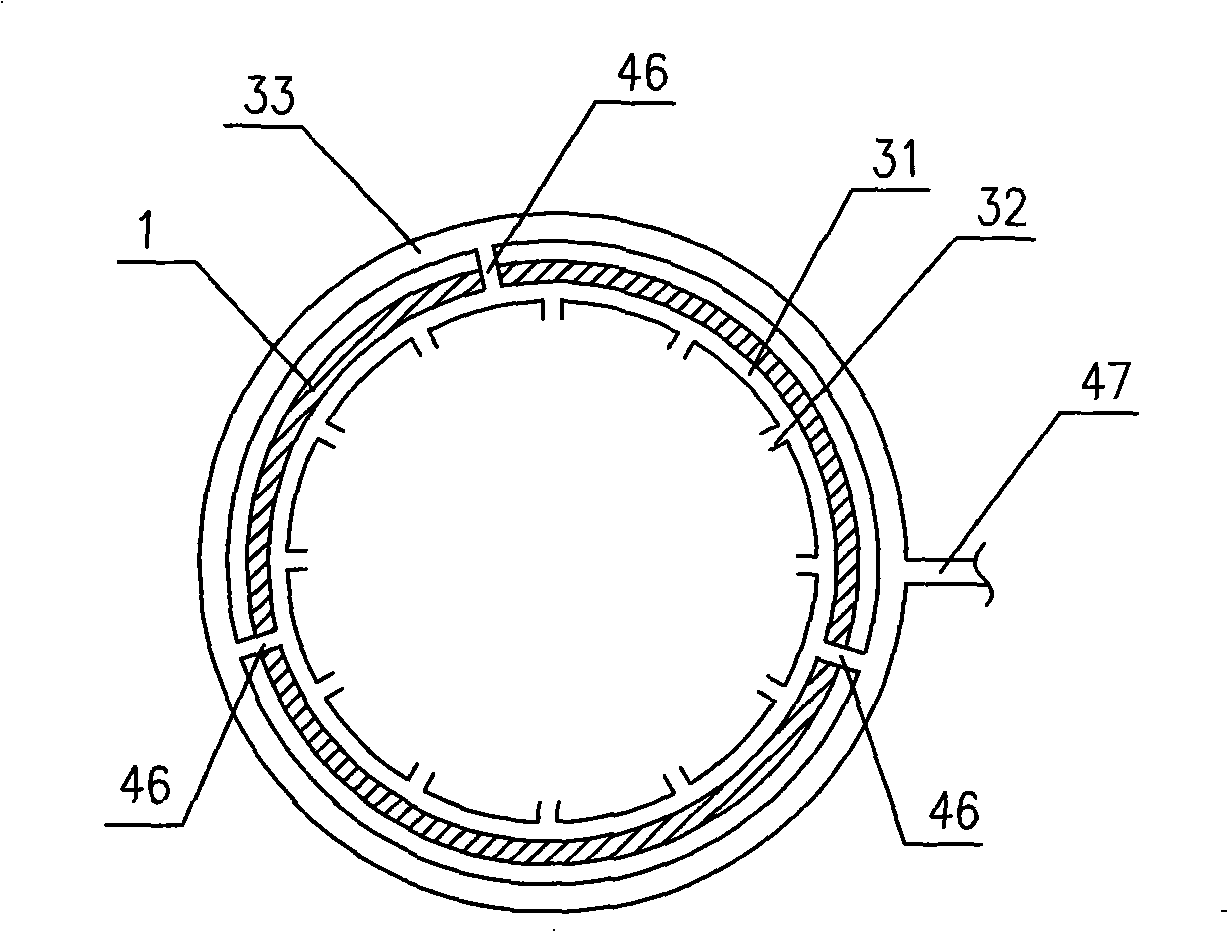

Metal powder and metal sintering mesh composite filter element and production method thereof

InactiveCN104857775AAddressing inhomogeneitySolve bridgingFiltration separationMetal layered productsMetallurgyWork in process

The invention discloses a metal powder and metal sintering mesh composite filter element which adopts a round pipe structure, and comprises a metal mesh layer and a metal powder layer which are formed through sintering in sequence from outside to inside; the metal mesh layer comprises an outer dutch wire mesh, an inner dutch wire mesh and a plurality of plain meshes; the outer dutch wire mesh and the inner dutch wire mesh are consistent in structure, and vertically crossed and stacked according to lines; the plain meshes are arranged between the inner surface of the inner dutch wire mesh and the metal powder layer. The production method comprises the following steps: 1) arranging the metal layers, 2) sintering the metal layers, 3) preparing suspension slurry, 4) preparing the metal powder layer, 5) sintering a semi-finished product, and 6) pressing the finished product. The metal powder and metal sintering mesh composite filter element has the advantages of being small in filter resistance, high in fluid flux, strong in regeneration capacity, long in service cycle, and especially suitable for being used continuously during the process of production technology, needing continuous operation, of petrochemical engineering and the like.

