Foundation protection structure of heat recovery coke oven

A protection structure and heat recovery technology, applied to the foundation of the furnace, etc., can solve the problems of the overall strength of the structure without integral reinforcement, the limited heat dissipation area of the ventilation hole, and the inability to quickly export heat, etc., so as to improve the service life, improve the overall strength, The effect of enhanced protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

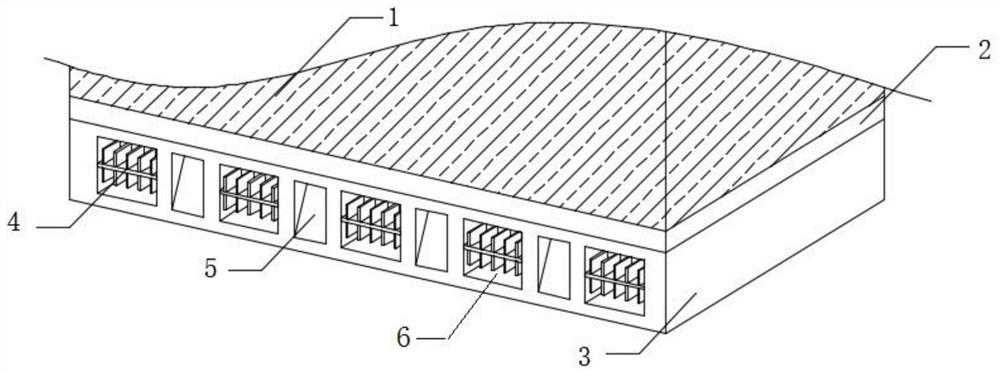

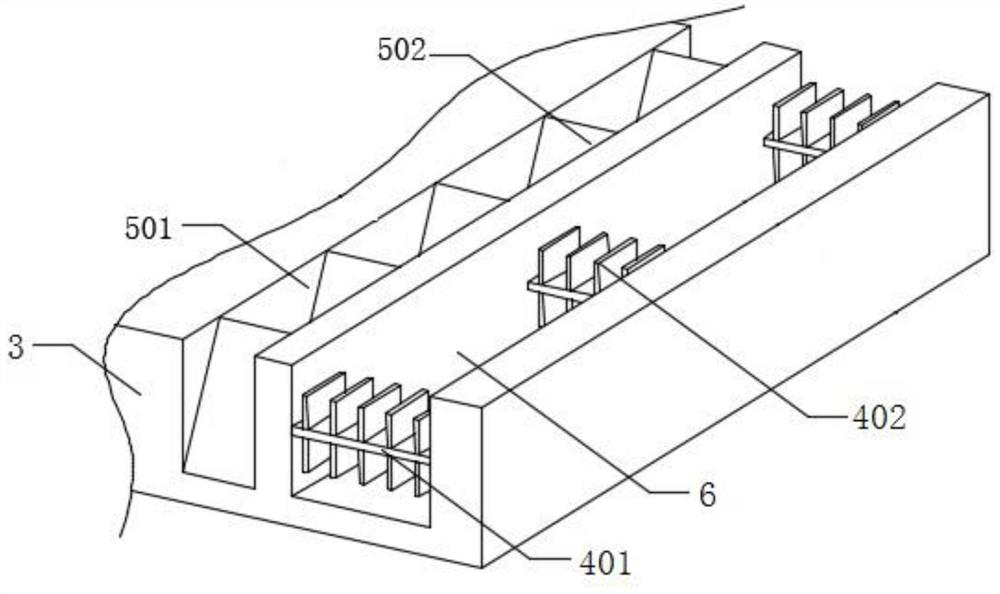

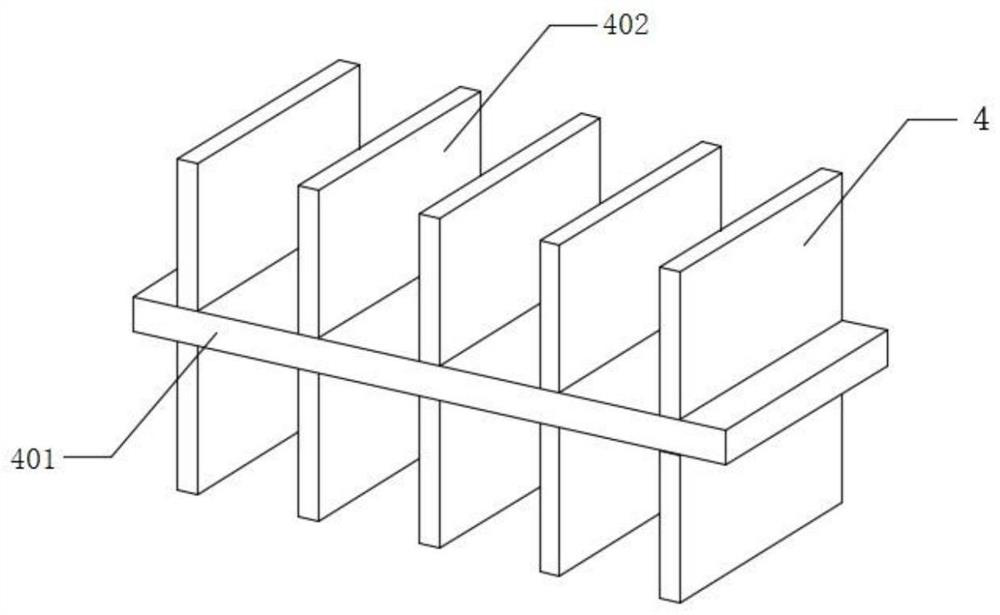

[0023] Such as figure 1 , figure 2 As shown, a heat recovery coke oven foundation protection structure according to the present invention includes a furnace bottom protection beam support plate 2 and a foundation protection base 3, and the foundation protection base 3 is provided with ventilation holes 6; the heat recovery coke oven The basic protection structure also includes heat dissipation components 4 and reinforcement components 5; the heat dissipation components 4 are multiple groups, and multiple groups of heat dissipation components 4 are arranged at intervals along the lengthwise direction in each ventilation hole 6; the reinforcement components 5 are multiple groups, and each group The reinforcement components 5 are all composed of an installation channel 501, a support frame 502 and a plurality of reinforcement columns 503; the insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com