Leveling method in coke oven base roof plate small bracket construction

A construction and basic technology, applied to the foundation of the furnace, etc., can solve the problems of leveling materials, high direct labor costs, difficult to meet the requirements of seat grouting and pad grouting, loss of key lines, etc., to save key processes The effect of construction period, saving auxiliary materials and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

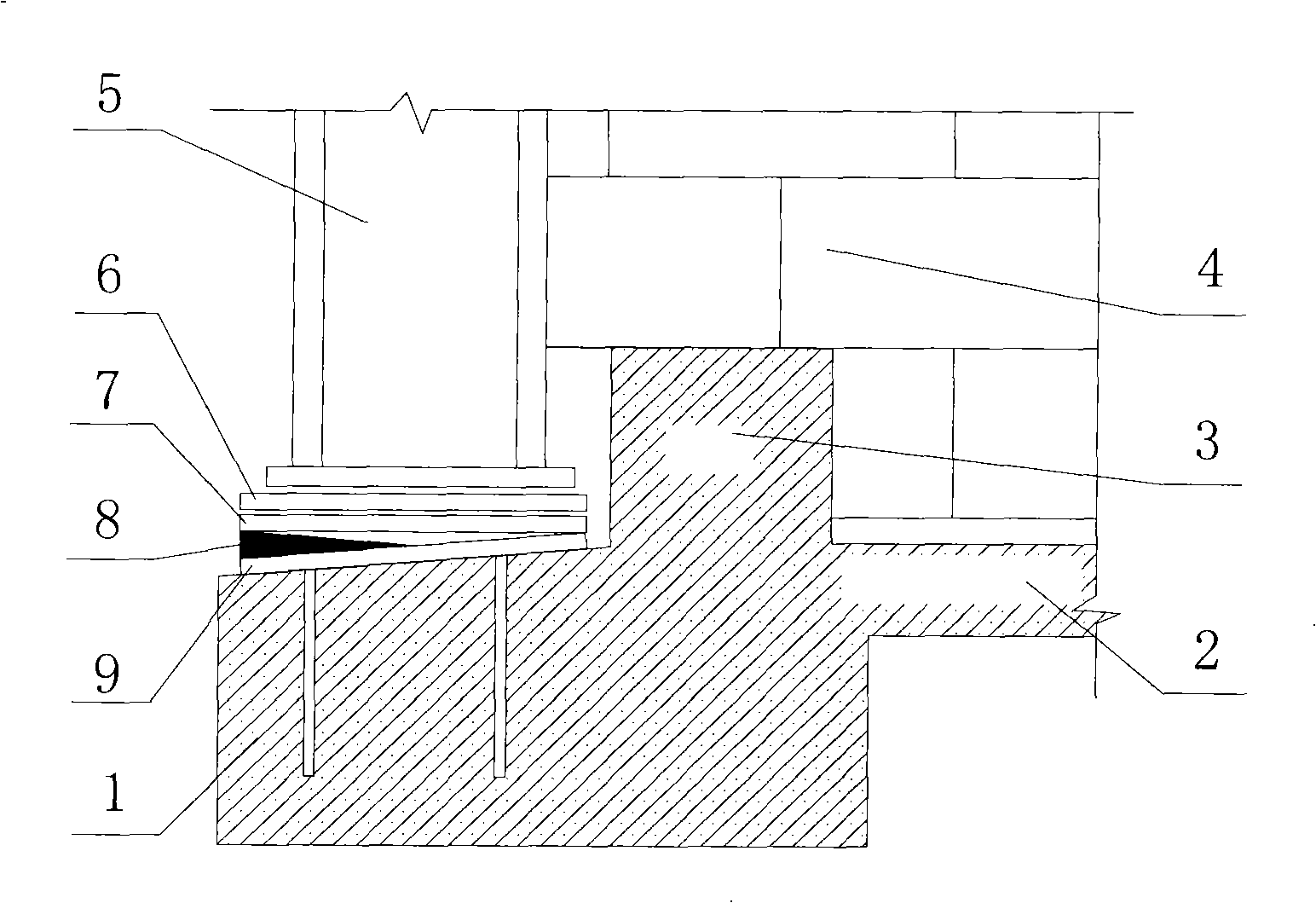

[0040] The leveling method in the construction of the calf leg of the coke oven foundation roof includes the following steps:

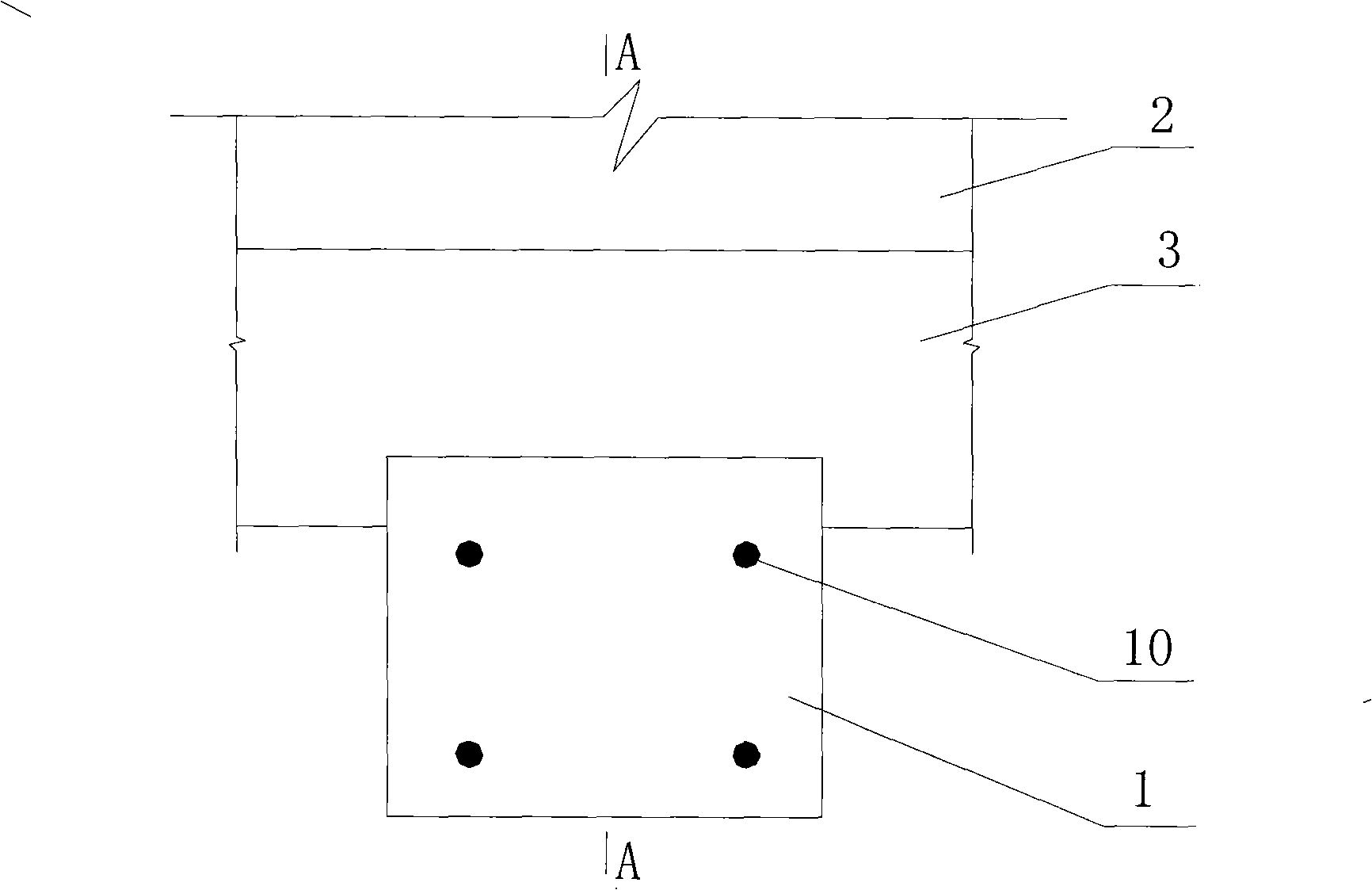

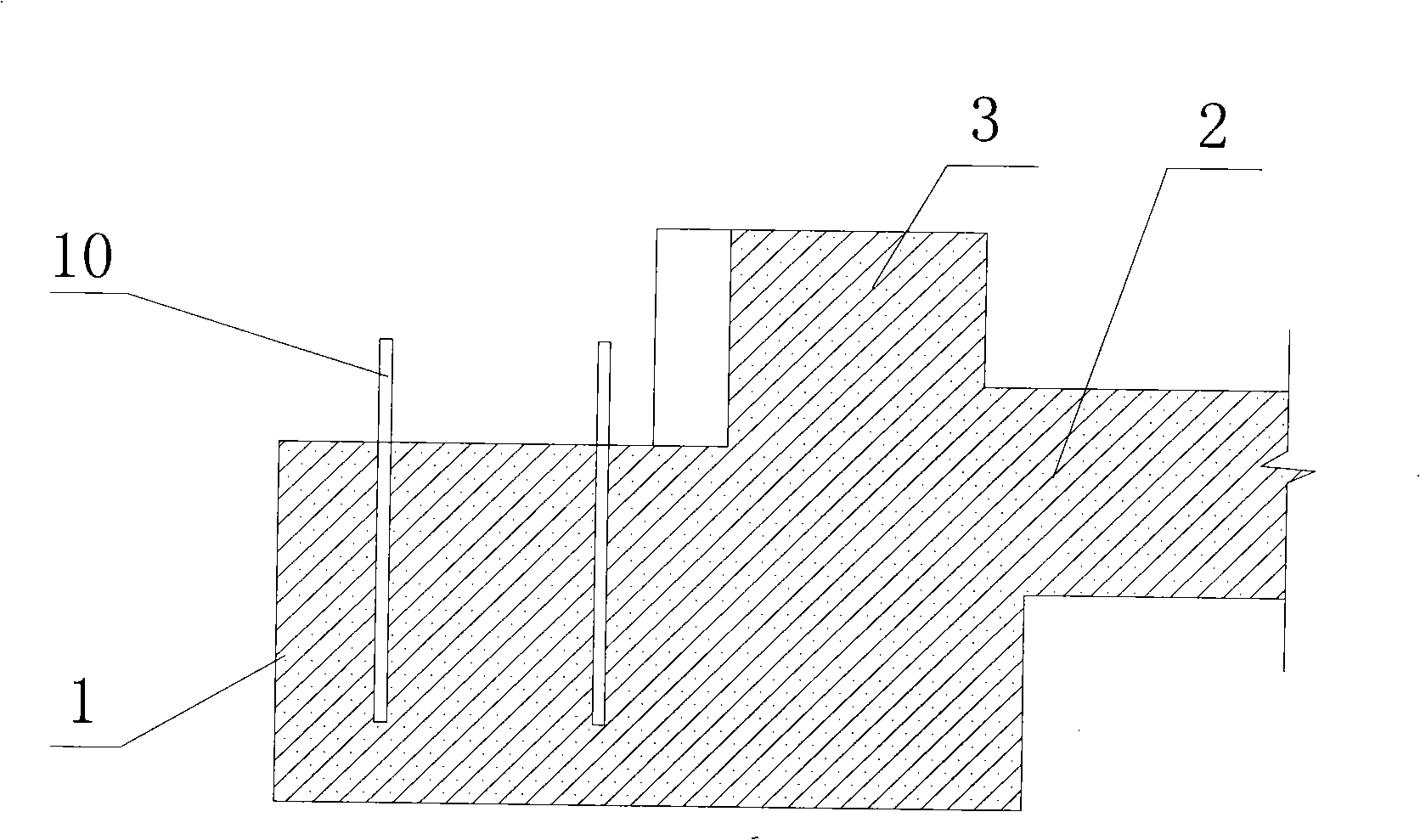

[0041] 1) if figure 2 , image 3 As shown, during the construction of the calf-leg concrete structure, the design-required number of anchoring steel bars 10 is pre-embedded on the calf-leg where the furnace column 5 is installed; The design elevation minus the control elevation of the furnace column leveling steel plate thickness, with a negative tolerance of 5mm;

[0042] 2) Two days before the installation of the furnace column, mark the design elevation of the sliding steel plate surface of the furnace column on the pre-embedded anchoring steel bar 10;

[0043] 3) if Figure 4 As shown, according to the design elevation of the furnace column sliding steel plate surface measured on the anchoring steel bar 10 on the calf leg, the thickness of the furnace column leveling steel plate is the bottom elevation of the post-installation steel plate, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com