Owner:徐小平

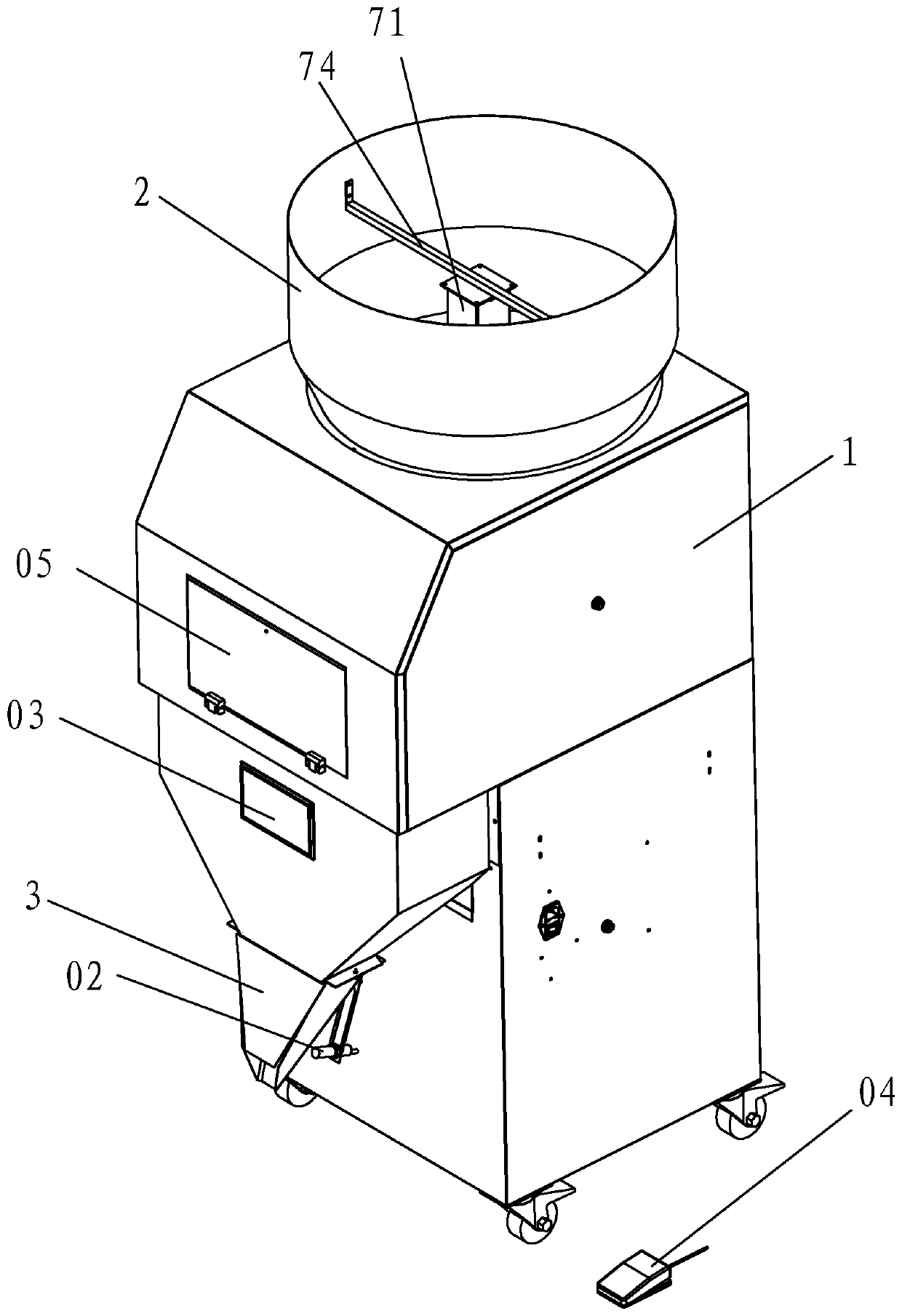

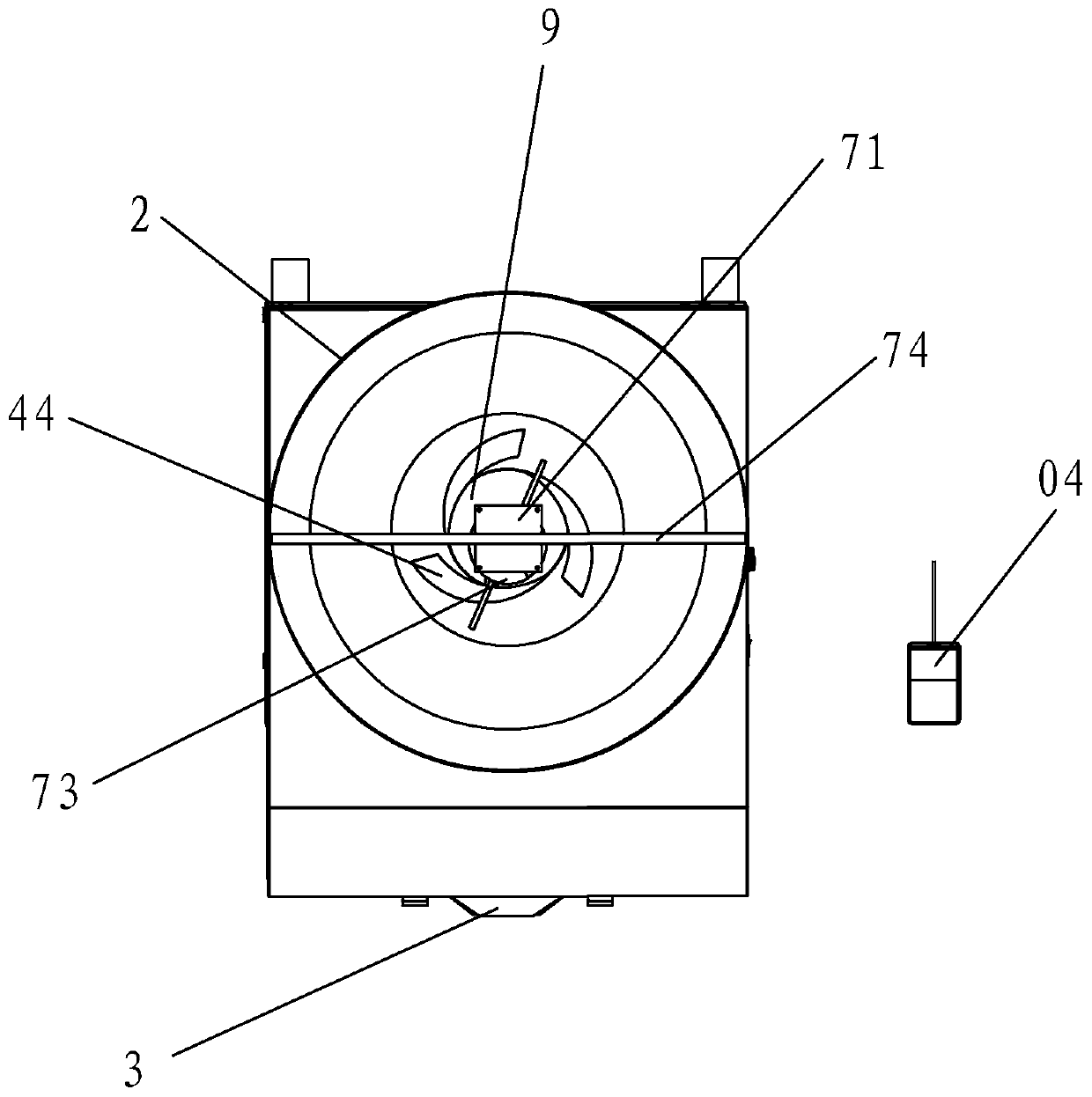

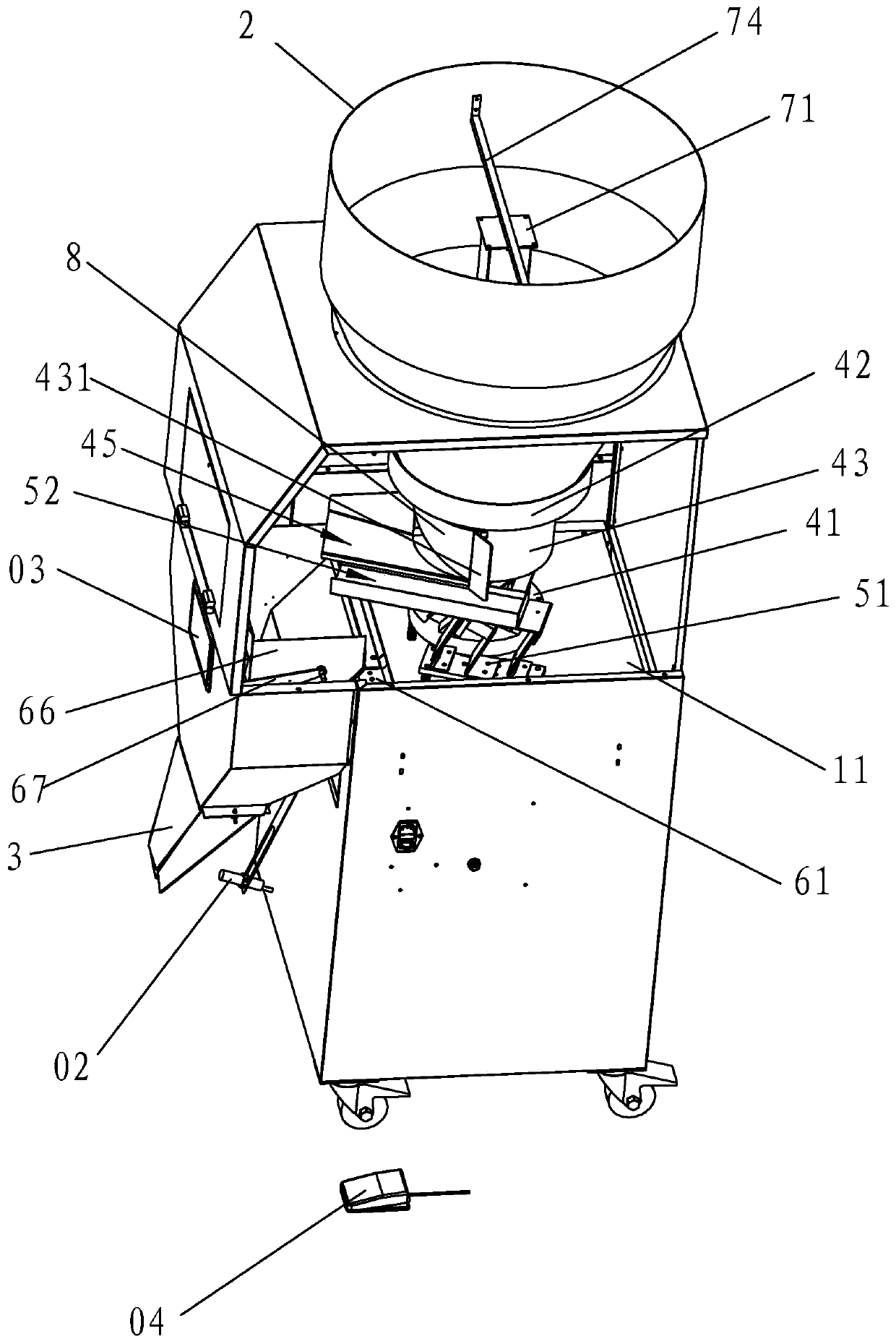

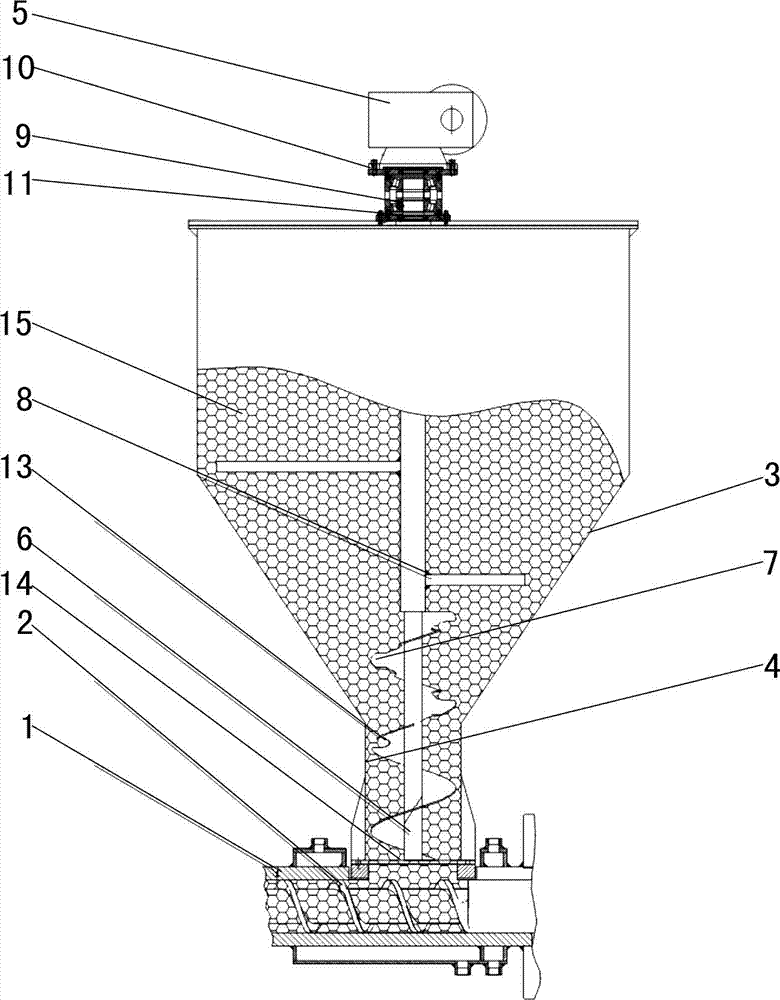

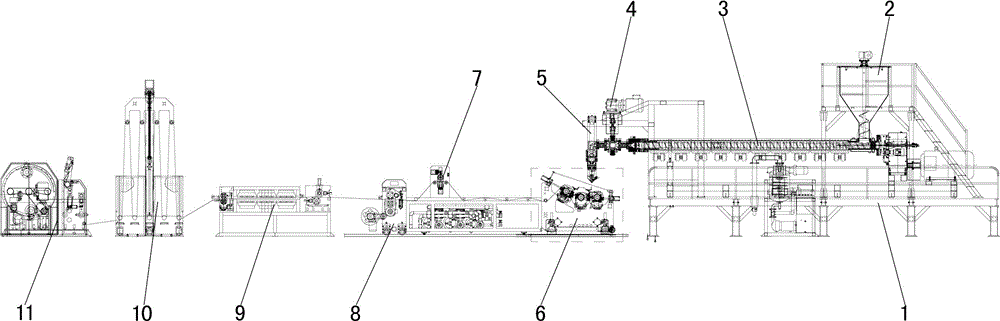

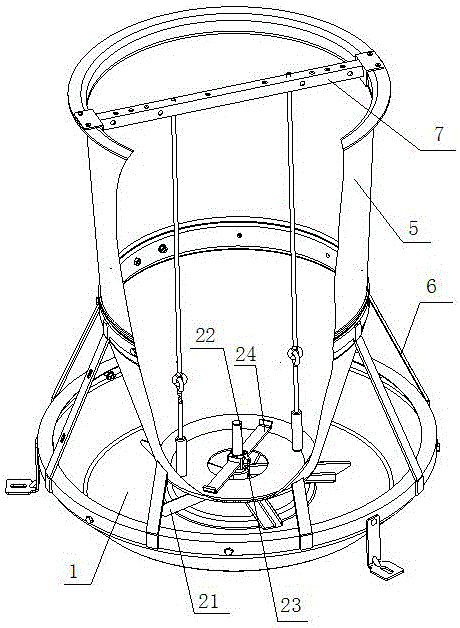

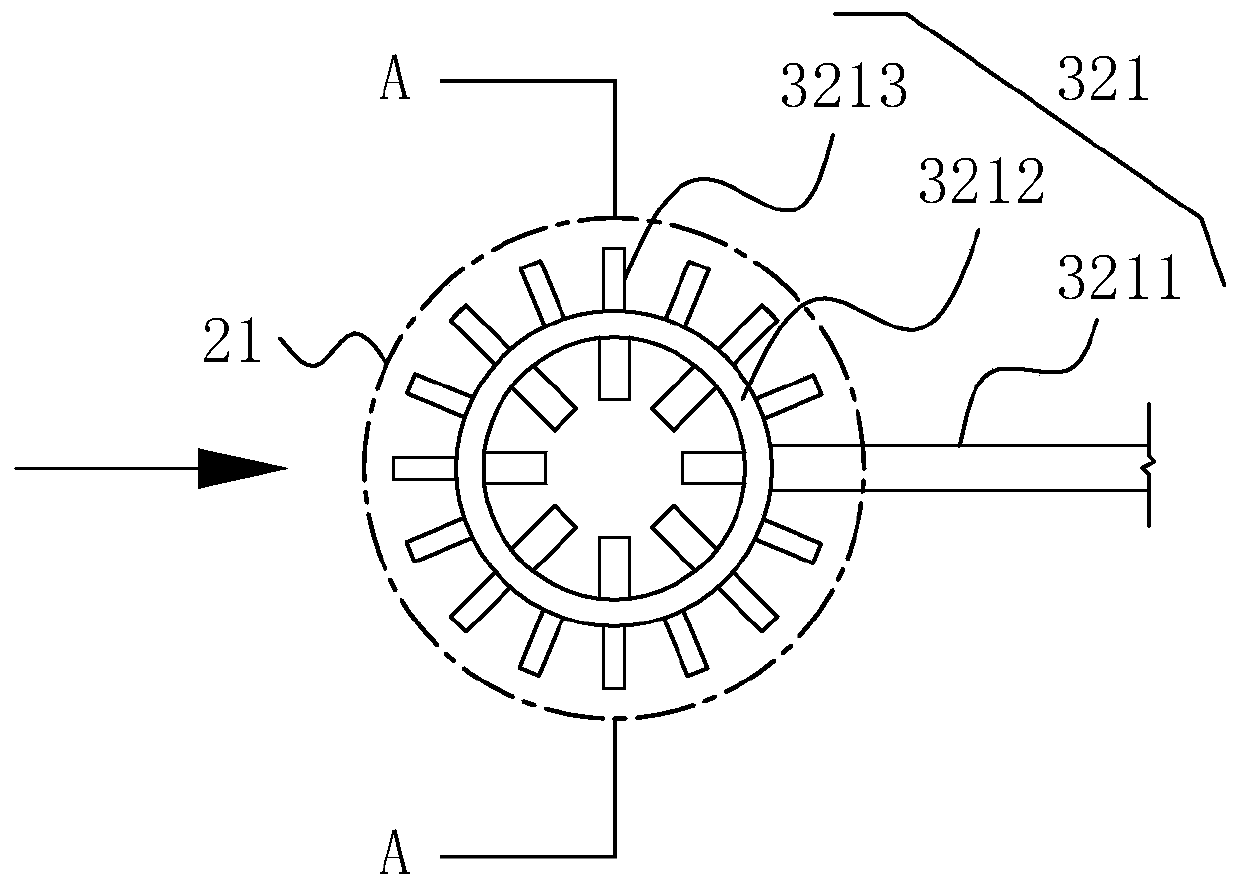

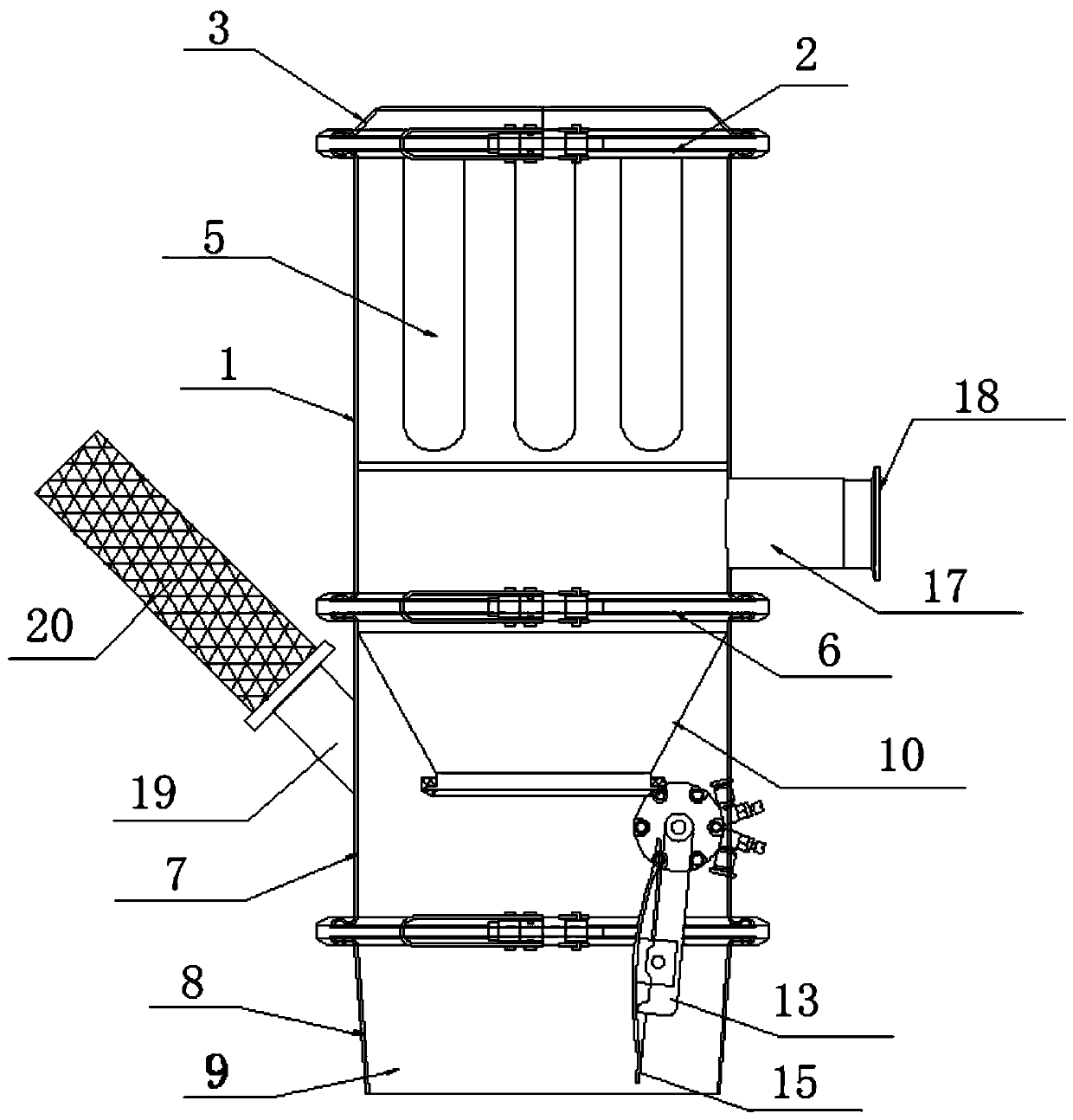

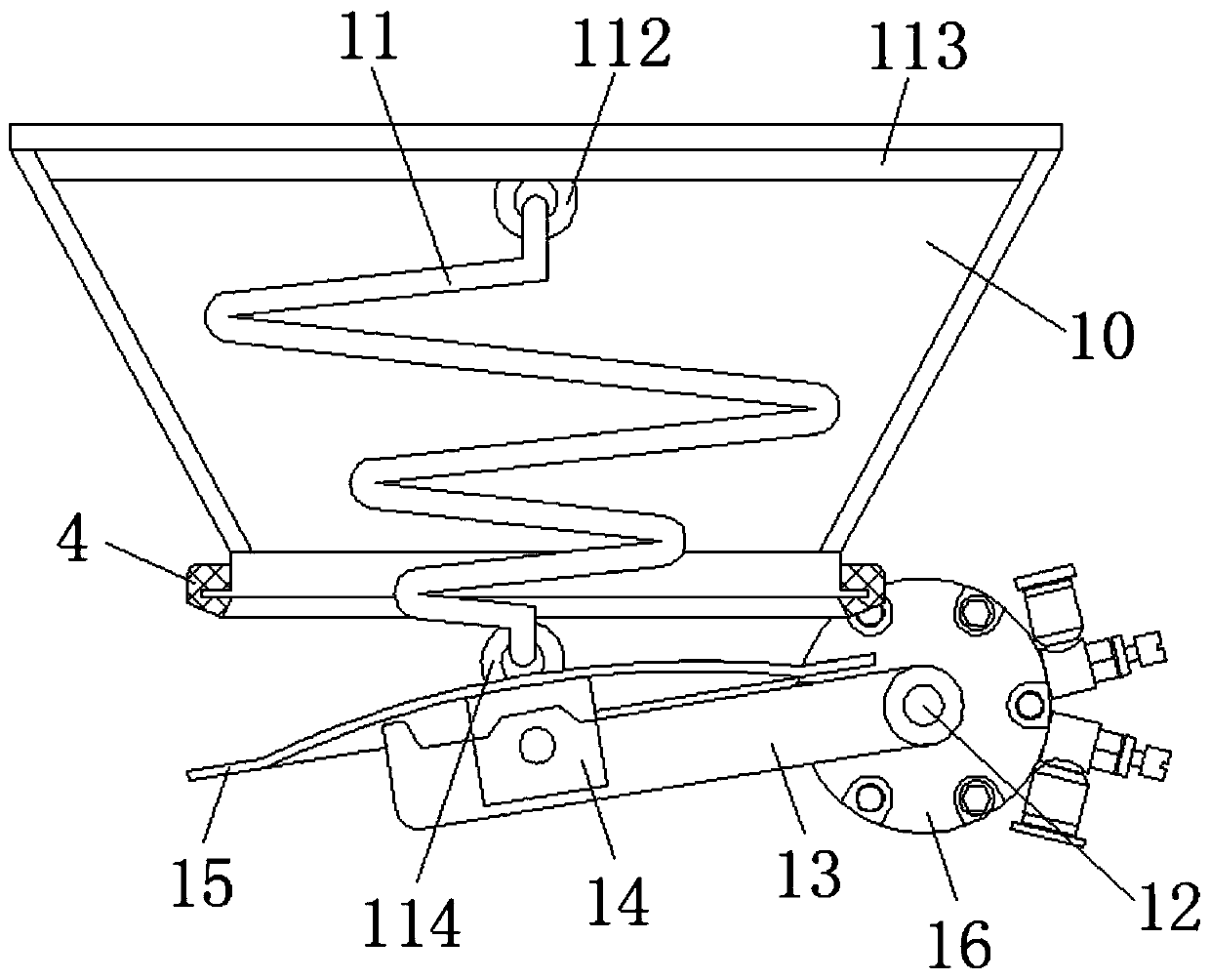

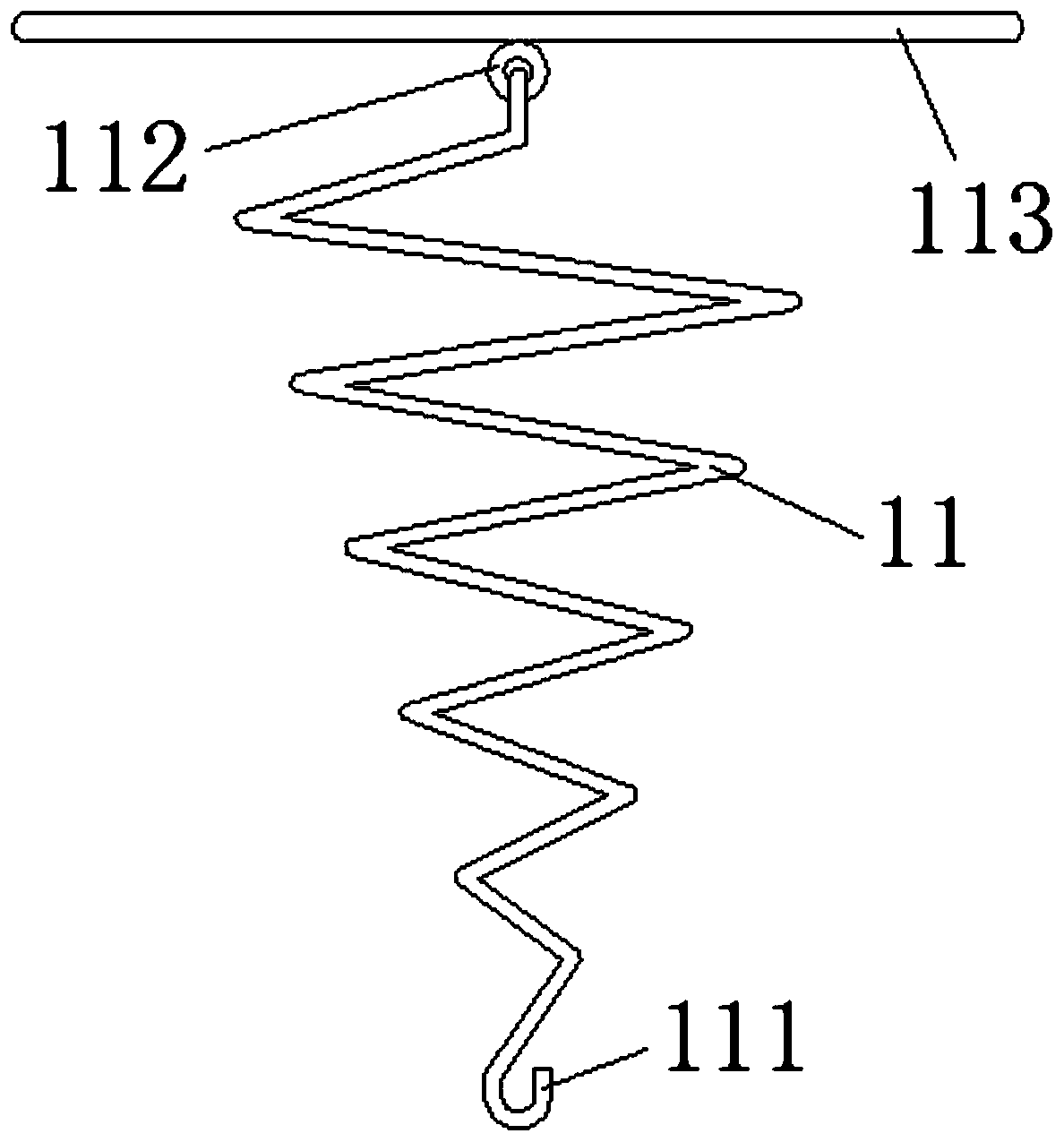

Precise discharging and distributing machine for strip-shaped and block-shaped materials suitable for clamping and bridging

PendingCN111547281ASolve bridgingSolve difficult cuttingSolid materialPackaging automatic controlEngineeringMechanical engineering

The invention discloses a precise discharging and distributing machine for strip-shaped and block-shaped materials suitable for clamping and bridging. The precise discharging and distributing machinecomprises a box body and a first conical hopper which is installed on the box body, wherein a vibrating discharging device and a weighing device are installed in the box body; a discharging hopper isinstalled on the box body; the vibrating discharging device comprises a vibrating main body A, a second conical hopper and a discharging barrel; the discharging barrel is a cylindrical chamber, and arightward opening is formed in the side wall of the discharging barrel; the discharging barrel is installed on the vibrating main body A; at least two guide pieces are arranged on the second conical hopper spirally from high to low; a material overturning device is installed in the first conical hopper; and a vibrating supplementing device comprises a vibrating main body B and a second discharginggroove structure. According to the precise discharging and distributing machine for the strip-shaped and block-shaped materials suitable for the clamping and the bridging, not only is the phenomenonof tea blocking in a feeding hopper effectively avoided, but also the phenomenon of inaccurate weighing caused by the fact that the discharging amount cannot be accurately controlled is also effectively avoided.

