Patents

Literature

53results about "Oven foundations" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Coke oven column installation method

The invention relates to a coke oven column installation method. A coke oven body is built after a coke oven column is installed. The method is characterized by comprising the following steps of: a, acceptance inspecting the foundation; b, transporting and hoisting the oven column; c, temporarily fixing facilities; d, installing and temporarily fixing the oven column; e, adjusting the oven column. The coke oven column installation method has the advantages that the installation procedure design is reasonable, simplicity in operation can be realized, the geometric dimension of a coke oven body refractory brick building body is accurately controlled, the system error is reduced, the building precision is improved, the sealing property of the coke oven is effectively guaranteed, the normal production of the coke oven can be favored, and the service life of the coke oven can be prolonged.

Owner:MCC5 GROUP CORP SHANGHAI

Quick installation method of coke oven guard plate and oven column

The invention discloses a quick installation method of a coke oven guard plate and an oven column, comprising the following steps: 1) after a coke oven body is built, a temporary fixed mount is respectively arranged on the positions on two sides of an oven top machine, which correspond to the installation positions of a guard plate and an oven column; 2) after the guard plate is hung to the proper position and adjusted, a binding piece connects the upper part of the guard plate with the temporary fixed mount so as to temporarily fix the guard plate; 3) after the guard plate is temporarily fixed, the oven column is hung to the proper position, and then the oven column is adjusted, the binding piece connects the upper part of the oven column with the temporary fixed mount so as to temporarily fix the oven column; 4) the cross-brace of the oven column is installed to formally fix the guard plate and the oven column; and 5) the binding piece and the temporary fixed mount are disassembled.The invention is simple and easy to realize, is easy to operate and master, can be flexibly adjusted according to the conditions, such as manpower, equipment and the like, can centralize the superiorforce of relevant type of work and improves quality and efficiency; the coke oven guard plate and the oven column can be intensively installed so as to reduce lifting machine transit shipment time and save installation time and machinery cost.

Owner:TIANJIN 20 CONSTR

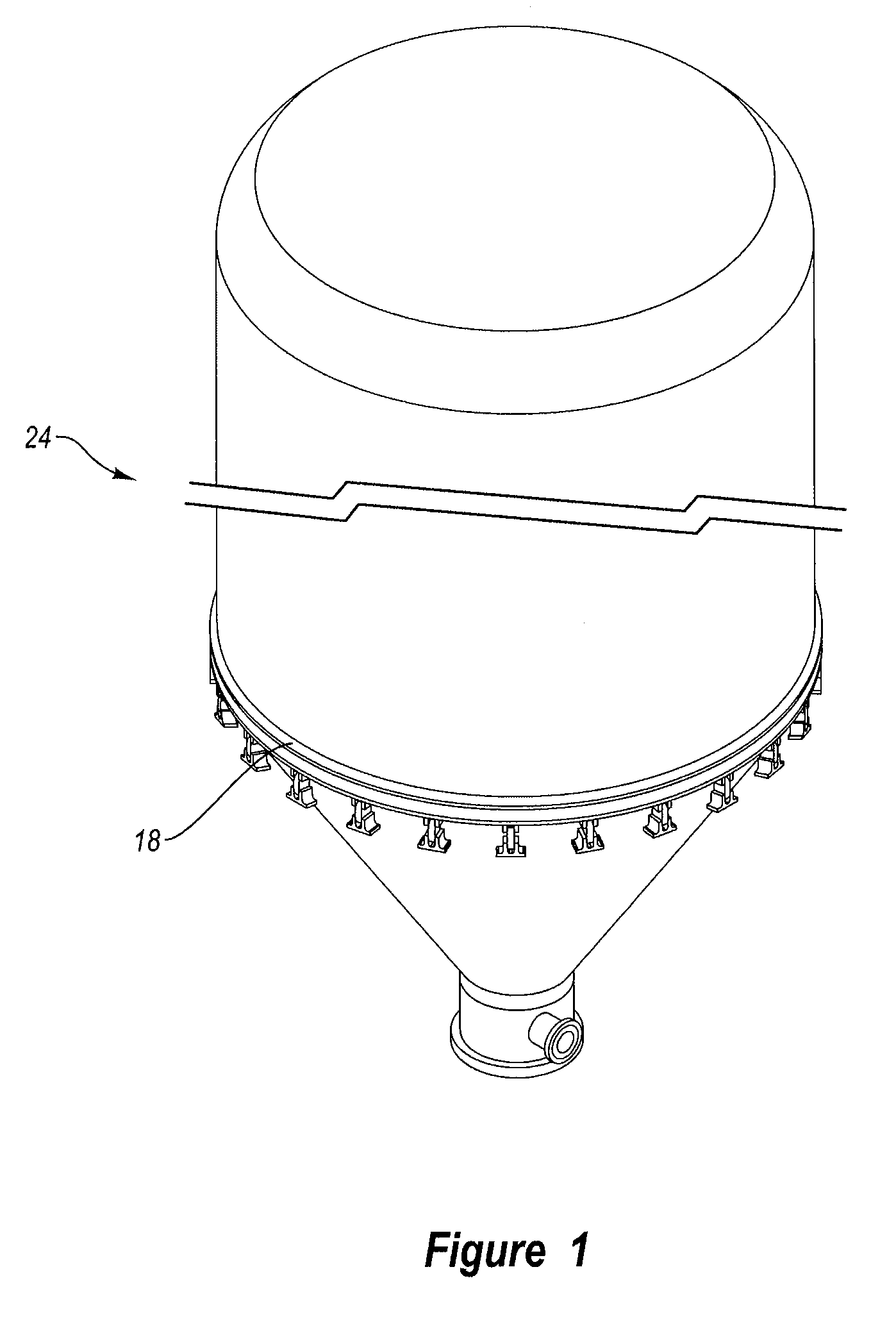

Coke drum skirt

ActiveUS7871500B2Prevent tippingRelieve pressureMechanical conveying coke ovensCoke oven expansion/contraction preventionEngineeringMechanical engineering

Owner:DELTAVALVE

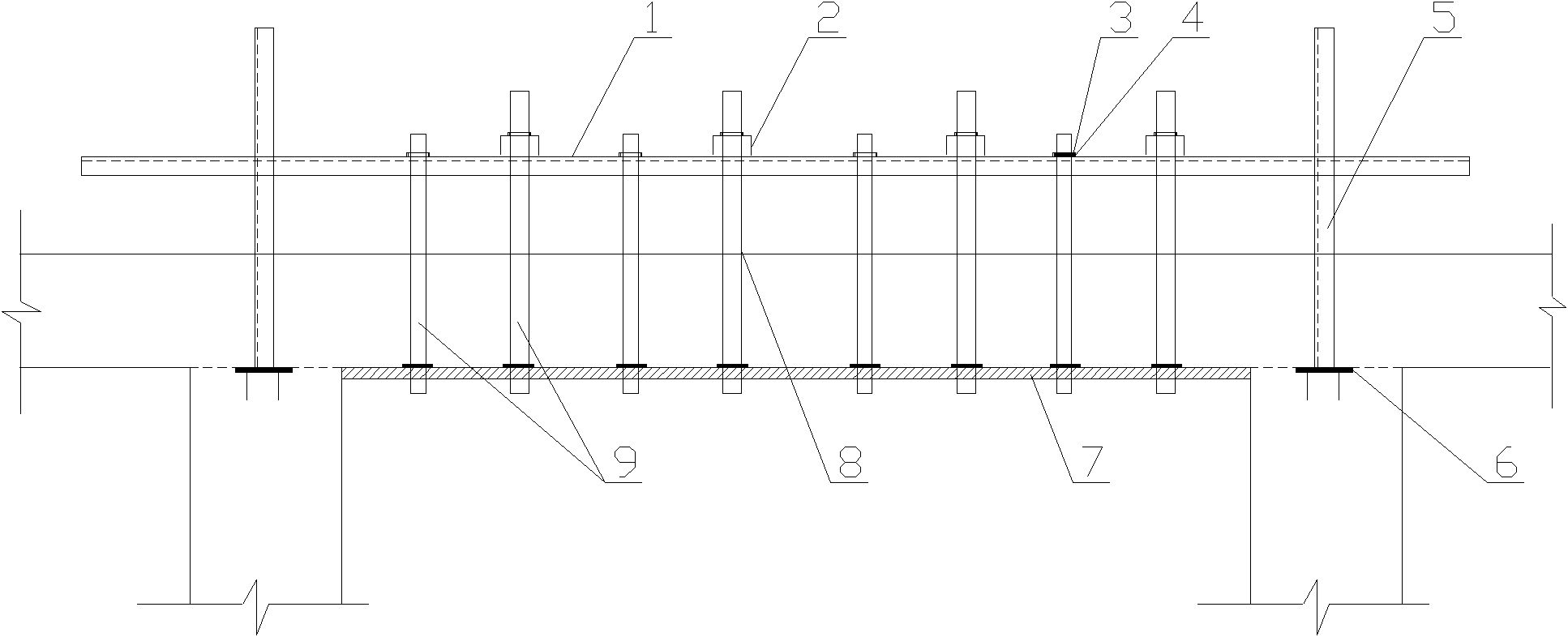

Integral fixed installation method of embedded steel pipe on roof of coal furnace foundation

InactiveCN101892672AReduce labor intensityLow costOven foundationsFoundation engineeringCouplingUltimate tensile strength

The invention discloses an integral fixed installation method of embedded steel pipe on the roof of coal furnace foundation, which is characterized in that channel steel is used as a horizontal cross beam fixed rack and a horizontal longitudinal beam fixed rack, which are welded onto a channel steel post fixed on an embedded iron part, the lower end of the embedded pipe is positioned through a square iron sheet fixed on a multilayered plate, the upper end of the embedded pipe is positioned and elevated by the horizontal cross beam fixed rack and the horizontal longitudinal beam fixed rack via an adjustment pipe coupling, thereby guaranteeing the verticality of the embedded pipe. According to the method, the fixed installation of a plurality of embedded pipes can be completed by means of one-step alignment and adjustment, thus the method is convenient and fast and reduces labor intensity to a great extent, enhances working efficiency, achieves less manpower and lowers expenditure, in addition, the embedded pipes are so fixed and firm that the positioning thereof cannot be impacted by the implementation of other procedures, so the elevation and vertical precision of the embedded pipes are guaranteed.

Owner:TIANJIN 20 CONSTR

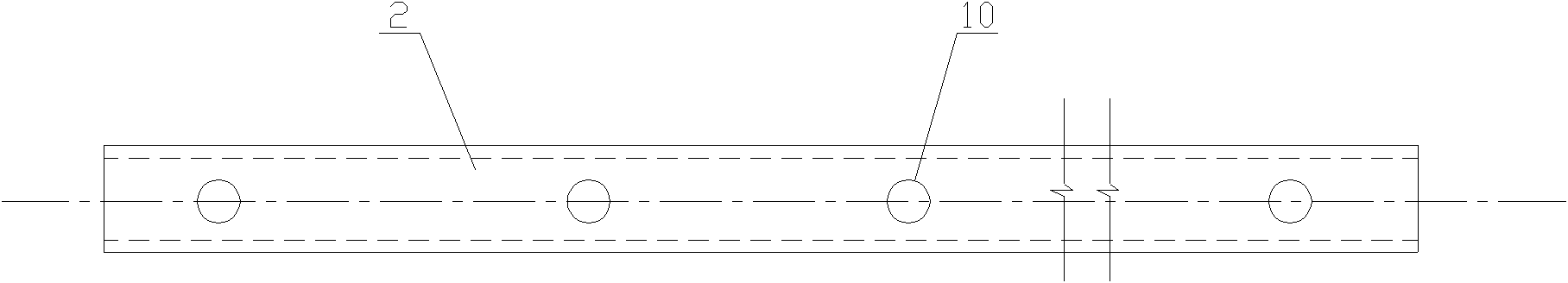

Thermal-exchange construction method of coke oven column

Owner:CHINA 22MCC GROUP CORP

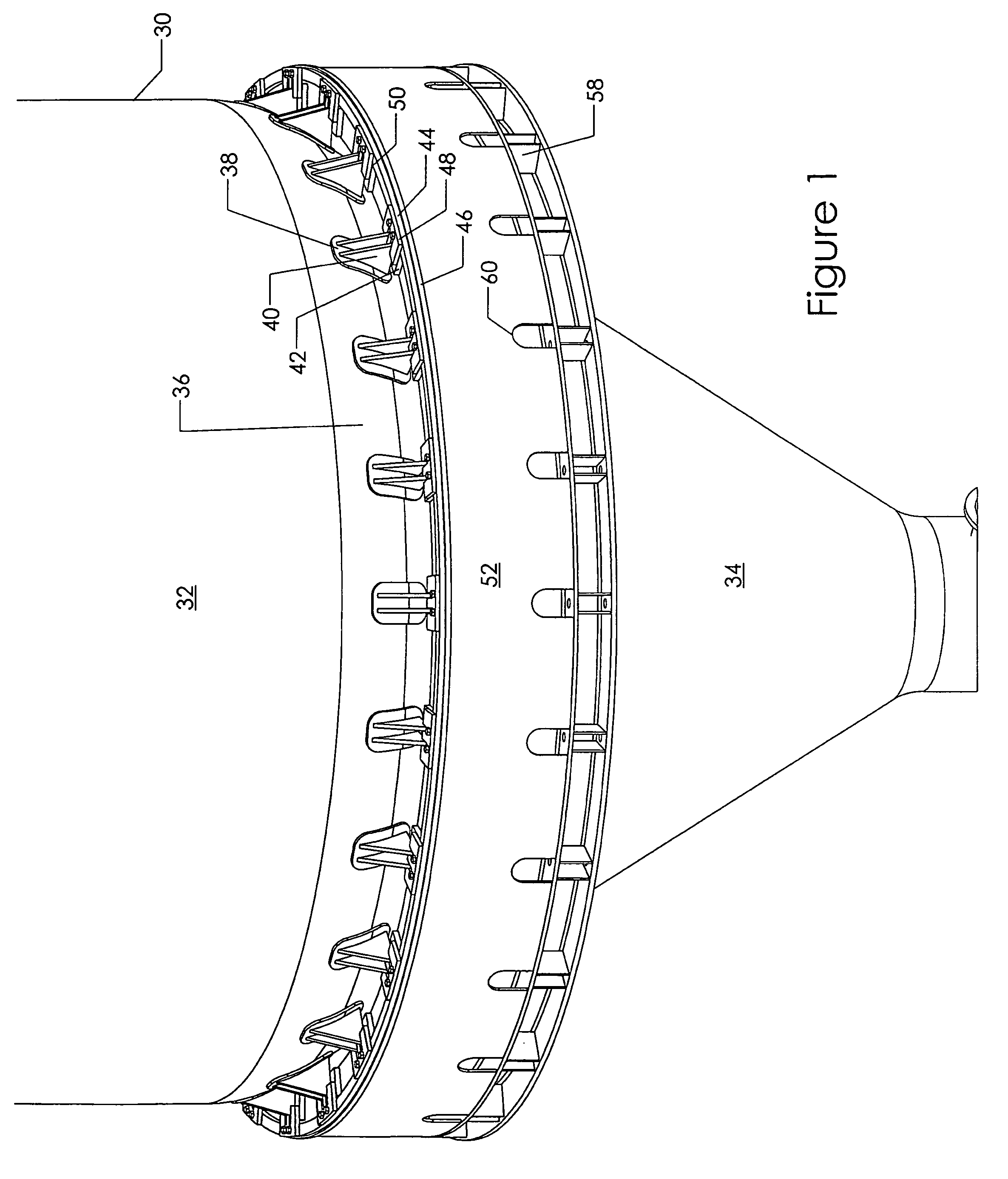

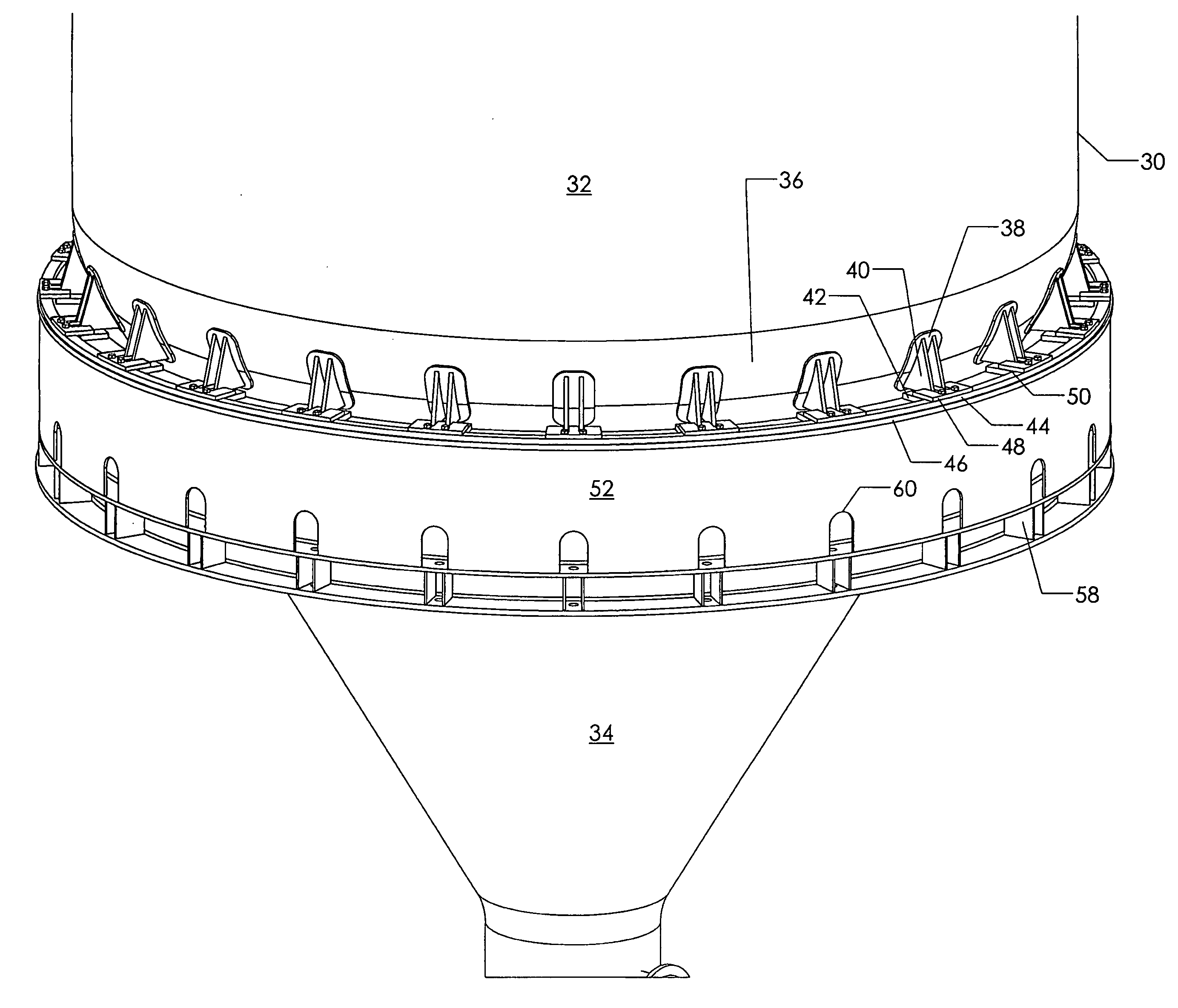

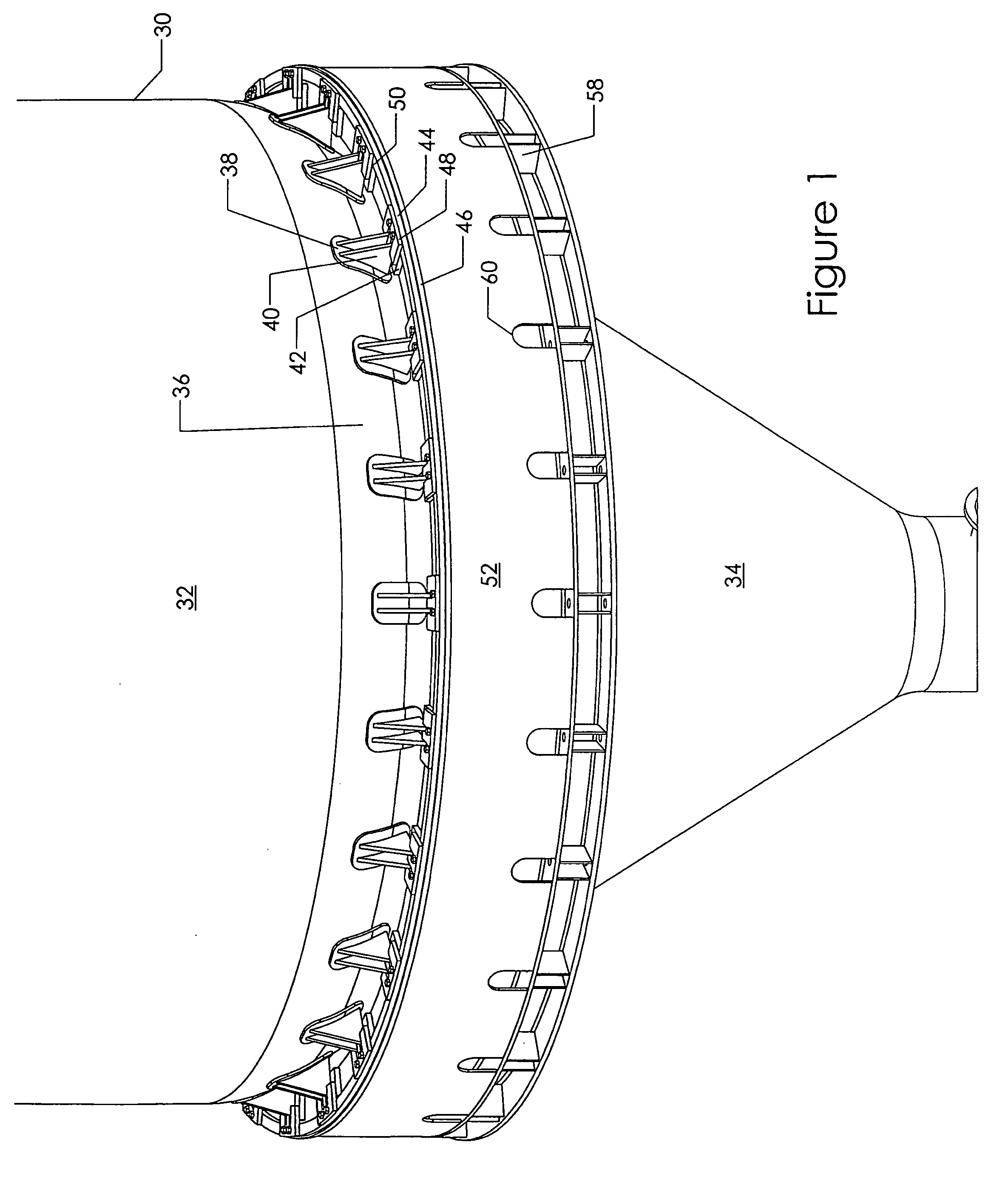

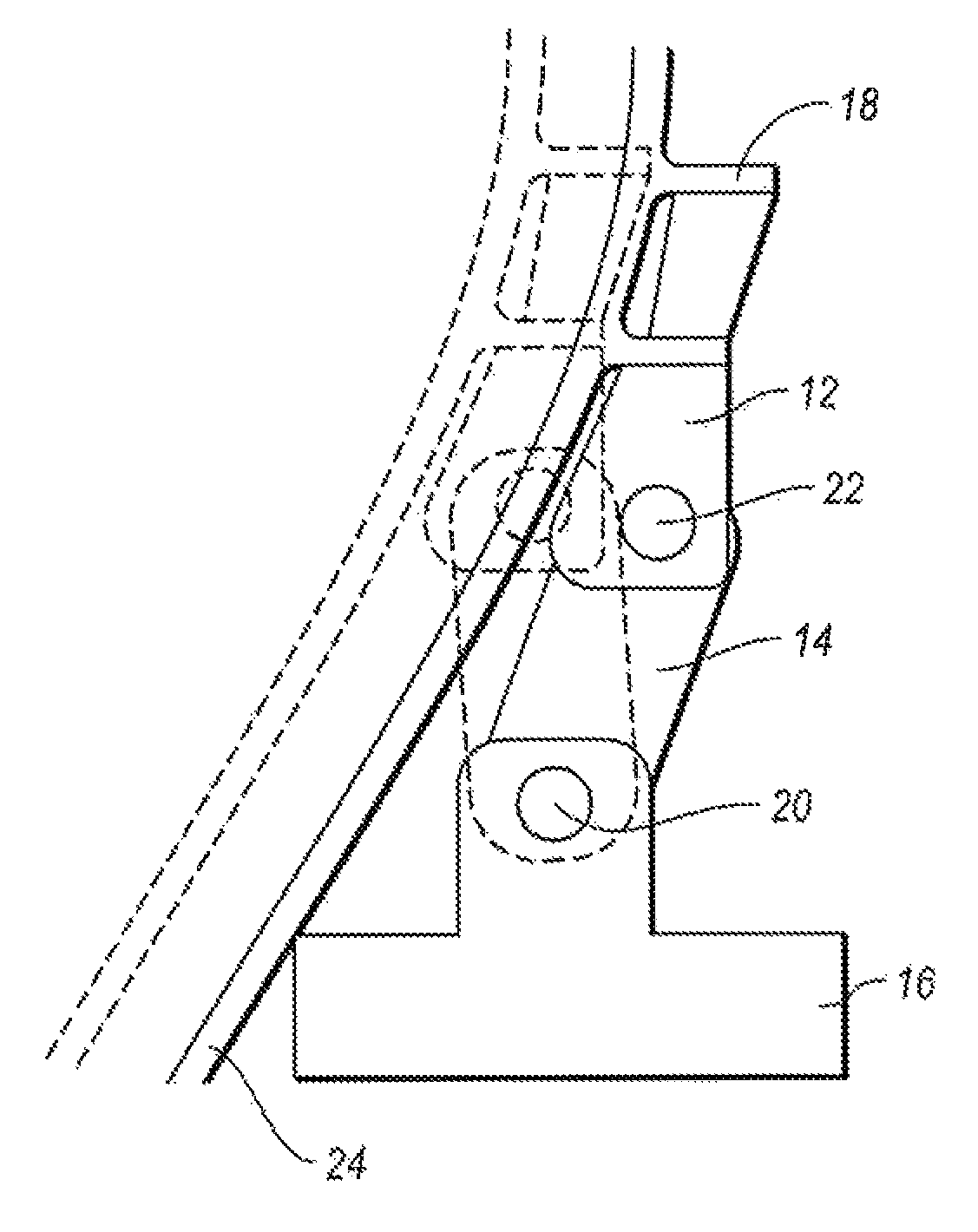

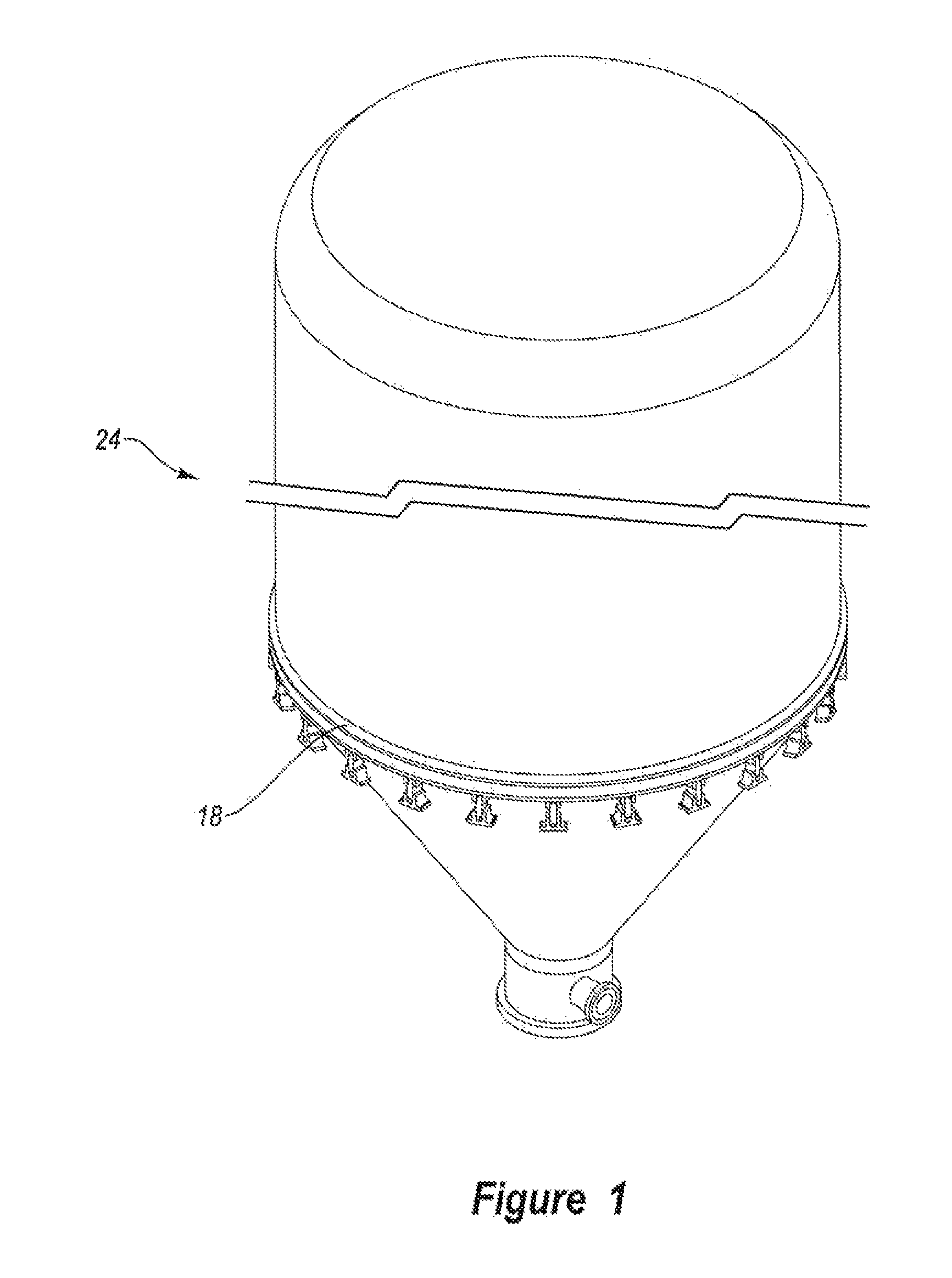

Coke Drum Skirt

ActiveUS20090183980A1Prevent tippingRelieve pressureMechanical conveying coke ovensCoke oven expansion/contraction preventionEngineeringMechanical engineering

A coke drum skirt to minimize the stresses experienced by the coke drum and the supporting structure of the coke drum is described. The skirt includes one circumferential horizontal plate attached to the coke drum, and the circumferential horizontal plate is slidingly sandwiched between a lower supporting plate that supports the weight of the drum through the circumferential horizontal plate and an upper retaining plate that prevents the coke drum from tipping or falling over. The upper retaining plate may be embodied as a series of retaining clips that also keep the coke drum centered and prevent rotation of the coke drum. The upper and lower plates are anchored to a concrete support base. The sliding connection of the plates allows the coke drum to thermally expand and contract while reducing stresses and metal fatigue from the typical fixed securing of the coke drum to the support base.

