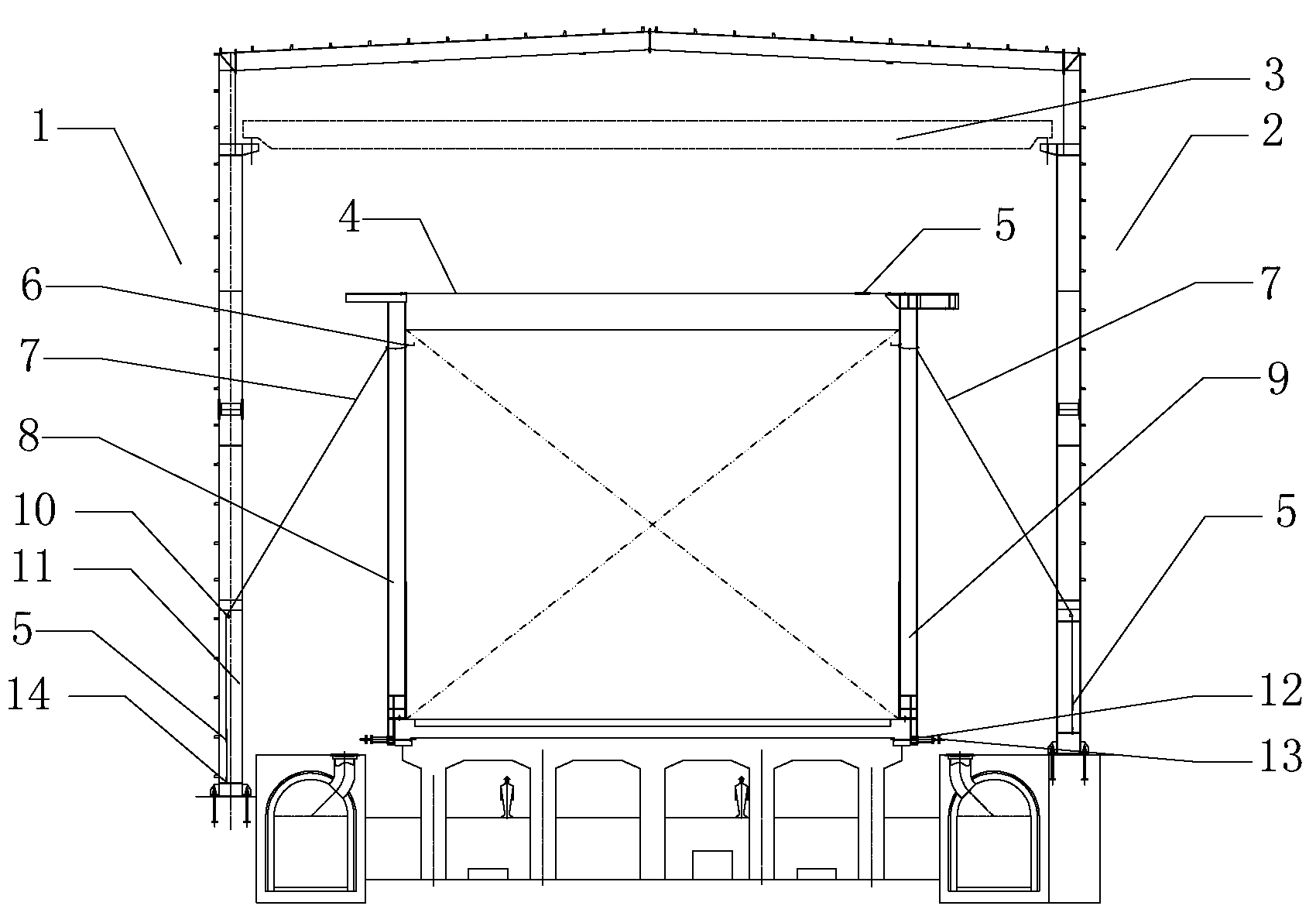

Coke oven column installation method

An installation method and technology of the furnace column, applied to the foundation of the furnace, etc., can solve the problems of inconvenient installation of the coke oven column, and achieve the effects of improving masonry accuracy, reducing system errors, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