Owner:福建省泉州佳利机械科技有限公司

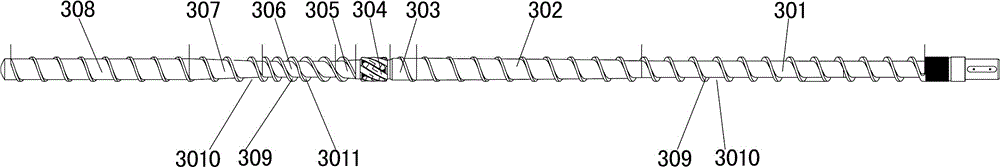

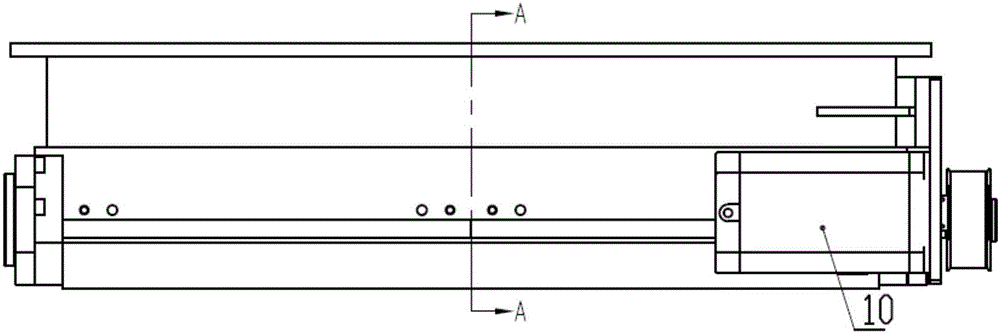

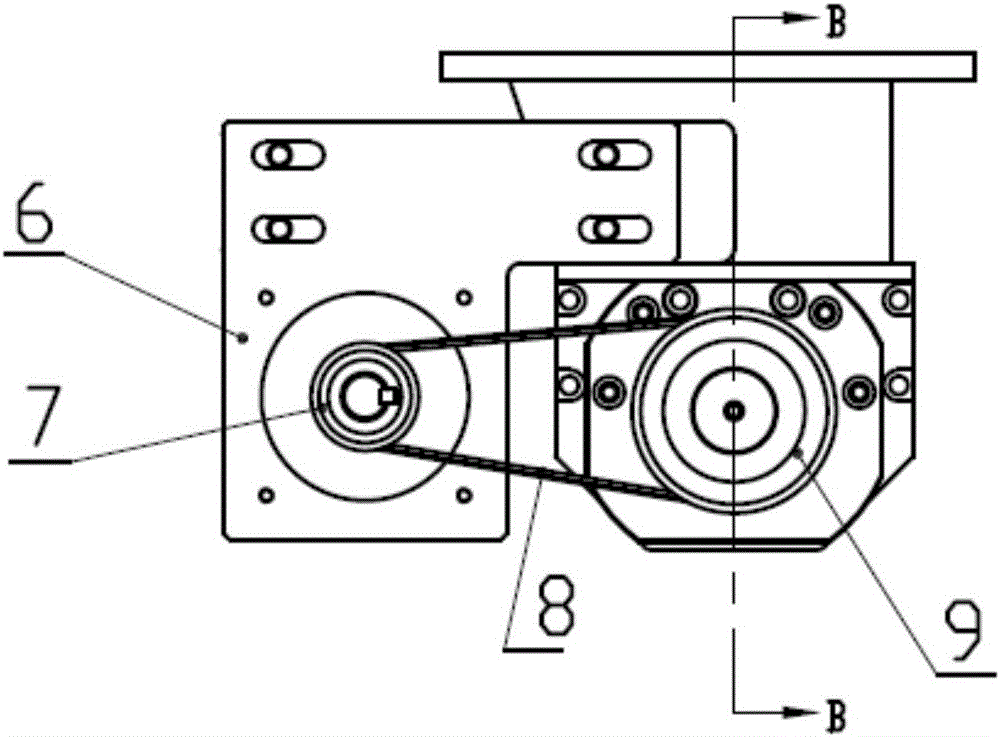

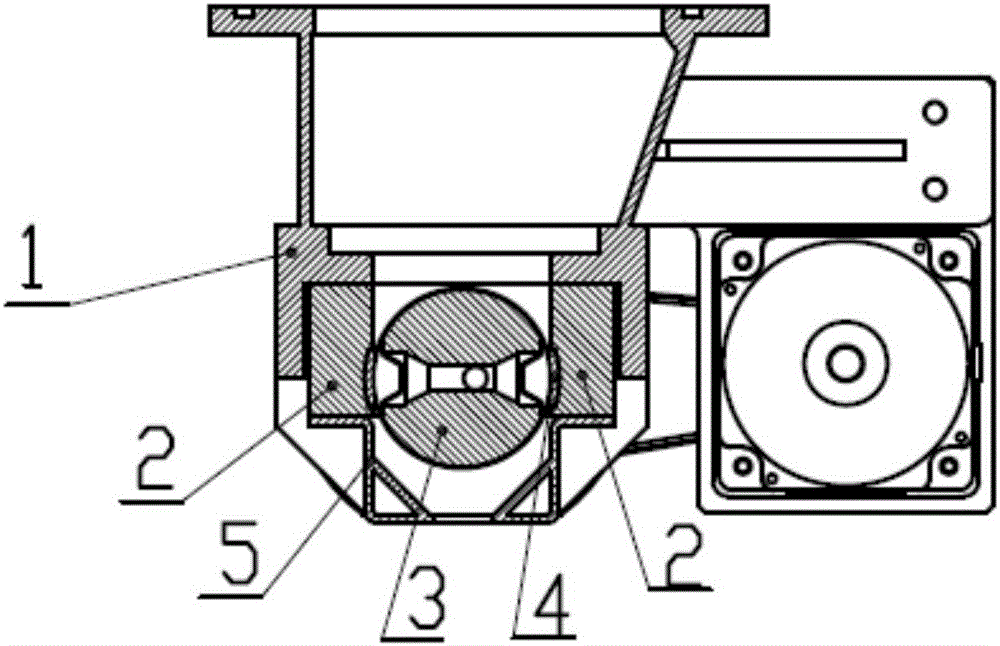

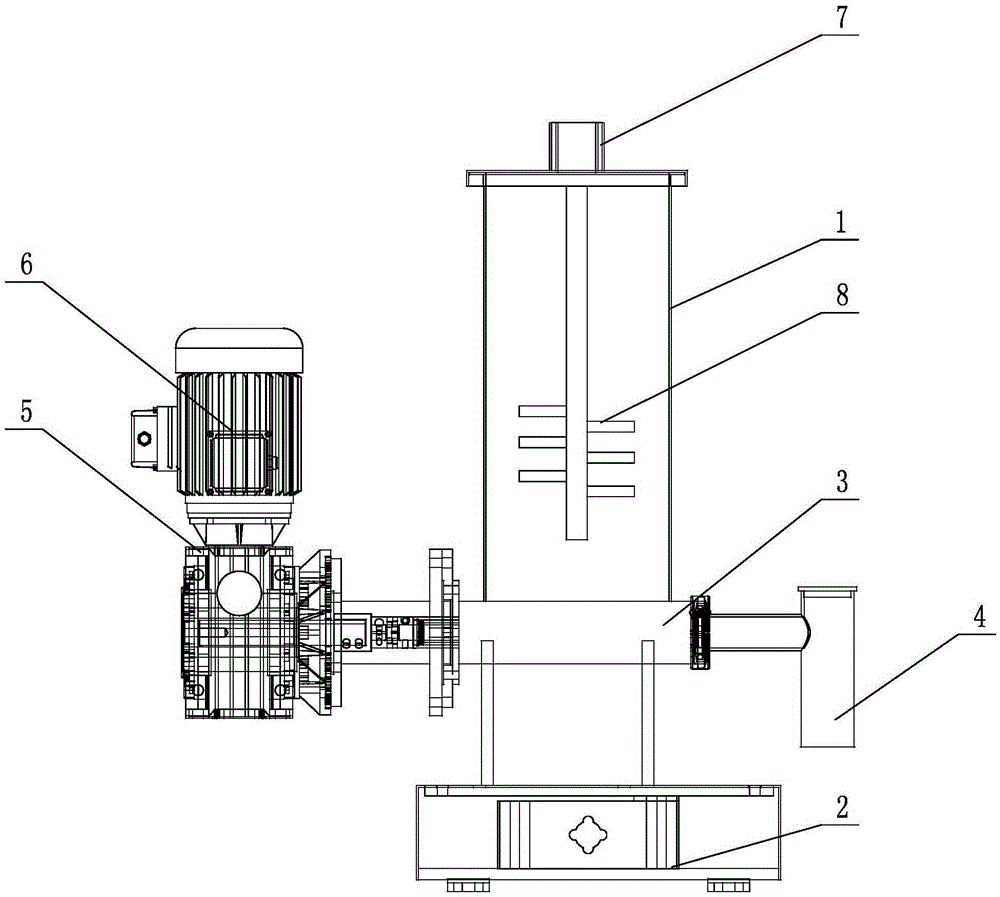

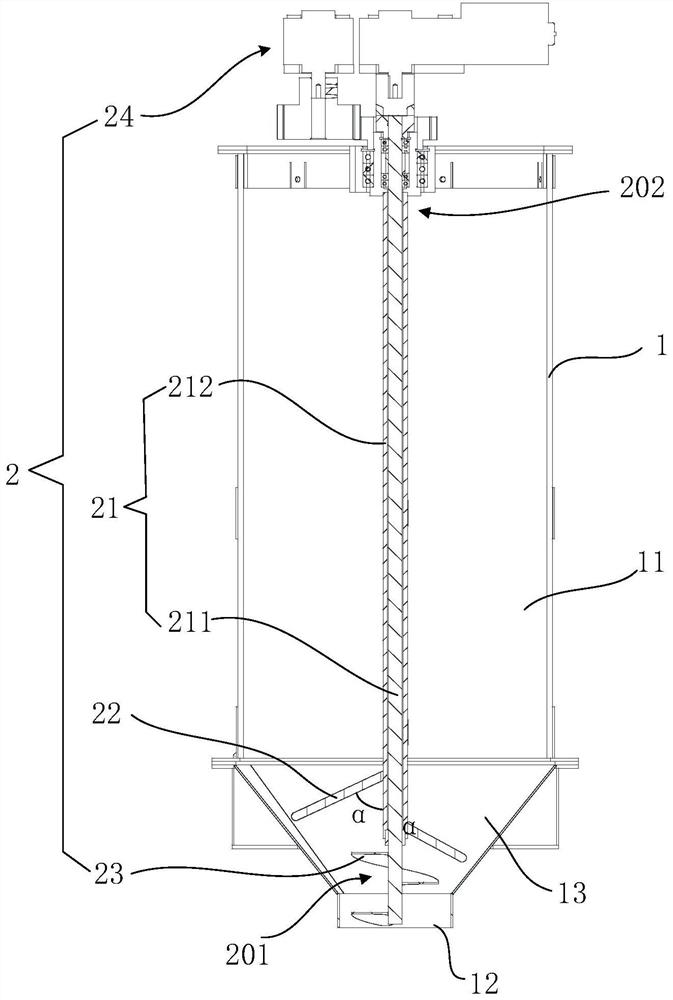

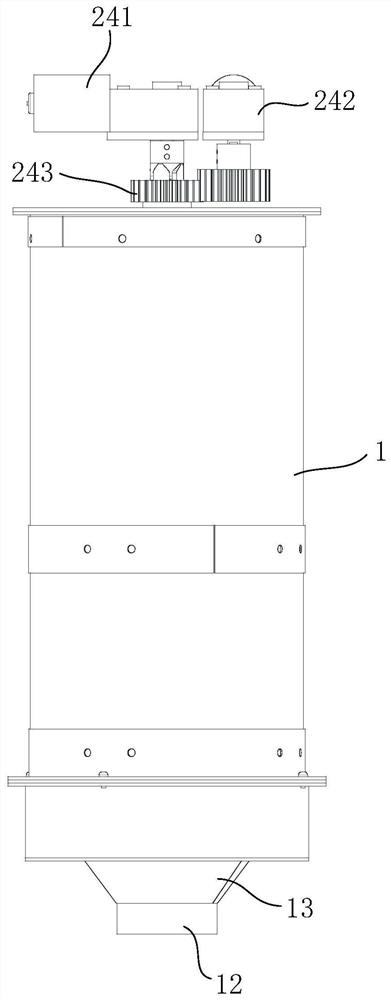

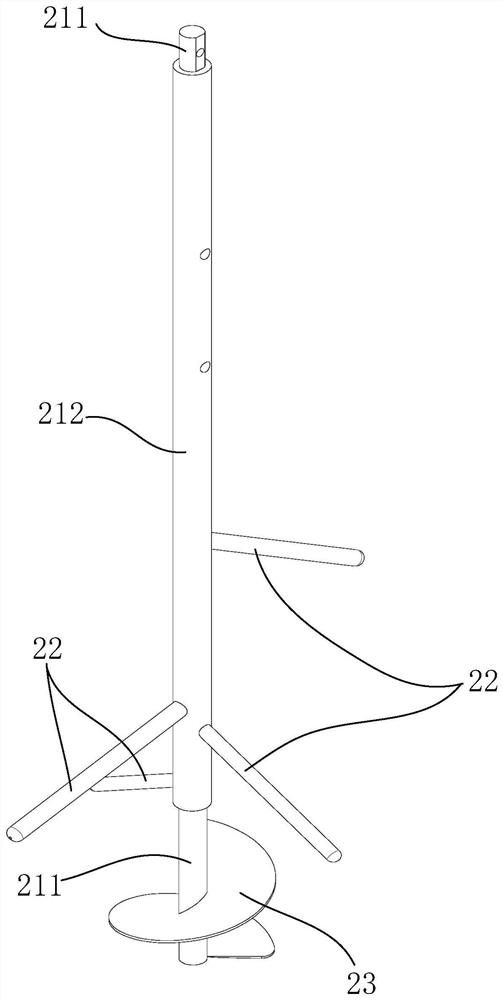

Spiral forced feeding device

The invention relates to a spiral forced feeding device. The spiral forced feeding device comprises a material conveying barrel, a material conveying screw, a material conveying motor, a material storage hopper, a material falling barrel, a propulsion motor, a propulsion shaft, a spiral propulsion blade and an anti-bridging shaft, wherein the material conveying screw is mounted in the material conveying barrel; the material conveying motor is in transmission connection with the material conveying screw; a charging opening is formed in a barrel body of the material conveying barrel; a material falling opening of the material storage hoper is communicated and connected with the charging opening through the material falling barrel; the upper end of the propulsion shaft is rotatably mounted at the top of the material storage hopper; the propulsion shaft is positioned in the material storage hopper, and the lower end of the propulsion shaft extends to the charging opening; the propulsion motor is in transmission connection with the propulsion shaft; the spiral propulsion blade is mounted at the lower part of the propulsion shaft; the upper part of the spiral propulsion blade is positioned in the material storage hopper, and the lower part of the spiral propulsion blade is positioned in the material falling barrel; the anti-bridging shaft is mounted at the upper part of the propulsion shaft.

Owner:GUANGDONG DESIGNER MASCH CO LTD

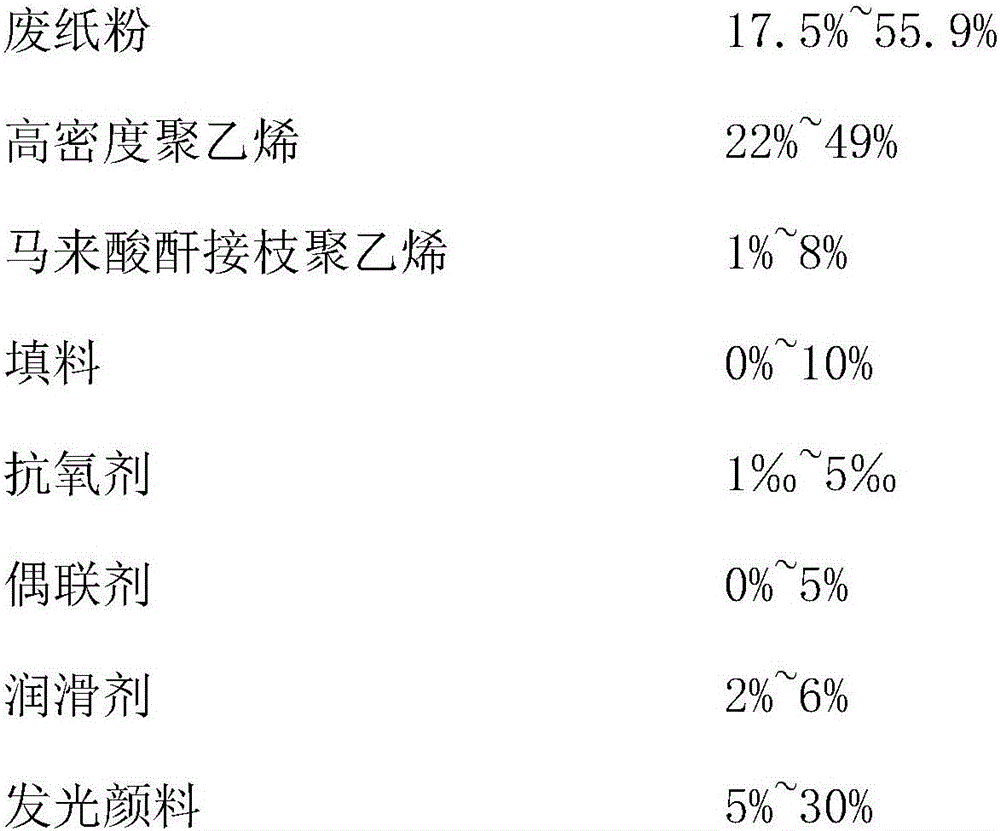

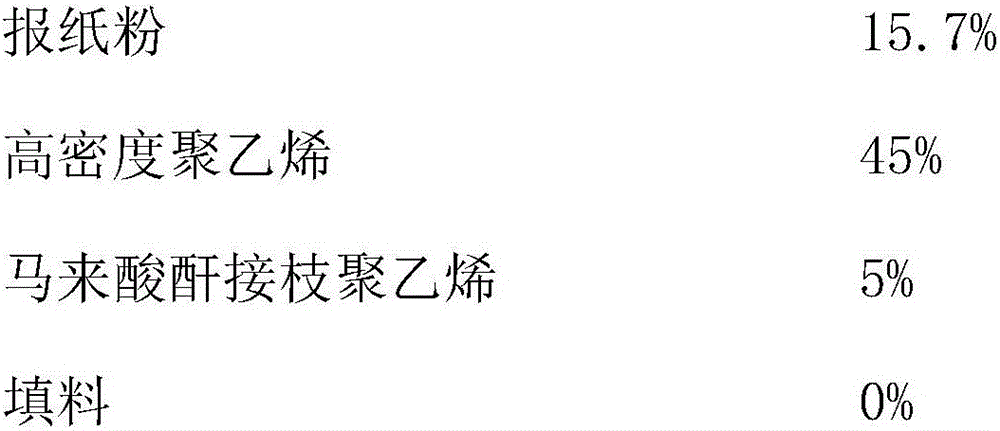

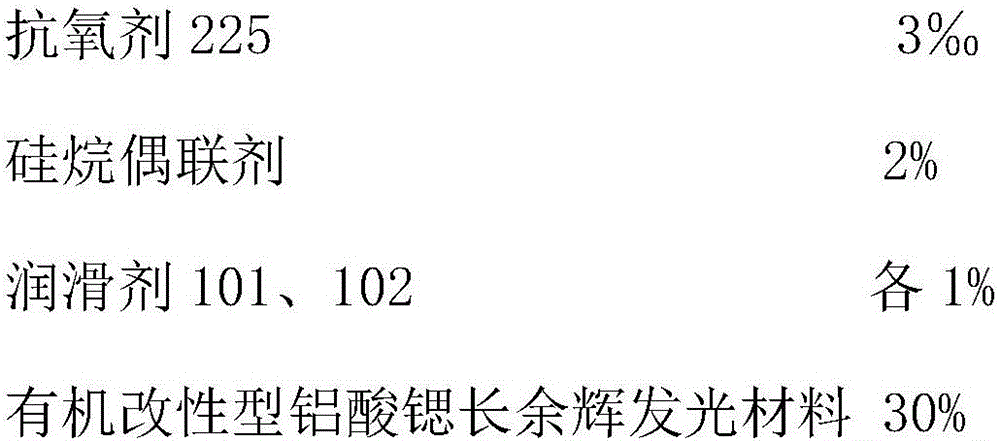

Waste paper/high-density polyethylene luminescent composite and preparation method thereof

The invention relates to a composite, and provides a waste paper / high-density polyethylene luminescent composite and a preparation method thereof. A long-persistence luminescent material subjected to organic modification is adopted as luminescent pigment, the long-persistence luminescent material, pretreated waste paper fiber powder, high-density polyethylene, a coupling agent, a processing agent and the like are subjected to blending extrusion, and the luminescent wood-plastic composite is obtained. According to the waste paper / high-density polyethylene luminescent composite and the preparation method thereof, the comprehensive utilization level of waste resources is greatly improved, and environmental pollution caused by treatment of waste resources is greatly reduced; compared with a traditional board and a traditional wood-plastic composite, the luminescent composite is easy to process, low in cost, wide in raw material source, environmentally friendly, free of pollution and the like; besides, by adding the luminescent material, the advantages of practicability, attractiveness, safety and the like of the luminescent composite are improved, and based on an existing wood-plastic board production process, the luminescent composite is a wood-plastic board very suitable for large-scale production.