Owner:DELTAVALVE

Quick repair method for bottom of coke oven carbonization chamber

The invention relates to a quick repair method for the bottom of a coke oven carbonization chamber. The repair steps are as follows: 1, preparation of tools and materials; 2, setting of stuffy furnacenumbers; 3, temperature control of the vertical flue in the repair area; 4, repair of bricks at the bottom of the carbonization chamber; and 5, heat preservation treatment of the carbonization chamber, so far, the repair work of the bottom of the carbonization chamber is completely finished. The maintenance of the bottom of the carbonization chamber should be carried out according to the above steps when bricks at the bottom of the carbonization chamber break or fall off in the future.

Owner:SGIS SONGSHAN CO LTD

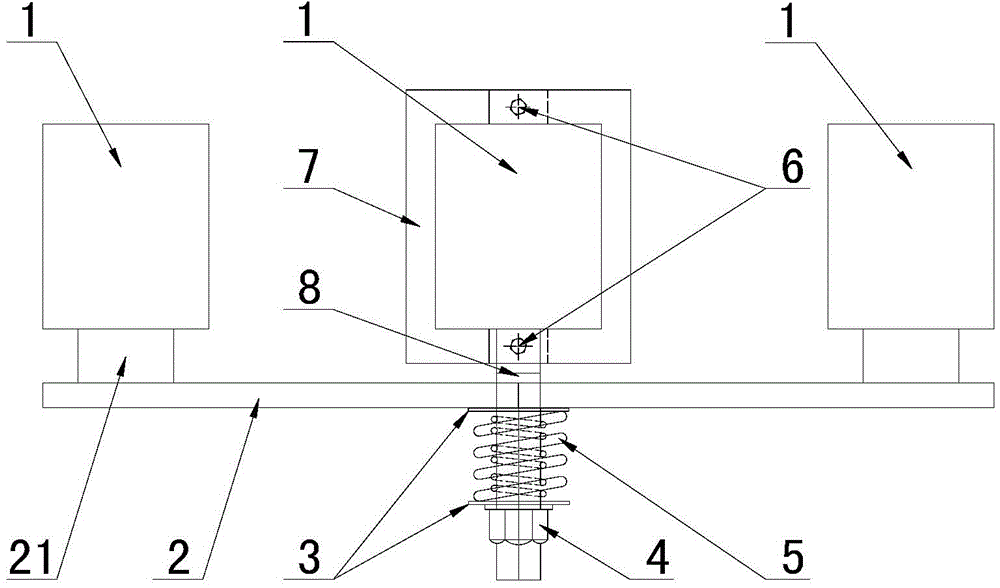

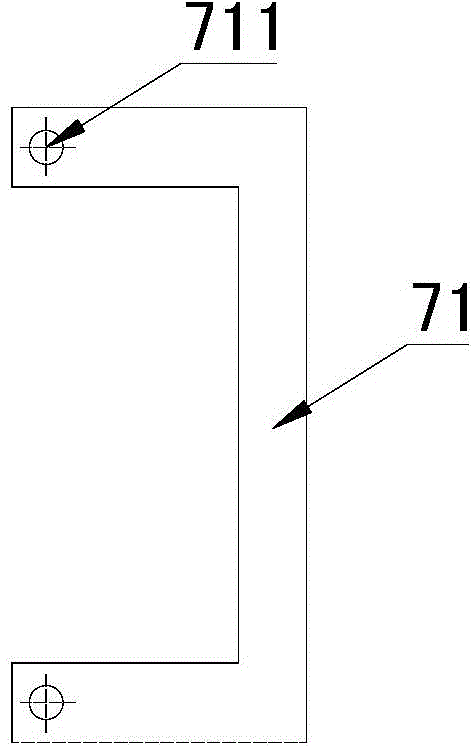

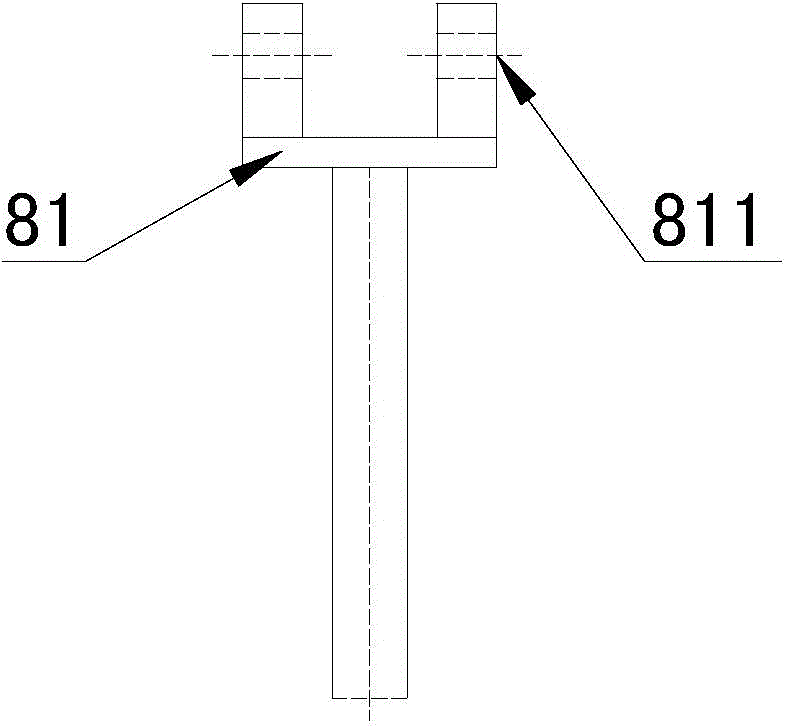

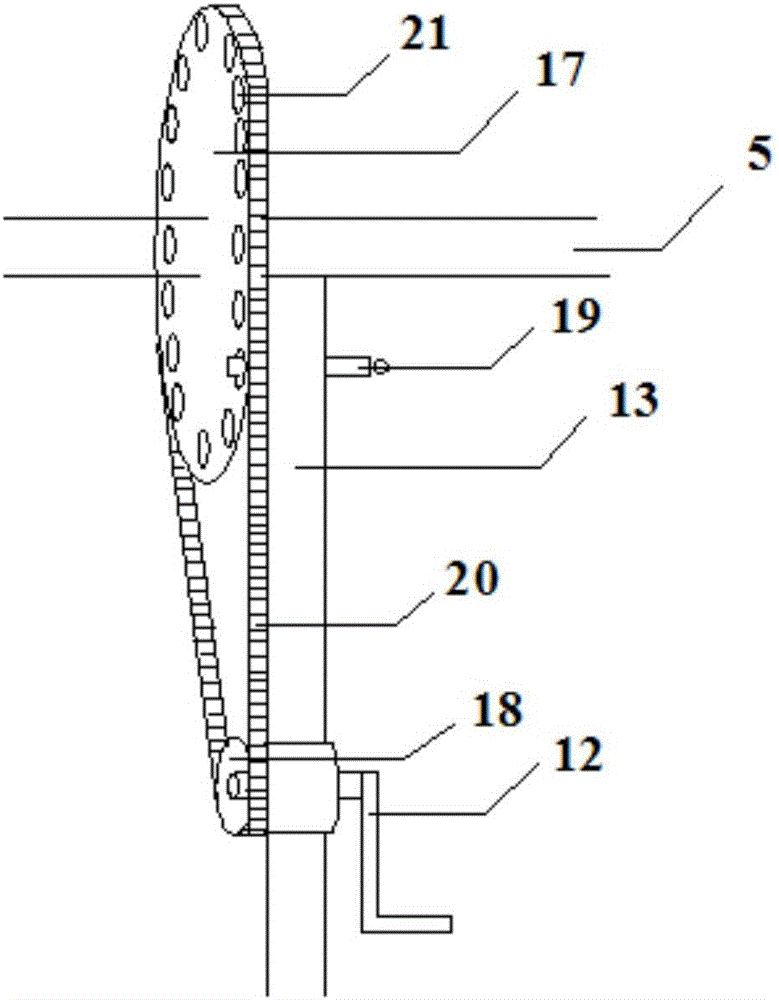

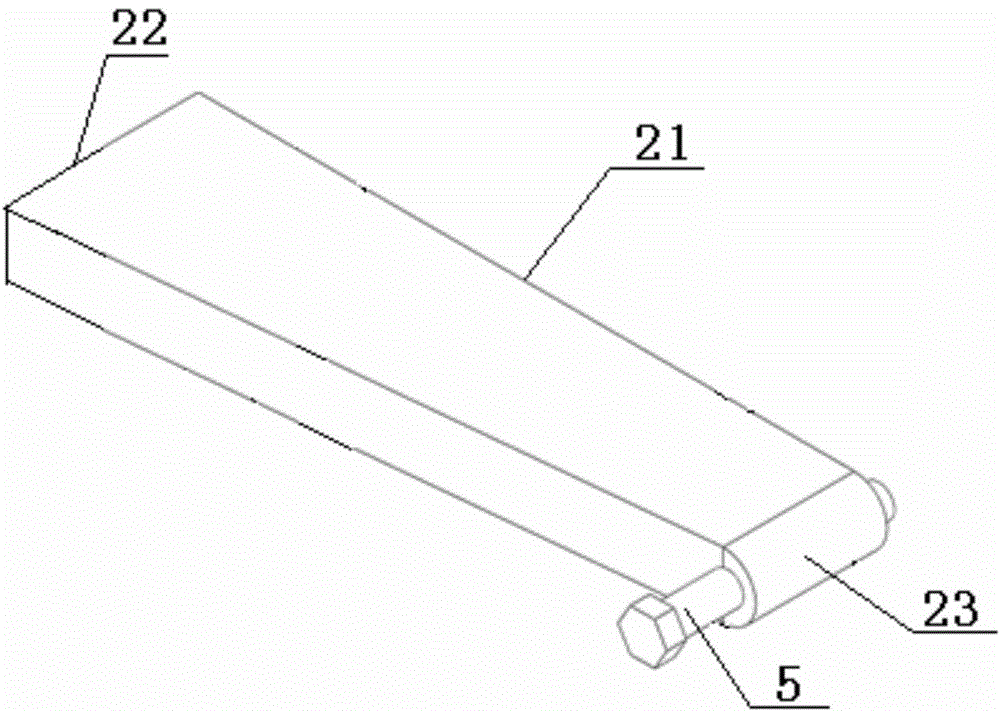

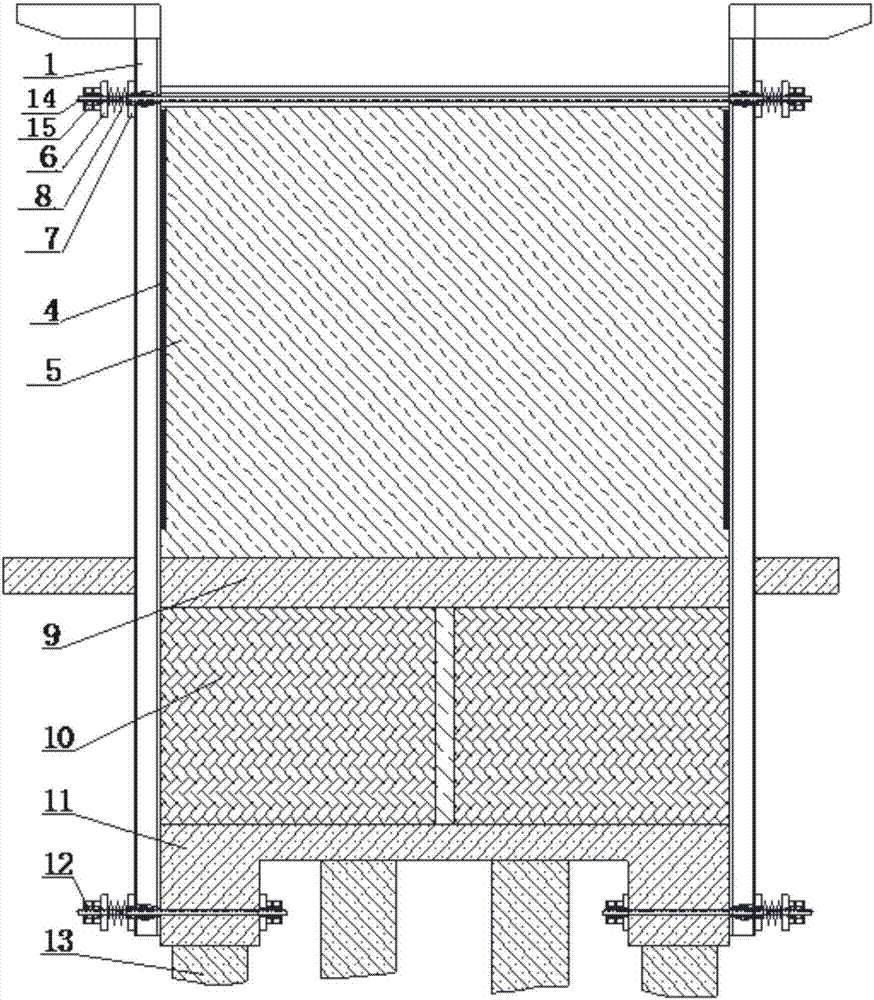

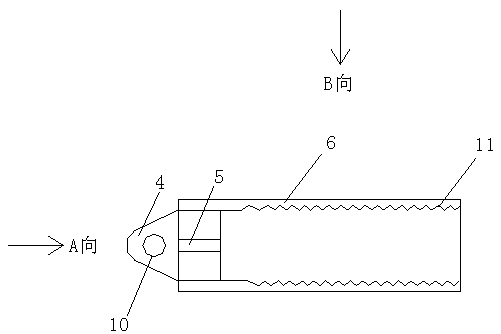

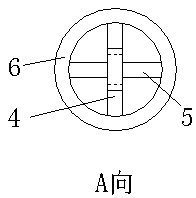

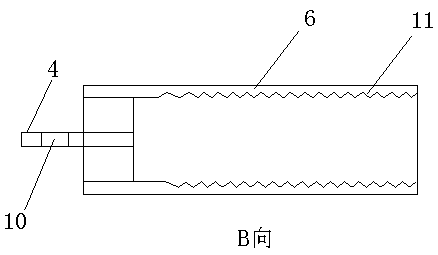

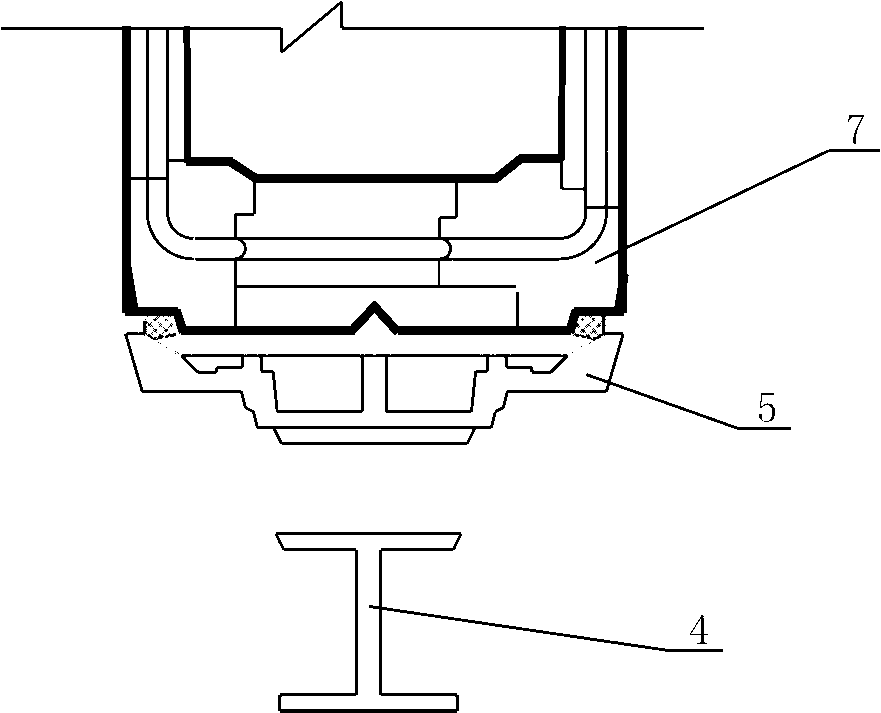

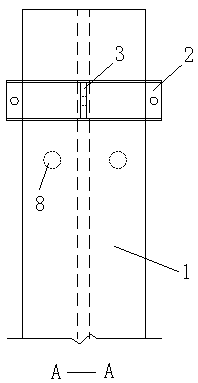

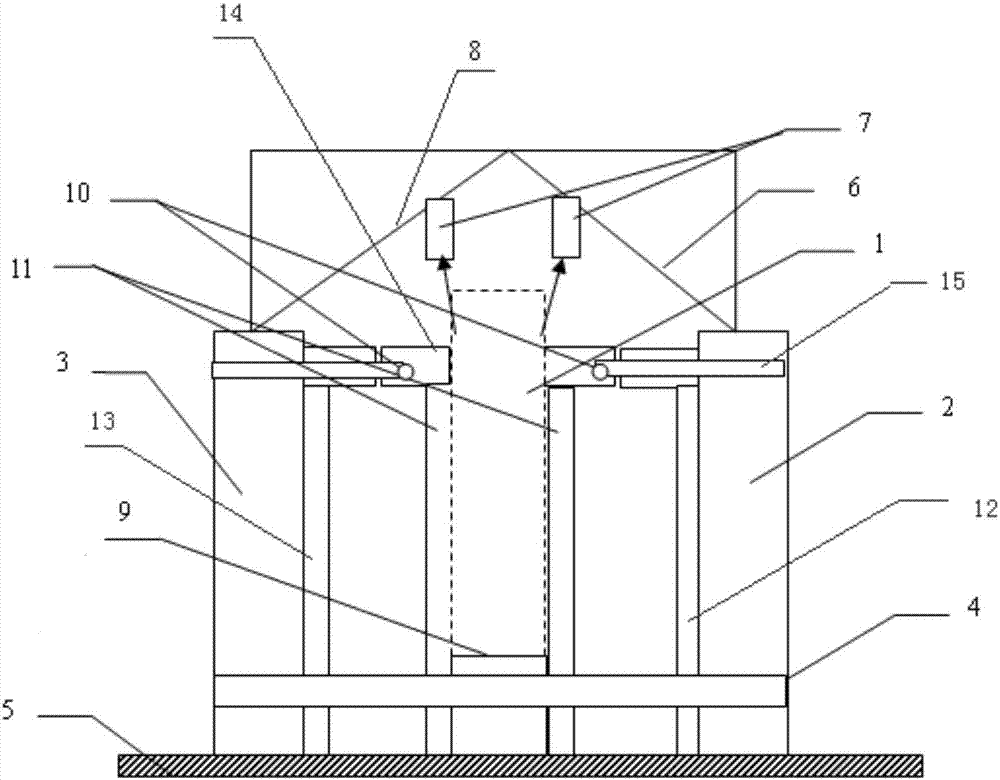

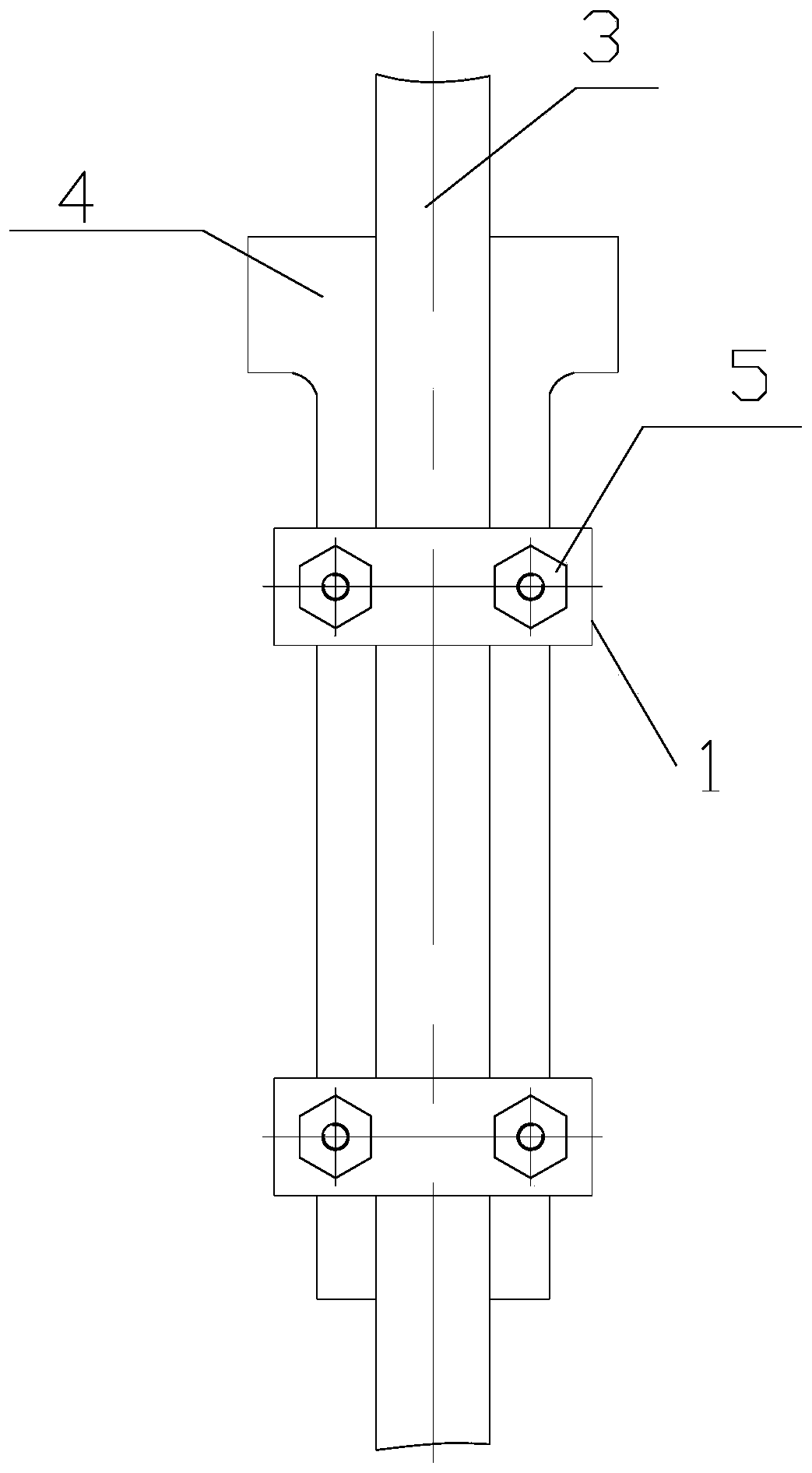

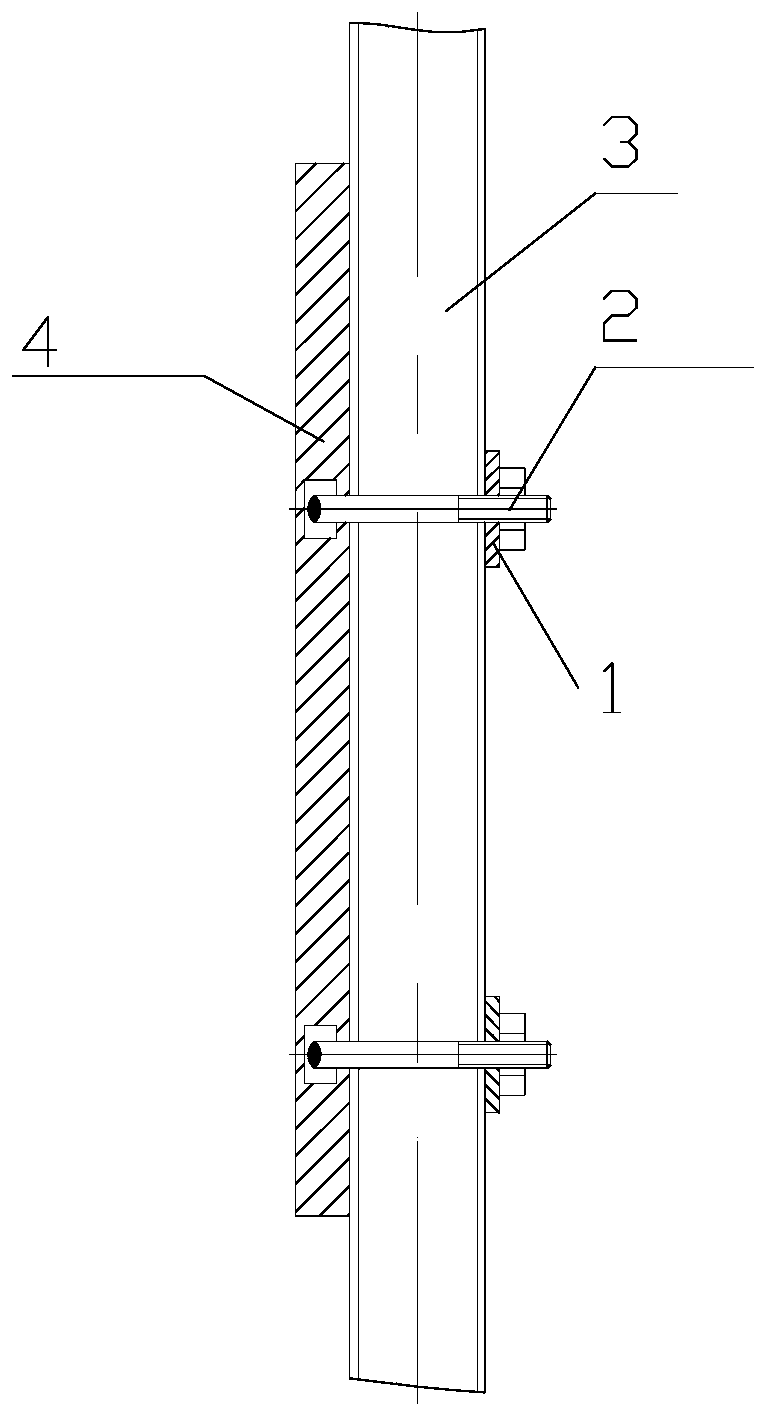

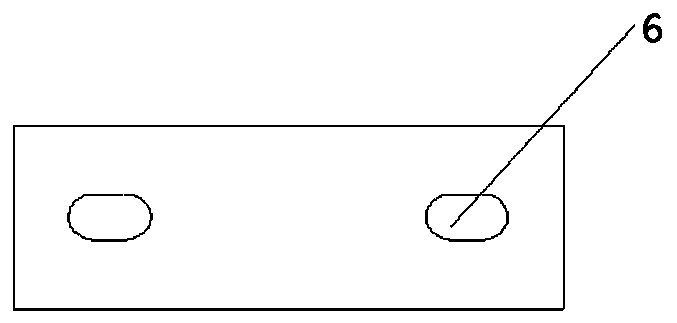

Furnace stay fixing device used for replacing coke oven cross brace

InactiveCN104560067AGuaranteed fixed effectReduce the impact of normal productionOven foundationsButt jointEngineering

The invention provides a furnace stay fixing device used for replacing a coke oven cross brace. The furnace stay fixing device comprises a cross beam (2), a nut (4), a compression spring (5), a connecting piece (7) and a pull rod (8). The furnace stay fixing device is characterized in that the length of the cross beam (2) is not less than twice of the distance between two adjacent furnace stays, a through hole is formed in the middle of the cross beam (2), supporting leg parts (21) are arranged at two ends of the cross beam (2), and the distance between the supporting leg parts (21) and the through hole is equal to the distance between two adjacent furnace stays; the pull rod (8) passes through the through hole of the cross beam (2); the nut (4) is in threaded connection with one end of the pull rod (8); the connecting piece (7) is positioned at one end of the pull rod (8) far away from the nut (4) for connecting the furnace stays with the pull rod (8); and the compression spring (5) sleeves the pull rod (8), one end of the compression spring (5) is butt-jointed with the nut (4), and the other end of the compression spring (5) is butt-jointed with the cross beam (2). The furnace stay fixing device provided by the invention can reduce the impact of replacement of the cross brace on the normal production of a coke oven, shorten the replacement time, and improve the security of a replacement process.

