Installation method of phenolic aldehyde compound air hoses

A technology of composite air duct and installation method, which is applied in the direction of pipeline laying and maintenance, pipes/pipe joints/fittings, mechanical equipment, etc. It can solve the problems of phenolic air duct processing, cutting and bonding, difficult connection, short construction period, and inconvenience. To achieve the effect of ensuring tightness, quick connection and ensuring the rigidity of the air duct

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

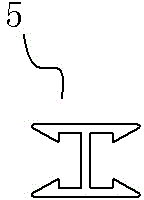

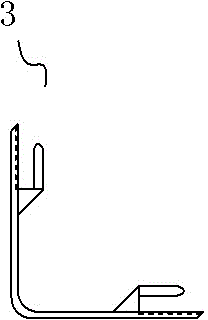

Image

Examples

Embodiment 1

[0051] The installation method of a kind of phenolic composite air duct of the present invention uses the straight pipe length≤4000mm of each phenolic composite air duct, and the size of each phenolic composite board is 3m×1.2m×20mm, and is characterized in that it comprises the following steps:

[0052] a. Cutting

[0053] According to the size of the air pipe, choose to install it in the vertical and horizontal directions, so that the longest length of each straight pipe is 4000mm and 1200mm respectively, so as to achieve the optimization of materials and labor;

[0054] b. cutting

[0055] (1) The incision of the phenolic composite board should be accurate, and the tangent line should be straight or follow the line;

[0056] (2) The incision of the phenolic composite board should be smooth and free of damage;

[0057] (3) The dimensions of the diagonals of the rectangular air duct should be consistent, with an error of ≤1.5mm. The two adjacent surfaces of the air duct sho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com