Owner:SOUTH CHINA AGRI UNIV

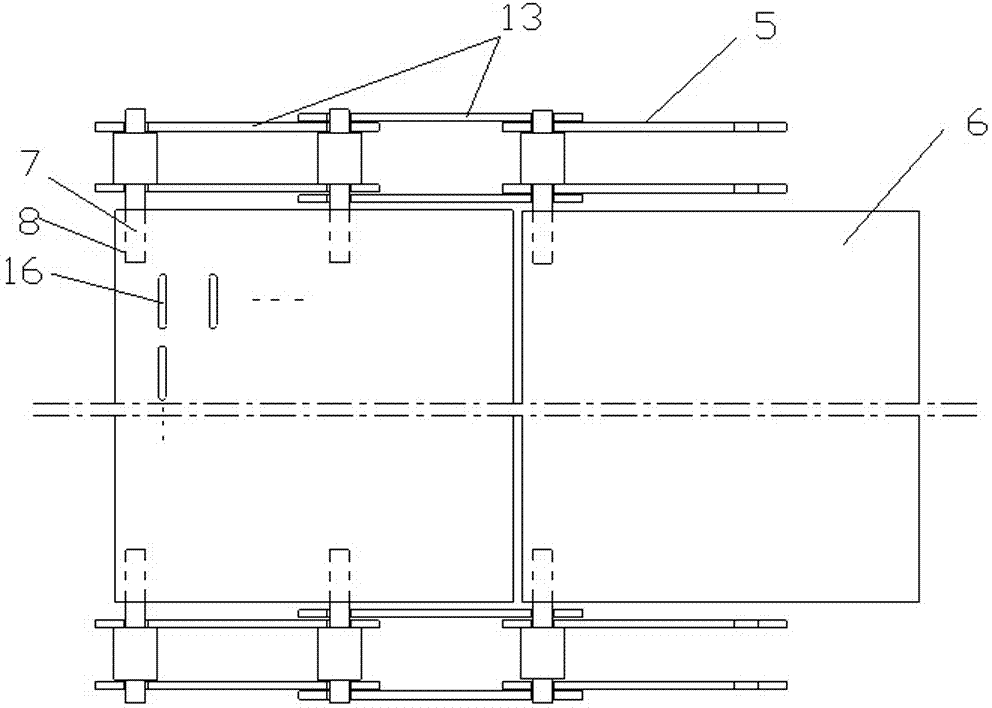

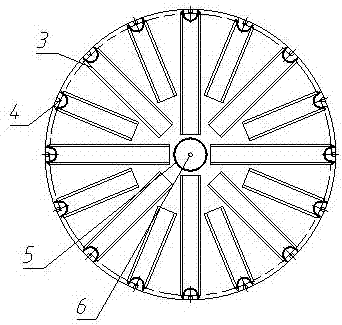

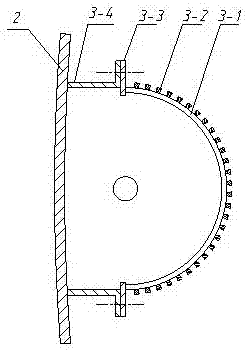

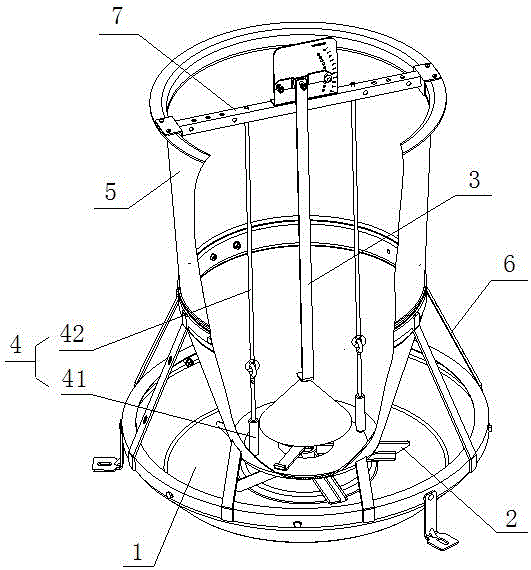

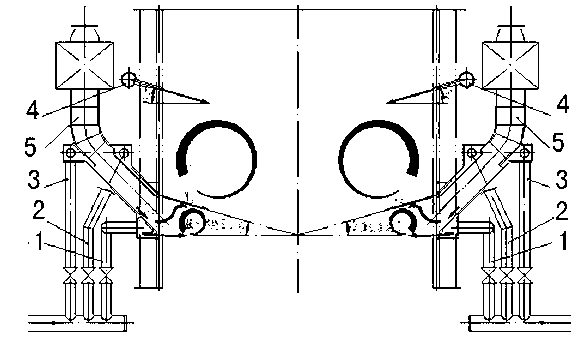

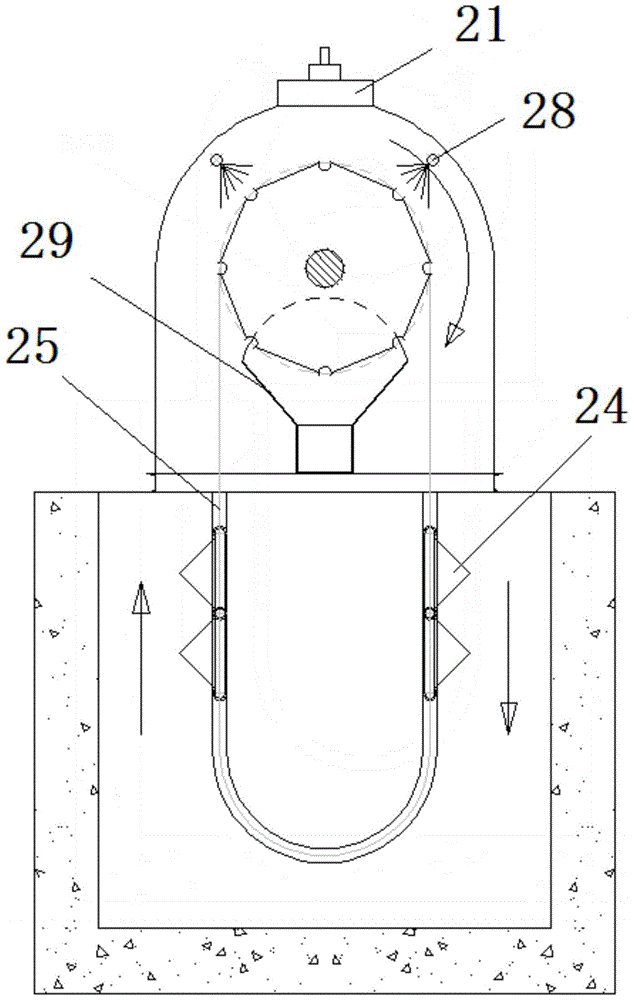

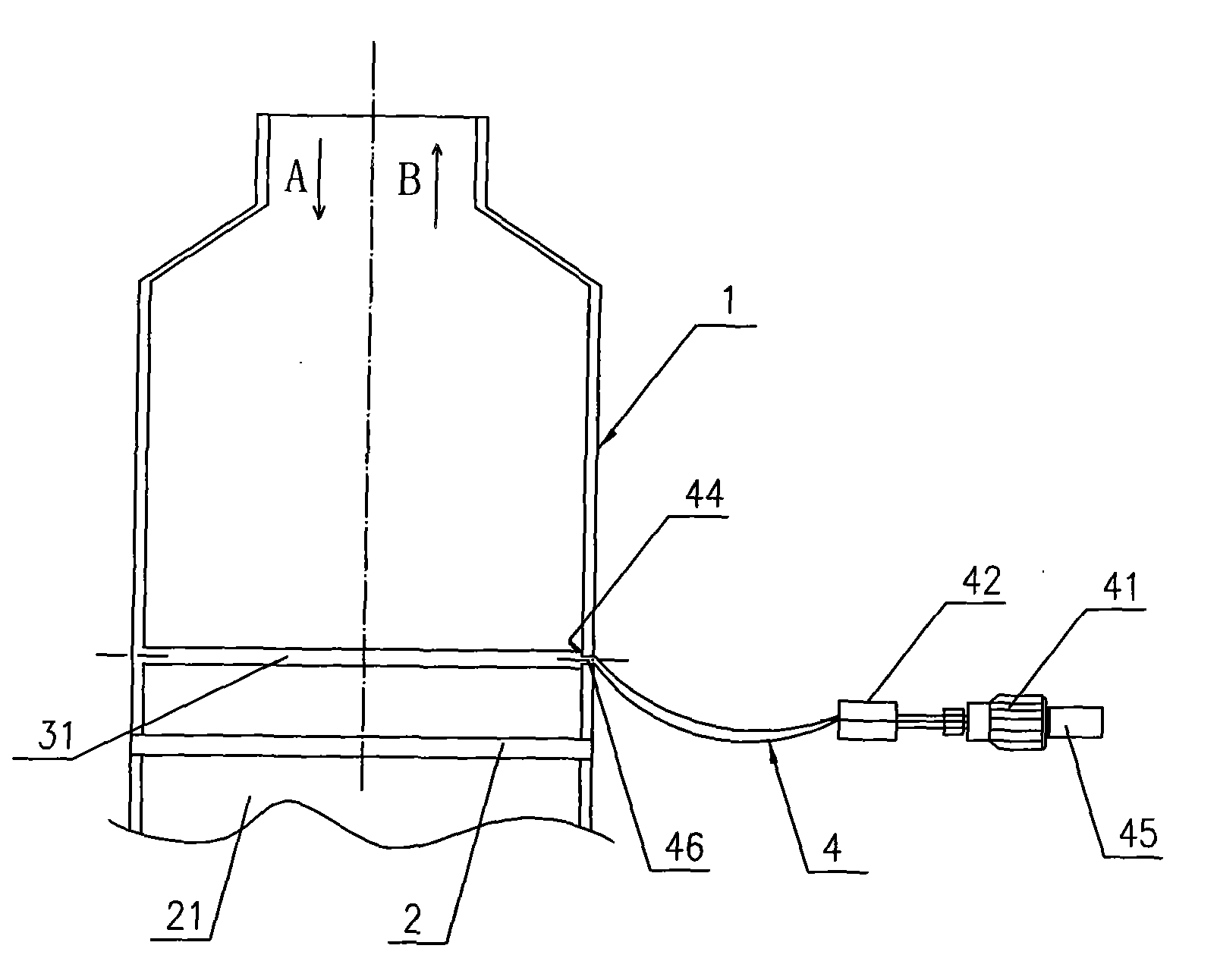

Reciprocating bridge-breaking scraper apparatus used in sludge bin

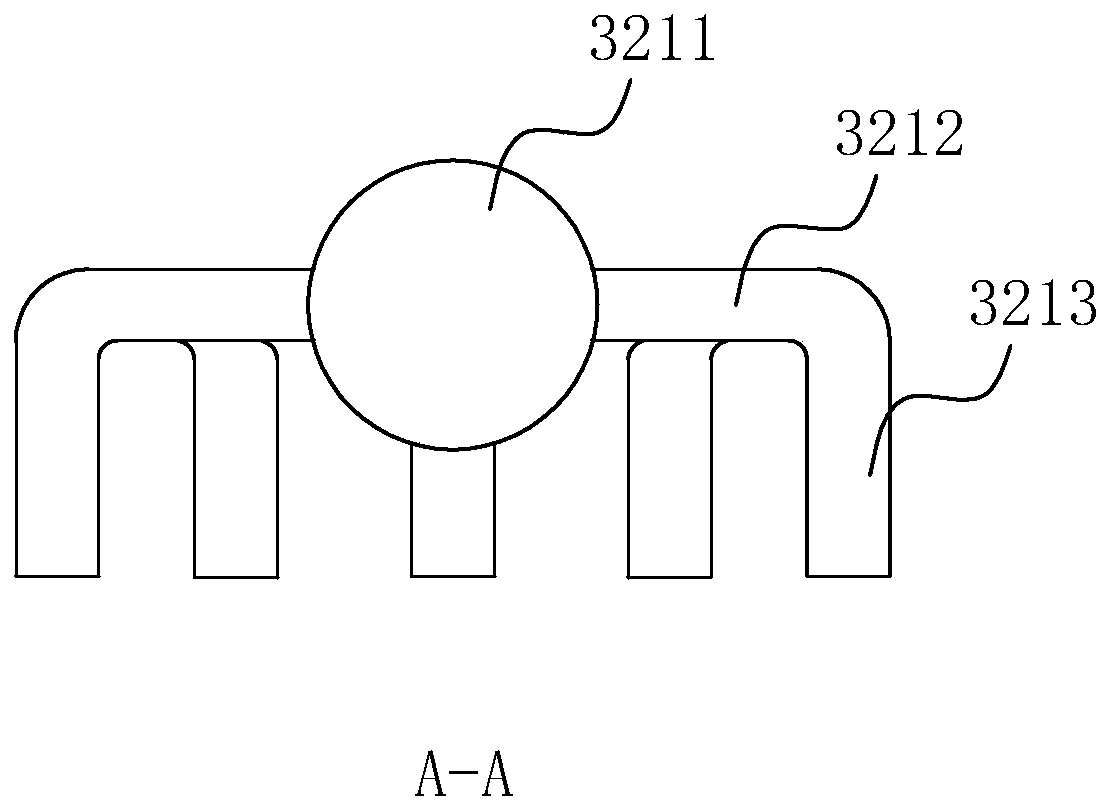

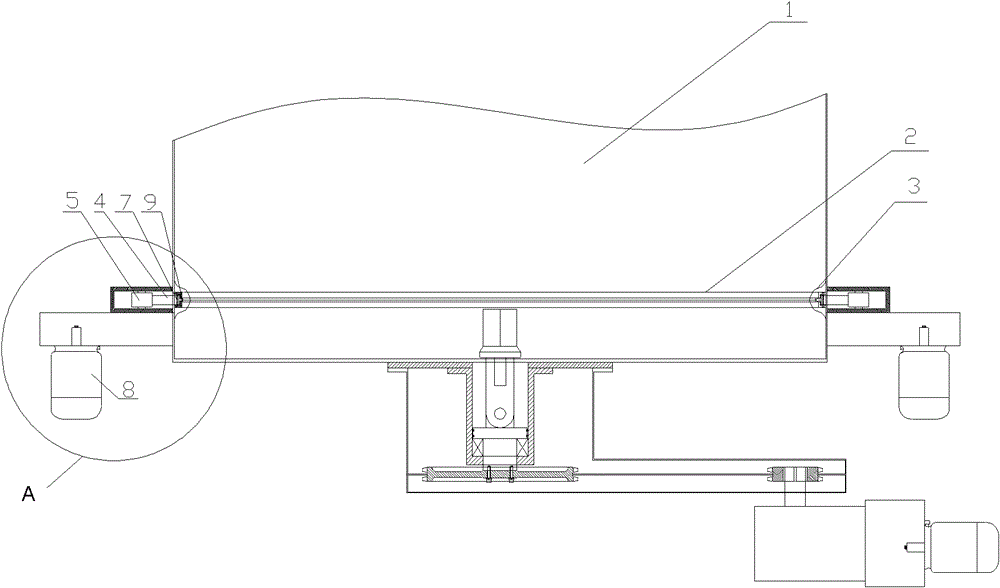

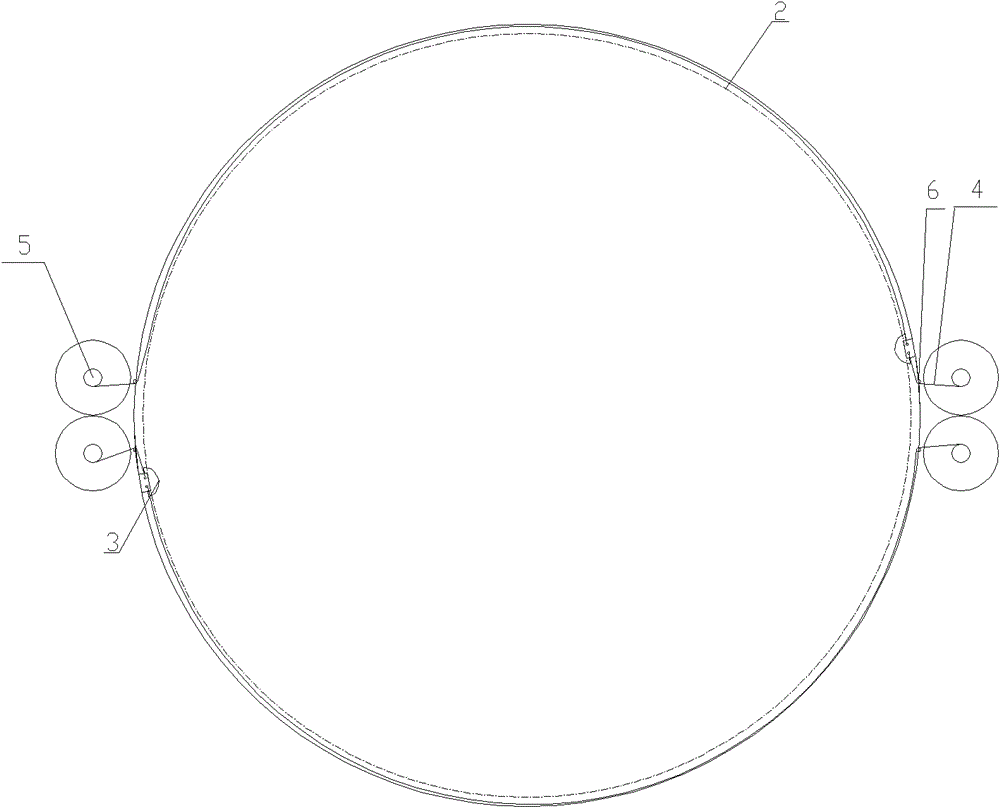

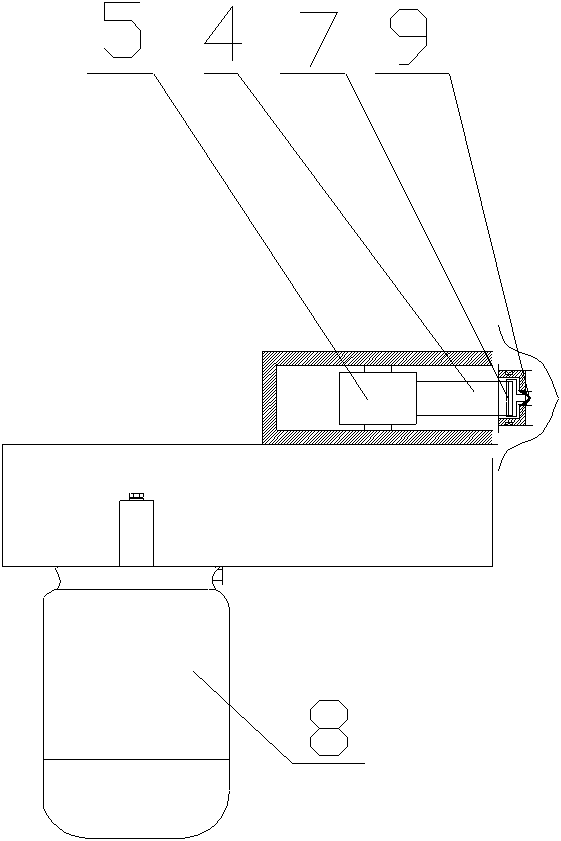

The invention discloses a reciprocating bridge-breaking scraper apparatus used in a sludge bin. The scraper apparatus comprises: a cylindrical sludge bin for storing sludge. Two segments of semicircular horizontal tracks are disposed on a lower part of an inner wall of the sludge bin; two groups of conveyor belt contraction rollers are disposed on a position outside the sludge bin, the position having the height the same as that of the tracks outside the sludge bin, wherein each group of the conveyor belt contraction rollers includes two conveyor belt contraction rollers disposed on boundaries of the two segments of semicircular tracks respectively; a quadricuspid arc scraper matched with the tracks is disposed on each of the two segments of semicircular tracks; a conveyor-belt fixing shaft connected with conveyor belts and disposed on a base of the quadricuspid arc scrapers is in transmission connection with a corresponding group of the conveyor belt contraction rollers through a rotating shaft disposed on the wall of sludge bin; and an output shaft of a transmission motor is in transmission connection with each group of the conveyor belt contraction rollers. The scraper apparatus designed through the invention is characterized by a simple structure and easy operation and solves the problem of sludge bridge usually existing in the sludge bin with only low power.

Owner:SHANGHAI CENTRIFUGE INST

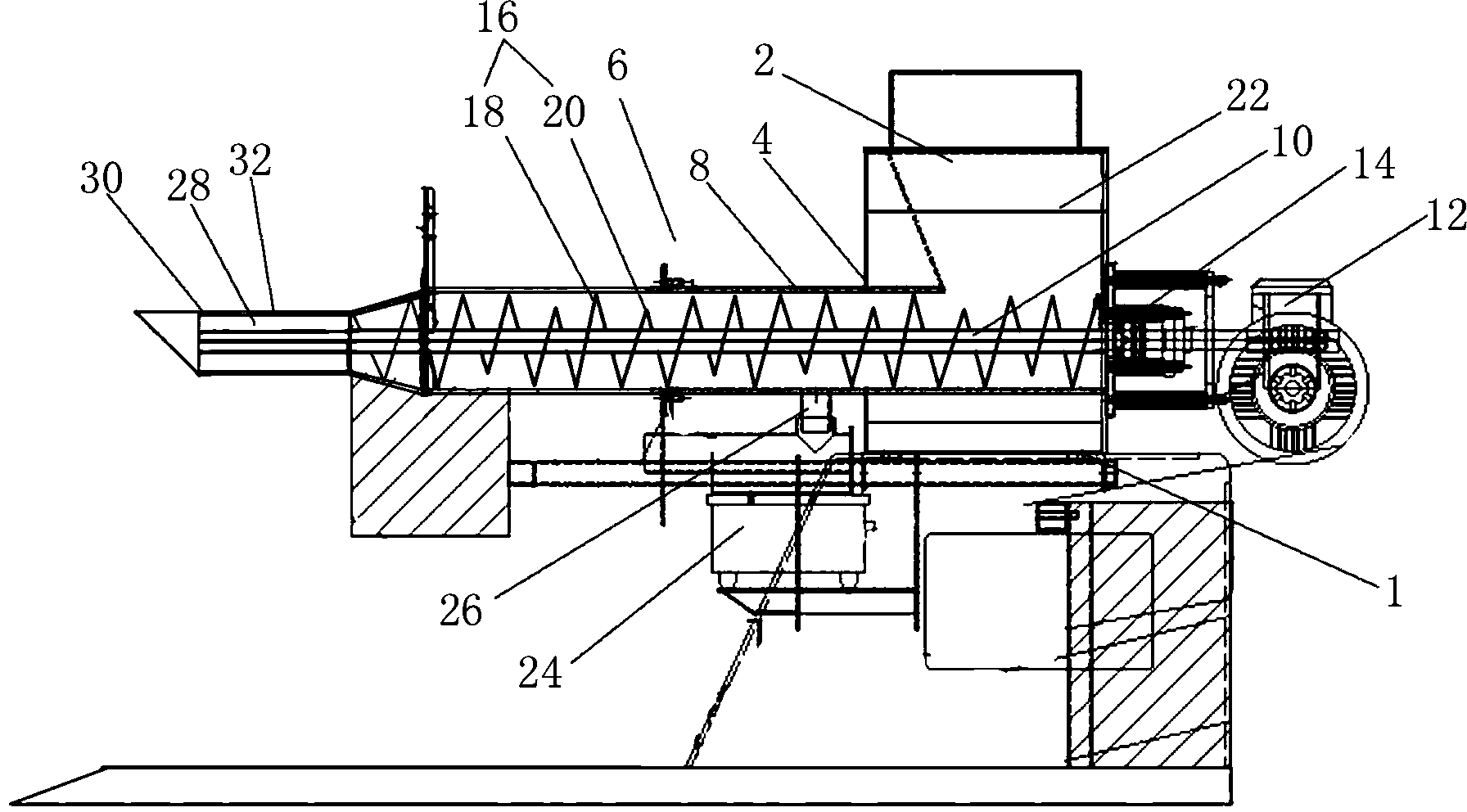

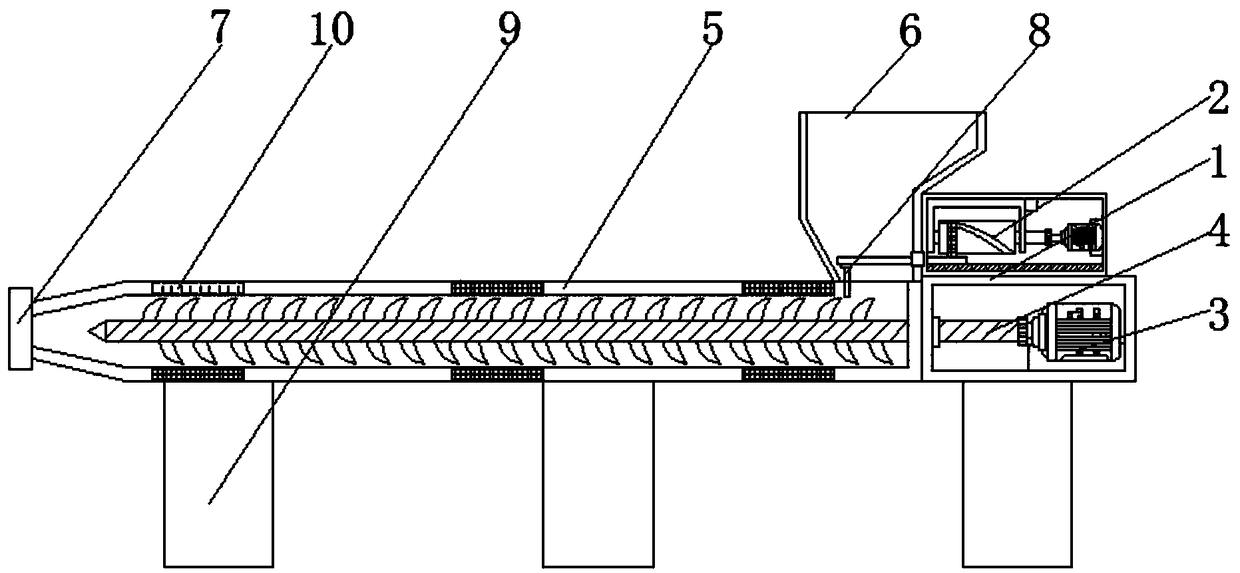

Single-screw sheet extruder

InactiveCN104786471AEnsure uninterrupted continuous feedingImprove delivery capacityEngineeringPressure reduction

The invention discloses a single-screw sheet extruder. The single-screw sheet extruder comprises a machine frame, a feeding device, an exhaust type single extrusion screw, a gear pump, an extrusion die head, a glazing press, an edge pressing and dividing machine, a traction device, a drying device, a storage shelf and a winding device, wherein the exhaust type single extrusion screw successively comprises a feeding section, a first compression section, a first metering section, a mixing section, a pressure reduction section, an exhaust section, a second compression section and a second metering section from front to back. According to the single-screw sheet extruder disclosed by the invention, the exhaust type structure is adopted, and through reasonable segmentation, the material conveying capability, the plasticizing effect and the exhaust effect are effectively improved; the single-screw sheet extruder has the exhaust function, so that water in the raw materials of plastics can be vaporized and pumped during extrusion processing, the water content of the prepared material is guaranteed to conform to requirements; the raw materials do not need to be dried before being added in the extruder, so that the drying time of the raw materials can be shortened, the energy consumption is lowered, the equipment cost is reduced, and improvement of the production efficiency can be facilitated.

Owner:GUANGDONG DESIGNER MASCH CO LTD

Spiral pusher

ActiveCN103482316ASolve bridgingSolve the clumpingLarge containersLoading/unloadingElectric machineryStructural engineering

The invention discloses a spiral pusher, comprising a storage silo and a pusher, wherein a fixed frame of the storage silo is arranged on a horizontal workbench; an opening is formed in the lower end of one side of the storage silo; the pusher which is used for pushing materials is communicated with the interior of the storage silo by the opening; the pusher comprises a hollow feeding pipe body, a push rod and a motor; the push rod penetrates through the feeding pipe body and is coaxially arranged with the feeding pipe body; the motor is used for driving the push rod to rotate around the self-axis of the push rod; one end, rotatably connected with the motor, of the push rod penetrates through the interior of the storage silo, outwards extends out of the storage silo and is rotatably connected with the motor by a bearing frame. The spiral pusher is characterized in that blades which are used for pushing materials are spirally coiled at the outer wall of the push rod. Compared with the traditional pusher, for the materials which are high in water content and poor in mobility and are easily caked and clotted, the spiral pusher solves the problems of bridging or clotting, and has the advantages that the structure is simple and the feeding efficiency is high.

Owner:CHINA WEIGHING EQUIP SUZHOU FACTORY

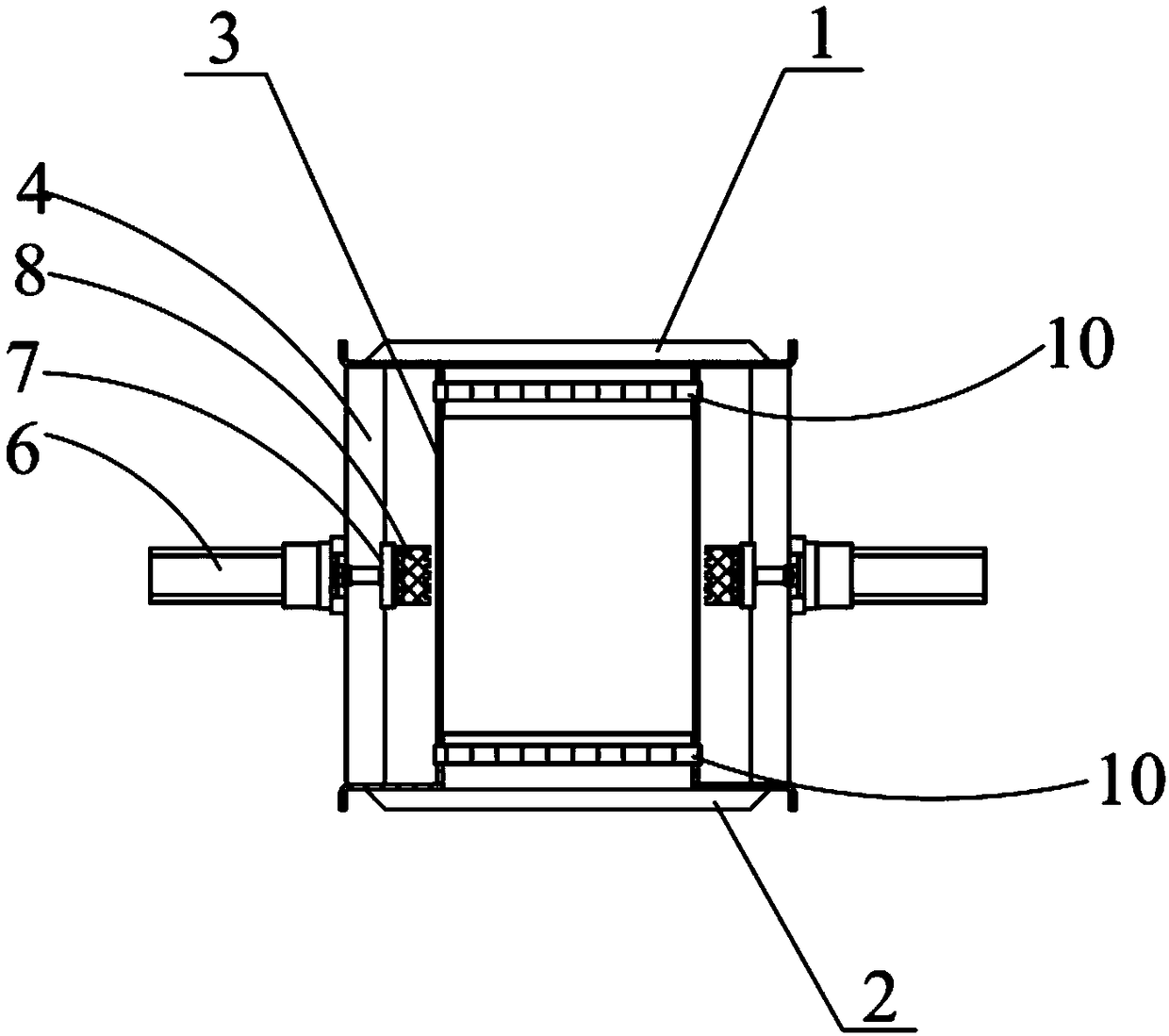

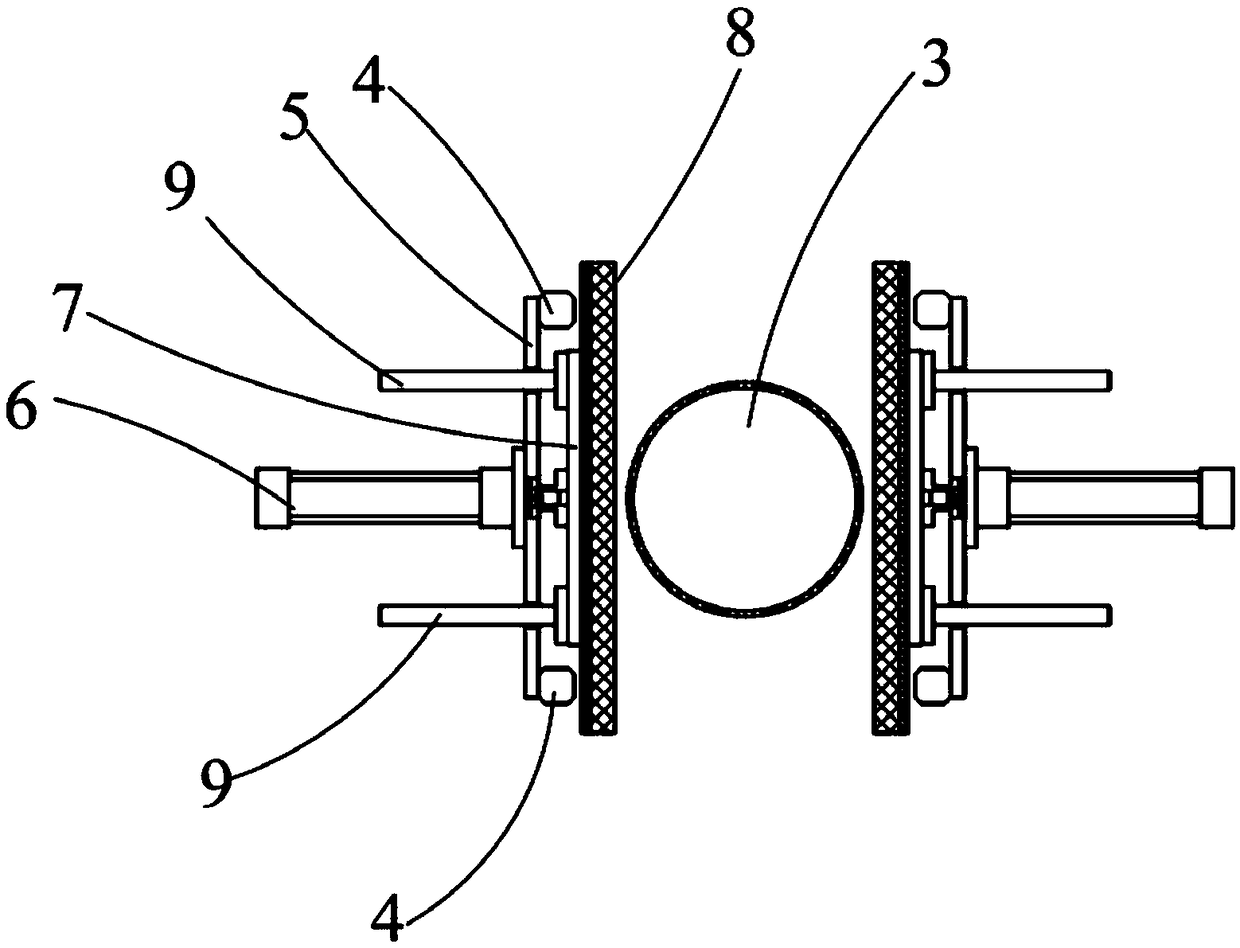

Multi-type-powder quantitative feeding mechanism suitable for rapid prototyping equipment