Owner:SHANDONG IRON & STEEL CO LTD

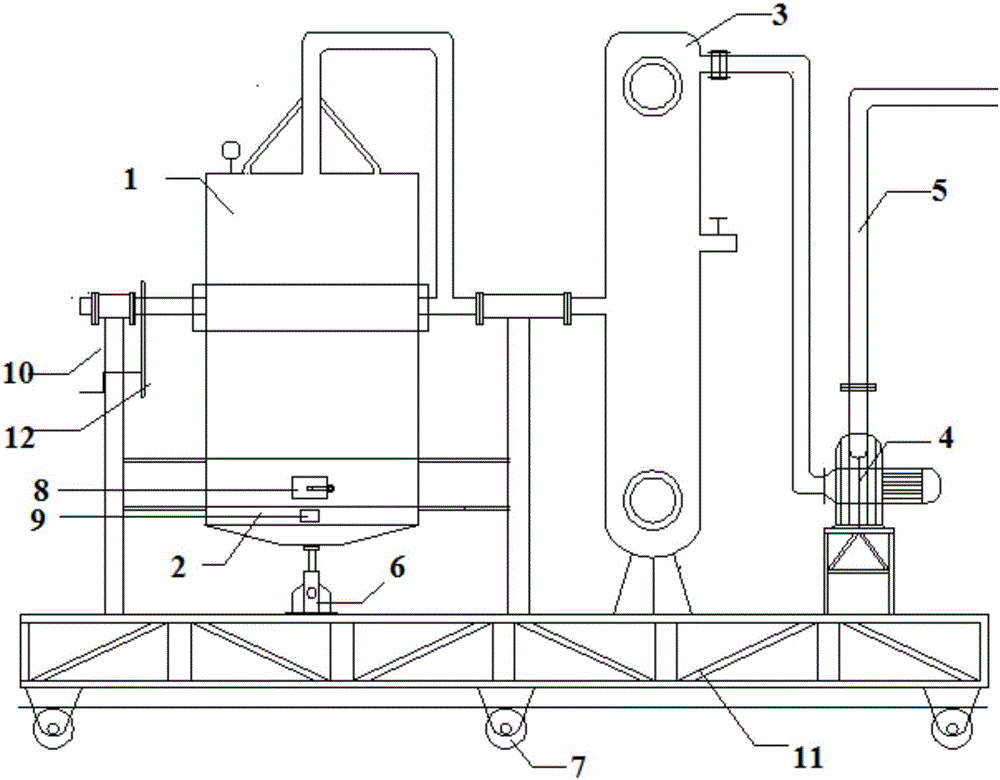

Low-consumption environment-friendly biochar production equipment

ActiveCN106010599ANo crushing requiredSave energyCombination devicesGas treatmentCombustion chamberCombustible gas

The invention relates to low-consumption environment-friendly biochar production equipment, which consists of a pedestal, a carbonization furnace, a gas purification device, a draught fan, an exhaust pipeline, a thermometer, a carbonization chamber support, a combustion chamber fixation bracket and a rotary handle. The carbonization furnace is composed of a carbonization chamber and a combustion chamber. The combustion chamber bottom is fixed on the pedestal through the combustion chamber bracket. The upper part of the carbonization chamber is movably fixed on a cross beam, and the carbonization chamber can turn freely and rotate around the cross beam. A set of gear linkage system is fixed on a steel pipe at the front end of the carbonization chamber support to adjust the inclination angle of the carbonization chamber. The carbonization chamber, the exhaust gas purification device and the draught fan are communicated through the exhaust pipeline. The carbonization chamber is internally provided with several independent pyrolysis chambers. While saving energy and protecting the environment, the equipment provided by the invention also can rapidly and effectively pyrolyze biomass into biochar, and utilizes the combustible gas generated by biomass pyrolysis to heat itself.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

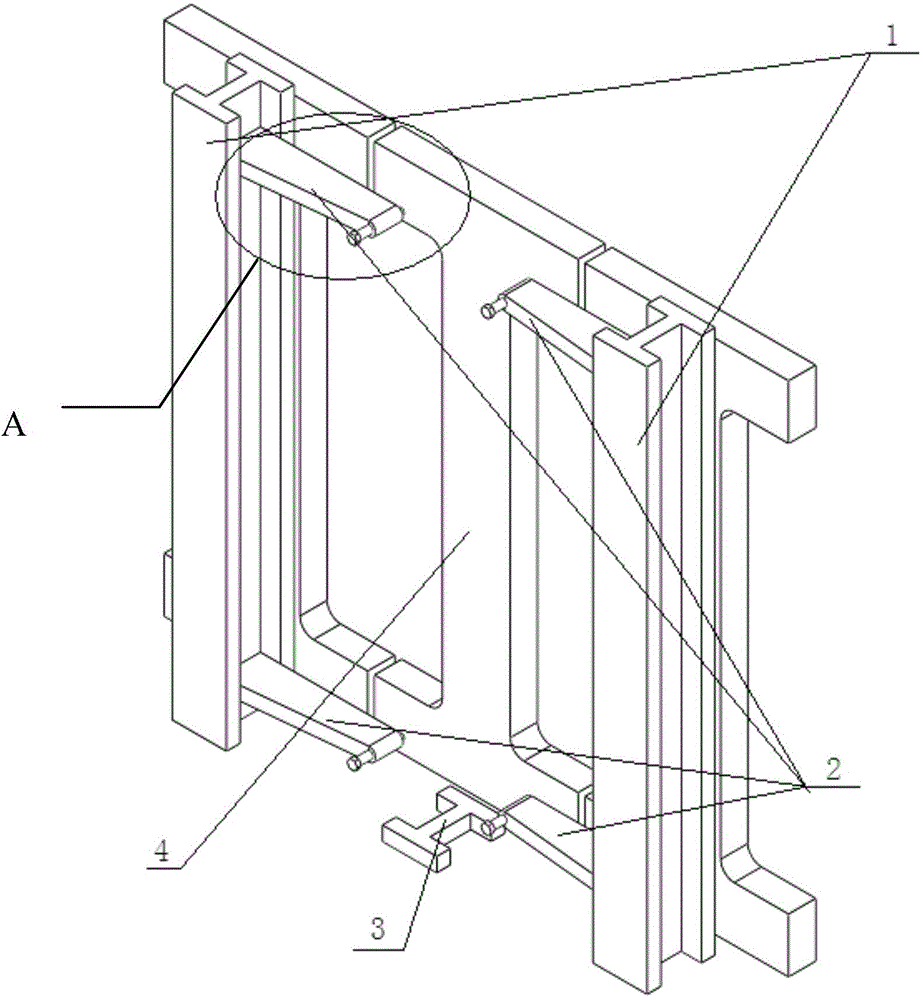

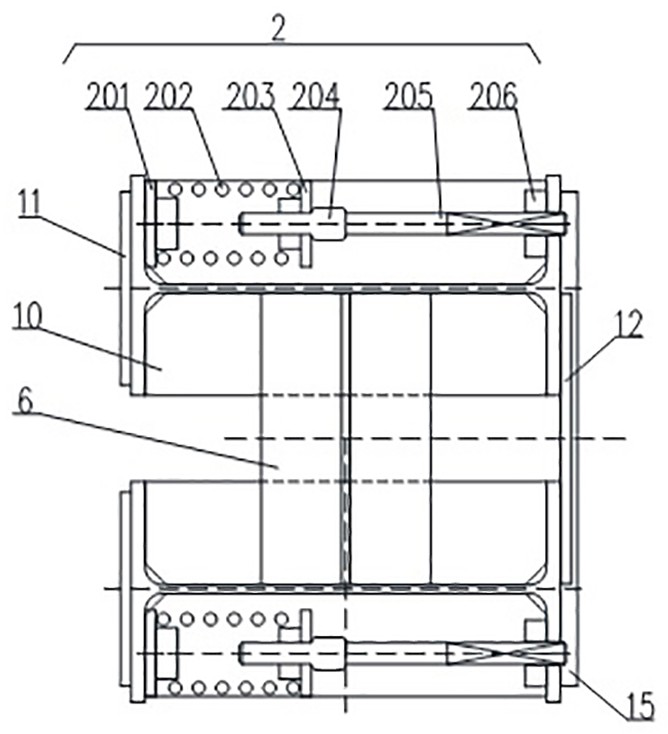

Protection plate fixing device and method during replacement of coke oven column

The invention provides a protection plate fixing device and method during replacement of a coke oven column. The fixing device comprises a bracket and an adjusting structure, wherein the first end of the bracket is used for being fixed on a normal oven column, the second end of the bracket is used for extending to the outer side of a protection plate fixed by a to-be-replaced oven column; the bracket is used for being arranged on the outer side of the protection plate; and the adjusting structure is arranged at the second end of the bracket and is used for pressing against the outer side of the protection plate and adjusting the pressure applied to the protection plate. When the oven column is replaced, the oven column fixed protection plate can be effectively replaced, the operation is convenient, the structure is simple, the pressure applied to the protection plate is adjustable, and the coke oven production is not influenced.

Owner:SHANDONG IRON & STEEL CO LTD

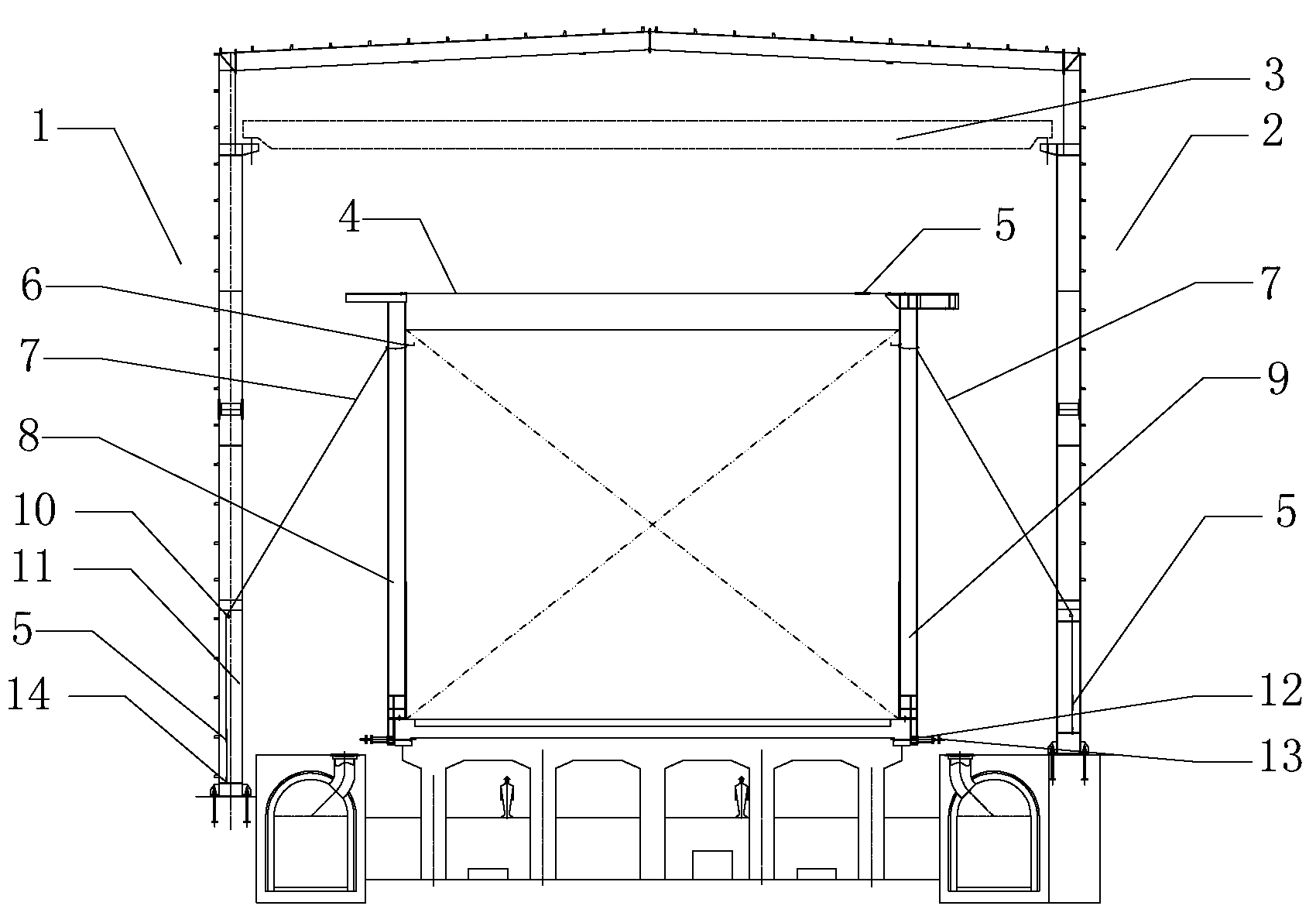

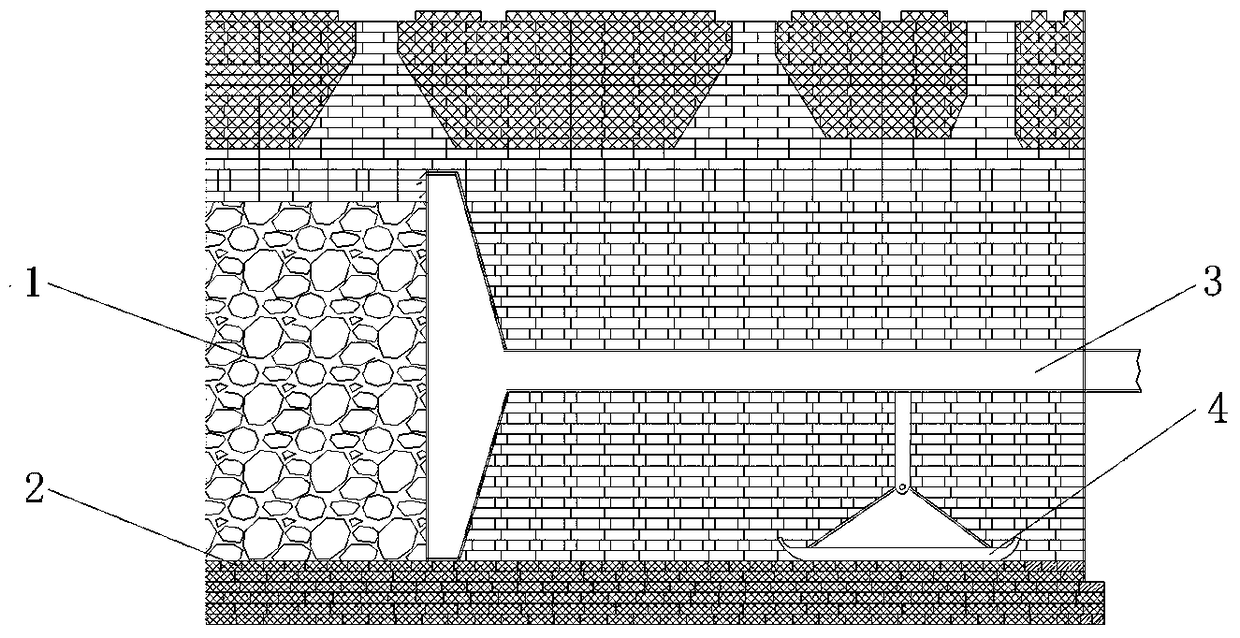

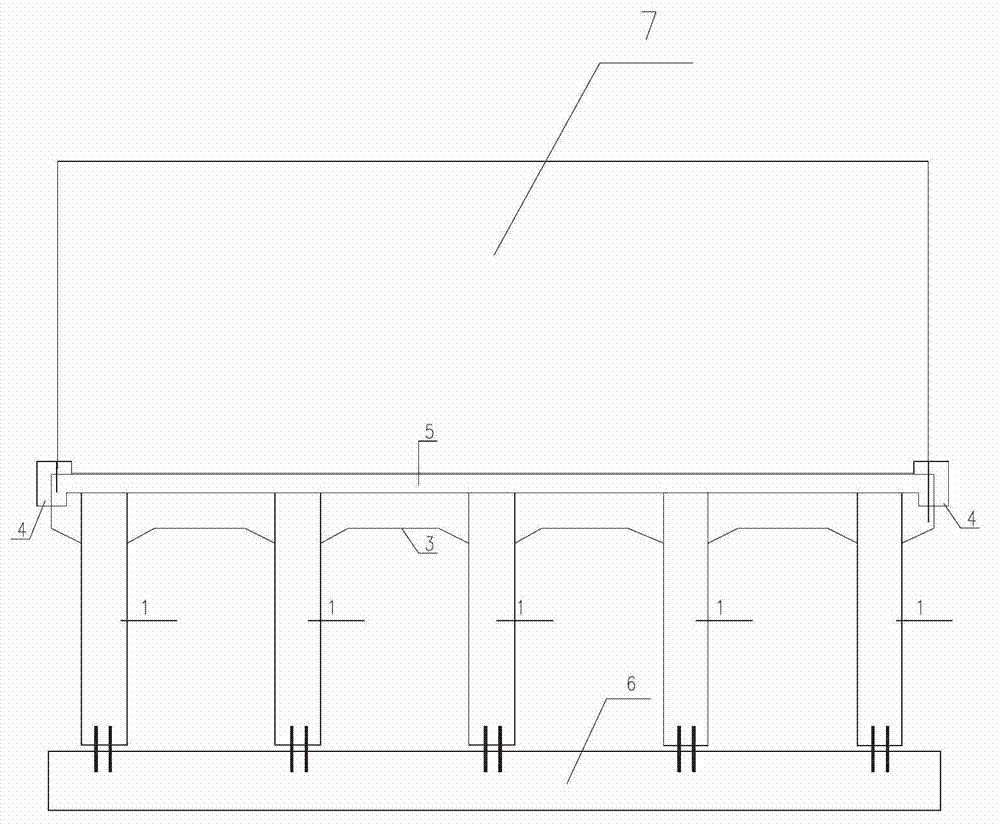

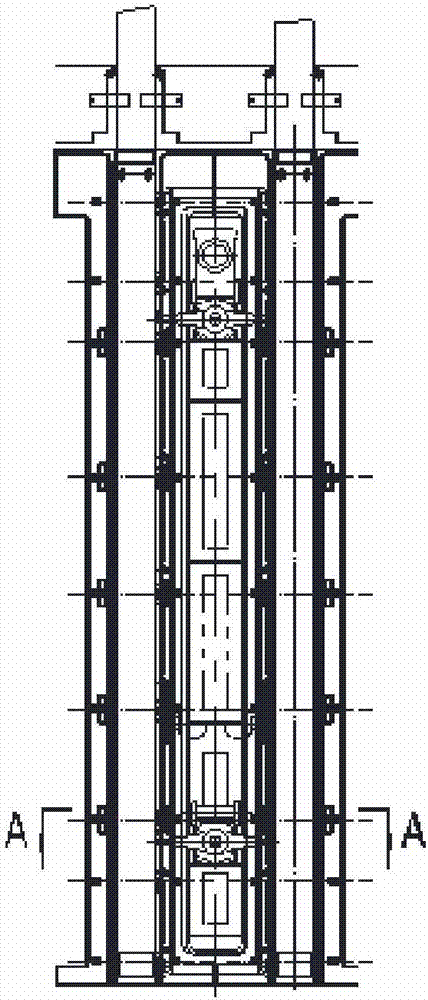

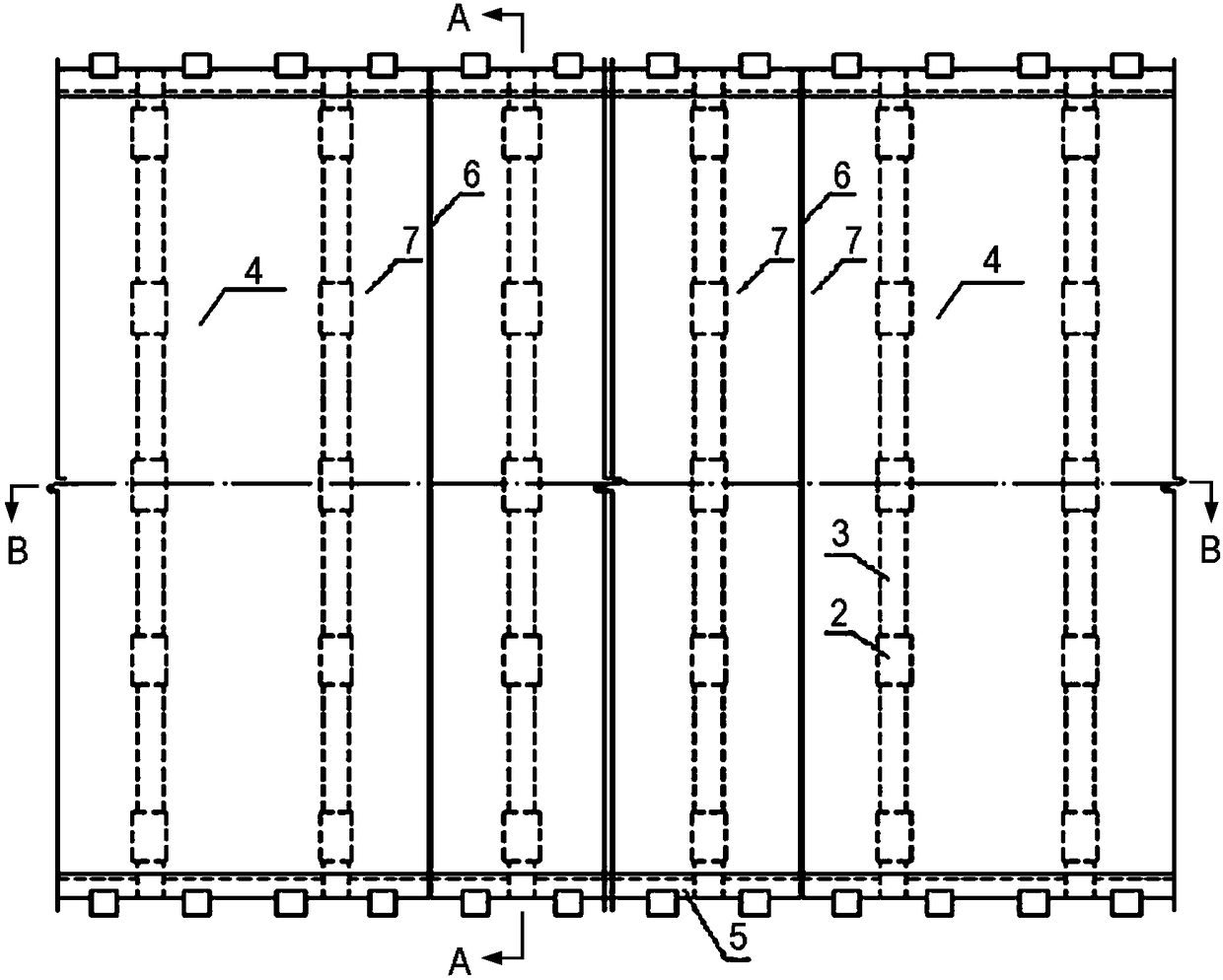

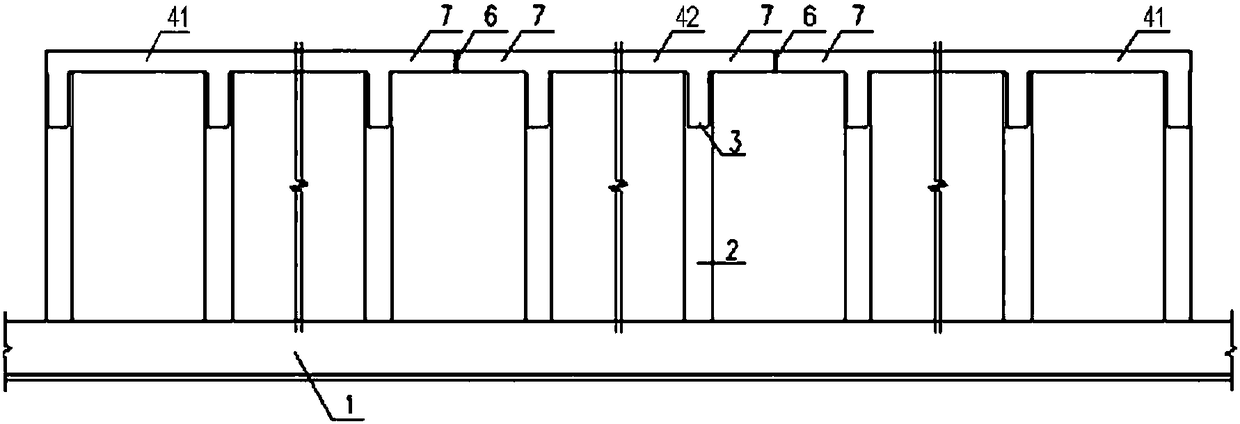

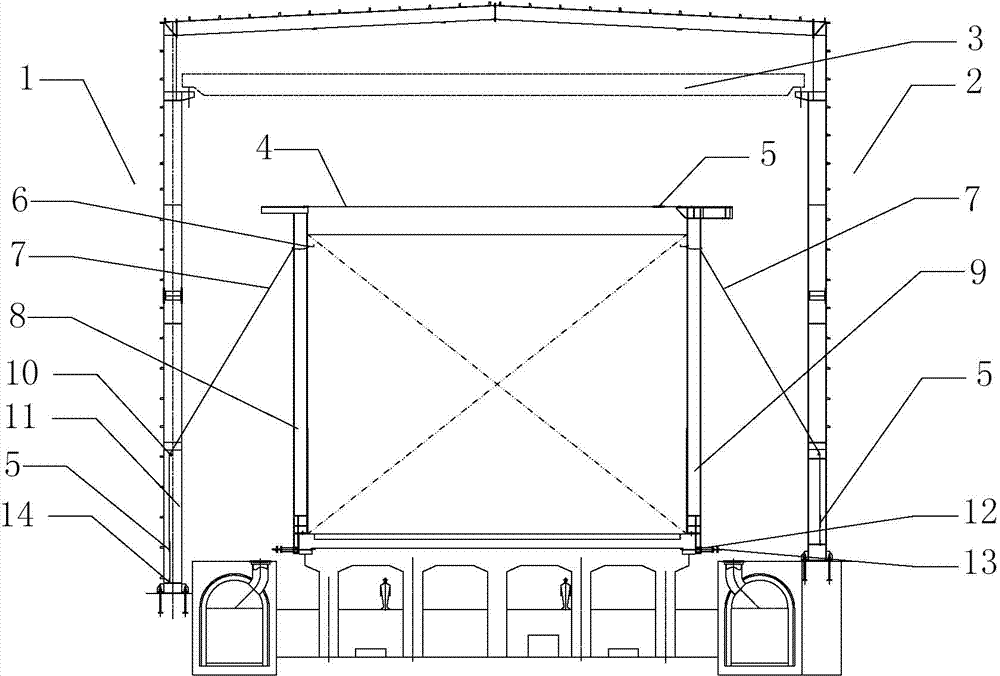

Base structure of coke oven

InactiveCN102965124ARealization of process planMeet the process requirementsOven foundationsTemperature stressCoke oven