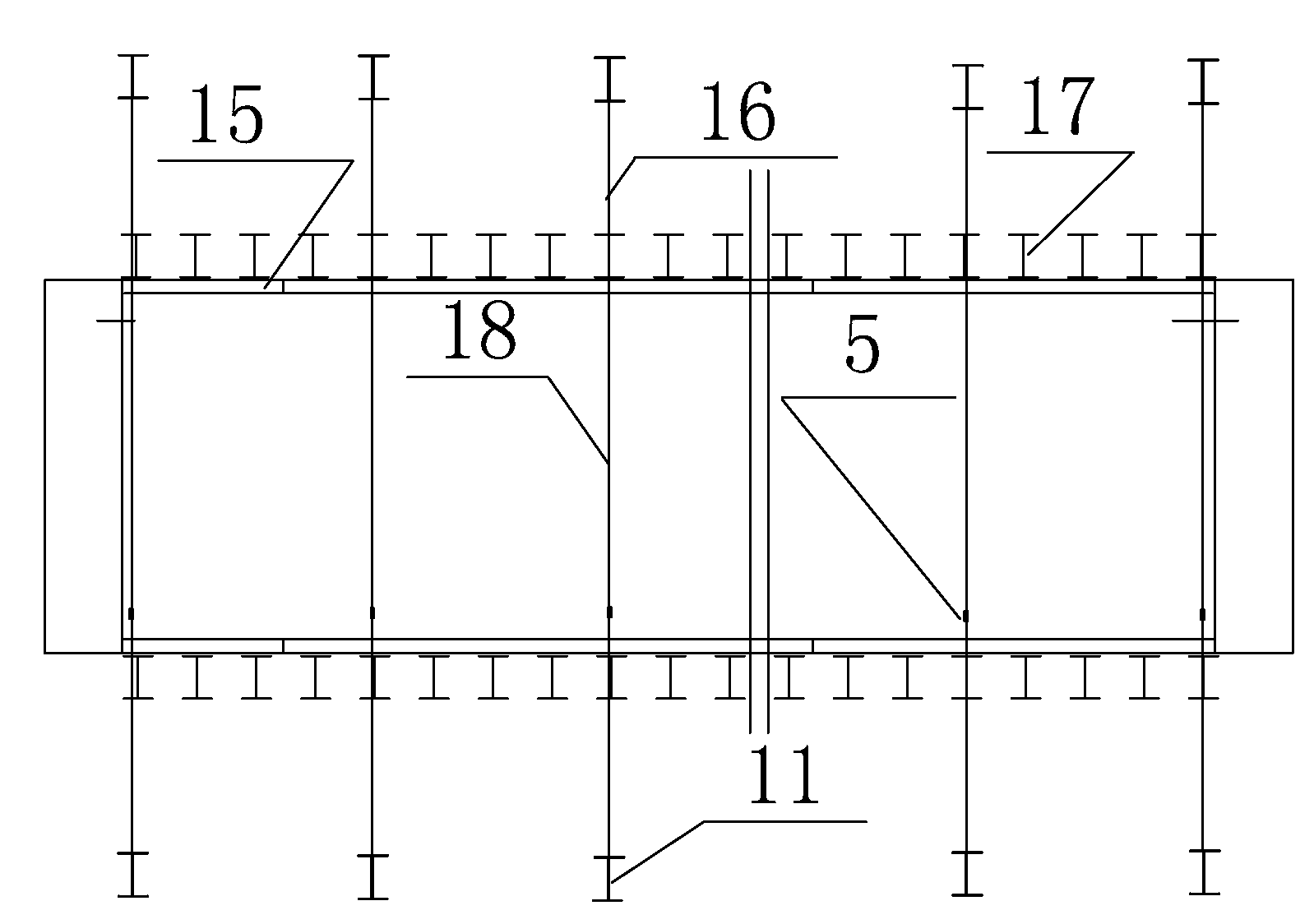

[0037] The present invention will be further described below in conjunction with embodiment and accompanying drawing.

[0038] A coke oven column installation method is characterized in that it comprises the following steps:

[0039] a. Basic inspection and acceptance

[0040] Check whether the base elevation and center line deviation of the civil engineering handover are within the allowable deviation range and do not affect the installation accuracy, and adjust the base elevation. According to the design elevation of the drawings, level the base surface of the furnace column with steel plates, the adjusted elevation deviation is ±1mm, and record the measured value for the record. Grease must be applied on the surface of the backing plate after laying, so as to facilitate the sliding of the furnace column during the oven;

[0041] b. Furnace column transportation

[0042] The furnace column has the characteristics of long length, heavy weight, and cannot be deformed by for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com