ActiveCN105966791ASolve uneven powder fallingSimple structureConveyorsLarge containersPower controlEngineering

Owner:武汉华科三维科技有限公司

Powder material adding mechanism

The invention relates to a powder material adding mechanism which comprises a metering scale hopper. A metering sensor is arranged at the bottom of the metering scale hopper. A discharge barrel is arranged at the lower portion of the metering scale hopper, a discharge outlet is formed in one end of the discharge barrel, and a feed screw rod is arranged in the discharge barrel. The powder material adding mechanism is characterized in that a micromotor is installed on the top of the metering scale hopper, and a stirring device is installed at the power output end of the micromotor. The feed screw rod is connected with the power output end of a speed reducer, and the power input end of the speed reducer is connected with the power output end of the micromotor. The bottom end of the stirring device is located above the discharge barrel. According to the powder material adding mechanism, due to the facts that the stirring device is additionally installed on the metering scale hopper, and materials in the metering scale hopper are stirred under driving of the micromotor, bridging is avoided, and discharge smoothness and precision are ensured.

Owner:WUXI KING CONTROL INSTR

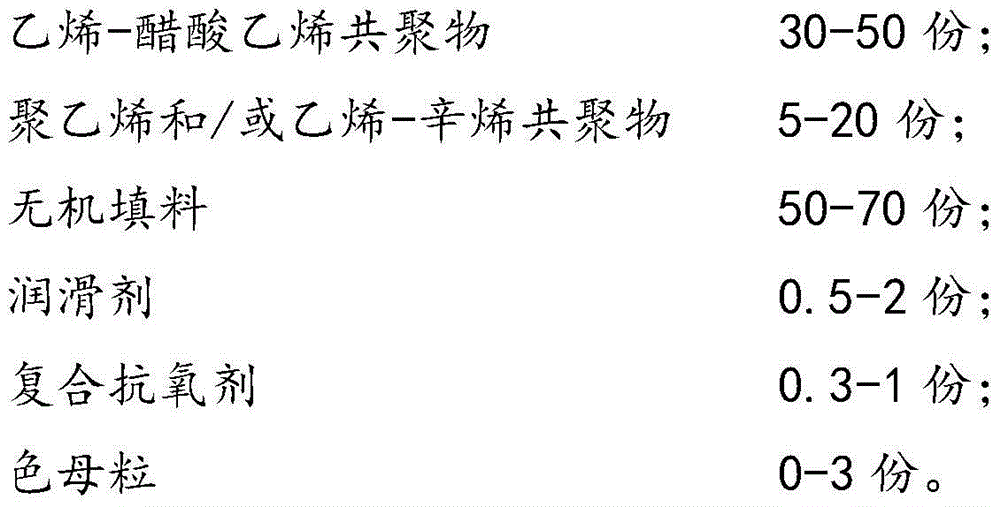

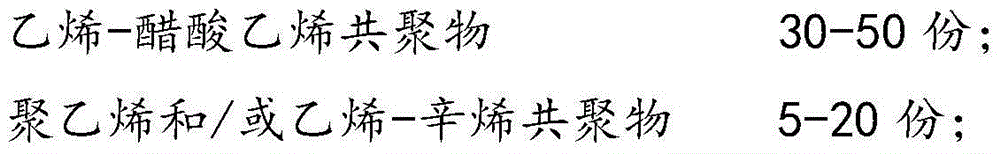

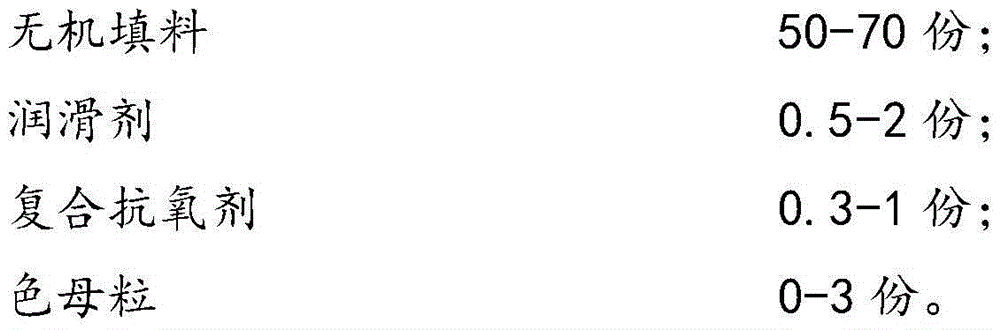

Halogen-free heat shrinkable casing pipe and preparation method thereof

InactiveCN105801991AImprove mechanical propertiesImprove insulation performanceMasterbatchEnvironmental resistance

The invention relates to a halogen-free environment-friendly material and an application thereof, and in particular, relates to a low-cost and halogen-free environment-friendly heat shrinkable pipe and a preparation method thereof, wherein the halogen-free environment-friendly heat shrinkable pipe comprises the following components by weight: 30-50 parts of an ethylene-vinyl acetate copolymer; 5-20 parts of a polyethylene and / or ethylene-octene copolymer; 50-70 parts of an inorganic filler; 0.5-2 parts of a lubricant; 0.3-1 part of a composite antioxidant; and 0-3 parts of a masterbatch; the influence of a halogen element contained in the heat shrinkable casing pipe on environments and body health is solved, and the heat shrinkable casing pipe has the advantages of simple production, easy industrialization, low cost and the like.

Owner:SHANGHAI CHANGYUAN ELECTRONICS MATERIAL +1

Product connection line extrusion device

InactiveCN108312465AIncrease productivityImprove molding effectDomestic articlesElectric machineryComputer case

The invention discloses a product connection line extrusion device and relates to the technical field of digital products. The product connection line extrusion device comprises a motor box, the top of the motor box is fixedly connected with a transmission device, the right side of the bottom of an inner cavity of the motor box is fixedly connected with a first motor, an output shaft of the firstmotor is fixedly connected with a threaded rod through a coupler, the left side of the motor box is fixedly connected with an extrusion box, the left end of the threaded rod sequentially runs throughthe left side of the motor box and the right side of the extrusion box from right to left and extends to the inner portion of the extrusion box, the right side of the top of the extrusion box communicates with a material inlet hopper, the left side end surface of the extrusion box is in threaded connection with a mould, and the transmission device comprises a shell. By means of the digital productconnection line extrusion device, the problem that bridging will appear at the communicating position of the material inlet hopper and the extrusion box when the heating temperature is too high is solved, the situation that production is stopped for adjustment is not needed, the production efficiency of workers is improved, the forming effect of extrusion materials is increased, and the use effect of users is met.

Owner:合肥市硕理机电科技有限公司

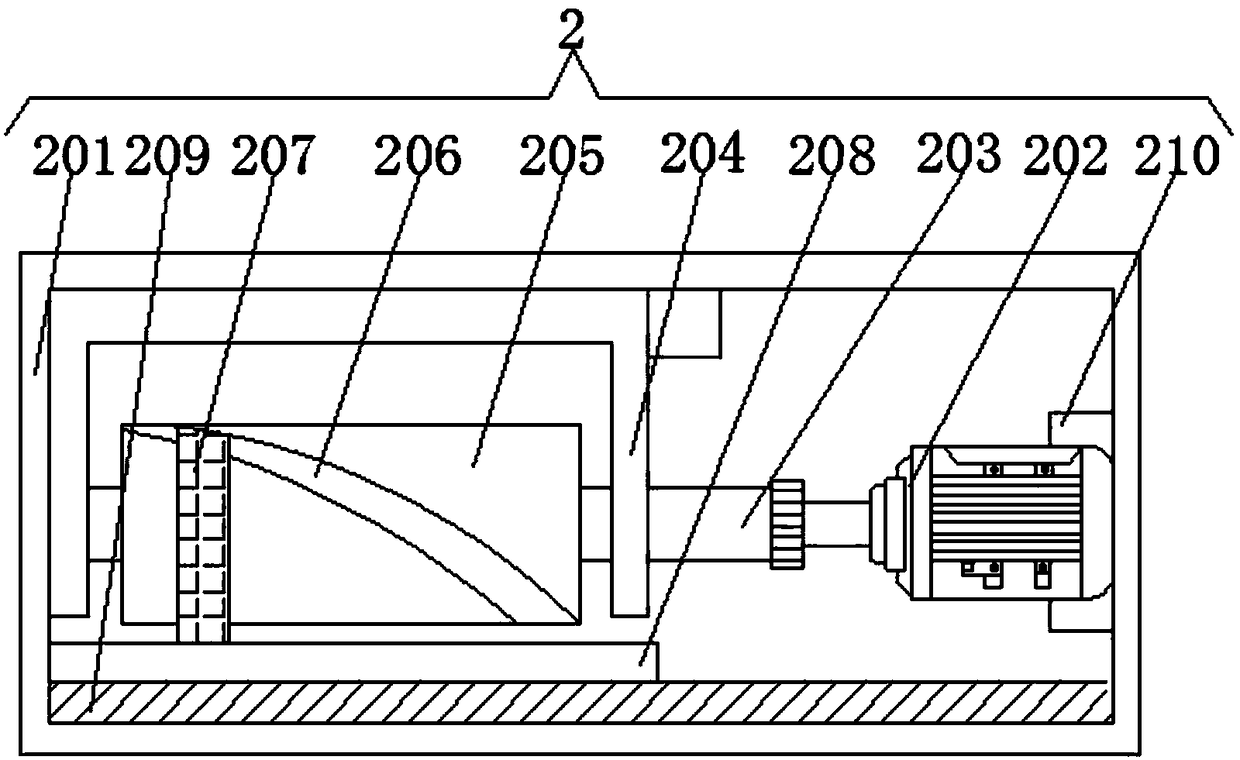

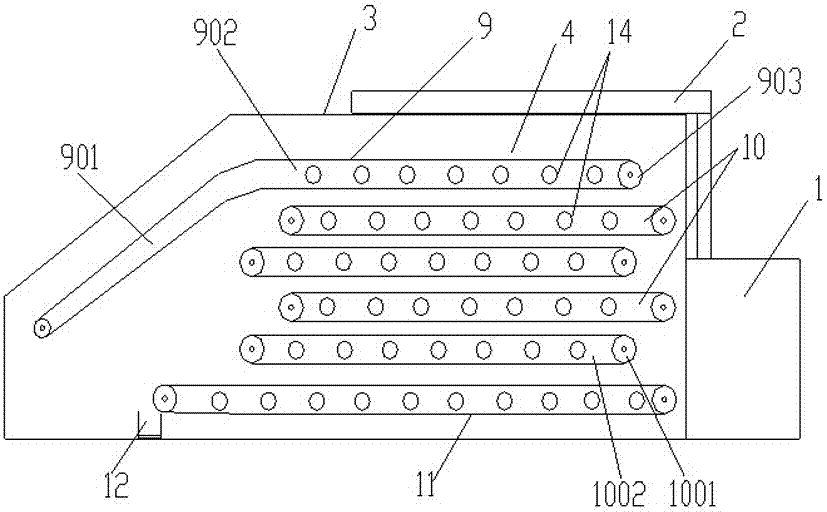

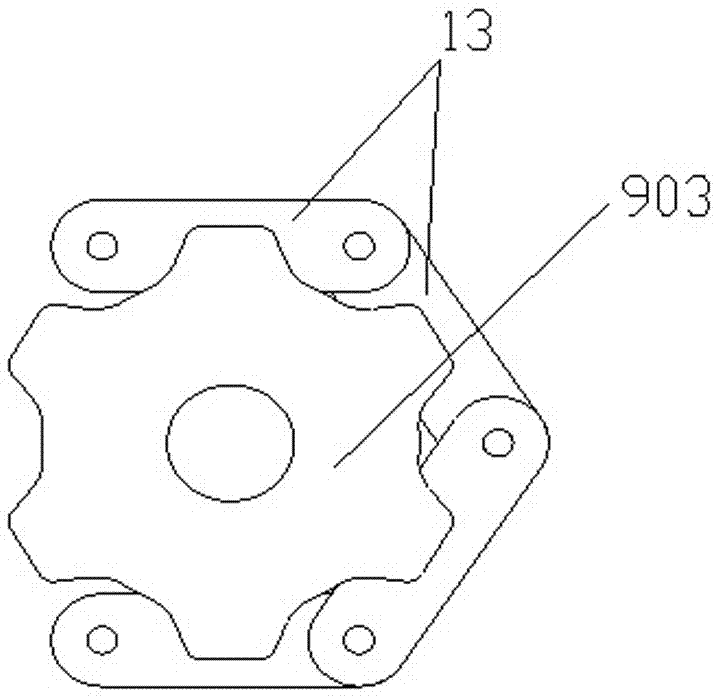

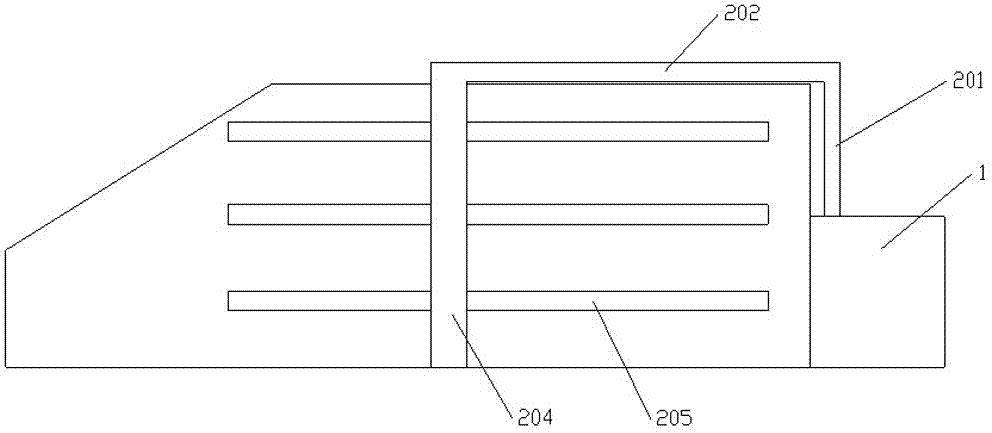

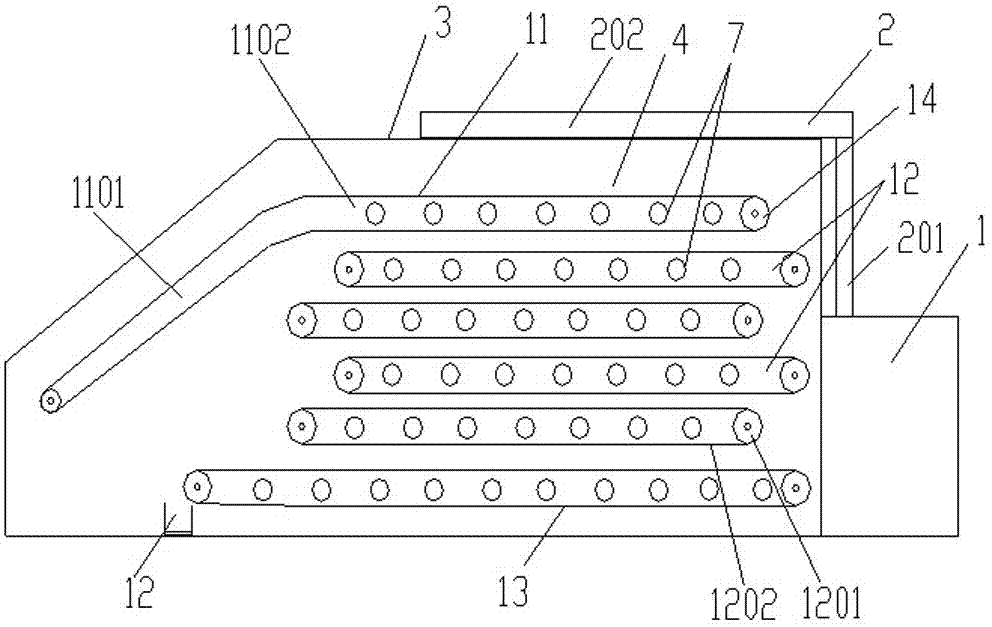

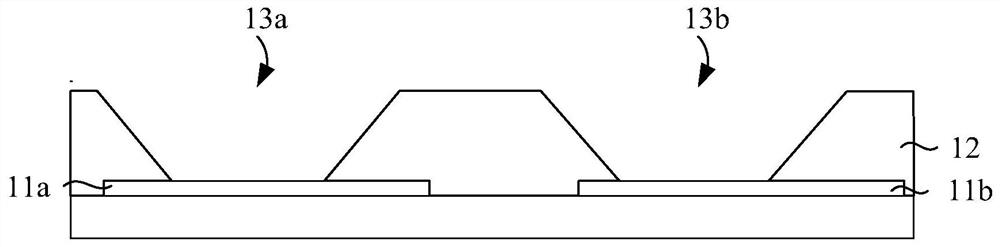

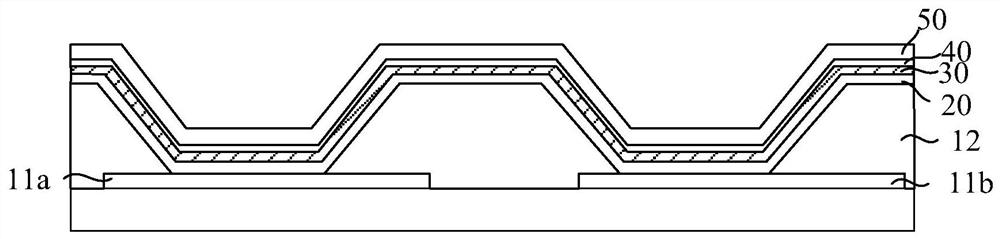

Transmission device of chain plate circulation type tea leaf withering drying machine and work method thereof

PendingCN106993671AAvoid contactGuaranteed to fall fully intoConveyorsPre-extraction tea treatmentEngineeringFriction force

The invention relates to a transmission device of a chain plate circulation type tea leaf withering drying machine and a work method thereof. The transmission device is characterized by comprising a hot air furnace and a withering drying room connected with the hot air furnace through an air supply pipeline, wherein a conveying belt used for conveying tea leaves to be subjected to withering drying is arranged in the withering drying room; the conveying belt comprises conveying chains arranged at the two sides and a conveying plate in close adjacent arrangement between the conveying chains positioned at the two sides; an inner convex pin is arranged in each chain section hinging position of the conveying chain; the two side parts of the conveying plate are respectively provided with insertion pin grooves in matched connection with the inner convex pins; the two insertion pin grooves are positioned in the middle back positions of the advancing direction of the conveying plate; a conveying plate is arranged among the three inner convex pins arranged on the two chain sections. The transmission device has the advantages that in the transmission process, the friction force is small; the noise is reduced; the load is reduced; the motor can realize the positive and reverse rotation; the machinery stability is improved; the tea leaf clamping, bridging and tea hanging phenomena are basically avoided.

Owner:张财生

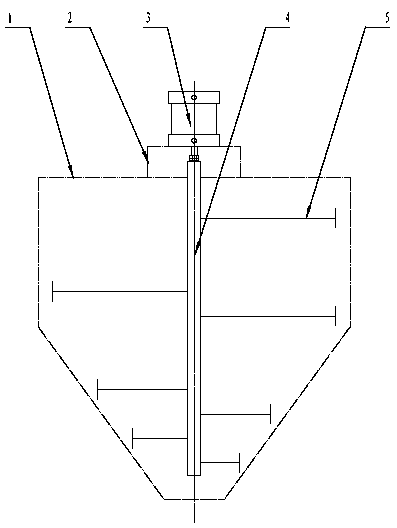

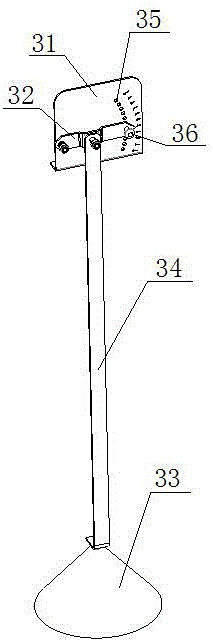

Lifting type bridge breaking device

A lifting type bridge breaking device is used for preventing powdery materials from adhering to each other and setting up a bridge in a hopper during measurement, transportation and storage, bridge breaking stirring rods are installed on a main rod at the center of the hopper, an air cylinder on the top of the hopper drives the main rod to move up and down, the length of each bridge breaking stirring rod can be designed according to the shape of a bin, even when the hopper is in a special shape, the bridge breaking stirring rods can touch irregular parts of the special-shaped hopper without leaving any material storage dead corners, and therefore the problem that materials can not be smoothly discharged due to the fact that the bridge is produced after the powdery materials adhere to the barrel wall of the bin is solved.