The invention discloses a base structure of a coke oven. The base structure consists of N rows of frames, two boundary beams and a top plate, wherein the top plate is of a structure that longitudinal ultra-long concrete of more than 90m is adopted, and no gap is left; four spans are formed in the horizontal direction, the distances between the frame columns in the spans are equal, and a central line of the middle frame column is superposed with the central line of the coke oven; in the N rows of frames in the longitudinal direction, the front six rows of column frames at the two ends are hinged with a bottom plate, the middle N-12 rows of frame columns are fixedly connected with the bottom plate. According to the base structure of the coke oven, for the condition that the ultra-long concrete structure of more than 90m is positioned in the environment with the average temperature of 110 DEG C, the temperature stress and the seismic stress can be eliminated simultaneously. According to the base structure, the normal operation of the coke oven is met, the production efficiency and the product quality are improved, and the safety and construction feasibility of a base structure system of the coke oven can be ensured. The base structure is simple, advanced in technology, safe and reliable, and can be applied to a coke oven with an oversized volume.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP

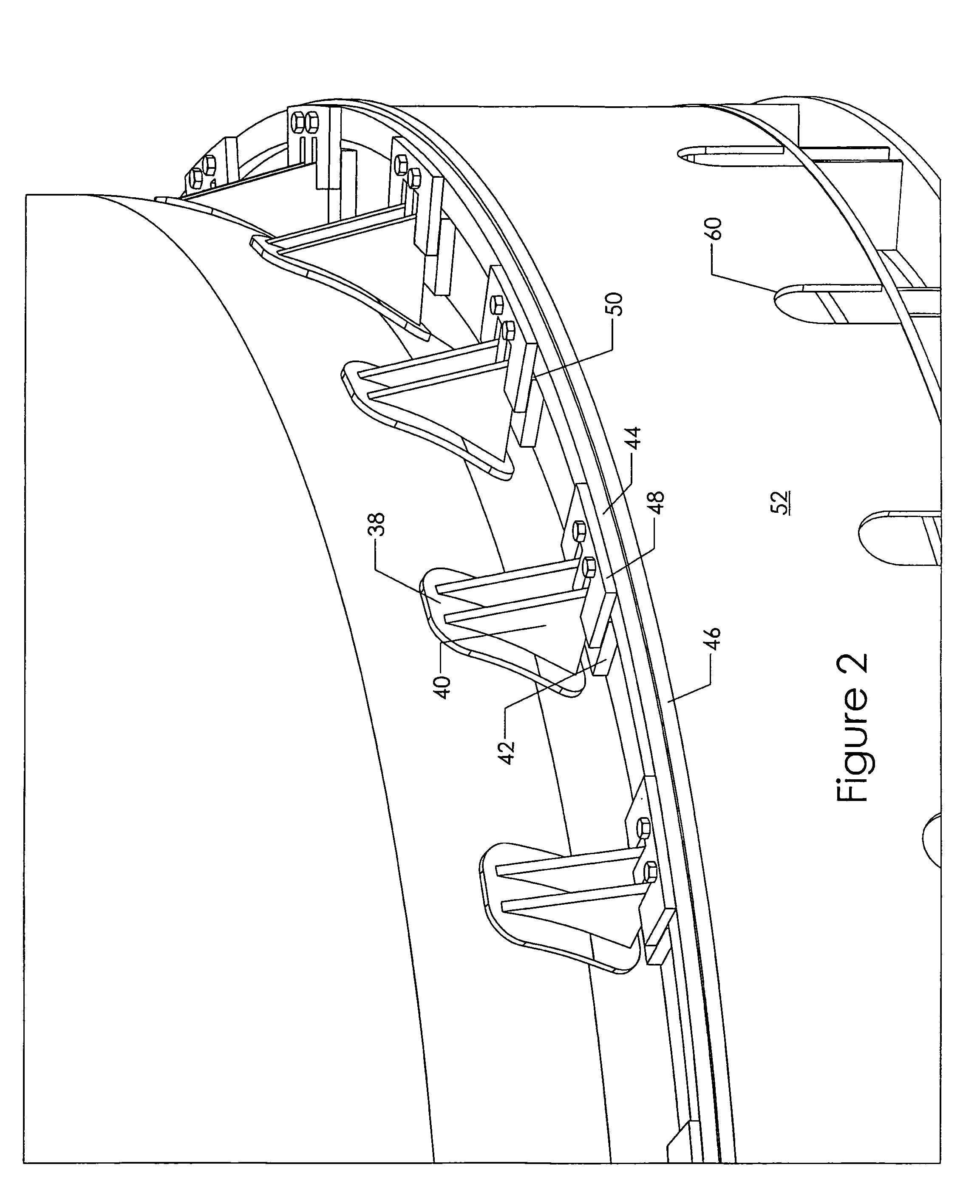

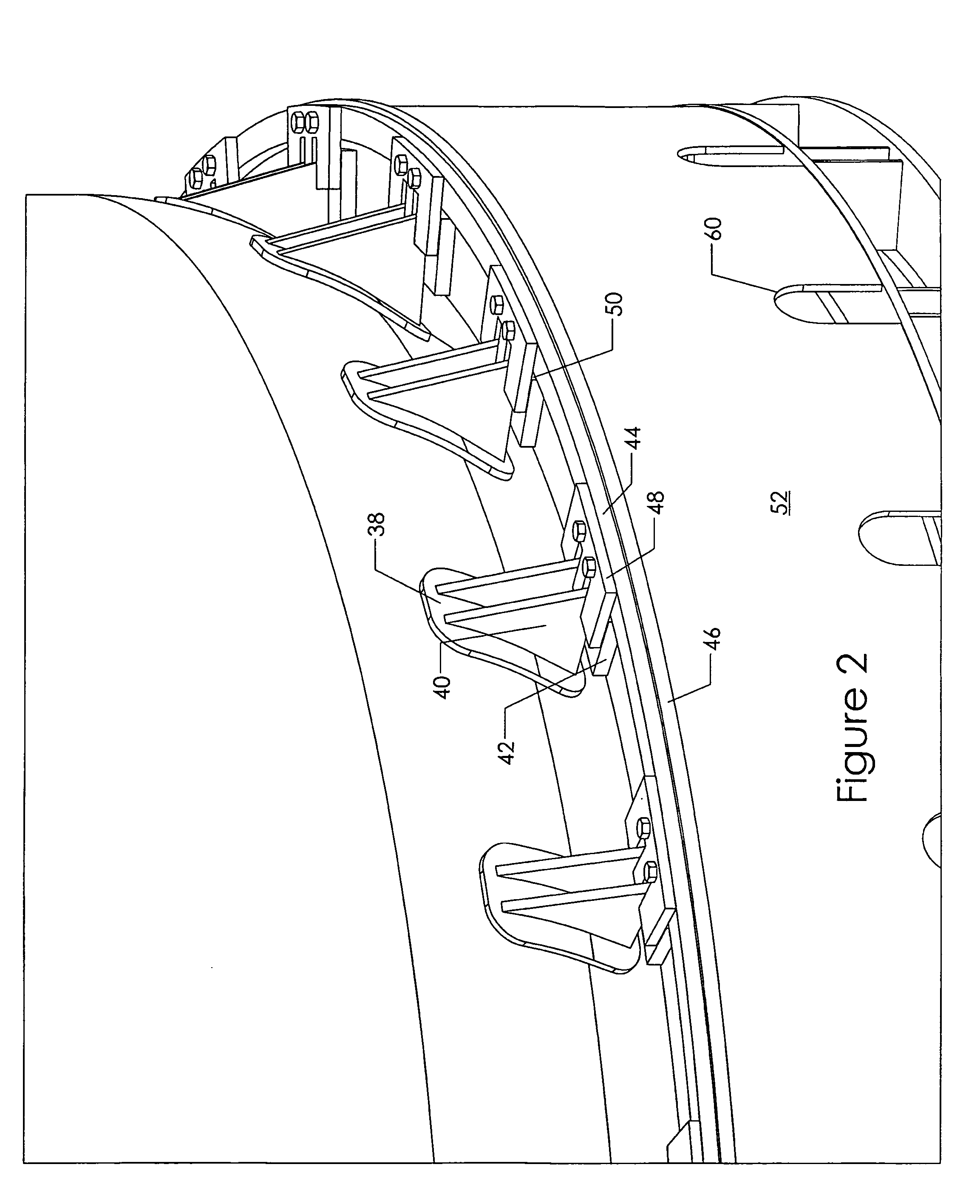

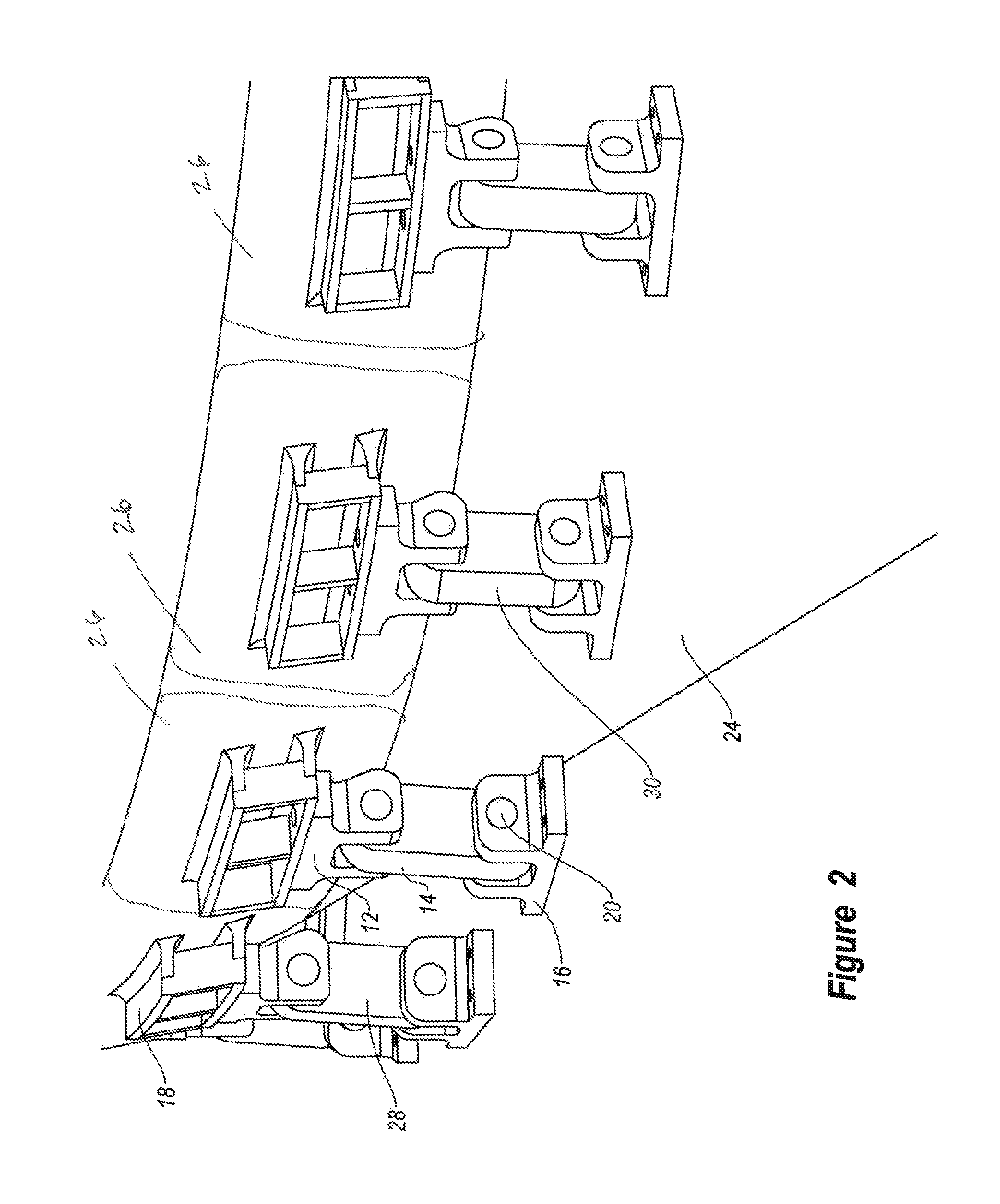

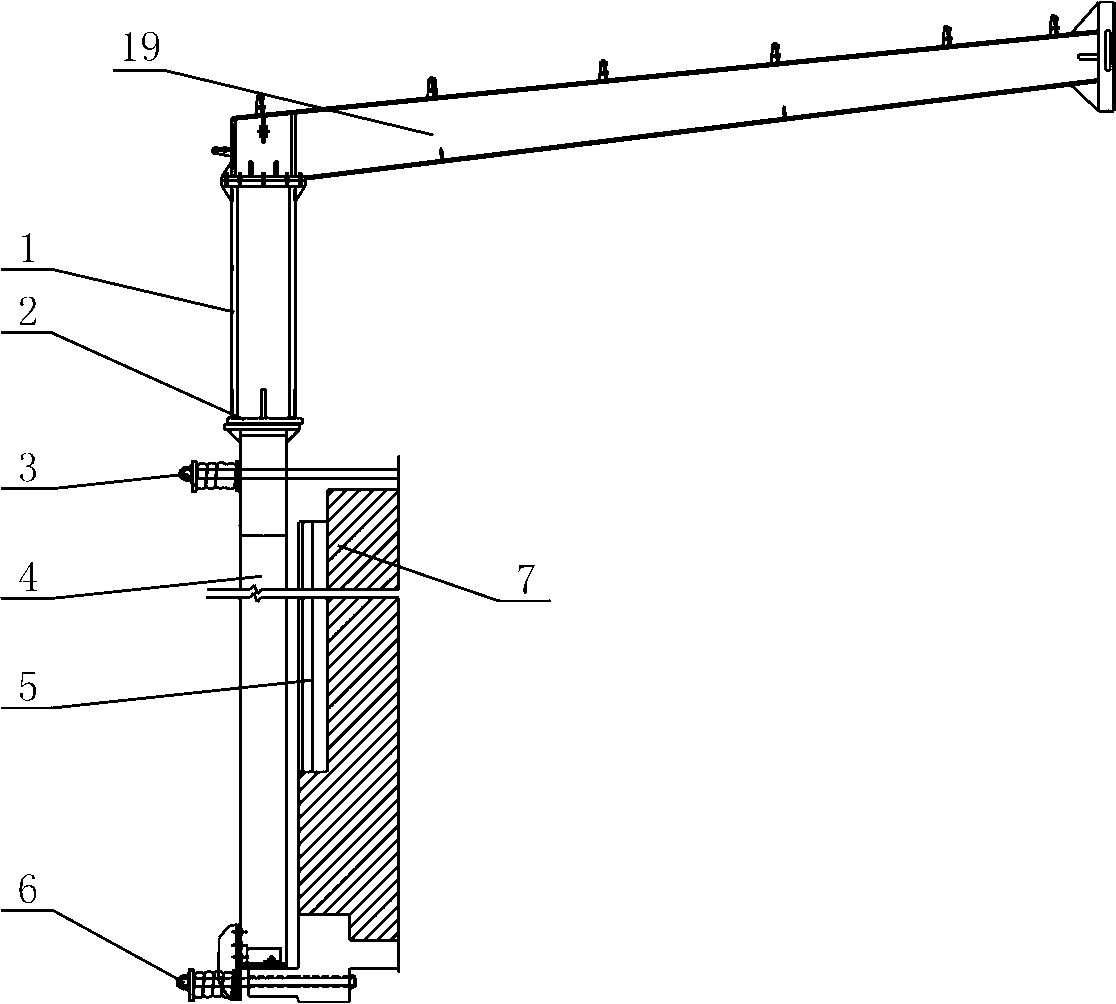

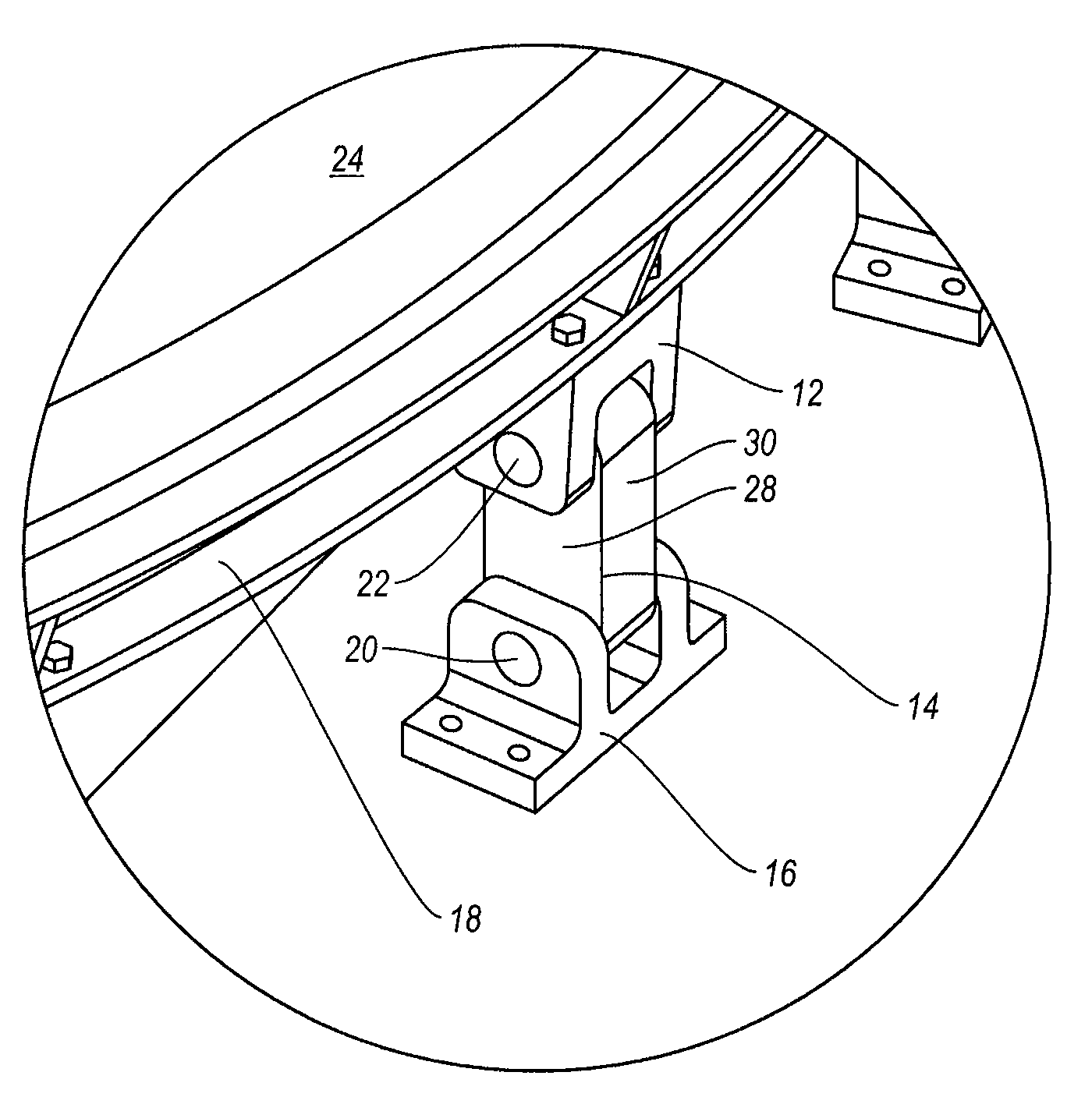

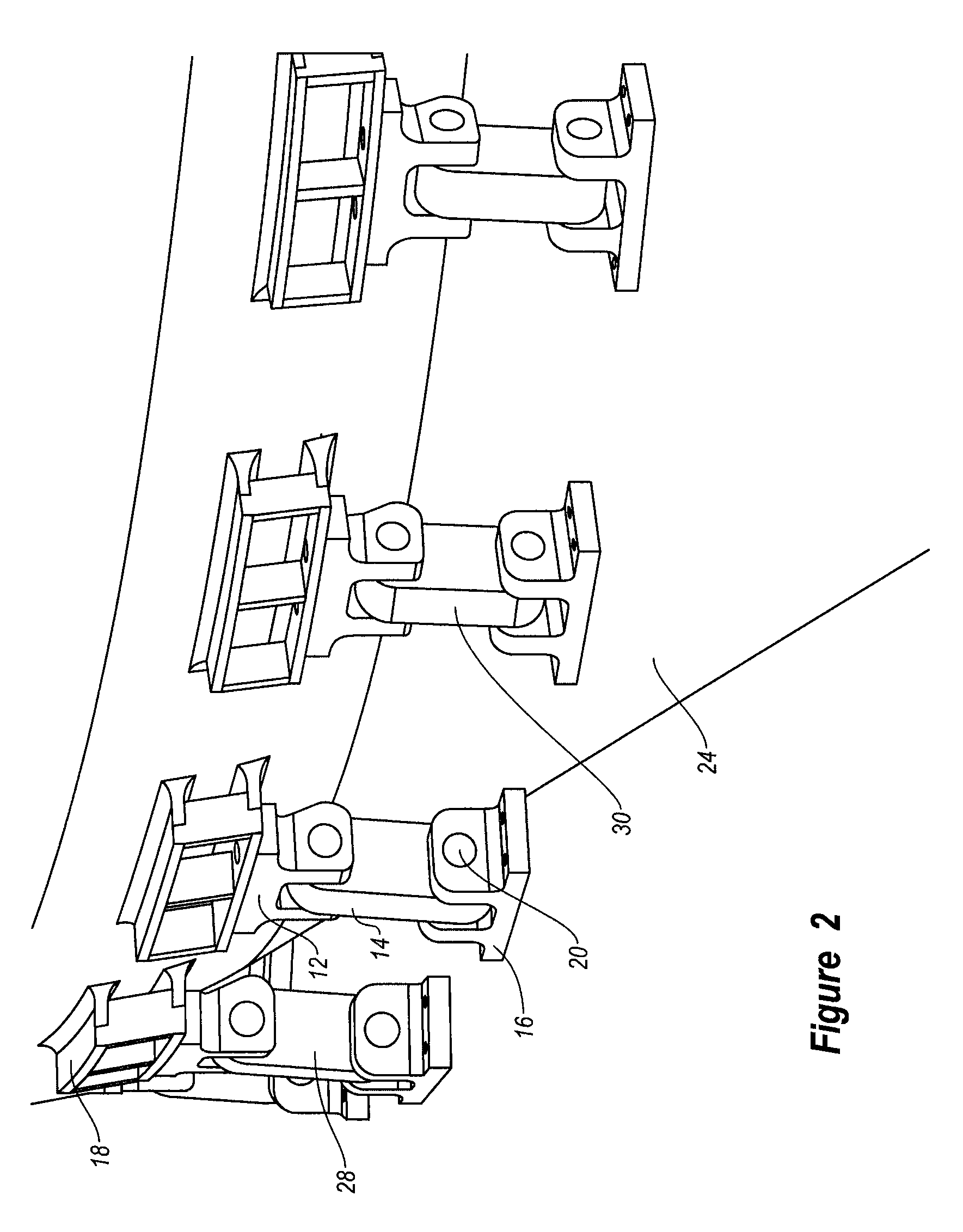

Linked coke drum support

ActiveUS8440057B2High strengthLow friction pivoting of the connecting linkMechanical conveying coke ovensCoke oven expansion/contraction preventionElectrical and Electronics engineering

A linked coke drum connection to minimize the stresses experienced by the joint between the coke drum and the supporting structure of the coke drum is described. The connection may be attached to a circumferential connection plate attached to the coke drum or directly to the drum. Some embodiments connect to a segmented circumferential connection plate. The connection includes a coke drum link, a connecting link, and a ground link. The links are pivotally connected with connecting pins. As the coke drum is heated and expands, the connecting link pivots outwardly about a point centered in the connecting pin in the ground link.

Owner:DELTAVALVE

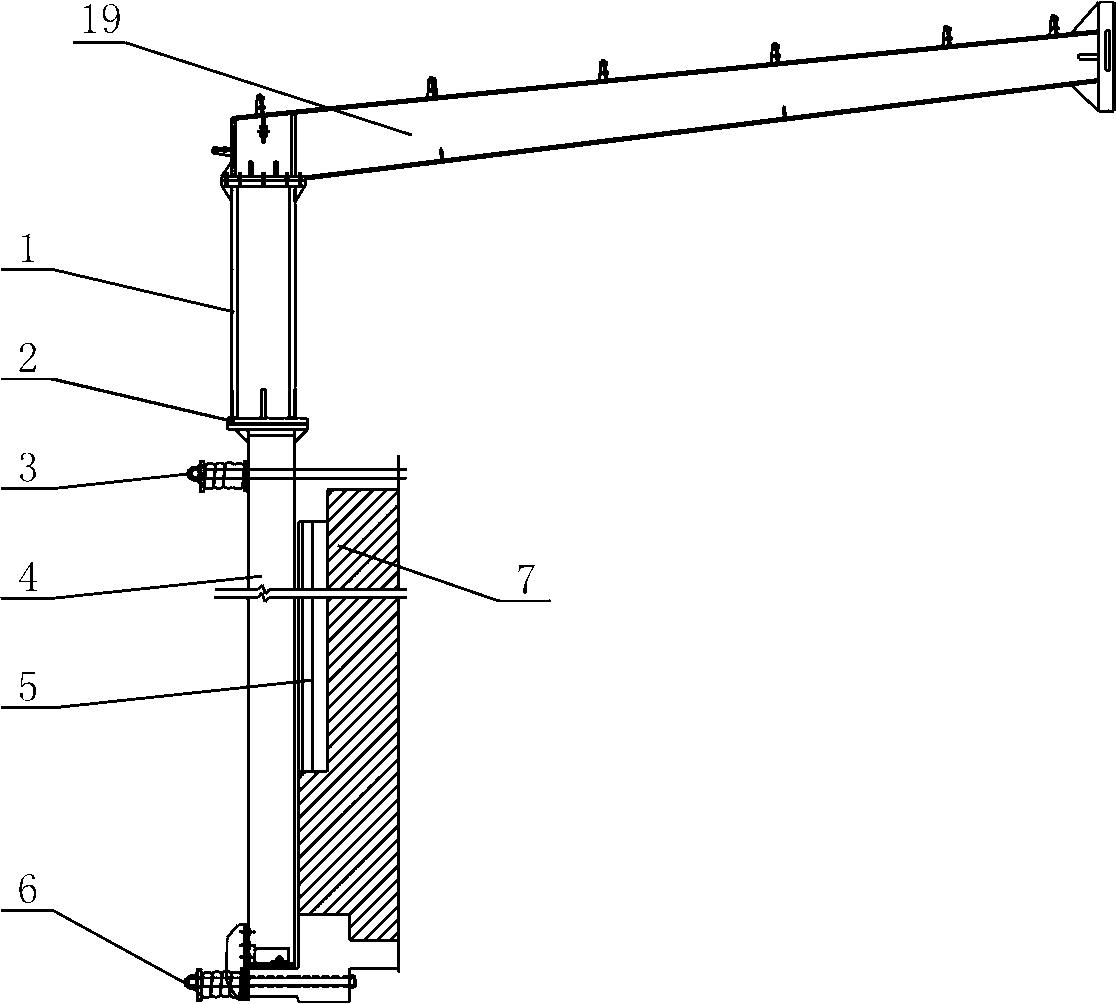

Device, system and method for replacing furnace column of coking furnace

ActiveCN107033928AAvoid crooked pullingGood safety workOven foundationsEnergy inputCoke burnerProcess engineering

The invention discloses a device, a system and a method for replacing a furnace column of a coking furnace. The device comprises a fixing unit, a limiting unit and a support, wherein the fixing unit is used for fixing the support of the device; the front end of the limiting unit is provided with a furnace column limiting part which is used for limiting a moving furnace column in a process of replacing the furnace column; the rear end of the limiting unit is movably connected with the support, and the furnace column limiting part is used for adjusting relative motion between the limiting unit and the support and controlling motion speed and direction of replacement of the furnace column. According to the system disclosed by the invention, hoisting is carried out by a winch, inclined pulling and hanging can be avoided, and security operation is facilitated; a large-scale crane is not used, so that machine-shift expense is reduced. The method is simple, convenient to implement and low in cost, and can be popularized to replacement construction of the furnace column of the coking furnace of any specification.

