Installation method of prefabricated staircase

An installation method and stair technology, applied in the direction of stairs and other directions, can solve the problems of easy collision, inconvenient installation of stairs, difficult alignment and other problems, and achieve the effect of improving efficiency and safe and reliable engineering quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

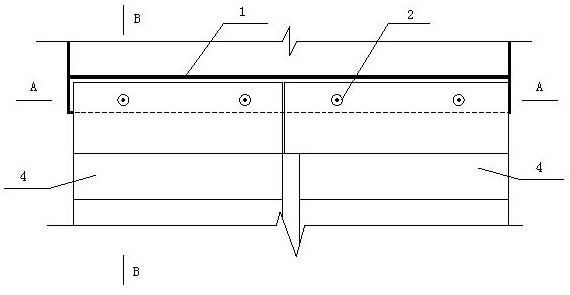

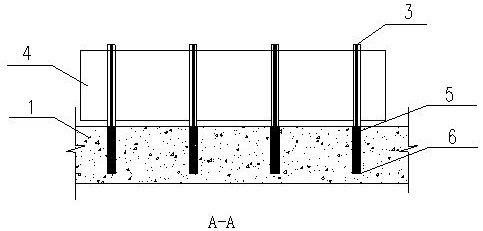

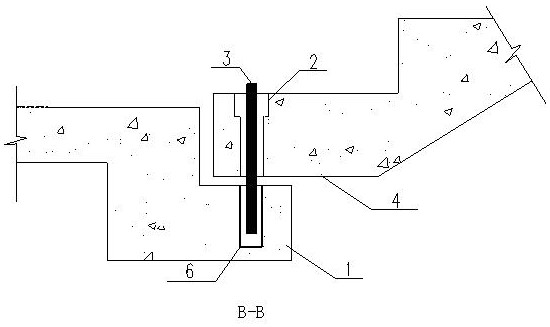

[0026] see now Figure 1-Figure 3 , figure 1 It is a schematic diagram of the installation structure of the prefabricated stairs of the embodiment of the present invention, figure 2 for figure 1 The sectional view of A-A in, image 3 for figure 1 Sectional view of B-B in middle. As shown in the figure, the ladder beam 1 is a prefabricated ladder beam.

[0027] The installation method of prefabricated stairs of the present invention comprises the steps of:

[0028] a. Pre-embed the steel casing during the construction of the ladder beam structure, and correspond to the reserved bolt holes 2 of the ladder section one by one;

[0029] b. The prefabricated ladder section 4 is hoisted in place, leveled, and high-strength bolts 3 are inserted into the reserved holes;

[0030] c. The gap between the high-strength bolts and the ladder beam steel pipe 6 is filled and consolidated with C35 grouting material 5;

[0031] d. The connection between the ladder section and the high-s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com