Owner:ZHANGJIAGANG BEIER MACHINERY

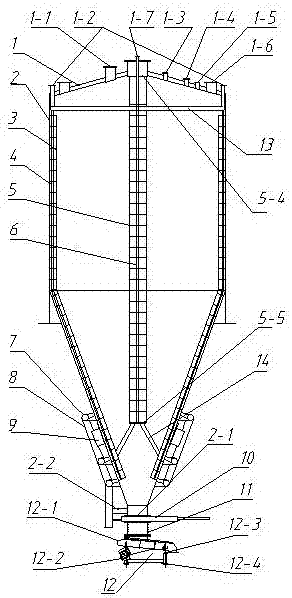

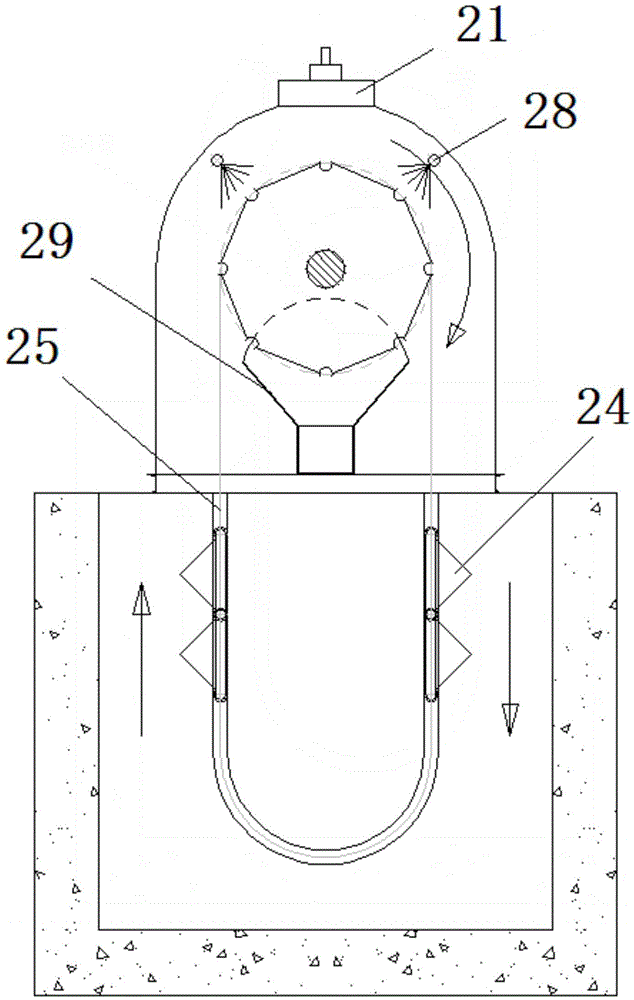

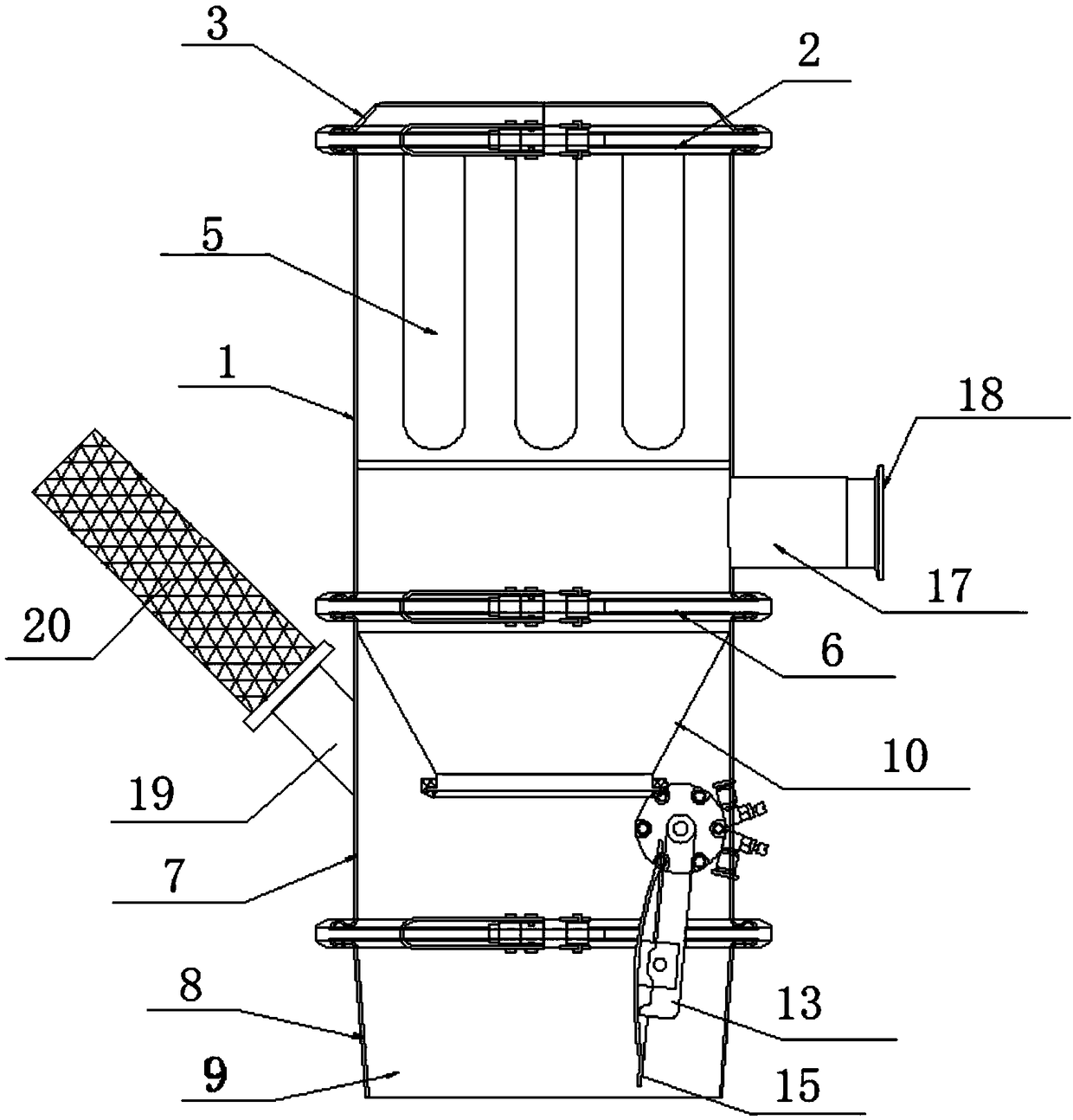

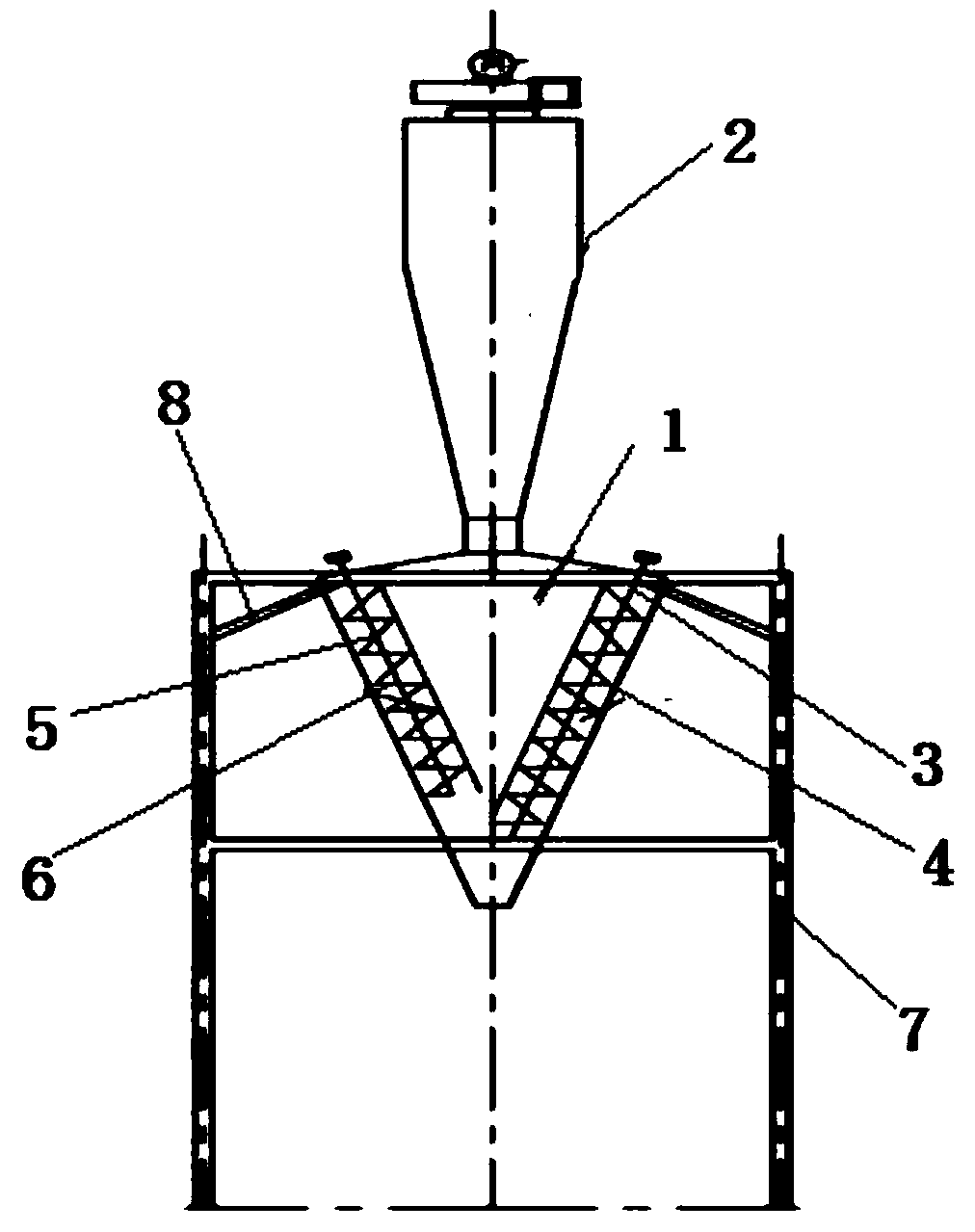

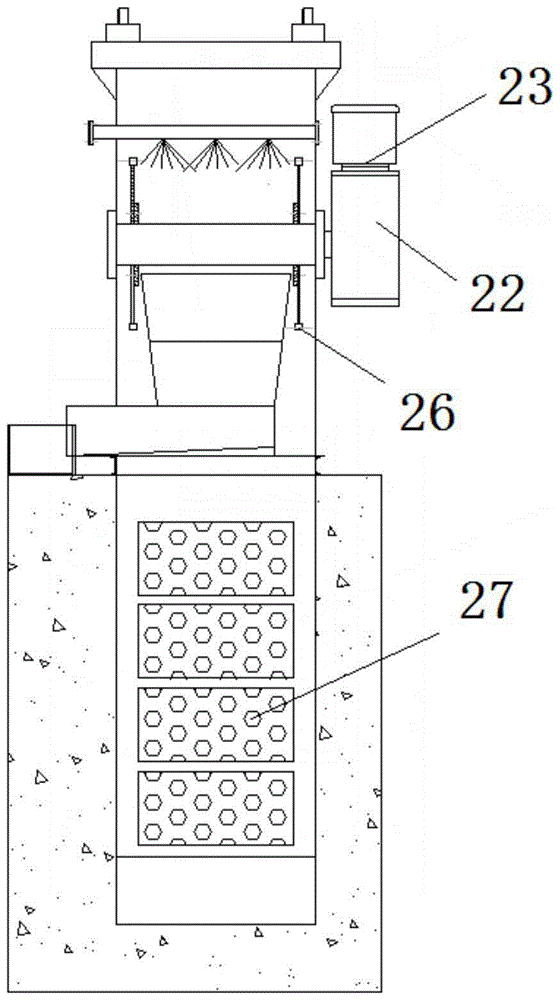

Petroleum coke dewatering bin

PendingCN107344031AUnhindered dischargeNo emissionsThermal non-catalytic crackingStationary filtering element filtersWater filterPetroleum coke

The invention relates to a petroleum coke dewatering bin. The petroleum coke dewatering bin comprises a bin body and a bin top, wherein the bin top is arranged at the upper end of the bin body, a petroleum coke inlet is formed in the bin top, a petroleum coke outlet is formed in the lower end of the bin body, a tubular peripheral water filtering net is arranged on the inner wall of the bin body, an external draining pipe communicated with the peripheral water filtering net is arranged on the outer wall of the lower part of the bin body, a tubular central water filtering net is arranged in the bin body, an internal draining connecting pipe is arranged between the central water filtering net and the peripheral water filtering net, and an exhausting interface connected with an odor treatment system is further formed in the bin top. According to the petroleum coke dewatering bin, the technical purpose of full-closed dewatering can be realized, the dewatering efficiency is high, and the environment of a coking site can be improved.

Owner:LUOYANG JIANGUANG SPECIAL EQUIP

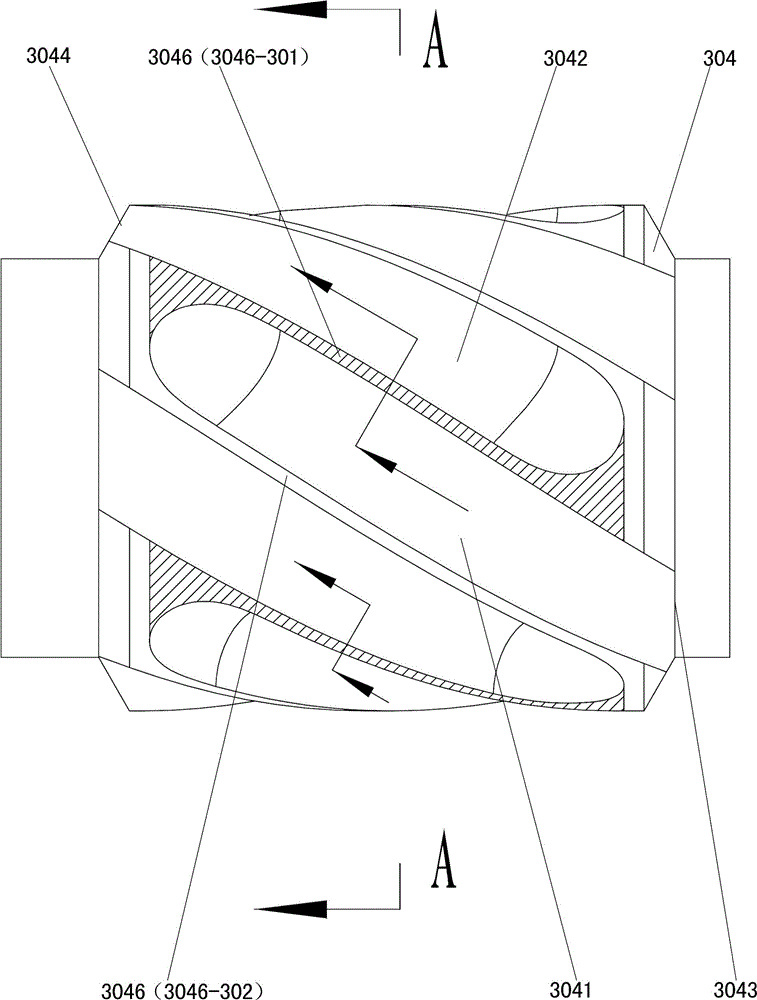

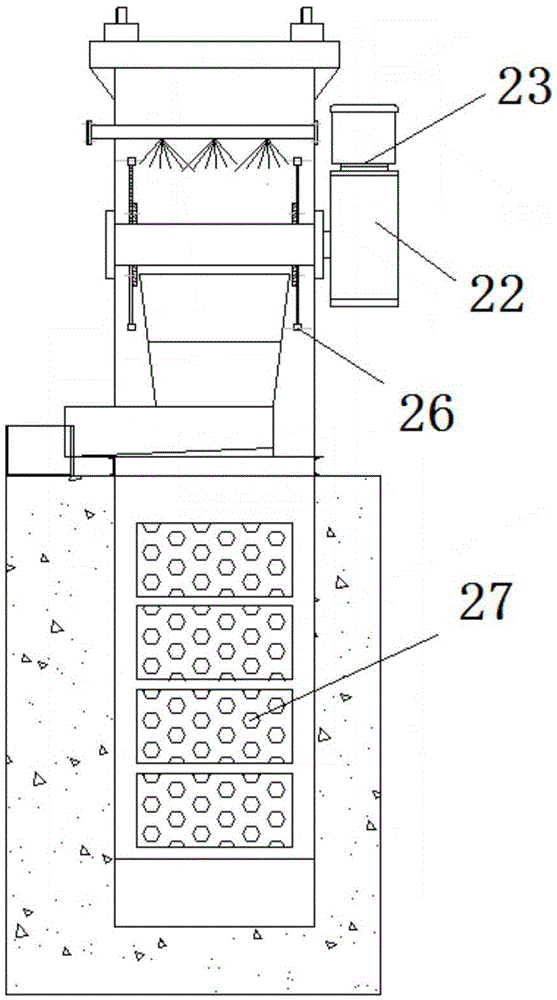

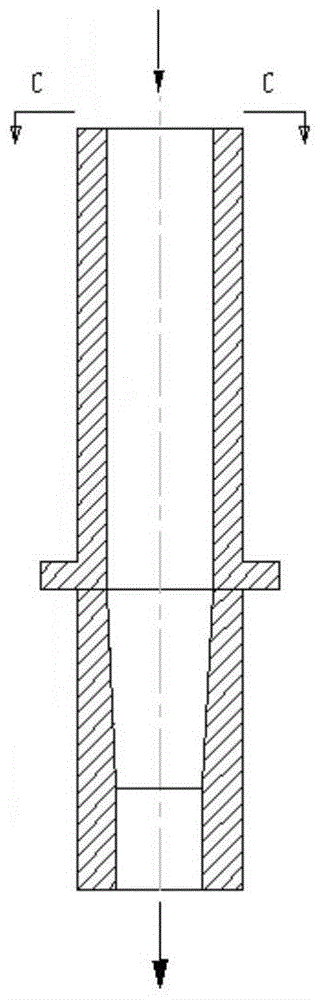

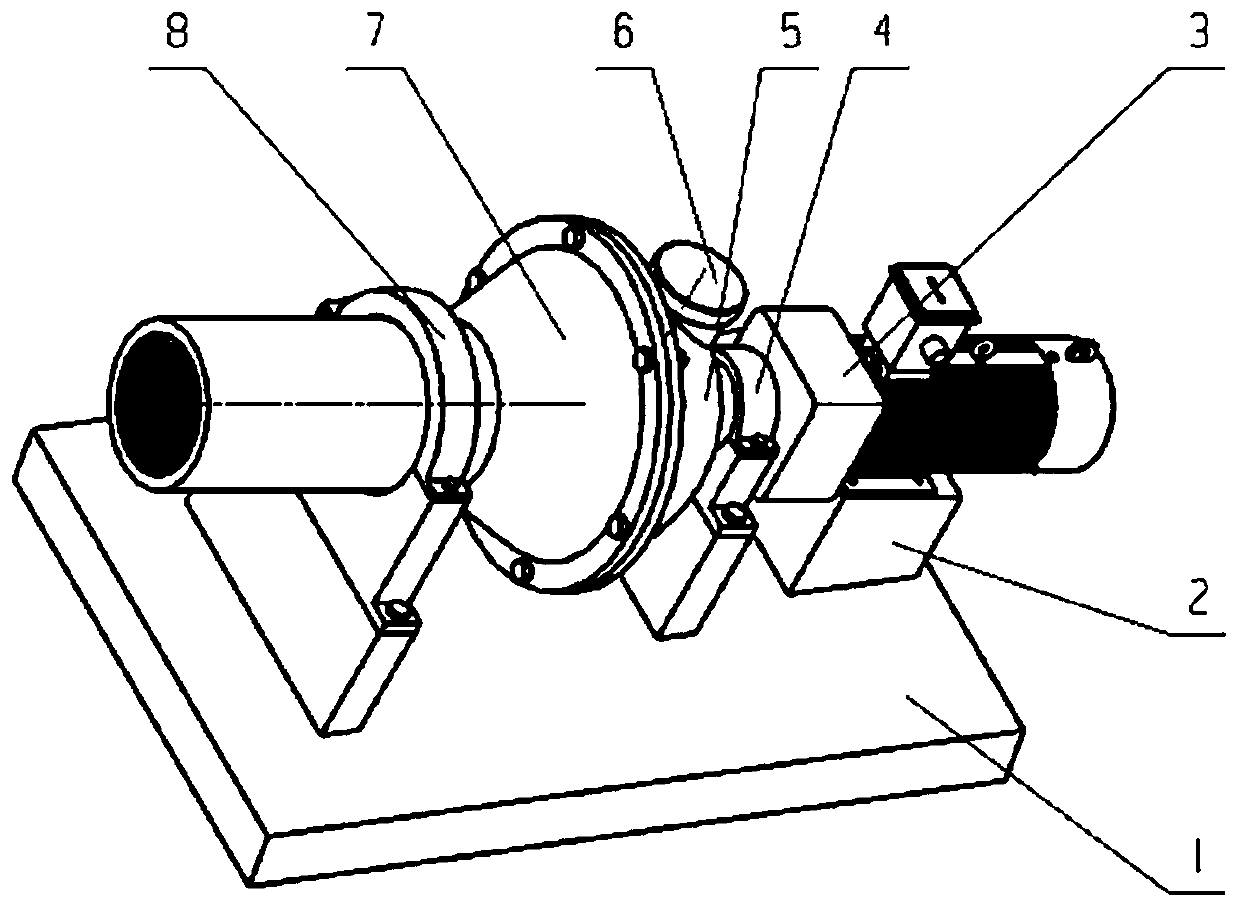

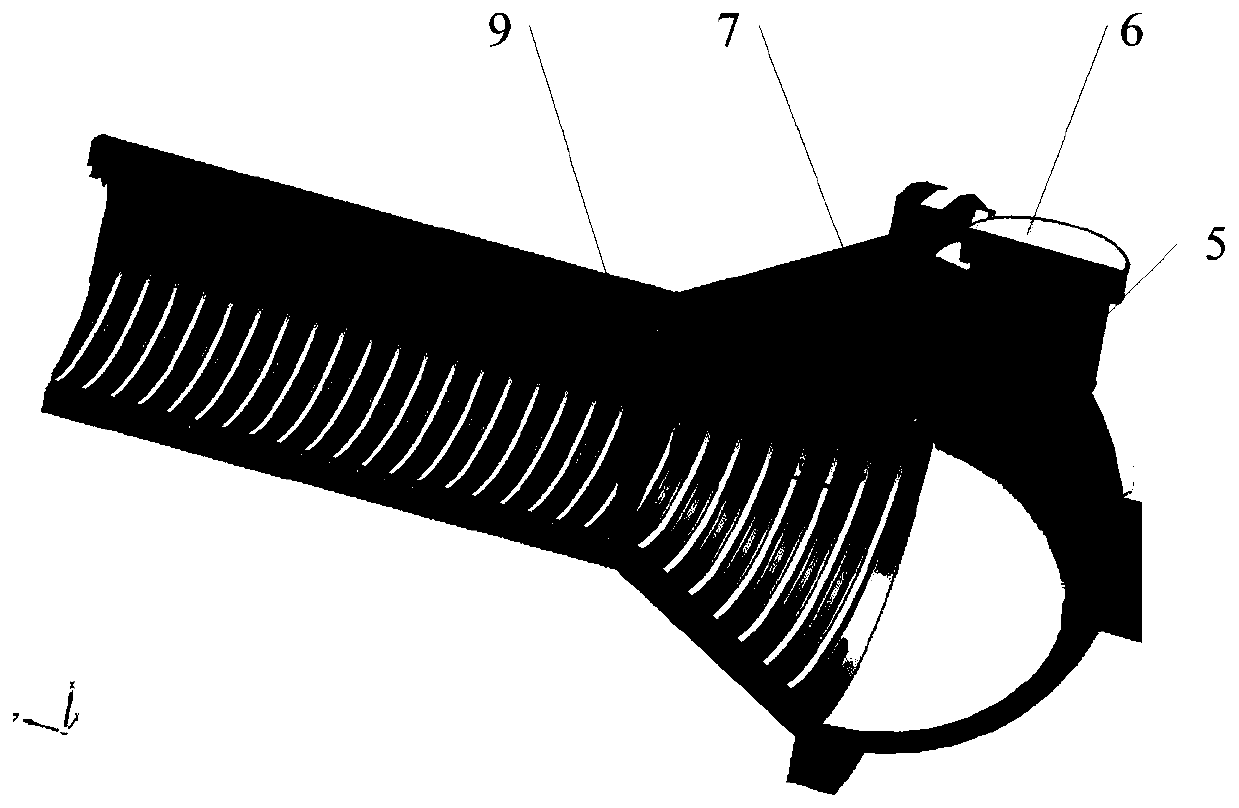

Frequency modulation type self-oscillation jetting device and use method thereof

ActiveCN105536339AReduce energy consumptionOvercome filter deformation and erosion damageMembrane filtersMoving filtering element filtersEngineeringImpact pressure