Owner:MCC5 GROUP CORP SHANGHAI

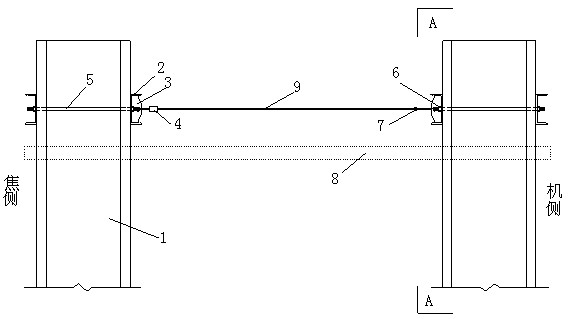

Mounting method of lower cross brace of ultra-large coke oven

The invention provides a mounting method of a lower cross brace of an ultra-large coke oven. The brace penetrates through a whole furnace bed plate from a coke side to a machine side, the length of the brace is greater than or equal to 21135mmm, the weight of the brace is greater than or equal to 430kg and the brace is made of Q345B; the mounting method is characterized by comprising the followingsteps: a, manufacturing a drawing device of the brace; b, providing a winch; c, connecting the drawing device; d, mounting the lower cross brace of the coke oven; and pulling one section of the braceand adjusting and moving the position of a winch base until the mounting work of the brace is finished. The mounting method of the lower cross brace of the ultra-large coke oven, provided by the invention, has the advantages that the drawing device is simple in structure and convenient to manufacture and a pulling device can be used for realizing the effect of protecting a screw thread; the windlass is used for carrying out pulling work and the working efficiency is greatly improved; and the labor cost is less and the installation engineering cost is reduced.

Owner:MCC5 GROUP CORP SHANGHAI

Support structure of a coke drum

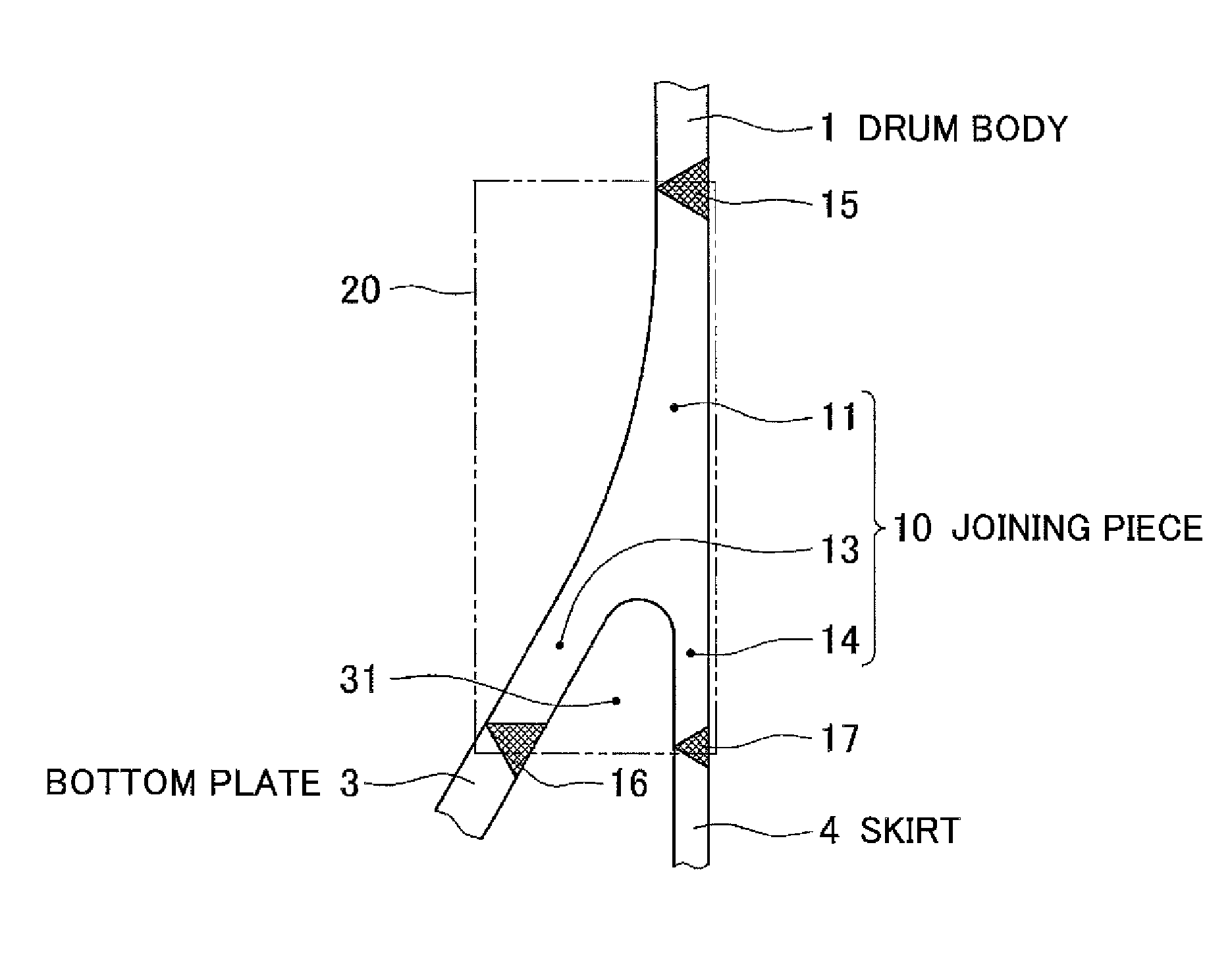

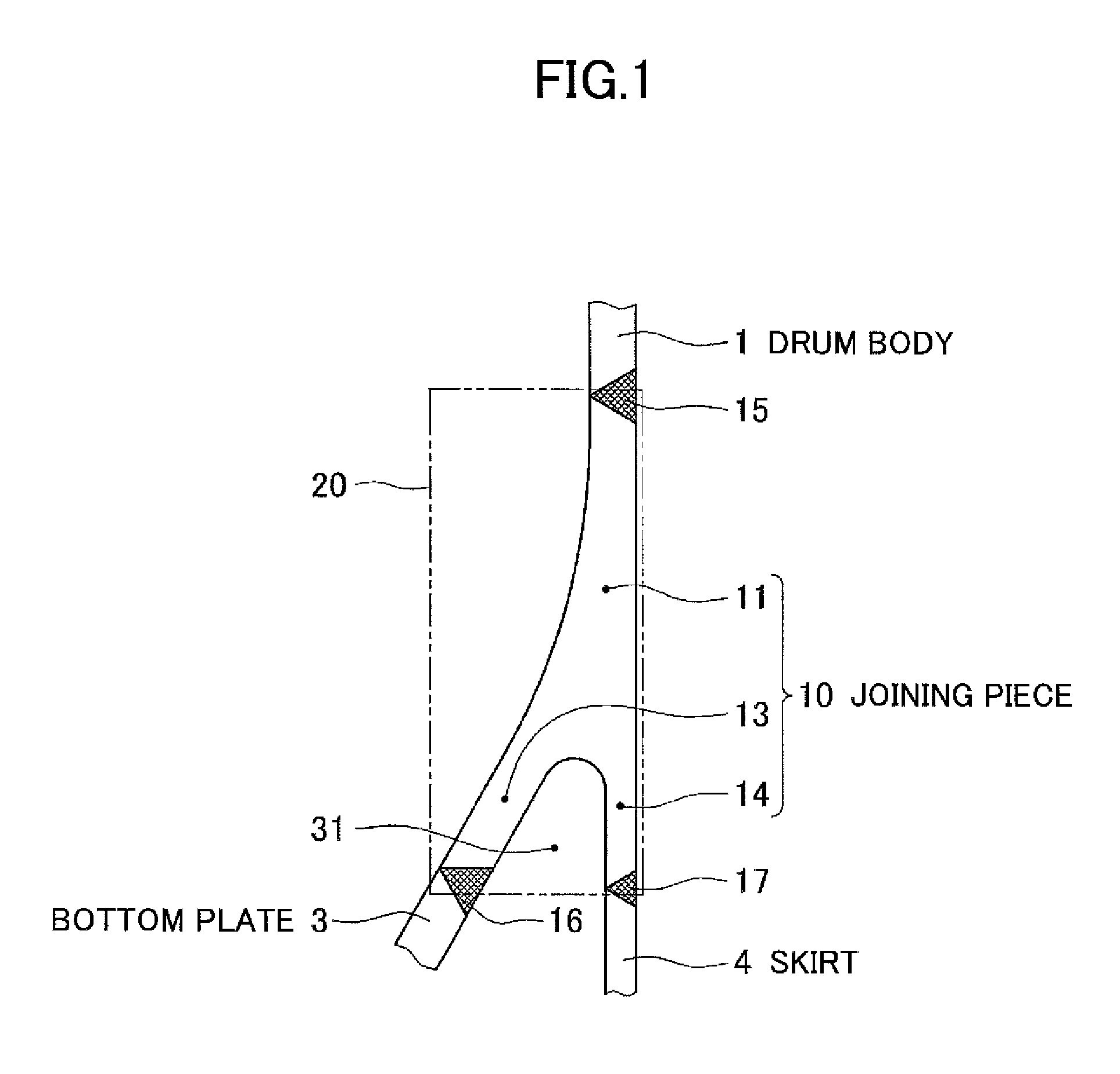

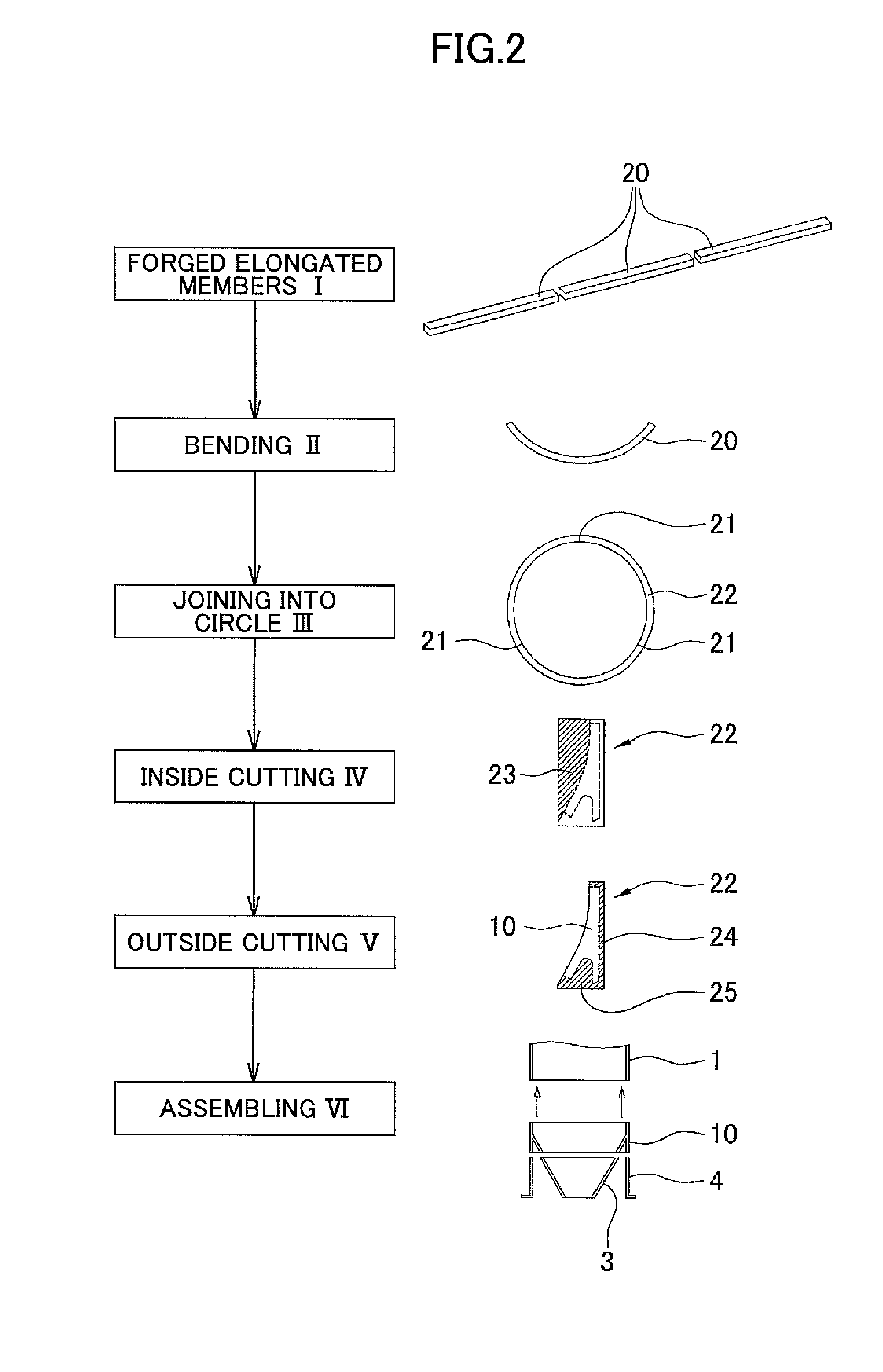

ActiveUS8317981B2Improve fatigueStable structureMechanical conveying coke ovensCoke oven expansion/contraction preventionEngineeringUpper body part

A support structure of a coke drum including a cylindrical drum body, an inverted-cone-shaped bottom plate connected to a bottom of the drum body, and a cylindrical skirt supporting the drum body includes an annular joining piece joining the drum body, the bottom plate, and the skirt to one another. The joining piece is a unitary member including an upper body part joined to a lower end of the drum body, a lower inner leg part joined to an upper end of the bottom plate, and a lower outer leg part joined to an upper end of the skirt.

Owner:SUMITOMO HEAVY IND PROCESS EQUIP CO LTD

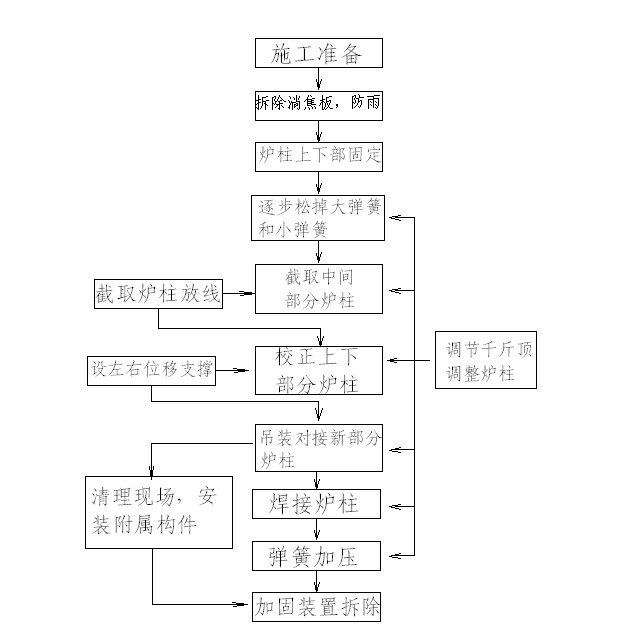

Local-slippage construction method of furnace column

ActiveCN103215051AShorten the construction periodSave installation timeOven foundationsCoke ovenEngineering

Owner:CHINA FIRST METALLURGICAL GROUP

Linked coke drum support

ActiveUS20090236212A1High strengthLow friction pivoting of the connecting linkMechanical conveying coke ovensOven foundationsEngineeringElectrical and Electronics engineering

A linked coke drum connection to minimize the stresses experienced by the joint between the coke drum and the supporting structure of the coke drum is described. The connection may be attached to a circumferential connection plate attached to the coke drum or directly to the drum. Some embodiments connect to a segmented circumferential connection plate. The connection includes a coke drum link, a connecting link, and a ground link. The links are pivotally connected with connecting pins. As the coke drum is heated and expands, the connecting link pivots outwardly about a point centered in the connecting pin in the ground link.

Owner:DELTAVALVE

Method for dismantling coke oven column and protection plate

ActiveCN110317615AReasonable designEasy to operateOven foundationsLoad-engaging elementsEconomic benefitsEngineering

The invention provides a method for dismantling a coke oven column and a protection plate. The method is characterized by including the following steps that a, preparation work is done for dismantlingthe coke oven column and the protection plate; b, a coke oven machine, an oven column on the coke side and the protection plate are dismantled at the same time; c, before the coke oven column and theprotection plate are dismantled, the coke oven machine and springs of an upper cross brace and a lower cross brace on the coke side are subjected to pressure relief; d, before the coke oven column and the protection plate are dismantled, the coke oven machine, and a big spring and a big spring baffle on the upper cross brace on the coke side are fixed; e, the protection plate is assembled and a lifting point is set; f, the oven column, a protection plate hoist, the coke oven machine, the oven column on the coke side and the protection plate need to be dismantled and hoisted at the same time.The method for dismantling the coke oven column and the protection plate has the advantages that the design of dismantling steps is reasonable, the operability is high, the demolition project is safeand reliable, the coke oven column and the protection plate can be quickly dismantled, the labor intensity is reduced, the construction period is shortened, the construction cost is saved, the projectcost is reduced and economic benefits are remarkable.

Owner:MCC5 GROUP CORP SHANGHAI

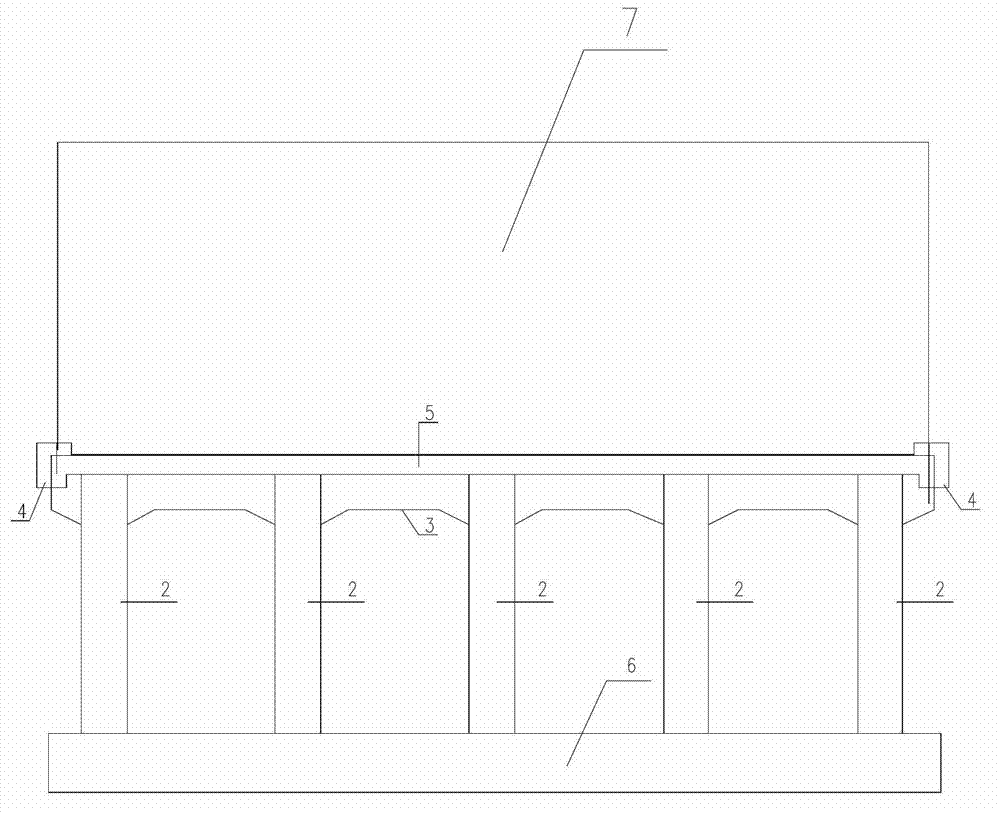

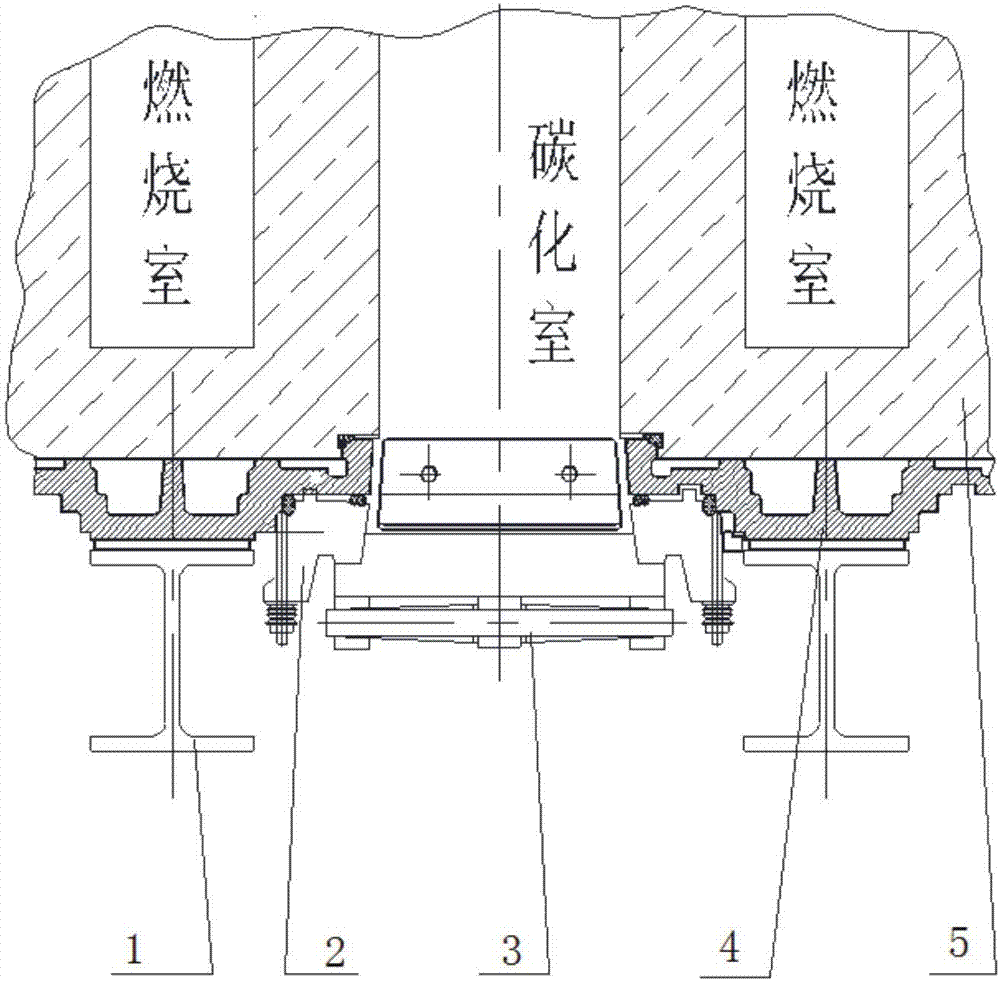

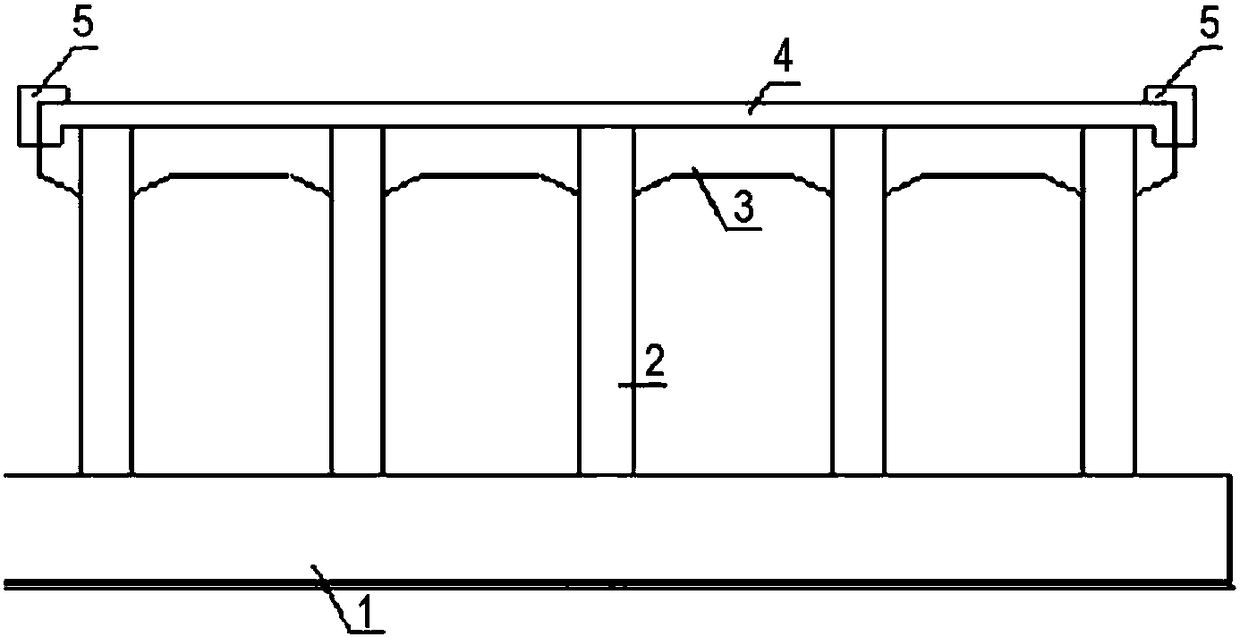

Coke oven foundation structure and coke oven

ActiveCN108264908AReduce investmentAvoid super long structuresOven foundationsEnergy inputTemperature stressCoke oven

The invention relates to a coke oven foundation structure and a coke oven. The coke oven foundation structure comprises a bottom plate and a top plate; a plurality of frame pillars are arranged between the bottom plate and the top plate to support the top plate; the top plate includes a plurality of top sub-plates arranged sequentially in a first horizontal direction; every two adjacent top sub-plates have an expansion joint. The coke oven foundation structure has the advantages that the integrated top plate structure of the prior art is replaced with a combination top plate structure formed by arranging the multiple top sub-plates in sequence, so that a super-long structure is avoided, construction complexity is relieved, and construction cost is reduced; every two adjacent top sub-platesare provided with the expansion joint, so that temperature stress of each top sub-plate can be released properly.

Owner:HUATAI YONGCHUANG BEIJING TECH CO LTD

Replacement method of coke oven column upper part cross-brace

ActiveCN110373214AAdvantages of replacement methodSimple structureOven foundationsCoke ovenReplacement method

The invention relates to a replacement method of a coke oven column upper part cross-brace. The replacement method is characterized by comprising the following steps that a, two clamping tools with the same structure are manufactured; b, ear plates are welded to the middles of inner side box irons of the corresponding well-shaped clamping tools; c, a steel wire rope tensioner is provided for beinghung on one of the ear plate, and a steel wire rope is provided; and d, the steel wire rope tensioner is used for tensioning the steel wire rope, and replacement of the oven column upper part cross-brace is conducted after oven columns on the machine side and the coke side are tensioned. The replacement method of the coke oven column upper part cross-brace has the advantages that the clamping tools are simple in structure, manufacturing is convenient, the engineering quality is safe and reliable, the clamping tools are adopted to avoid damage of the over column, the operation efficiency is greatly improved, the clamping tools can be repeatedly used, and the engineering cost is lowered.

Owner:MCC5 GROUP CORP SHANGHAI

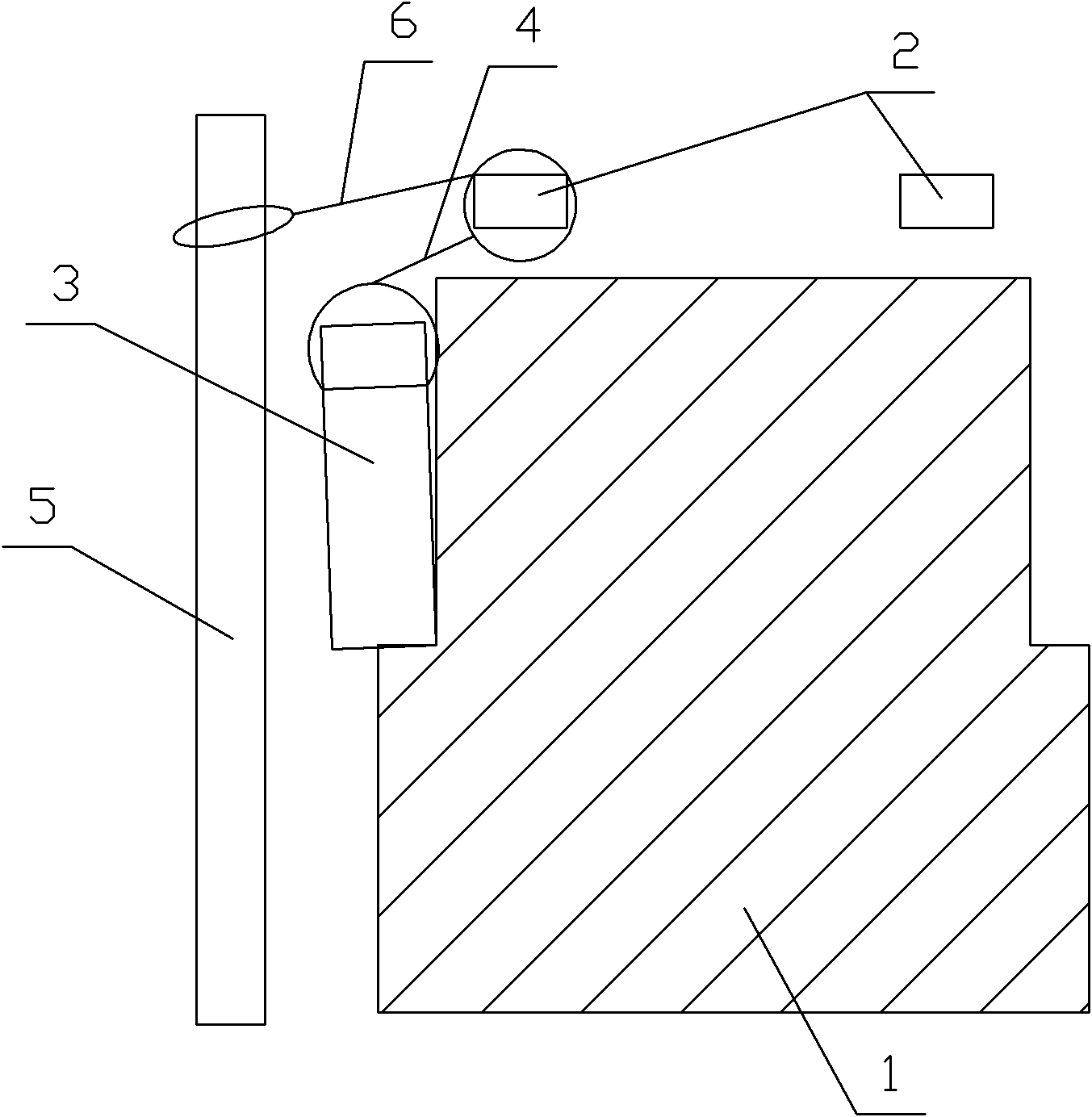

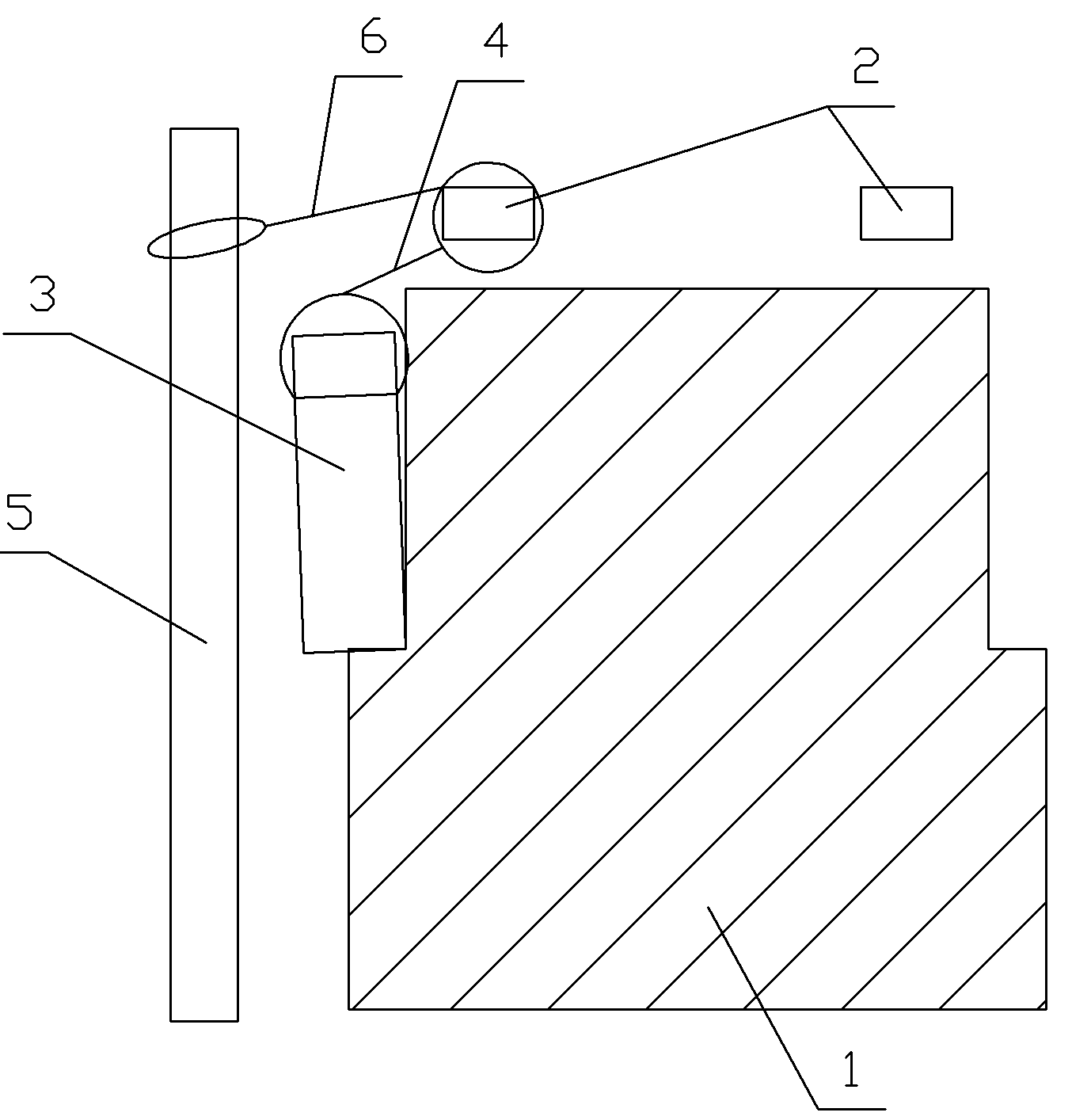

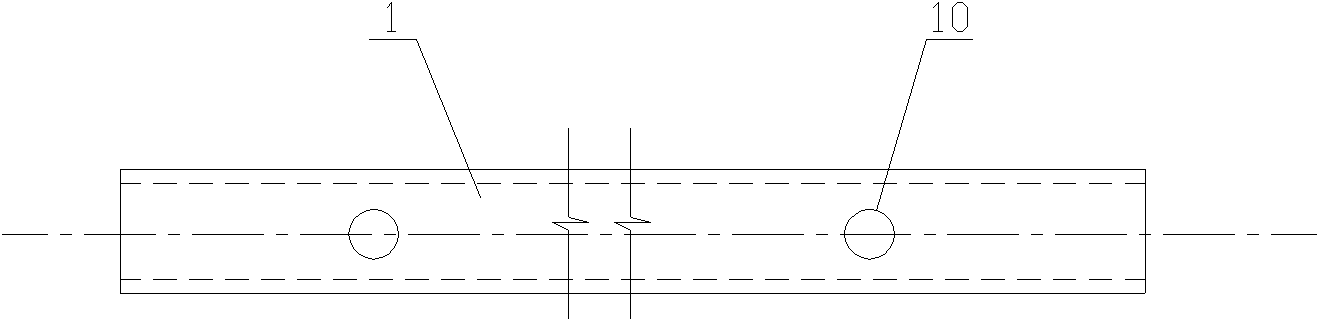

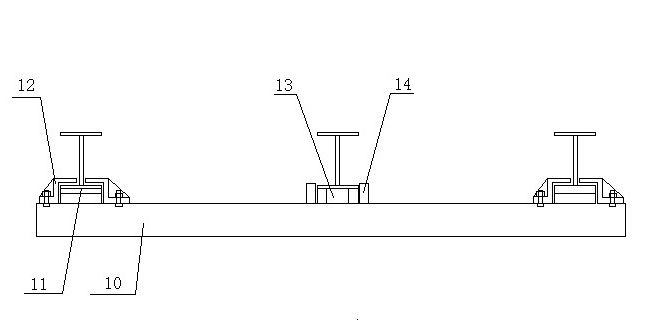

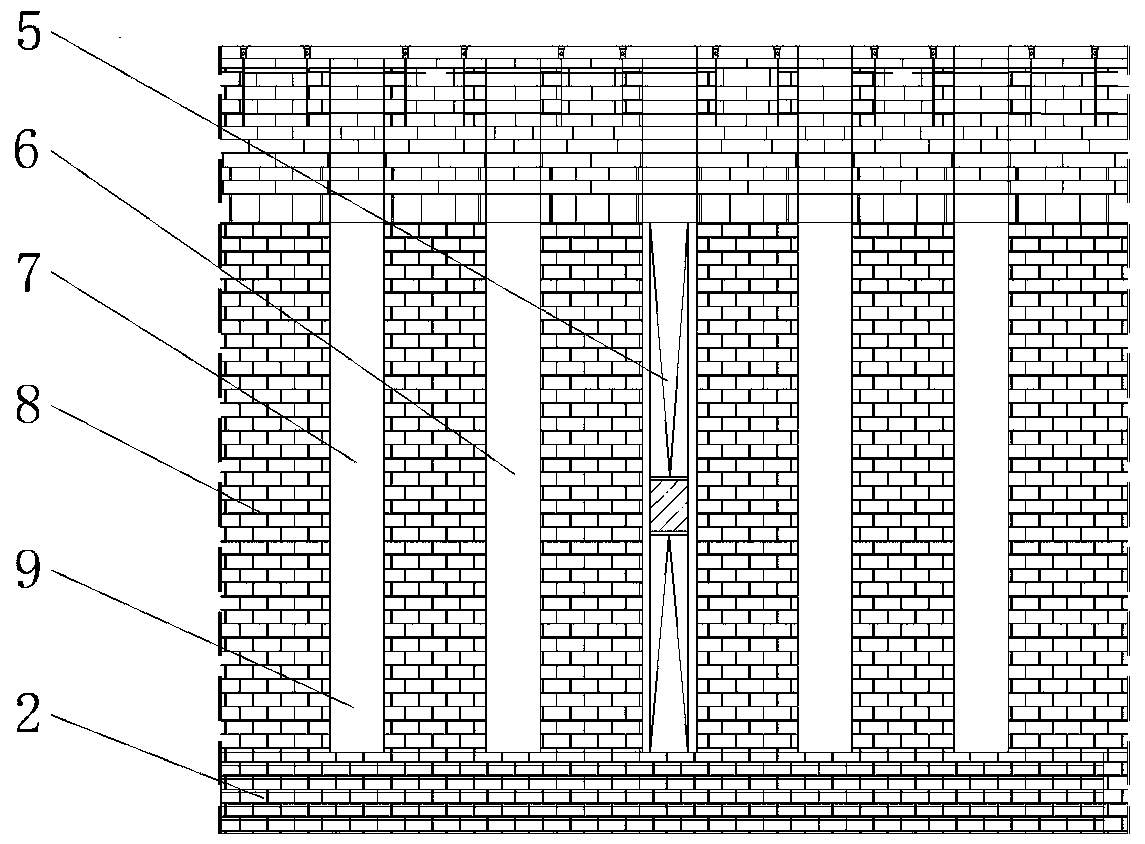

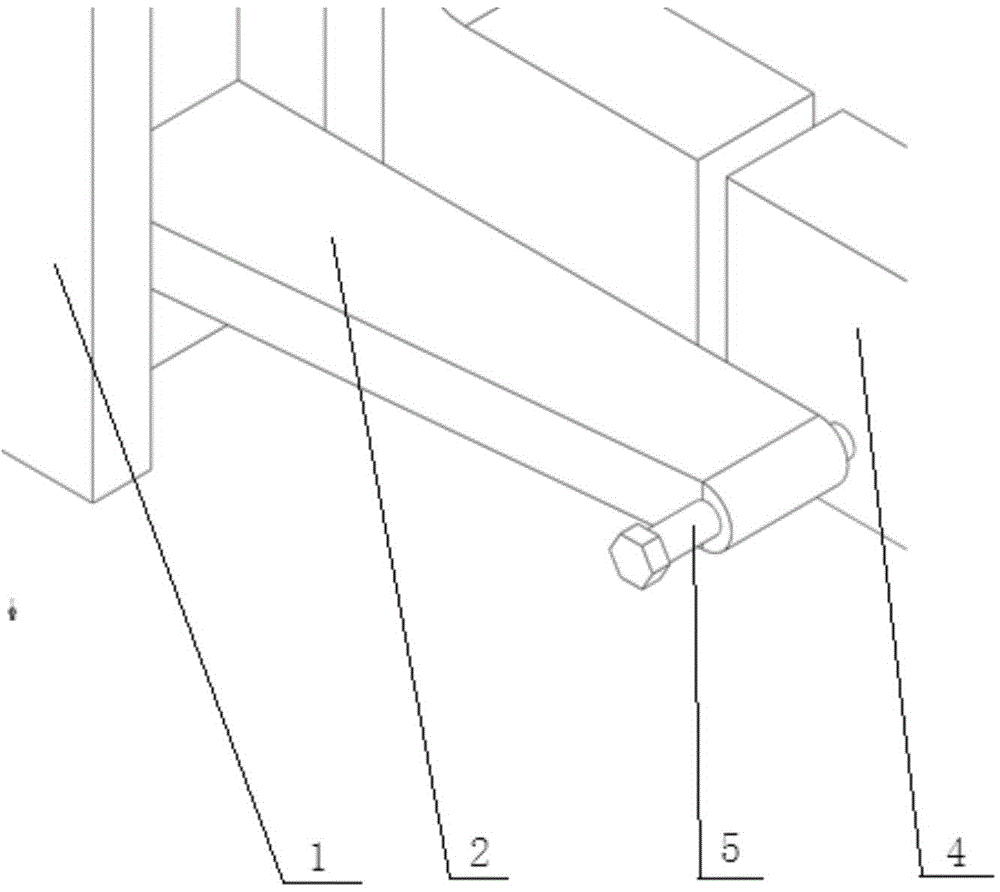

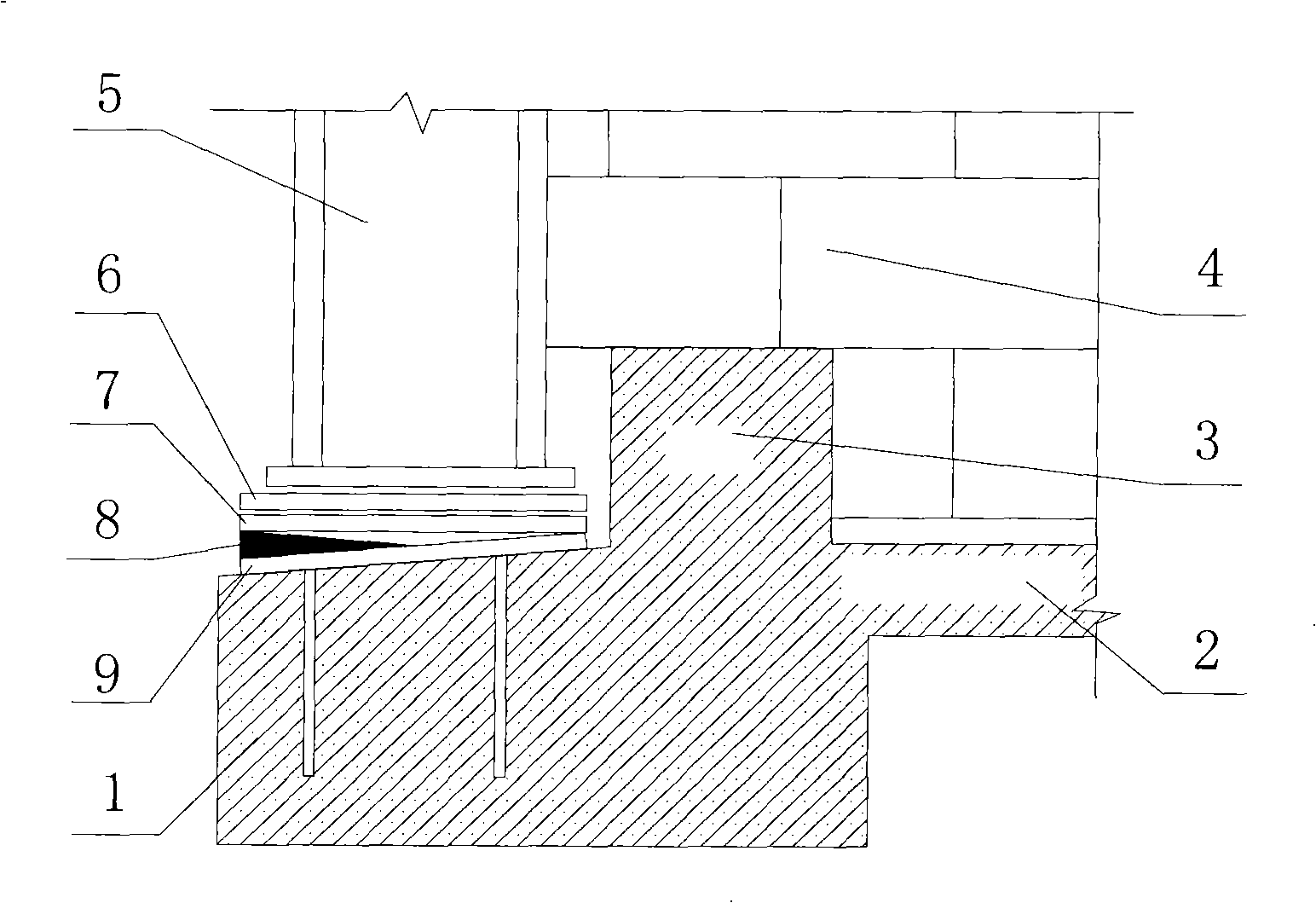

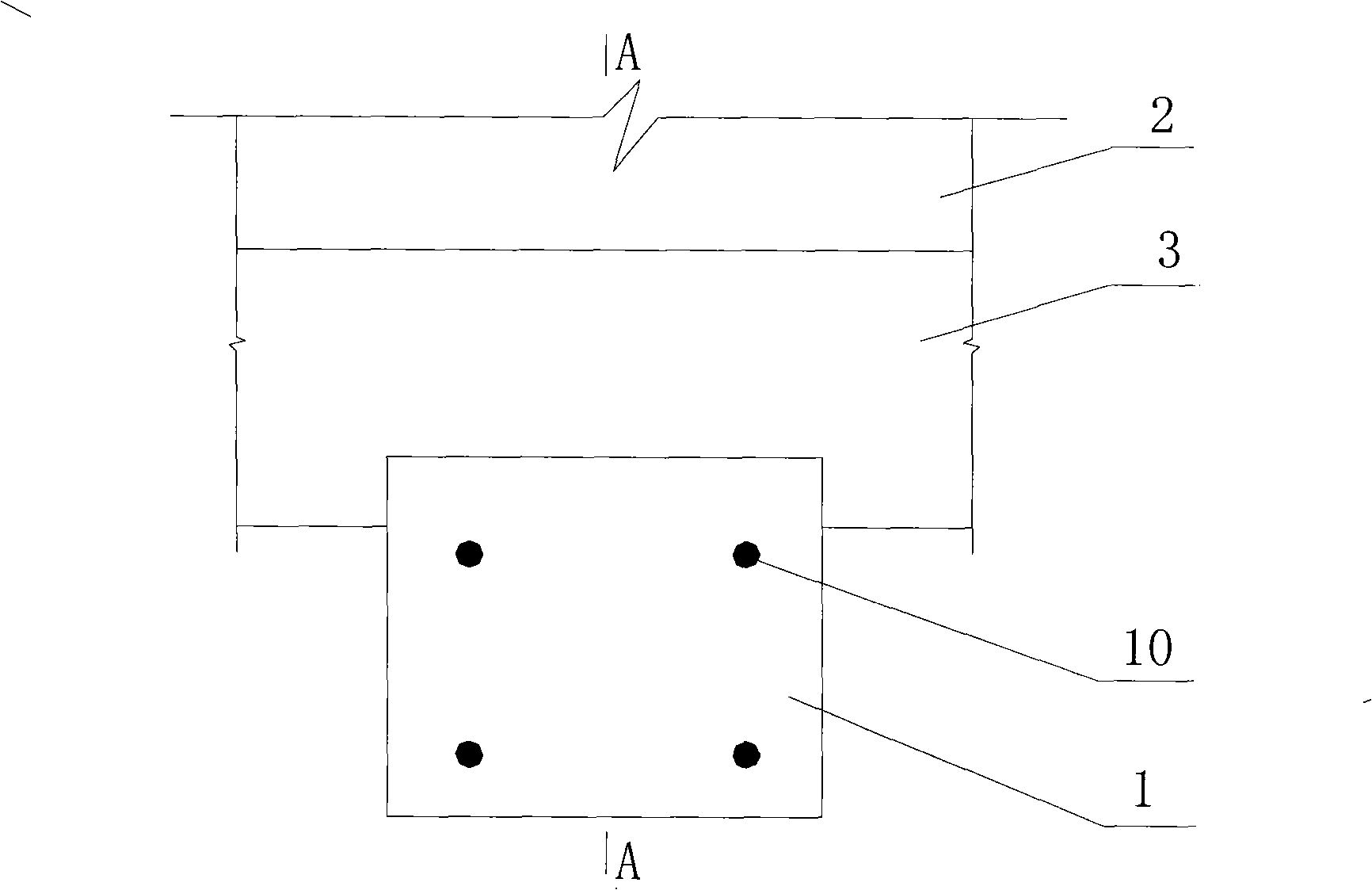

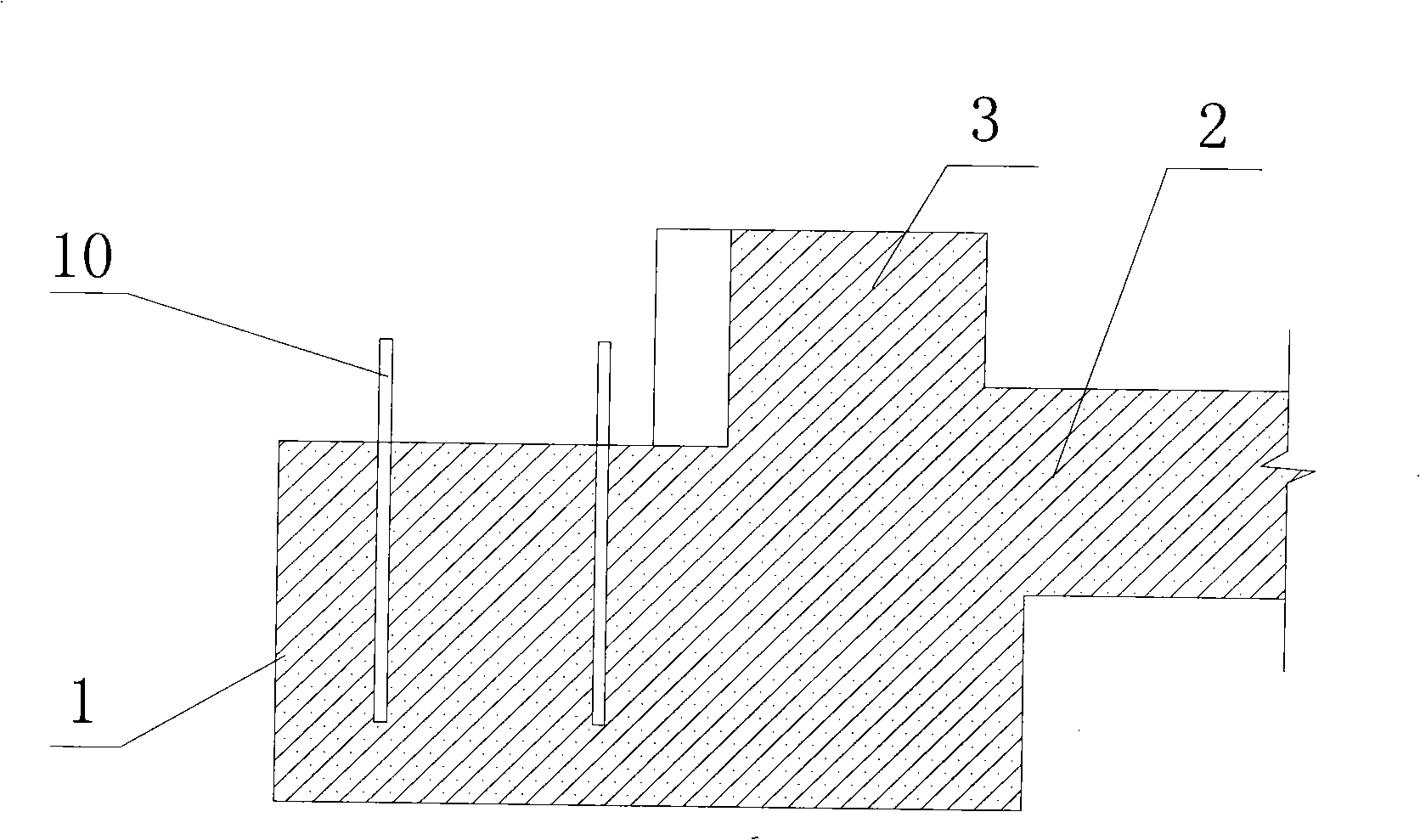

Leveling method in coke oven base roof plate small bracket construction

InactiveCN101294082AEasy constructionImprove construction efficiencyOven foundationsSteel platesRebar

The invention relates to a leveling method in small bracket construction of the roof of coke oven foundation. The leveling method is characterized in that the method comprises the following steps: (1) pre-embedding anchor bars (10) with numbers meeting the design requirement on the small bracket at a position for installing oven post (5) during construction of small bracket concrete structure; (2) marking the design elevation of sliding steel plate surface of the oven post on the pre-embedded anchor bars (10) two days before installing the oven post; (3) leveling downwards to the oven post by the thickness of the steel plate according to the measured design elevation of the sliding steel plate surface of the oven post on the anchor bars on the small bracket to obtain the bottom elevation of the post-installed steel plate; (4) post-installing the steel plate; and (5) pouring slurry material. By adopting post-installation of the steel plate, the method obviates pre-embedding and has the advantages of convenient concrete construction of building structures, no influence of non-uniform settlement of the solid on the steel plate, one-step and convenient leveling, high accuracy, obviating the needs of leveling steel plates and pads in conventional construction, etc.