The invention relates to a frequency modulation type self-oscillation jetting device and a use method thereof. The frequency modulation type self-oscillation jetting device comprises a shell with a tubular opening structure, a base plate, a vertical jetting inlet, a rectification cavity, a mixed flow cavity, a jetting outlet and tangent jetting inlets, wherein an opening in the bottom of the shell is fixedly connected with the base plate; the vertical jetting inlet is vertically arranged at the top of the shell; the inlet end of the vertical jetting inlet is connected with a backwashing pipeline; the outlet end of the vertical jetting inlet is communicated with the rectification cavity positioned at the upper part in the shell; a channel and the mixed flow cavity are arranged below the rectification cavity in sequence in the shell; the lower side of the rectification cavity is communicated with the inlet of the channel; the outlet of the channel is positioned above the inlet of the mixed flow cavity; the outlet of the mixed flow cavity penetrates through the base plate and is communicated with the jetting outlet; a jetting fusion region is formed between the channel outlet and the inlet of the mixed flow cavity; a plurality of tangent jetting inlets communicated with the upper part of the channel are formed in the outer side wall of the upper part of the shell at intervals. The frequency modulation type self-oscillation jetting device is energy-saving, so that the problems of local deformation, washout damage and the like to a filter screen due to extreme-high impact pressure are solved.

Owner:CHINA NAT OFFSHORE OIL CORP +1

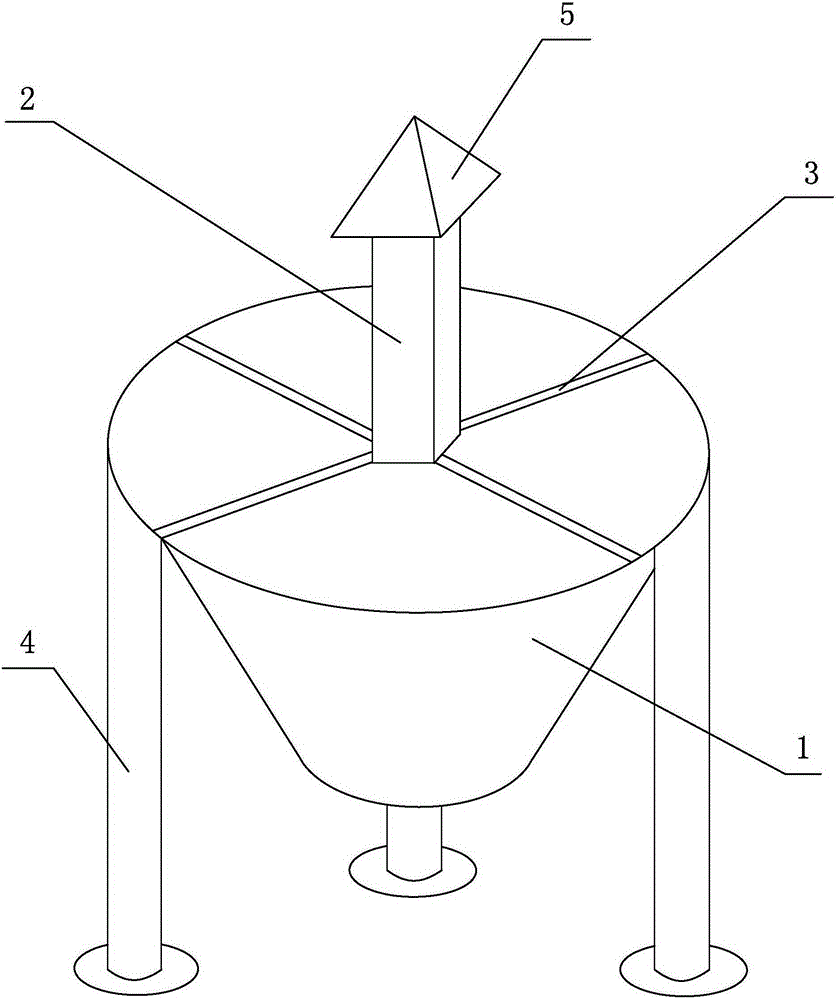

Conservation and fattening integrated trough

The invention discloses a conservation and fattening integrated trough. The conservation and fattening integrated trough comprises a trough body, a stirring wheel mechanism, a discharging speed regulating mechanism, a charging barrel and a support. The trough body is located below the charging barrel. The charging barrel and the trough body are fixed through the support. A cross beam is arranged on the top of the charging barrel. The discharging speed adjusting mechanism is located in the center in the charging barrel and fixed to the cross beam. The stirring wheel mechanism comprises a feed scraper blade, a stirring wheel and a center pedestal. The feed scraper blade is located on the bottom in the charging barrel. The stirring wheel is located below the charging barrel. The feed scraper blade is connected with the stirring wheel through a square pipe. The center pedestal is sleeved with the square pipe. The conservation and fattening integrated trough is novel in concept, simple in structure, capable of providing fresh feed at any time, the waste of pig feed is greatly reduced, the utilization rate of the pig feed is increased, the precious grain resources are saved, the problem of feed bridging can be effectively solved, the diameter of the stirring wheel is half of the diameter of the trough body, and conservation and fattening integrated use can be achieved.

Owner:COMAX LIVESTOCK TECH JIANGSU CO LTD

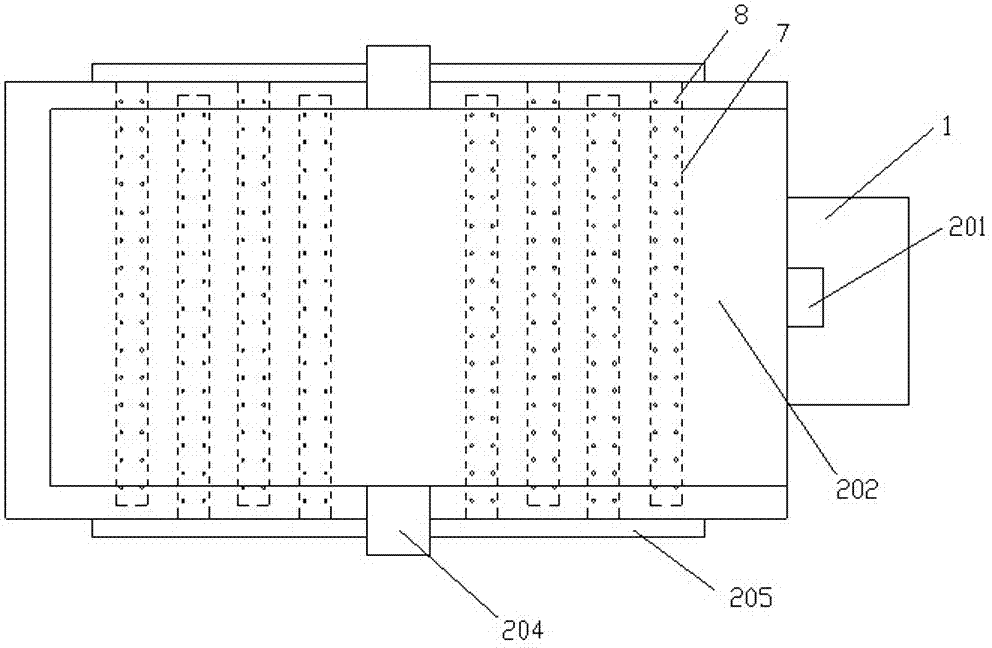

Chain plate circulating type air supply mechanism of tea withering and drying machine and working method of air supply mechanism

PendingCN107125342AStrong penetrating powerAvoid flyingPre-extraction tea treatmentDrying gas arrangementsCombustionVertical plane

The invention relates to an air supply mechanism and a working method of a chain-plate circulation type tea withering dryer, comprising a hot blast stove and a withering and drying room connected to the hot blast stove through an air supply pipe. The withering and drying room is equipped with a A conveyor belt for tea leaves to be withered and dried, the conveyor belt includes conveyor chains on both sides and conveyor plates located between the conveyor chains on both sides, and a hot gas discharge pipe is arranged horizontally between the upper and lower layers of the conveyor belt. The hot gas discharge pipe is provided with air outlet holes, two of which are arranged in the same length direction of the hot gas discharge pipe, and are symmetrical to the vertical plane of the center line of the superheated gas discharge pipe. Penetration to the withered drying material; the temperature of the drying layer is more uniform, and changes with the change of humidity, the higher the humidity, the higher the temperature, which improves the drying effect and reduces the energy loss at the discharge port; slows down the wind pressure, It prevents the drying objects from flying all over the sky, and prevents the drying objects from blowing onto the guide rails and being crushed, avoiding the burning of carbides and improving the safety performance of the equipment.

Owner:张财生

Slight fuel accumulation ignition increasing mechanical feeding method

ActiveCN102997229AImprove burnout rateExtended stayFluidized bed combustionSolid fuel combustionBoiler furnaceRetention time

The invention discloses a slight fuel accumulation ignition increasing mechanical feeding method. The slight fuel accumulation ignition increasing mechanical feeding method comprises the following steps of: feeding a light biologic material or a fine powder fuel or recycled material fine powder on a negative pressure position in a boiler furnace, utilizing a boiler with a certain pressure and using a primary or secondary air special organization to form a special burning zone with accumulation and afterburning action, prolonging retention time of the light biologic material or fine powder fuel or returning fine powder on a secondary furnace bottom, and combining characteristics of different fuels. The technology can effectively solve the technological problems that the light biologic material or the returning fine powder can cause lower burning efficiency or higher water containing light fuel such as light weight straw, a plastic film in garbage and high fine powder bunker coal, and the slight fuel accumulation ignition increasing mechanical feeding method has the advantages of effectively improving burning efficiency and reducing attrition aspect.

Owner:JIANGLIAN HEAVY IND GRP CO LTD

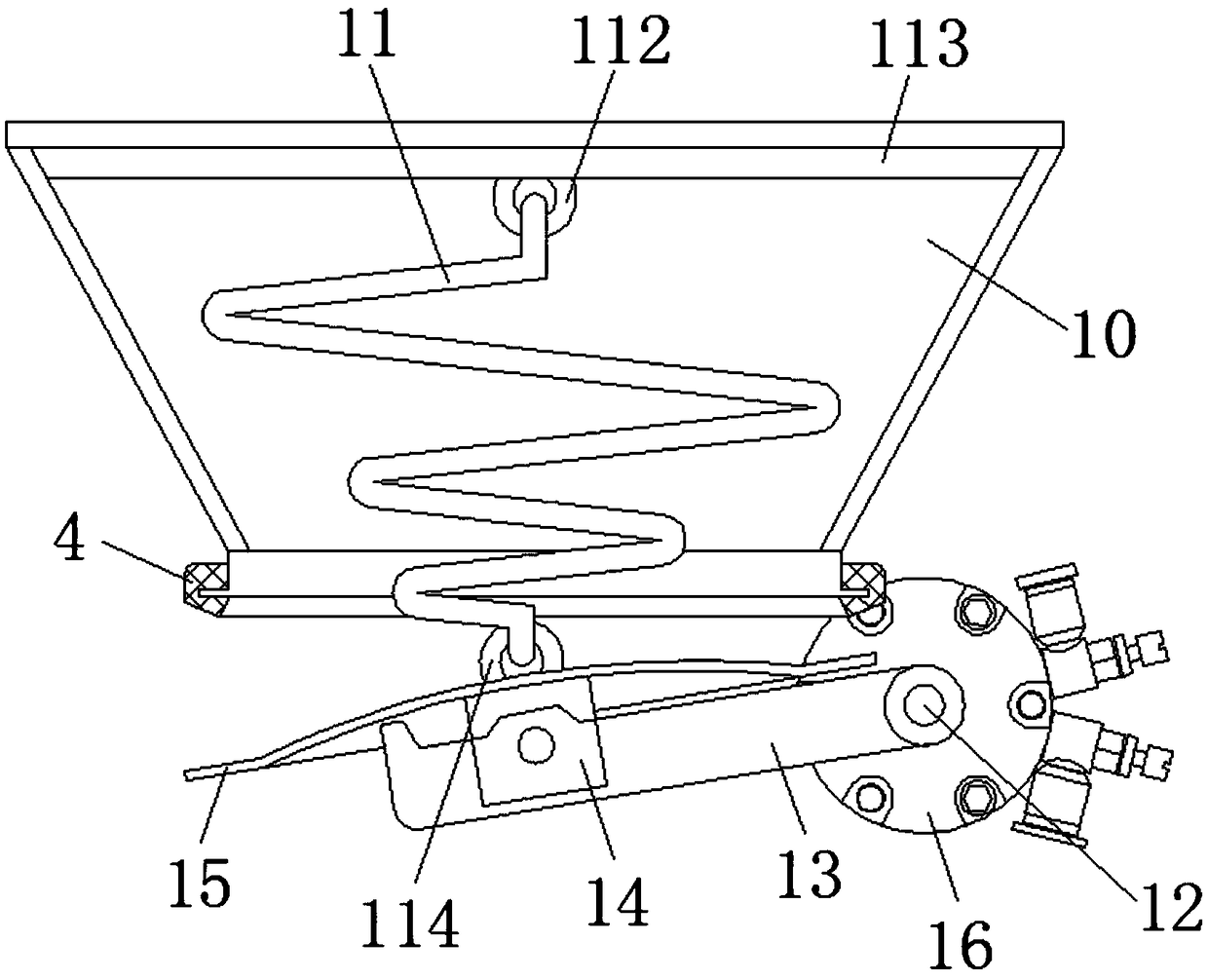

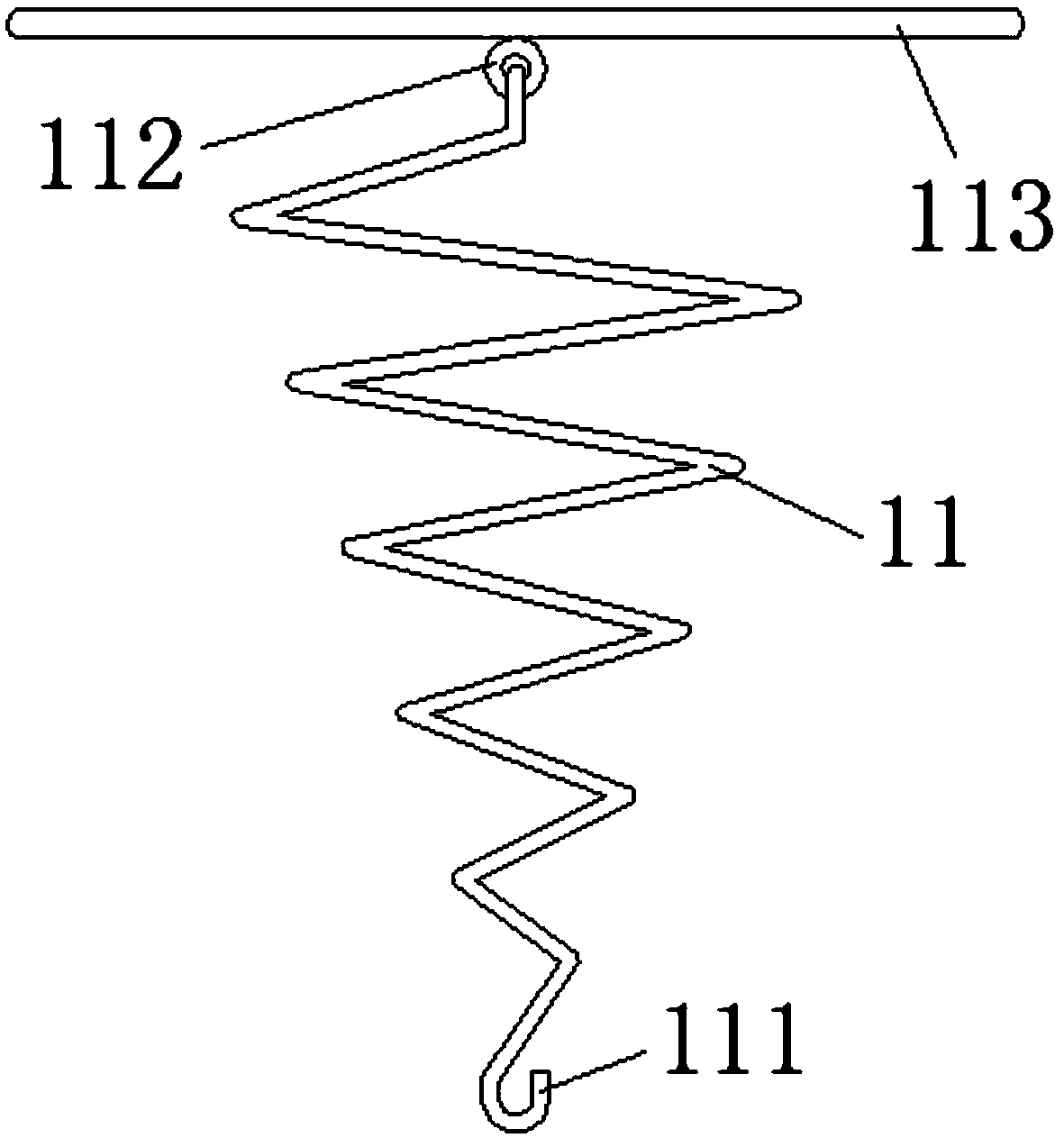

Arch breaking device for preventing material bridging

ActiveCN108792325ATo achieve the effect of breaking the archBroken arch hasLarge containersEngineeringButterfly valve

The invention discloses an arch breaking device for preventing material bridging. The arch breaking device comprises a material storage cylinder, wherein the upper surface of the storage cylinder is fixedly provided with an upper cover through a first tightening hoop, a breathing device is fixedly arranged on the inner top wall of the upper cover, the lower surface of the storage cylinder is fixedly communicated with a connecting cylinder through a second tightening hoop. According to the arch breaking device for preventing material bridging, the arch breaking device is used for solving the problem of bridging of powder materials; when the butterfly valve or the flap valve is opened, the arch bridge is damaged by the arch breaking device installed in the hopper to enable the materials to flow out, the arch breaking device comprises a cross rod, an upper hanging ring is welded on the upper hanging ring, hooks are both arranged on the upper portion and the lower portion of the conical spring, the upper portion of the conical spring is hung on the upper hanging ring of the cross rod, the lower part of the disc plate is hung on the lower hanging ring on the disc plate, when the disc plate is opened, the disc plate drives the conical spring, the tension of the conical spring is used for destroying the arch bridge formed by the materials, so that the materials can flow out smoothly,and then have the characteristic that the powder in the hopper is subjected to arch breaking.

Owner:常州优一机械有限公司

Rubber powder ton packaging unloading auxiliary device

InactiveCN104401763BSolve bridgingImprove work efficiencyLarge containersBags openingMechanical engineeringTon

The invention discloses a rubber powder ton package unloading auxiliary device, which comprises a hopper which is supported by foot stalls to be in position, an insertion rod and a support bracket, wherein the support bracket is erected on a feeding upper opening of the hopper; the insertion rod is vertically arranged on the support bracket and is located in the center of the feeding upper opening; a puncture head capable of puncturing a ton packaging bag is arranged on the top end of the inserting rod; a discharging lower opening of the hopper corresponds to the unloading position of the ton packaging bag; the puncture head is a conical body or a multi-pyramid body with the cone angle being less than or equal to 45 degrees; the height of the puncture head is ranged from 100mm to 200mm; the length of the insertion rod is ranged from 1000mm to 2000mm. According to the rubber powder ton package unloading auxiliary device, without consuming redundant manpower and energy cost, the problem that the rubber powder ton package is difficult to unload is solved, and the work efficiency is greatly improved.

Owner:GUANGXI YUANJING RUBBER TECH

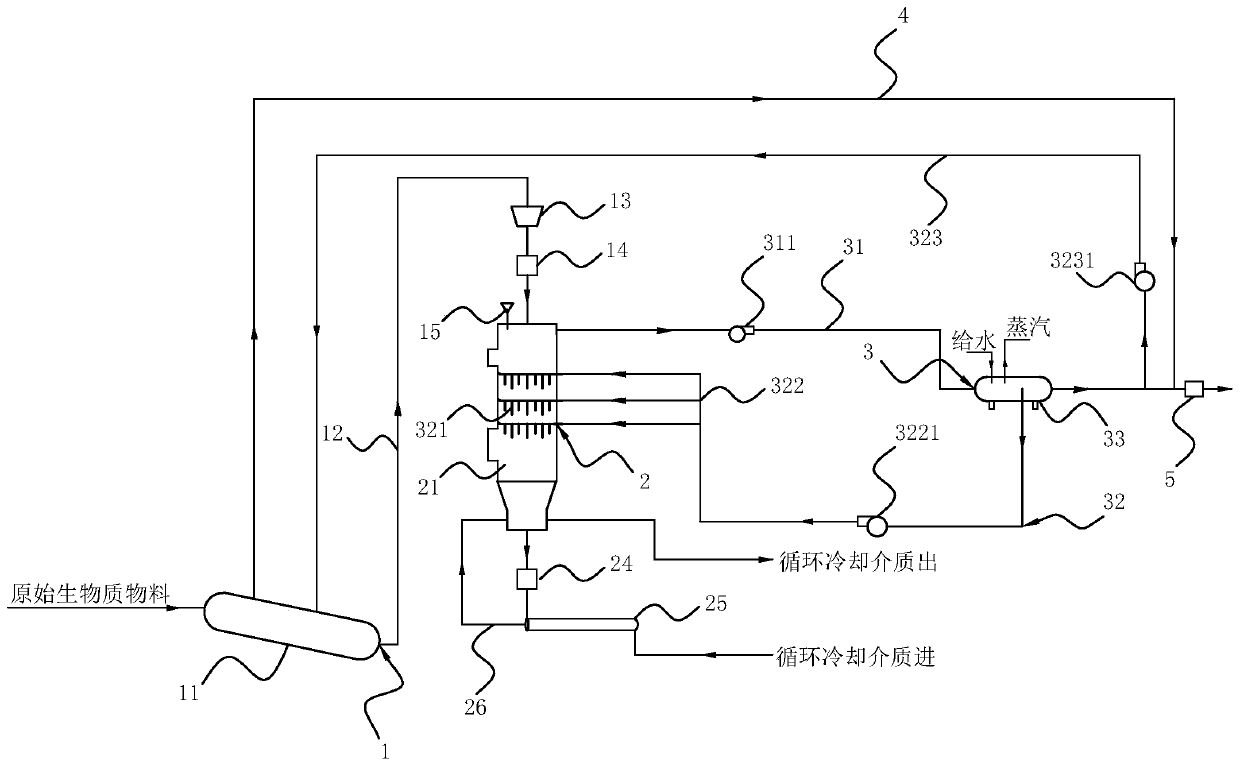

Biomass comprehensive utilization device of biomass pyrolysis carbonization coupled direct-fired boiler

PendingCN111454739AAvoid easy coking on the heated surfaceAvoid efficiencyBiofuelsOven foundationsThermodynamicsFlue gas

The invention discloses a biomass comprehensive utilization device of a biomass pyrolysis carbonization coupled direct-fired boiler, and relates to the technical field of biomass energies. The biomasscomprehensive utilization device comprises a feeding system, a pyrolysis carbonization and cooling system and a flue gas and air system, wherein the feeding system comprises a material drying device,a material conveying device, a material storage device, an upper end blanking device and a material control device; the pyrolysis carbonization and cooling system comprises a pyrolysis furnace, a lower end blanking device, a carbon block cooling and conveying device and a circulating cooling device; the flue gas and air system comprises a pyrolysis gas channel, a flue gas channel and a direct-fired boiler, a gas inlet of the direct-fired boiler is connected with the pyrolysis furnace through the pyrolysis gas channel, and a gas outlet of the direct-fired boiler is respectively connected witha user side, the pyrolysis furnace and the material drying device through the flue gas channel. The biomass pyrolysis system and the direct-fired boiler are coupled, so that the problems of equipmentblockage or equipment corrosion and the like caused by tar condensation are avoided, and efficient biomass application of energy cascade circulation is realized.

Owner:上海动银科技有限公司

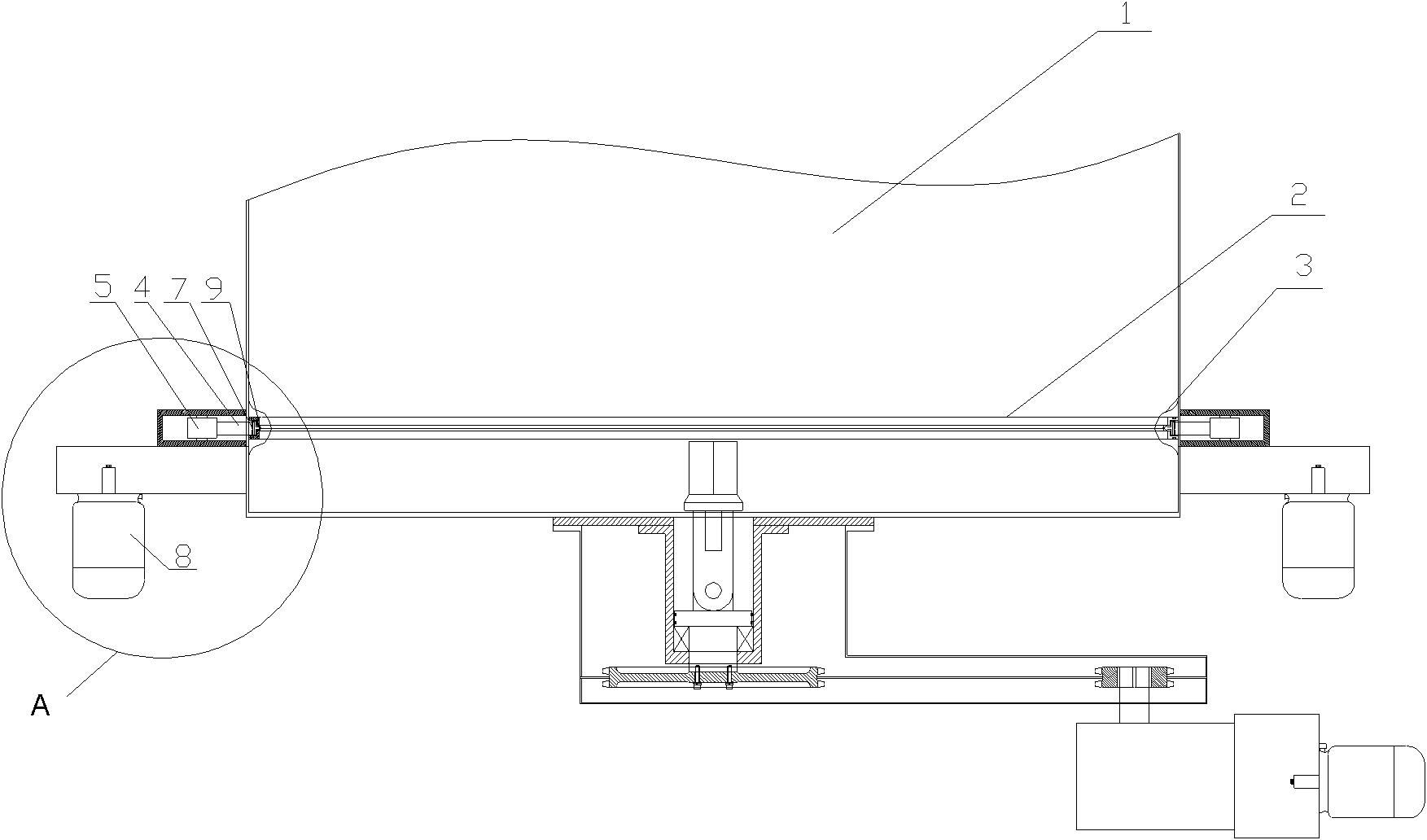

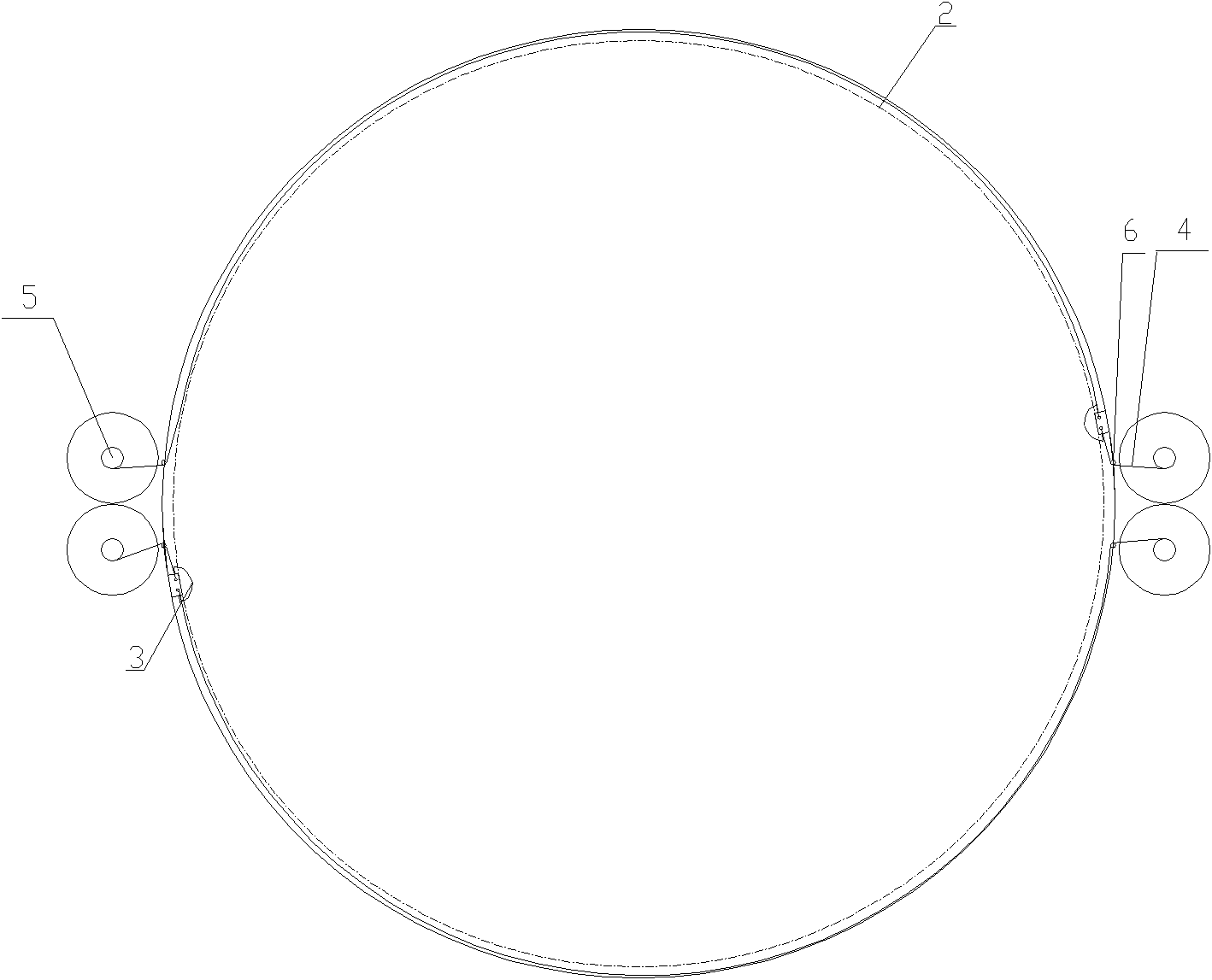

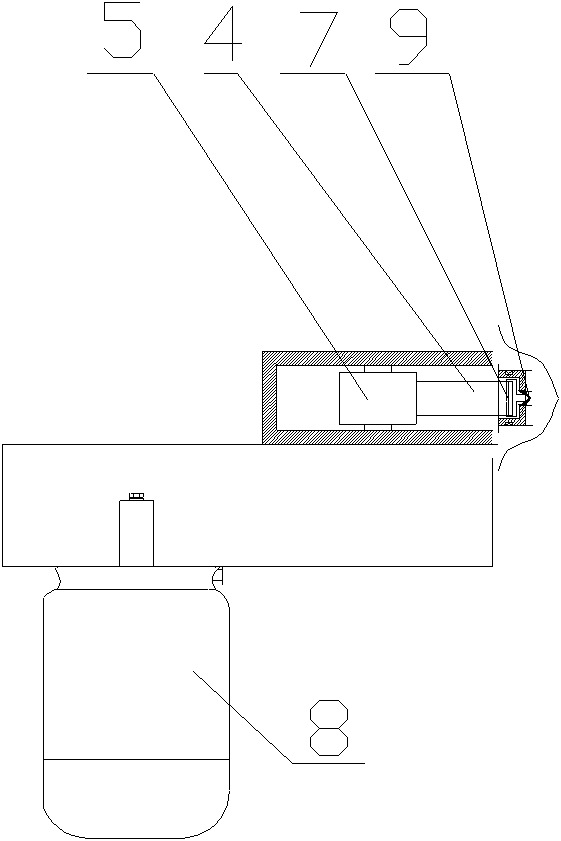

A reciprocating bridge breaking scraper device for mud bins

The invention discloses a reciprocating bridge-breaking scraper apparatus used in a sludge bin. The scraper apparatus comprises: a cylindrical sludge bin for storing sludge. Two segments of semicircular horizontal tracks are disposed on a lower part of an inner wall of the sludge bin; two groups of conveyor belt contraction rollers are disposed on a position outside the sludge bin, the position having the height the same as that of the tracks outside the sludge bin, wherein each group of the conveyor belt contraction rollers includes two conveyor belt contraction rollers disposed on boundaries of the two segments of semicircular tracks respectively; a quadricuspid arc scraper matched with the tracks is disposed on each of the two segments of semicircular tracks; a conveyor-belt fixing shaft connected with conveyor belts and disposed on a base of the quadricuspid arc scrapers is in transmission connection with a corresponding group of the conveyor belt contraction rollers through a rotating shaft disposed on the wall of sludge bin; and an output shaft of a transmission motor is in transmission connection with each group of the conveyor belt contraction rollers. The scraper apparatus designed through the invention is characterized by a simple structure and easy operation and solves the problem of sludge bridge usually existing in the sludge bin with only low power.

Owner:SHANGHAI CENTRIFUGE INST

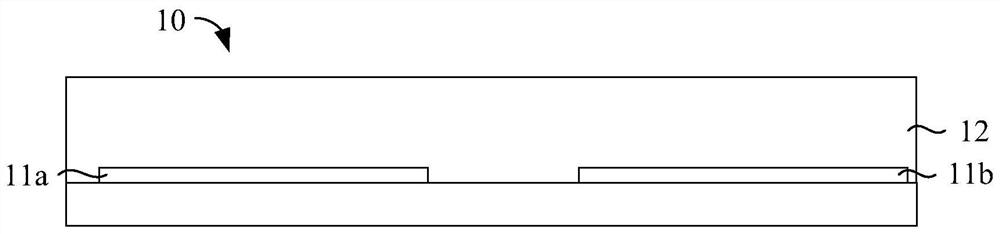

Control valve for metering scale

PendingCN109340401ASimple structureLow costDiaphragm valvesEngine diaphragmsEngineeringControl valves

The application discloses a control valve for a metering scale. The control valve for the metering scale comprises an upper flange, a lower flange and a rubber tube arranged between the upper flange and the lower flange. A pair of telescopic devices is symmetrically arranged on both sides of the rubber tube with a center of the rubber tube as a midpoint. The telescopic devices comprise a pluralityof vertical columns, supporting plates, cylinders, connecting plates and rubber strips. Two ends of the vertical columns are correspondingly connected with lower end faces of the upper flanges and the upper end faces of the lower flanges. The supporting plates are connected with the vertical columns. The output ends of the cylinders are set toward the rubber tube and are connected with the rubberstrips through the connecting plates after penetrating through the supporting plates. The rubber strips and the connecting plates are arranged horizontally perpendicular to the rubber tube. The control valve has a simple structure, is used to be connected to a feeding tube on the metering scale, and can control the feeding speed well, so that the problem of material bridging is solved effectively.

Owner:ZHANGJIAGANG GRACE MACHINERY CO LTD

Main extrusion feeding and stirring stock bin

PendingCN110898702AIncrease motor powerIncrease stirring speedRotary stirring mixersTransportation and packagingProcess engineeringPhencyclone

The invention discloses a main extrusion feeding and stirring stock bin. The main extrusion feeding and stirring stock bin comprises a stock bin body and a cyclone separator, a discharging port is formed in the bottom of the stock bin body, a feeding port is formed in the top end of the stock bin body, and a first stirring piece and a second stirring piece which are oppositely arranged are arranged on the two sides in the stock bin body; and a discharge port of the cyclone separator is connected with a feed port of the stock bin. Granules, sheet materials and rim charges are fed into the cyclone separator through a fan, the motor power of the cyclone separator is increased, and raw materials can smoothly enter the stock bin; the first stirring piece and the second stirring piece are arranged in the stock bin to stir together, the stirring speed of the sheet materials and the granules is increased, it is guaranteed that the sheet materials and the granules are evenly mixed and stirred,the bridging problem is effectively solved, and continuous and stable production is guaranteed.

Owner:ANHUI GUOFENG PLASTIC

A kind of triaxial magnetic sensor and preparation method thereof

ActiveCN110040679BThe process steps are simpleSolve bridgingTelevision system detailsMagnetic measurementsMechanical engineeringPhotoresist

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

A frequency-modulated self-excited oscillating jet device and its application method

ActiveCN105536339BStrong recycling abilityImprove recycling efficiencyMembrane filtersMoving filtering element filtersMixed flowSelf-oscillation

The invention relates to a frequency modulation type self-oscillation jetting device and a use method thereof. The frequency modulation type self-oscillation jetting device comprises a shell with a tubular opening structure, a base plate, a vertical jetting inlet, a rectification cavity, a mixed flow cavity, a jetting outlet and tangent jetting inlets, wherein an opening in the bottom of the shell is fixedly connected with the base plate; the vertical jetting inlet is vertically arranged at the top of the shell; the inlet end of the vertical jetting inlet is connected with a backwashing pipeline; the outlet end of the vertical jetting inlet is communicated with the rectification cavity positioned at the upper part in the shell; a channel and the mixed flow cavity are arranged below the rectification cavity in sequence in the shell; the lower side of the rectification cavity is communicated with the inlet of the channel; the outlet of the channel is positioned above the inlet of the mixed flow cavity; the outlet of the mixed flow cavity penetrates through the base plate and is communicated with the jetting outlet; a jetting fusion region is formed between the channel outlet and the inlet of the mixed flow cavity; a plurality of tangent jetting inlets communicated with the upper part of the channel are formed in the outer side wall of the upper part of the shell at intervals. The frequency modulation type self-oscillation jetting device is energy-saving, so that the problems of local deformation, washout damage and the like to a filter screen due to extreme-high impact pressure are solved.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Internal screw quantitative feeding device

The invention belongs to the technical field of explosive feeding equipment, and particularly relates to an internal screw quantitative feeding device for uniform-speed conveying of explosive powder.The feeding device comprises a support frame, a motor mounting seat, a motor, a speed reducer, a rear bearing, a stock bin, a stock bin lid, a material barrel, a front bearing and a baffle. The internal screw quantitative feeding device provided by the invention has the benefits that by utilizing spiral grooves in the inner wall of the material barrel and relying on the gravity of materials, quantitative forward conveying of the materials when the material barrel rotates is realized, and the forward conveying speed of the materials is controlled by controlling the rotating speed of the material barrel, therefore, the mechanical stimuli such as extrusion and impact of the feeding device on the materials are avoided, and the safety is improved; the feeding speed can be controlled by controlling the rotating speed of the material barrel and has nothing to do with the amount of the materials in the stock bin; the problem of material bridging in the stock bin of an existing feeding device can be solved.

Owner:XIAN MODERN CHEM RES INST

Multi-directional air distribution fixed bed biomass gasification stoves

InactiveCN101475814BIncrease reaction strengthIncrease powerSpecial form destructive distillationFixed bedForced-air

The invention discloses a multi-ventilation fixed bed biomass gasification furnace, which comprises a furnace body and a fire gate, wherein the fire gate is arranged in the middle part of the furnace body; the furnace body is provided with a forced air intake system which comprises an air feed mechanism, a ventilation device and a connecting pipe; the ventilation device is a ventilation pipeline which is positioned above the fire gate in the furnace body and is used for inletting air from a plurality of directions; and the air feed mechanism is positioned outside the furnace body and is connected with the ventilation pipeline through the connecting pipe which penetrates through the furnace wall so as to provide a forced air supply for the inside of the furnace. The multi-ventilation fixed bed biomass gasification furnace adopts a forced air feed mode that the air feed mechanism is combined with the ventilation device to feed air; and compared with the prior normal pressure air feed mode, the multi-ventilation fixed bed biomass gasification furnace improves the power of the gasification furnace, reduces the tar content in fuel gas, greatly reduces the tar content in waste water, and is advantageous for environmental protection; besides, the multi-ventilation fixed bed biomass gasification furnace does not have specific requirements on the dimension, the dryness, the feeding mode and the like of biomass raw materials, thereby widening the application range of the biomass raw materials.

Owner:广州市宇联机电有限公司

An arch breaking device for preventing materials from bridging

ActiveCN108792325BTo achieve the effect of breaking the archBroken arch hasLarge containersEngineeringFlap valve

Owner:常州优一机械有限公司

Vegetable outputting device

InactiveCN112078984ASolve bridgingAvoid cloggingLarge containersLoading/unloadingStructural engineeringMechanical engineering

The invention discloses a vegetable outputting device. The vegetable outputting device comprises a storage device and a blending mechanism, wherein a storage cavity and a discharging opening are formed in the storage device, and the discharging opening is located in the bottom of the storage cavity; and the blending mechanism comprises a rotating part, bridge-breaking rods, a screw panel and a driving assembly, the rotating part, the screw panel and the bridge-breaking rods are arranged in the storage cavity separately, the screw panel and the bridge-breaking rods are connected with the rotating part separately, the ends, extending to an inner wall of the storage device, of the bridge-breaking rods tilt in a direction of the discharging opening, and a driving assembly is connected with theend, away from the screw panel, of the rotating part. According to the vegetable outputting device, when vegetables are output, the bridge-breaking rods and the screw panel rotate at the same time, the vegetables are gathered and pressed downwards by the bridge-breaking rods, thus the vegetables can move towards a center of the bottom of the storage cavity and gather on the screw panel better, and then through rotation of the screw panel, the vegetables are discharged in a screwed mode, so that the problem of vegetable bridging is solved, and the problem that vegetables cannot be discharged due to blocking is avoided.

Owner:GUANGDONG ATHENE ROBOTIC TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com