Owner:CHINA FIRST METALLURGICAL GROUP

Installing method for oven protecting iron component for coke oven

InactiveCN108059964AAchieve straightReduce installation strengthOven foundationsMetal-working hand toolsComputer moduleEngineering

The invention provides an installing method for an oven protecting iron component for a coke oven. The method comprises the following steps: 1) an oven column and a protection board are separately transported into an operation table in the coke oven, the oven column and the protection board are fixed as a whole lifting module by using a special clamping tool, and the oven column is installed in alifting manner by adopting main crane and auxiliary crane structures; 2) a door frame is transported into the operation table, and the door frame is installed in a lifting manner by adopting the maincrane and auxiliary crane structures; and 3) an oven door is transported into the operation table, a special lifting tool is installed for the oven door, the special lifting tool and the oven door arecombined to form an integral lifting module, the module consisting of the oven door and the special lifting tool is placed on the operation table by using a main crane and an auxiliary crane, the auxiliary crane is removed, the top of the oven door is lifted by using a rotating base seat of the special lifting tool as a center to lift the oven door, and the oven door is lifted to the installationposition for installing and fixing. The oven protecting iron component provided by the invention is modularly assembled on the ground, and is installed through integrated lifting in place, so that the installation strength and installation safety risks are reduced, two cranes are cooperated, the moving speed of each module is well controlled, and the installation position can be straightened.

Owner:CHINA 22MCC GROUP CORP

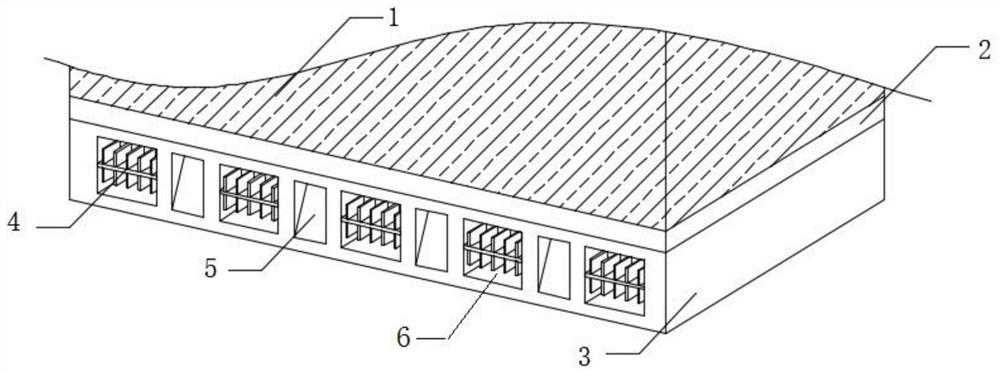

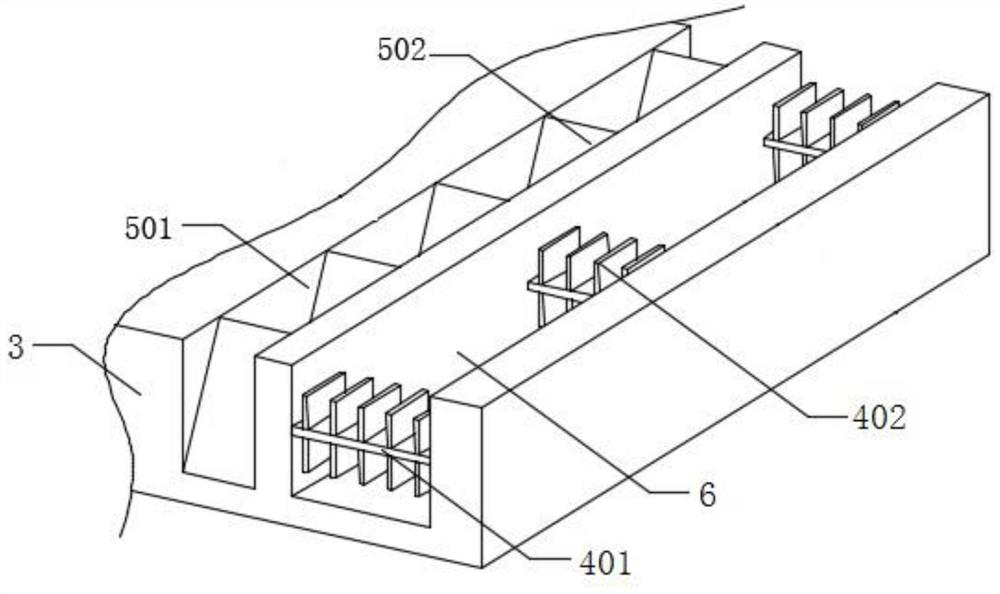

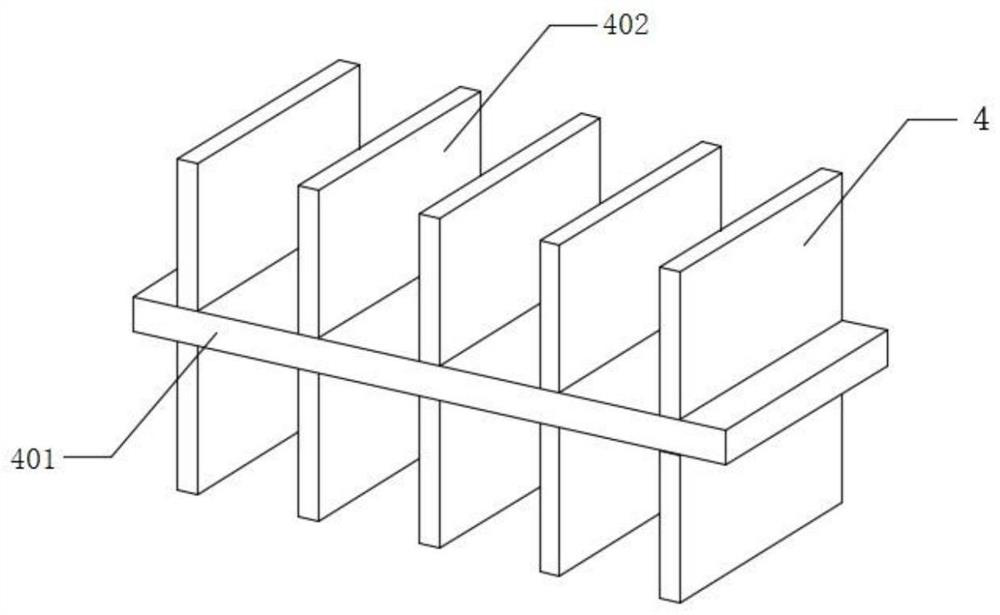

Foundation protection structure of heat recovery coke oven

The invention relates to a foundation protection structure of a heat recovery coke oven. The foundation protection structure comprises an oven bottom protection cross beam supporting plate, a foundation protection base, a heat dissipation assembly and reinforcing assemblies, wherein a plurality of groups of heat dissipation assemblies are arranged in each ventilation hole of the foundation protection base; multiple reinforcing assemblies are arranged, and each reinforcing assembly is composed of an installation channel, a supporting frame and a plurality of reinforcing columns; the installation channels penetrate through the foundation protection base, the supporting frames are arranged in the installation channels in a full-length mode, the supporting frames are each of a broken-line-shaped structure, and the reinforcing columns are vertically arranged between the inflection points of the tops of the supporting frames and the bottom faces of the installation channels. According to the invention, multiple sets of cooling fins are arranged in the ventilation holes, so a heat dissipation area is effectively increased, and ventilation cooling effect is enhanced; multiple rows of the reinforcing assemblies are arranged in the foundation protection base in the full-length mode, so the overall strength of the foundation protection base is effectively improved; and protection on the foundation of the heat recovery coke oven is enhanced, and the service life of the coke oven foundation is effectively prolonged.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

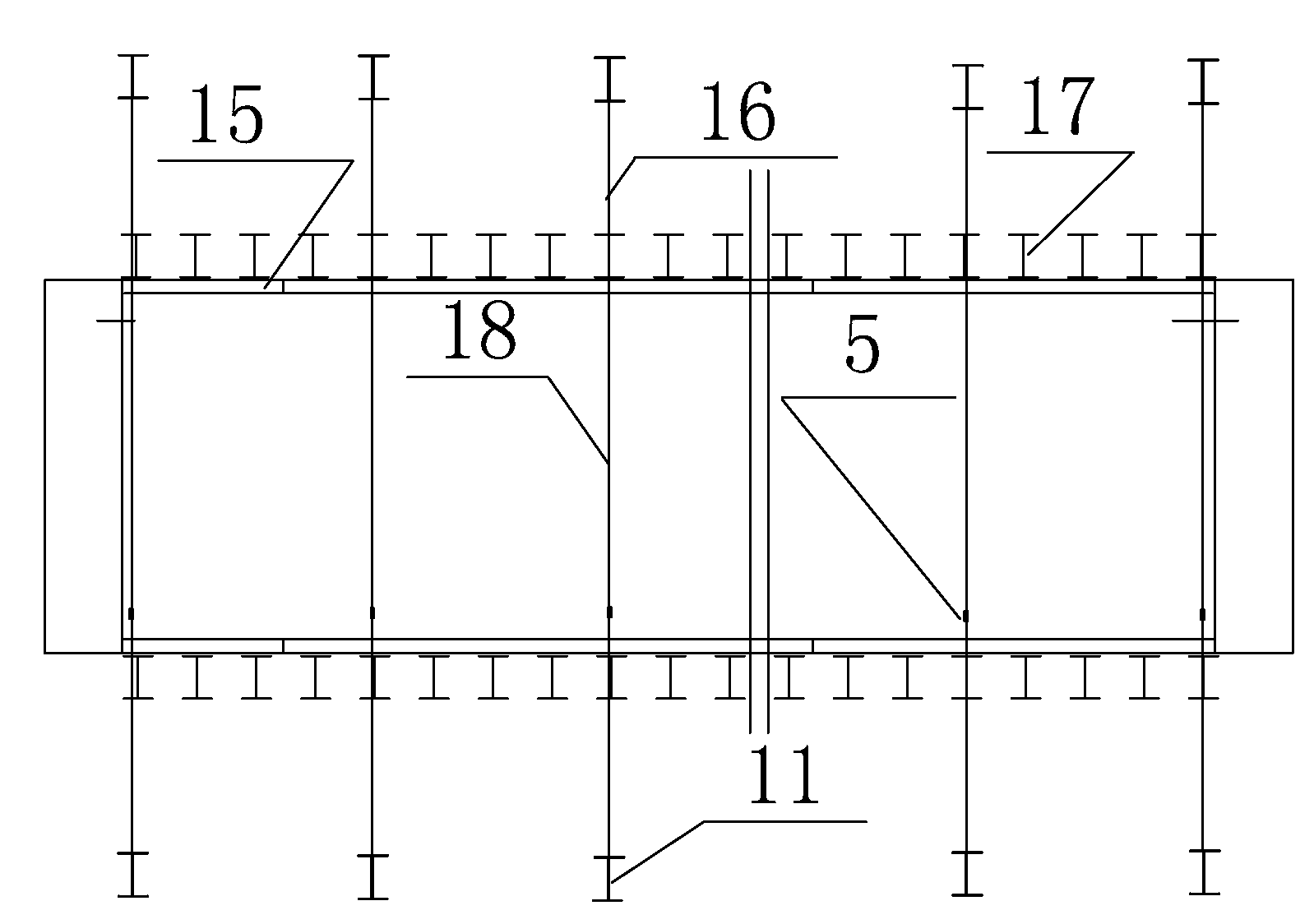

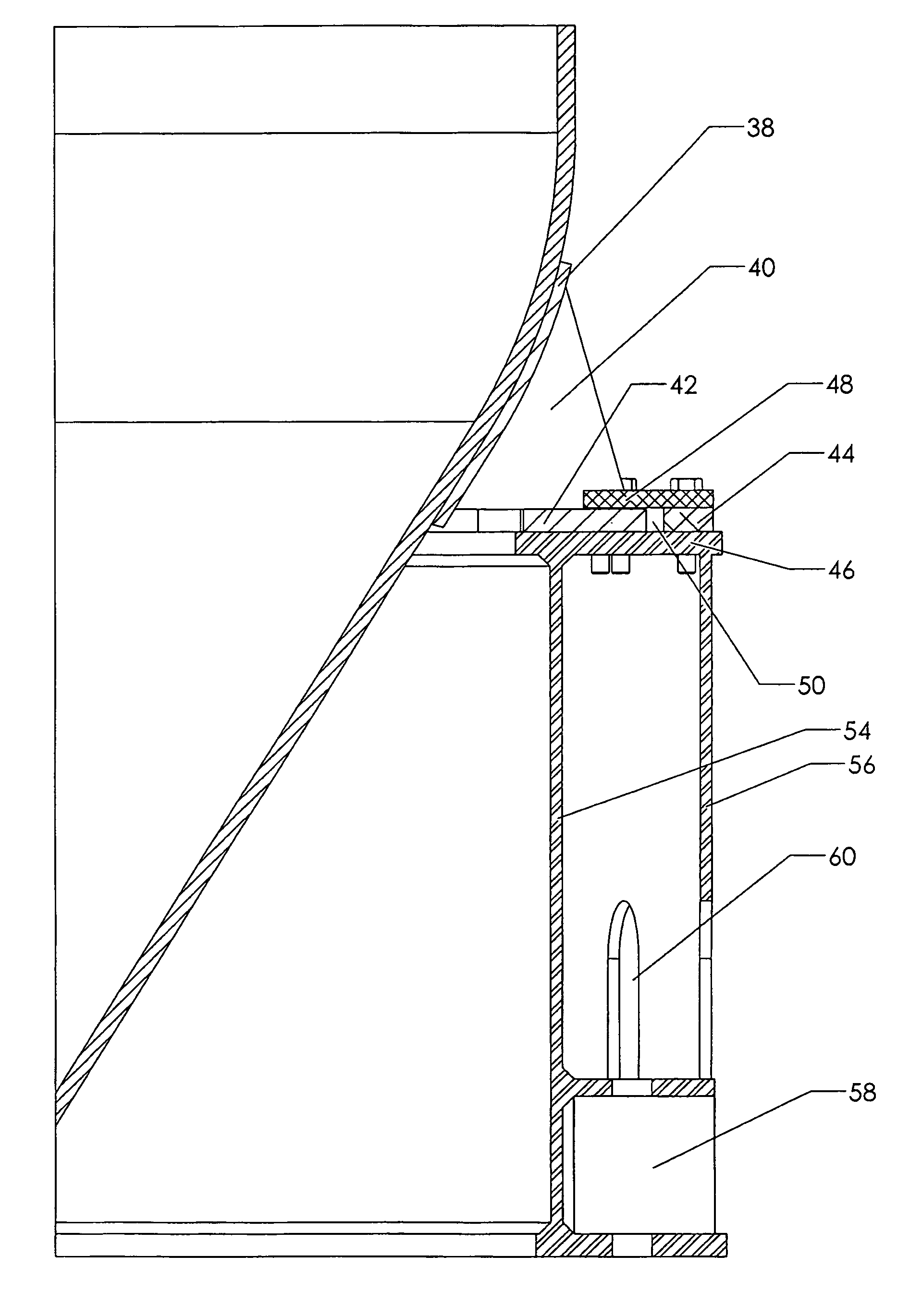

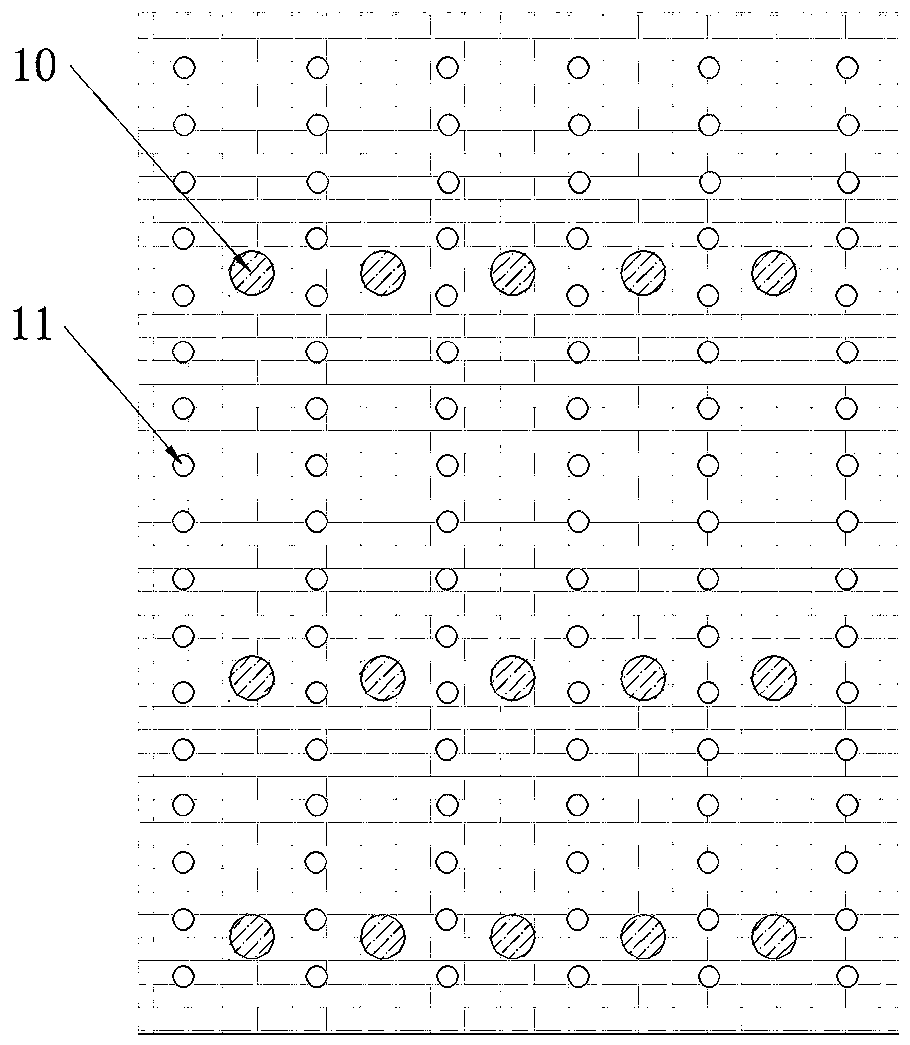

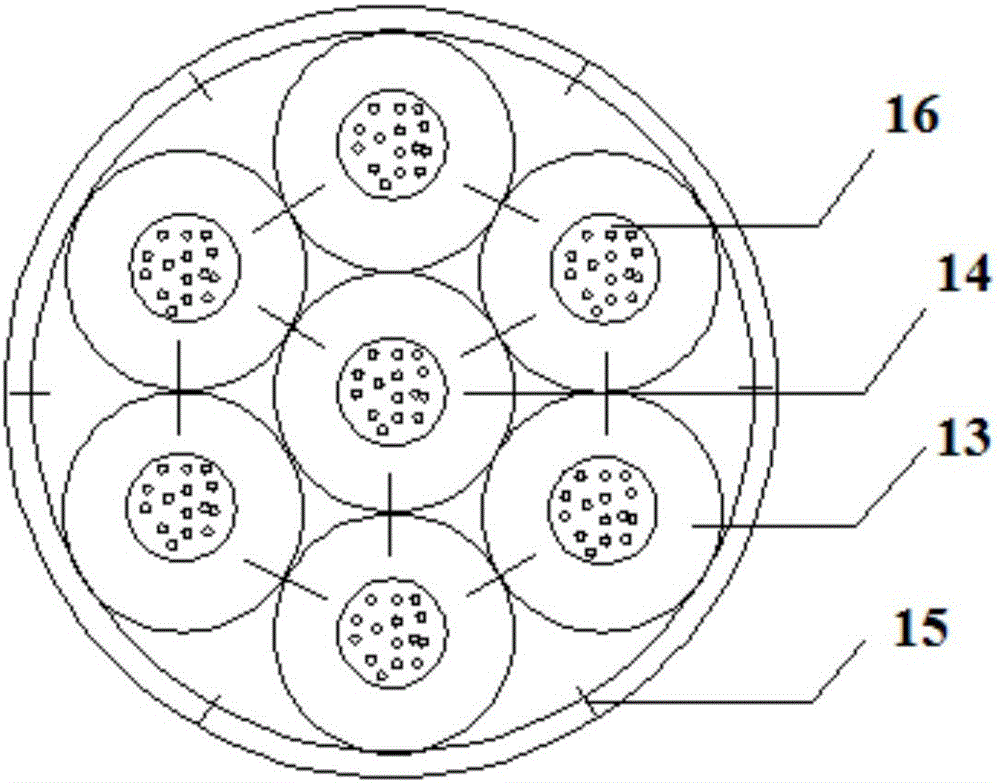

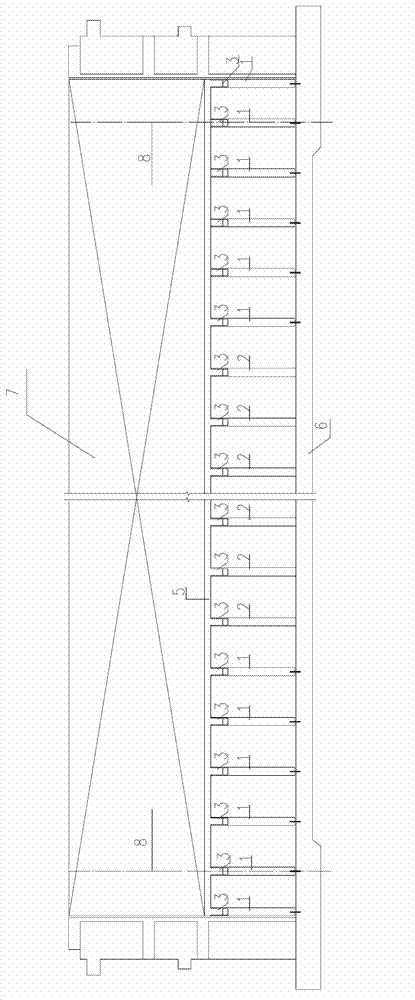

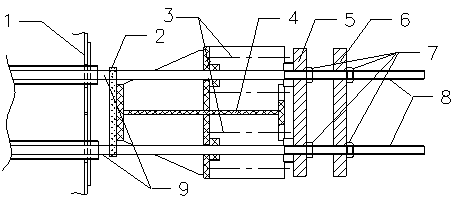

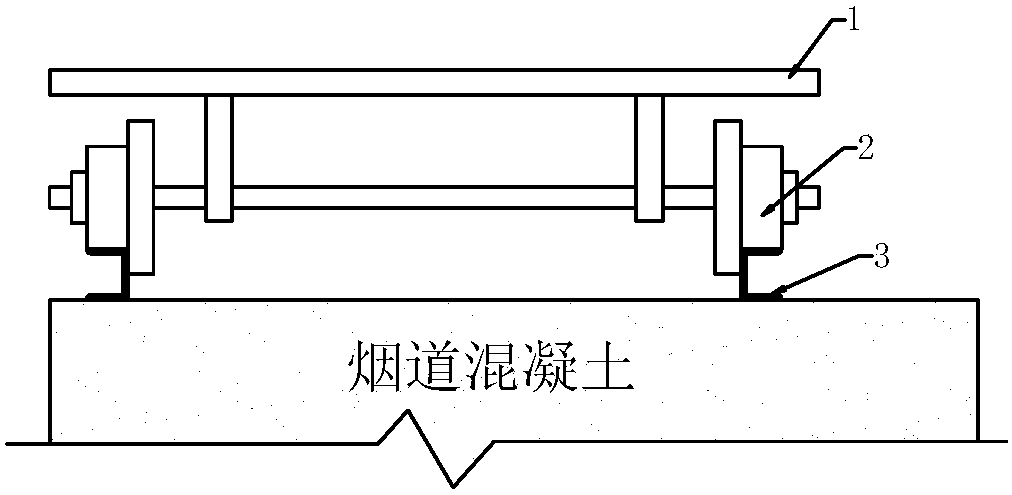

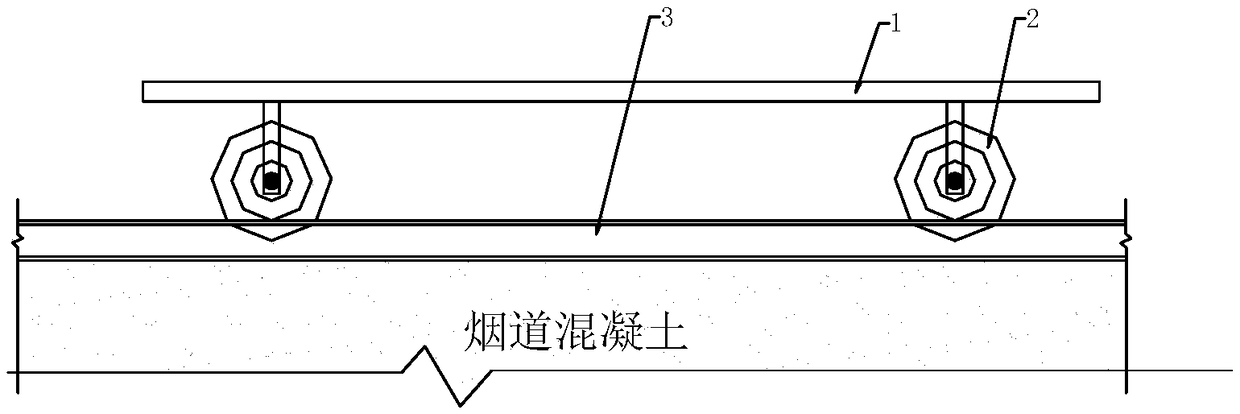

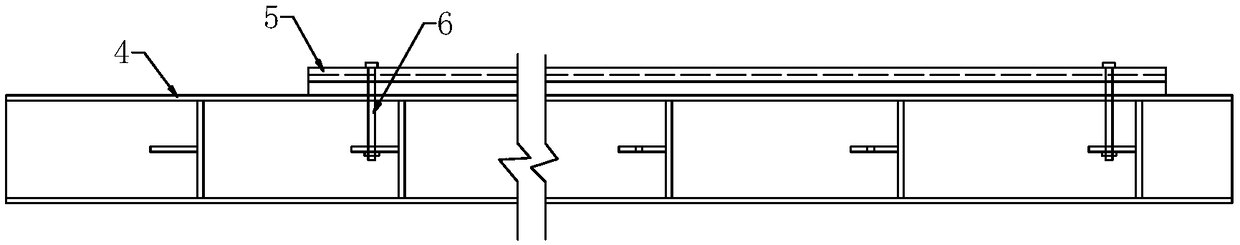

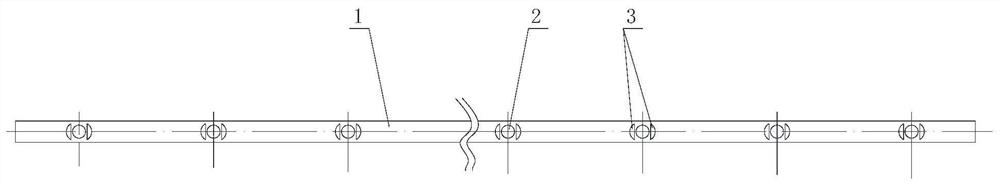

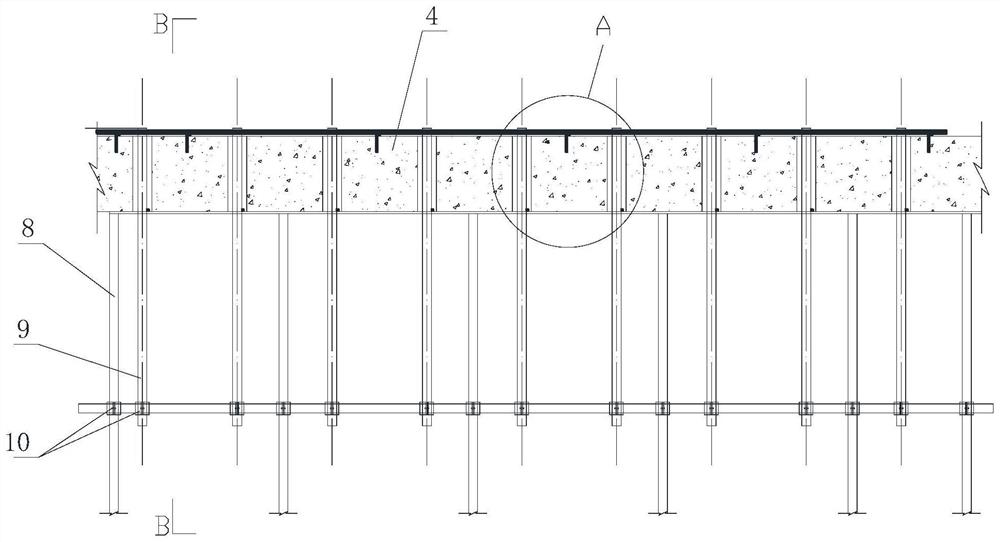

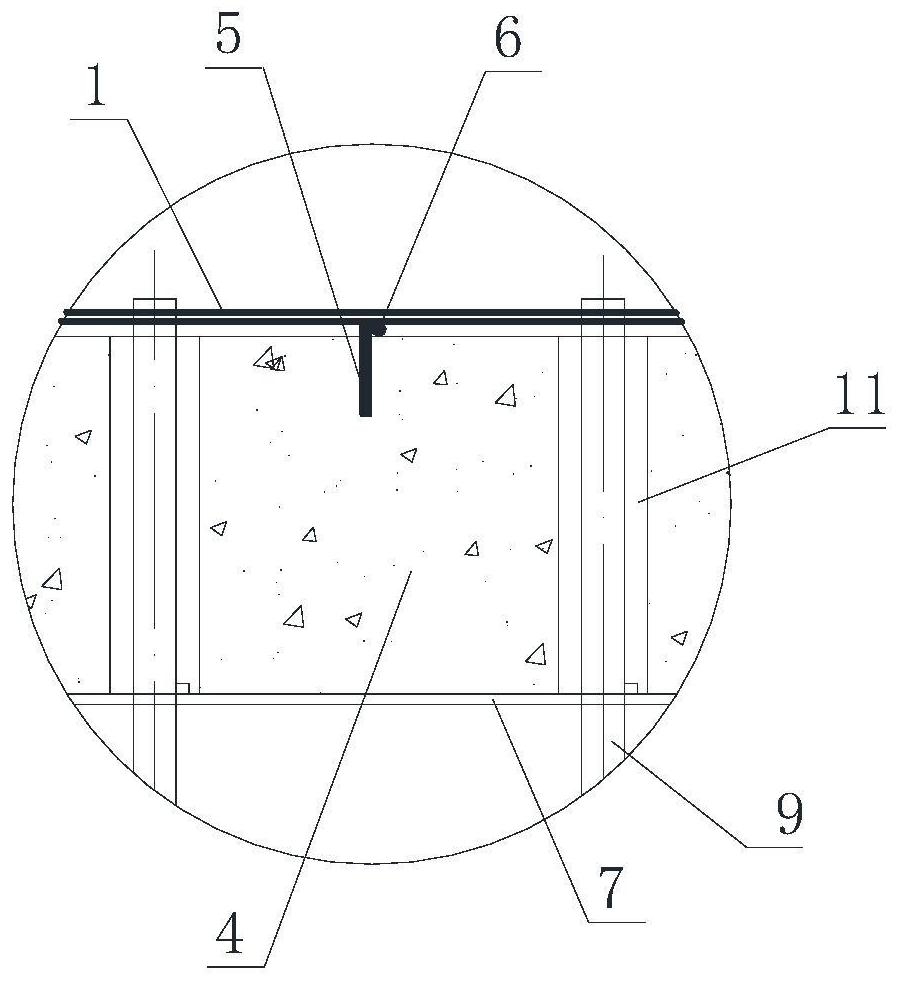

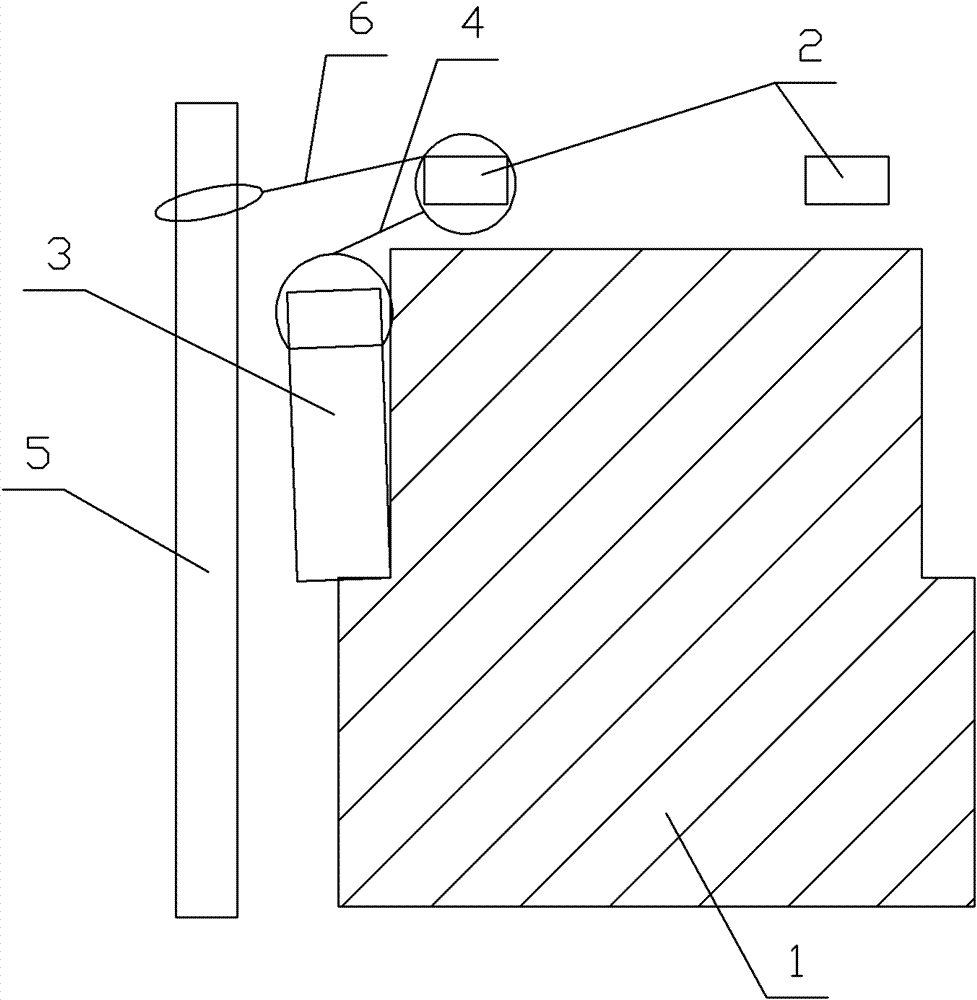

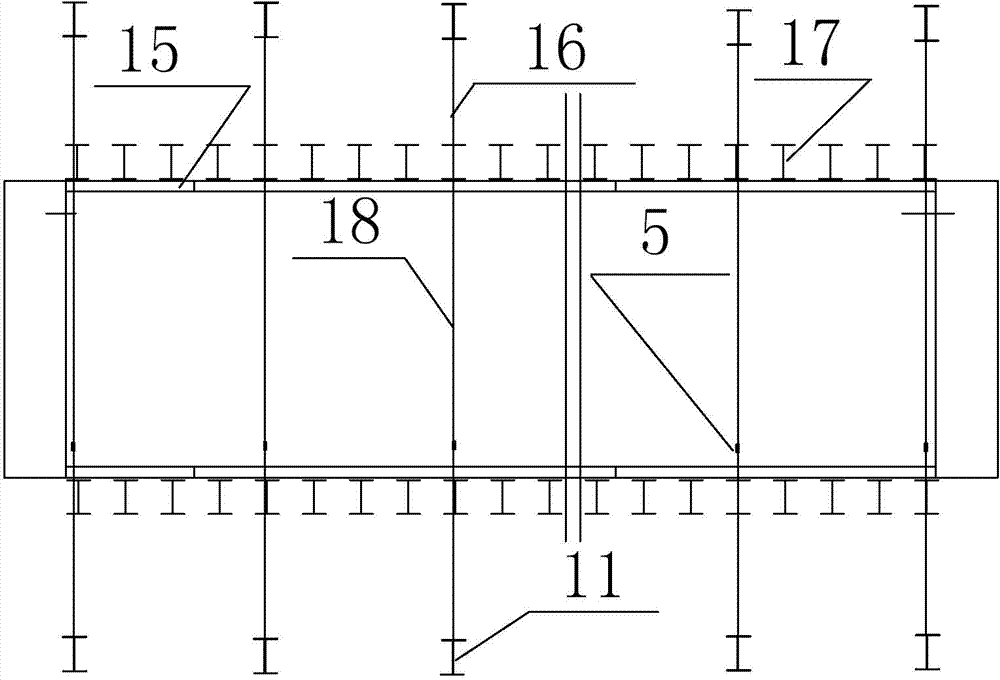

Embedding and fixing structure and embedding method for coal gas down-spraying pipes in coke oven foundation top plate

PendingCN112375577APrecise positioningPrecise fixationOven foundationsCoke ovenIndustrial engineering

The invention relates to an embedding and fixing structure and an embedding method for coal gas down-spraying pipes in a coke oven foundation top plate. Embedded sleeves are embedded in a foundation top plate, and the tops of expansion bolts extend out of the foundation top plate to be connected with a fixing cross beam; the fixing cross beam is fixedly connected with an upper fixing frame, a plurality of control round holes are formed in the upper fixing frame, and grouting holes are formed in the outer sides of the control round holes; after the upper fixing frame is fixed, the axes of the control round holes are coaxial with the axes of the embedded sleeves; a bottom formwork is arranged at the bottom of the foundation top plate, and a lower fixing frame is fixedly connected with the bottom formwork; and when coal gas down-spraying pipes are embedded, the lower ends of the coal gas down-spraying pipes sequentially penetrate through the control round holes in the upper fixing frame,the embedded sleeves and through holes in the bottom formwork and then extend to set positions, and the lower fixing frame is detachably and fixedly connected with the lower portions of the coal gas down-spraying pipes. Accurate positioning and fixing during rear-mounted embedding of the coal gas down-spraying pipes can be achieved, and it is guaranteed that the installation positions of the coalgas down-spraying pipes meet the design requirement.

Owner:CHINA THIRD METALLURGICAL GRP

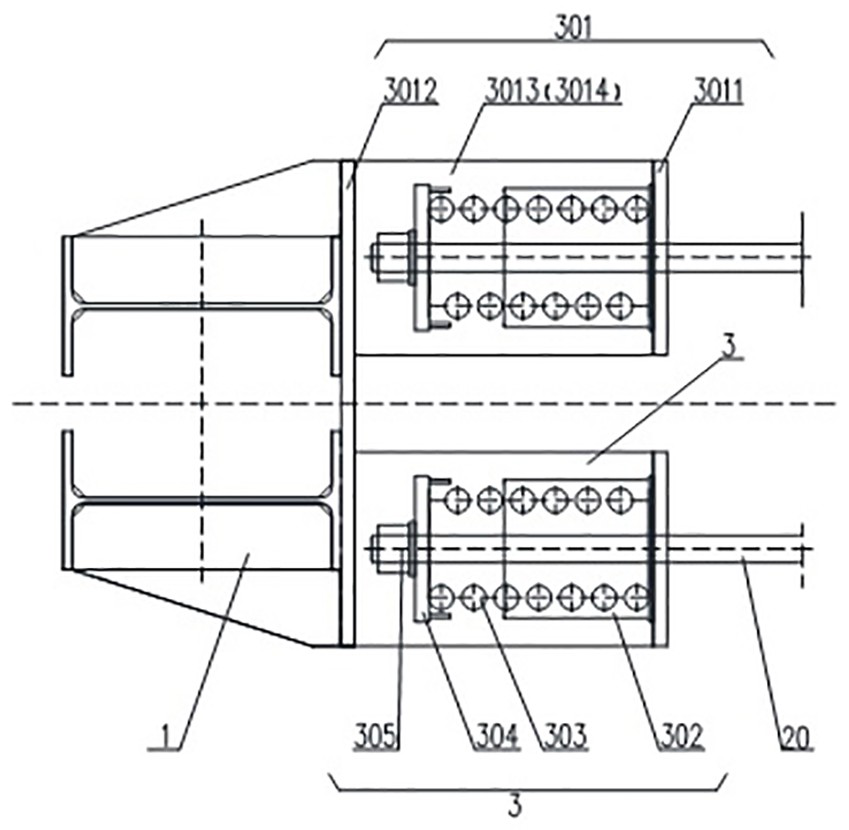

Quick installation method of coke oven guard plate and oven column

ActiveCN101781573BReduced transit timeEasy to operateOven foundationsSoftware engineeringEngineering

The invention discloses a quick installation method of a coke oven guard plate and an oven column, comprising the following steps: 1) after a coke oven body is built, a temporary fixed mount is respectively arranged on the positions on two sides of an oven top machine, which correspond to the installation positions of a guard plate and an oven column; 2) after the guard plate is hung to the proper position and adjusted, a binding piece connects the upper part of the guard plate with the temporary fixed mount so as to temporarily fix the guard plate; 3) after the guard plate is temporarily fixed, the oven column is hung to the proper position, and then the oven column is adjusted, the binding piece connects the upper part of the oven column with the temporary fixed mount so as to temporarily fix the oven column; 4) the cross-brace of the oven column is installed to formally fix the guard plate and the oven column; and 5) the binding piece and the temporary fixed mount are disassembled.The invention is simple and easy to realize, is easy to operate and master, can be flexibly adjusted according to the conditions, such as manpower, equipment and the like, can centralize the superiorforce of relevant type of work and improves quality and efficiency; the coke oven guard plate and the oven column can be intensively installed so as to reduce lifting machine transit shipment time and save installation time and machinery cost.

Owner:TIANJIN 20 CONSTR

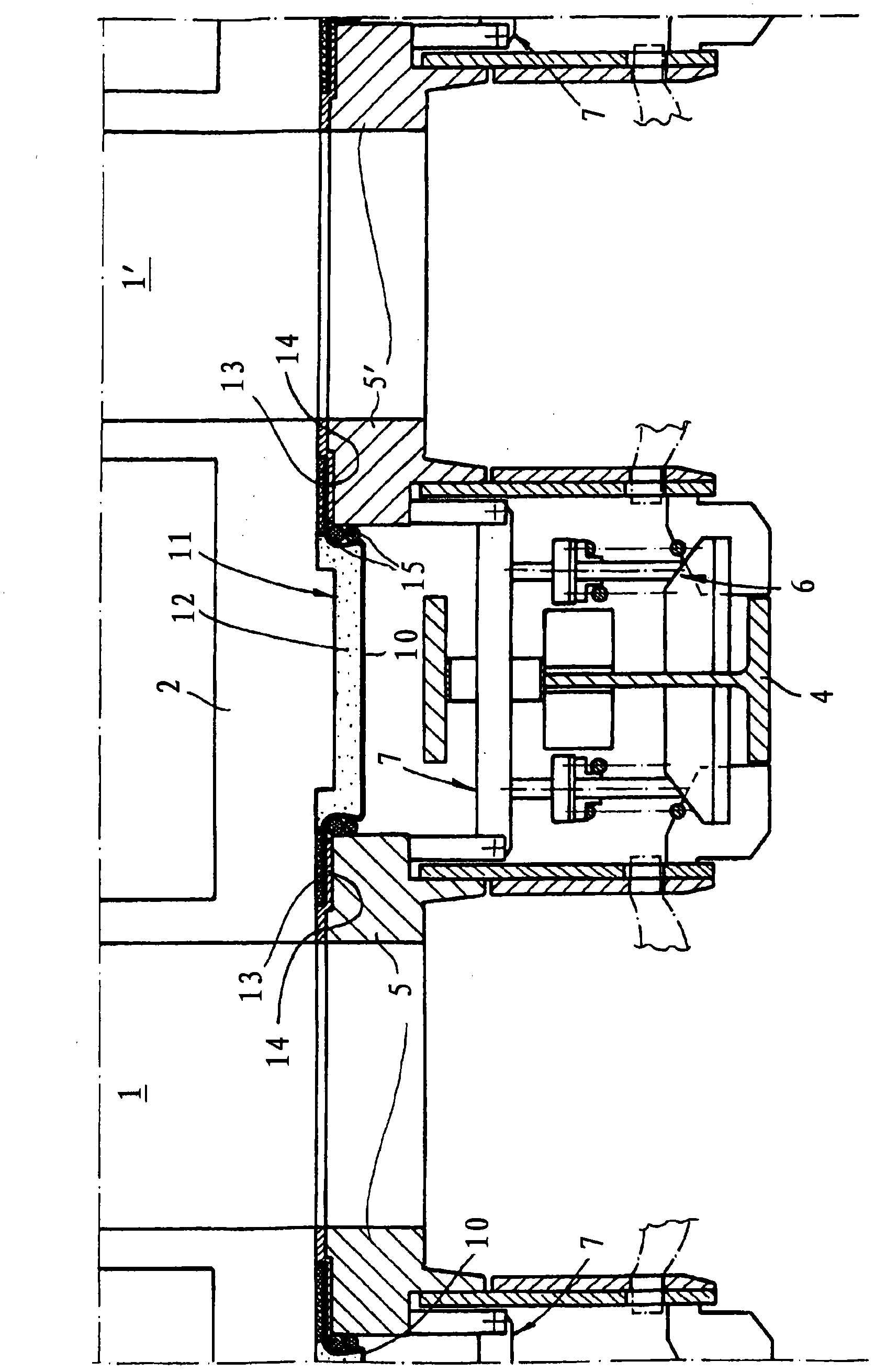

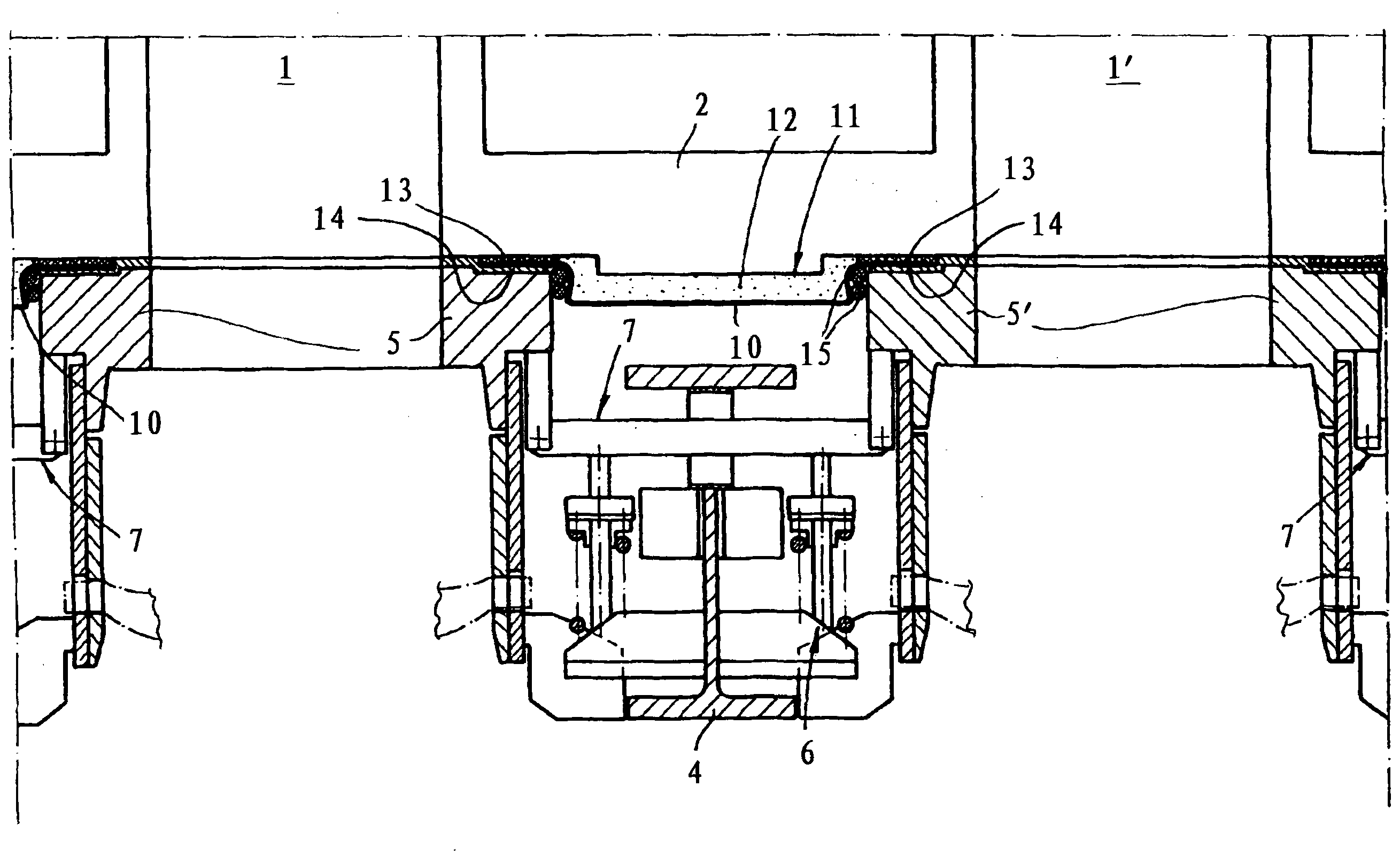

Wall protector for a heating wall head between two oven chamber openings of a coke oven battery

The invention relates to a wall protector for a heating oven head (2) between two oven chamber openings (1, 1') of a coke oven battery, said wall protector being laterally bounded by vertical frame elements (5, 5'). The wall protector comprises an anchor stand (4) arranged in front of the heating wall head (2), extending vertically, and pressing devices (6) fixed to said anchor stand (4). Additionally, the wall protector has U-shaped yoke elements (7) onto which pressure is exerted by the pressing devices (6), and a rectangular head cover (10) covering the heating wall head (2). According to the invention, the U-shaped yoke elements (7) fit tightly against supporting surfaces of the frame elements (5, 5') in a force-fitted manner and the head cover (10) consists of a thin-walled metal sheet constrained between the frame elements (5, 5') and the heating wall head (2).

Owner:UHDE GMBH

A coke oven column installation method

The invention relates to a coke oven column installation method. A coke oven body is built after a coke oven column is installed. The method is characterized by comprising the following steps of: a, acceptance inspecting the foundation; b, transporting and hoisting the oven column; c, temporarily fixing facilities; d, installing and temporarily fixing the oven column; e, adjusting the oven column. The coke oven column installation method has the advantages that the installation procedure design is reasonable, simplicity in operation can be realized, the geometric dimension of a coke oven body refractory brick building body is accurately controlled, the system error is reduced, the building precision is improved, the sealing property of the coke oven is effectively guaranteed, the normal production of the coke oven can be favored, and the service life of the coke oven can be prolonged.

Owner:MCC5 GROUP CORP SHANGHAI

Device and method for replacing furnace column parts above platform in coke side furnace

The invention discloses a device for replacing furnace column parts above a platform in a coke side furnace. The device comprises a first furnace column, a second furnace column, a third furnace column, the platform in the machine coke side furnace, a chain block and an upper portion fixing large protecting plate device, wherein the third furnace column, the first furnace column and the second furnace column are sequentially arranged on the platform from left to right, the third furnace column, the first furnace column and the second furnace column are fixed together through a furnace column lower portion fixing structure, a first coke furnace large protecting plate is arranged on each of the two sides of the first furnace column, one side, adjacent to the first furnace column, of the third furnace column is correspondingly provided with a second coke furnace large protecting plate, one side, adjacent to the first furnace column, of the second furnace column is correspondingly provided with a third coke furnace large protecting plate, the third furnace column, the second coke furnace large protecting plate and the first coke furnace large protecting plate are tightly connected together through the upper portion fixing large protecting plate device, and the second furnace column, the third coke furnace large protecting plate and the first coke furnace large protecting plate are tightly connected together through the upper portion fixing large protecting plate device. The device is simple in structure and high in replacing efficiency.

Owner:NANJING IRON & STEEL CO LTD

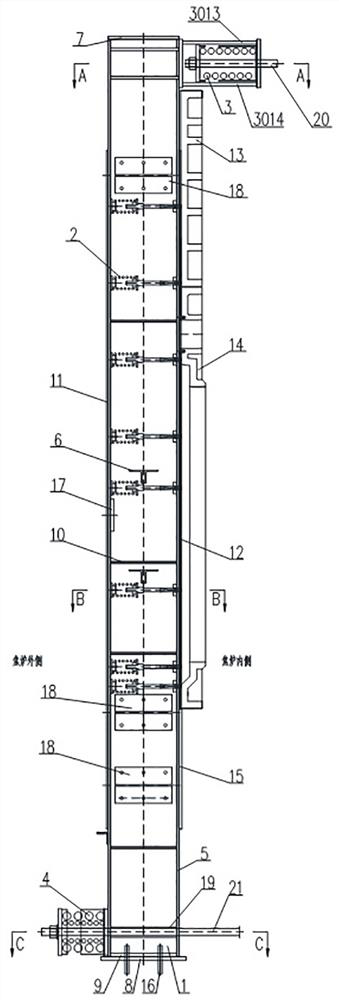

Oven column applied to heat recovery coke oven

PendingCN113322083AGood expansion curvatureExtended service lifeOven foundationsThermal dilatationThermodynamics

The invention belongs to the field of building of heat recovery coke ovens, and particularly relates to an oven column applied to a heat recovery coke oven. A vertical frame structure of the oven column is characterized by comprising a frame body, adjusting spring assemblies, an upper brace connecting device and a lower brace connecting device, wherein the upper brace connecting device is arranged at the top of the frame body, the lower brace connecting device is arranged at the bottom of the frame body, and a plurality of the adjusting spring assemblies are arranged on the middle section of the frame body; the frame body is formed by connecting the middle portions of two pieces H-shaped steel with the same height and a plurality of double-angle steel cross beams; and each adjusting spring assembly comprises an adjusting spring and a screw rod, the adjusting spring faces the outer side of the frame body, and the screw rod faces the inner side of the frame body. The oven column of the invention has the advantages that 1) a distance between an upper transverse brace and the high-temperature furnace end is increased, the springs and the brace are prevented from being damaged by high temperature; 2) a lower transverse brace can better protect the lower part of the coke oven against thermal expansion force; and 3) the environmental protection grade of the coke oven is improved, and the service life of the coke oven is prolonged.

Owner:辽宁科技大学工程技术有限公司

Coke oven combustor oven wall hot-repairing burner guard plate fixing device

The invention discloses a coke oven combustor over wall hot-repairing burner guard plate fixing device. The fixing device comprises a shoulder pole and a hook bolt; the length of the shoulder pole isgreater than the width of a furnace column; the hook bolt is connected with the shoulder pole and the burner protection plate; a bolt hole is arranged on the burner protection plate, one end of each hook bolt is fixed on the shoulder pole through a nut; and the hook bolts are arranged at two sides of the furnace column. The fixing device can protect the burner protection plate from being dismounted and deforming and breaking in the overhauling.

Owner:MCC5 GROUP CORP SHANGHAI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com